Device for testing material properties in high-temperature hydrogen environment

A technology for material properties and test devices, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying repetitive force/pulse force. , to achieve the effect of high accuracy, short heat transfer chain and shortened heat transfer chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

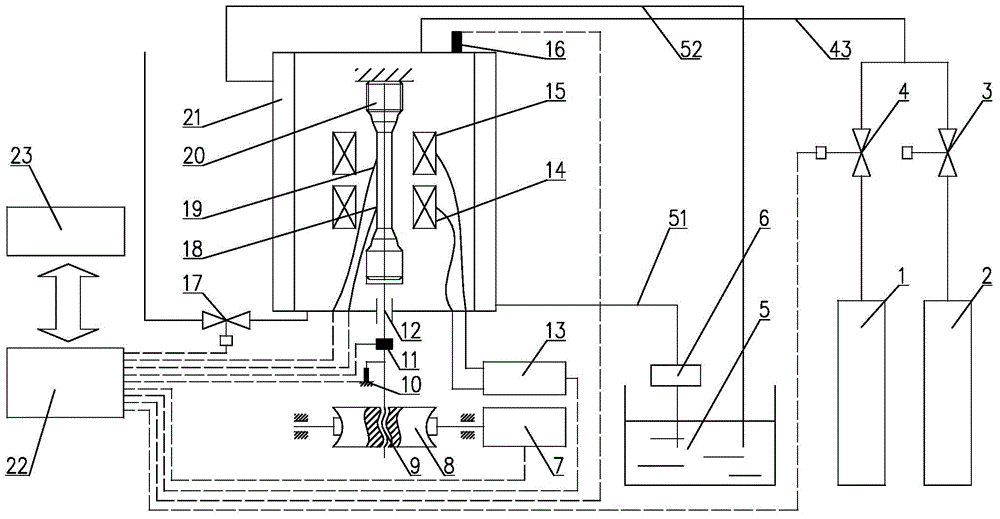

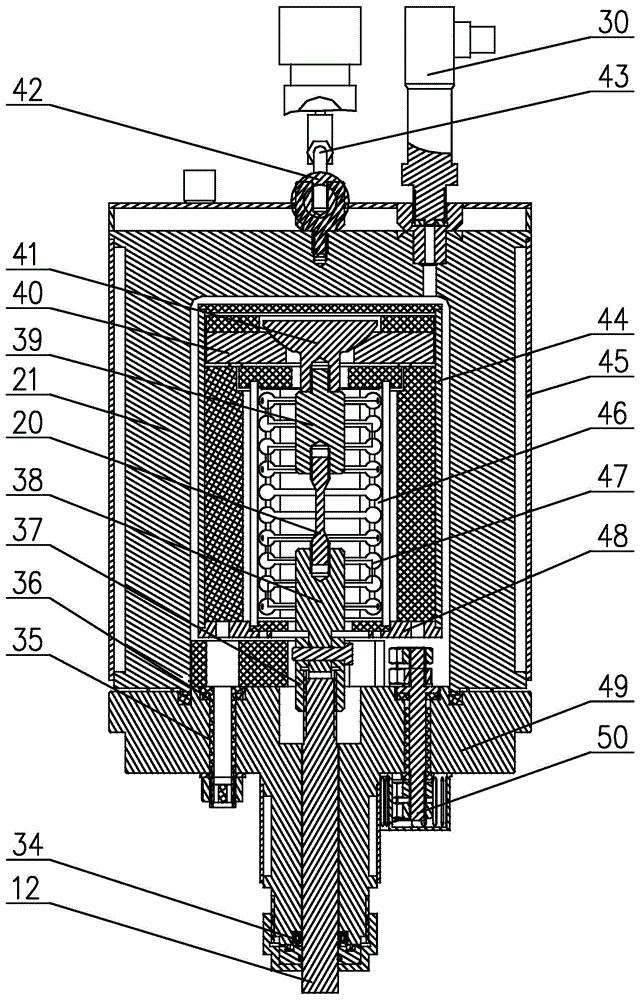

[0043] For ease of understanding, here in conjunction with accompanying drawing, specific testing device of the present invention and its operation process are further described as follows:

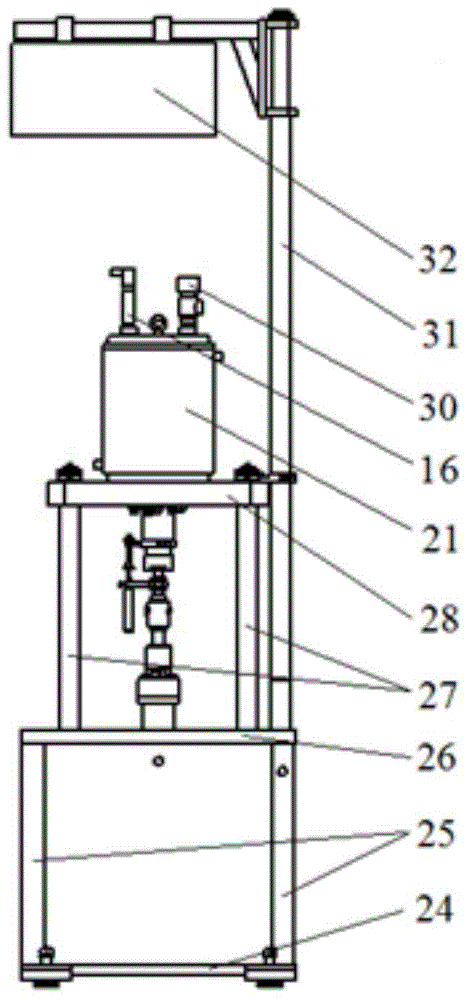

[0044] The structure of the present invention is as Figure 1~5 As shown, each component of the present invention is described in detail below:

[0045] 1. Host loading framework

[0046] The host loading frame can realize the creep-durable and tension-tension alternating load loading of the sample, and provide a hydrogen environment box to stabilize the installation platform. The host loads frameworks such as figure 2 As shown, it is composed of the lifting mechanism above, the horizontal surface of the workbench and the base below the workbench.

[0047] Specifically, if figure 1 , 2 As shown, the base is a cuboid space composed of a lower base plate 24, an upper base plate 25, and four angle steels 25. The loading drive mechanism composed of a servo motor 7, a reducer 8 and a bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com