Three-dimensional hierarchical air supply combined waste incinerator

An incineration device and waste technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of narrow application range and single function, and achieve the reduction of excess air coefficient, control of combustion temperature and oxygen content, and reduction of fly ash Take away the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

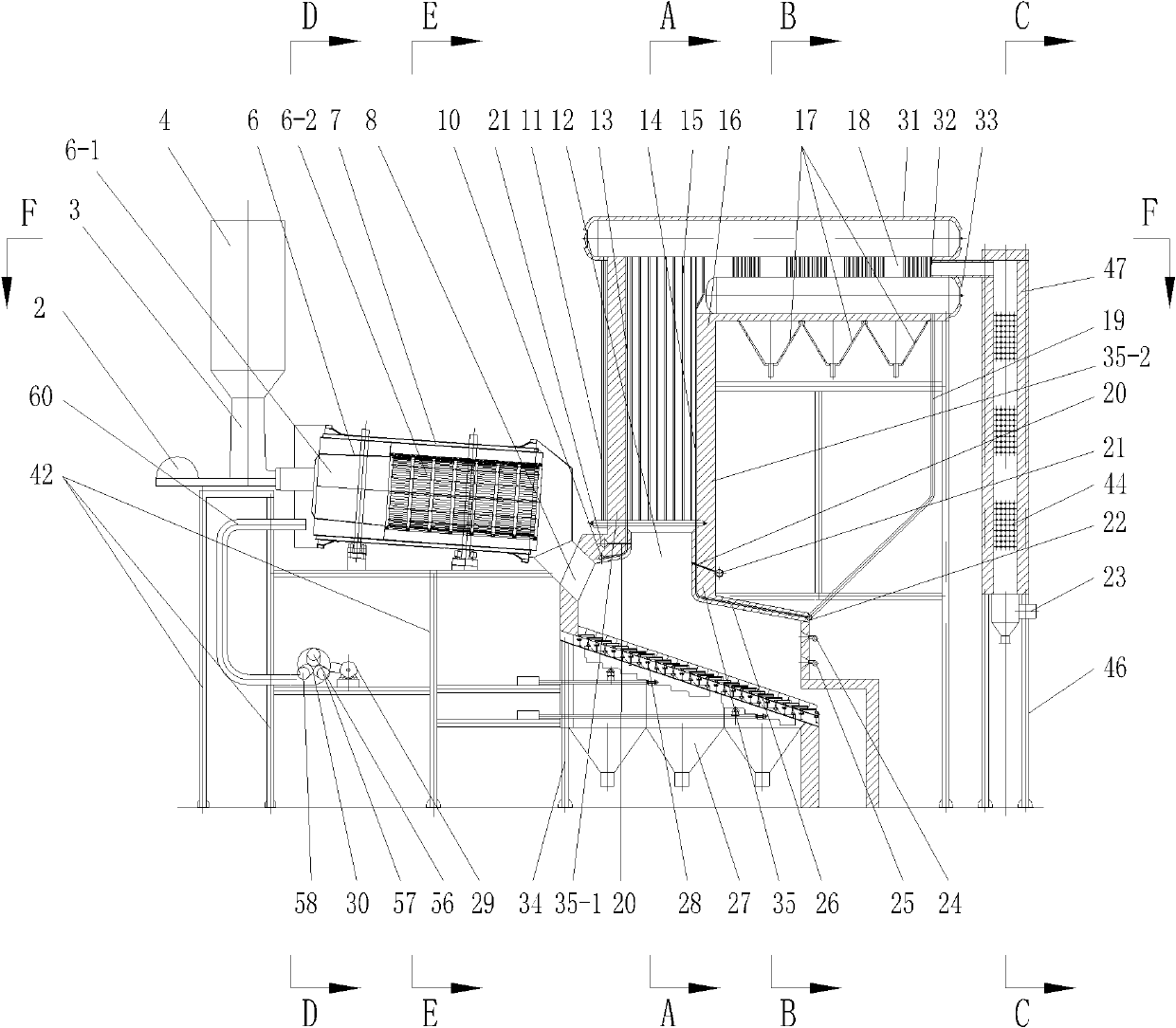

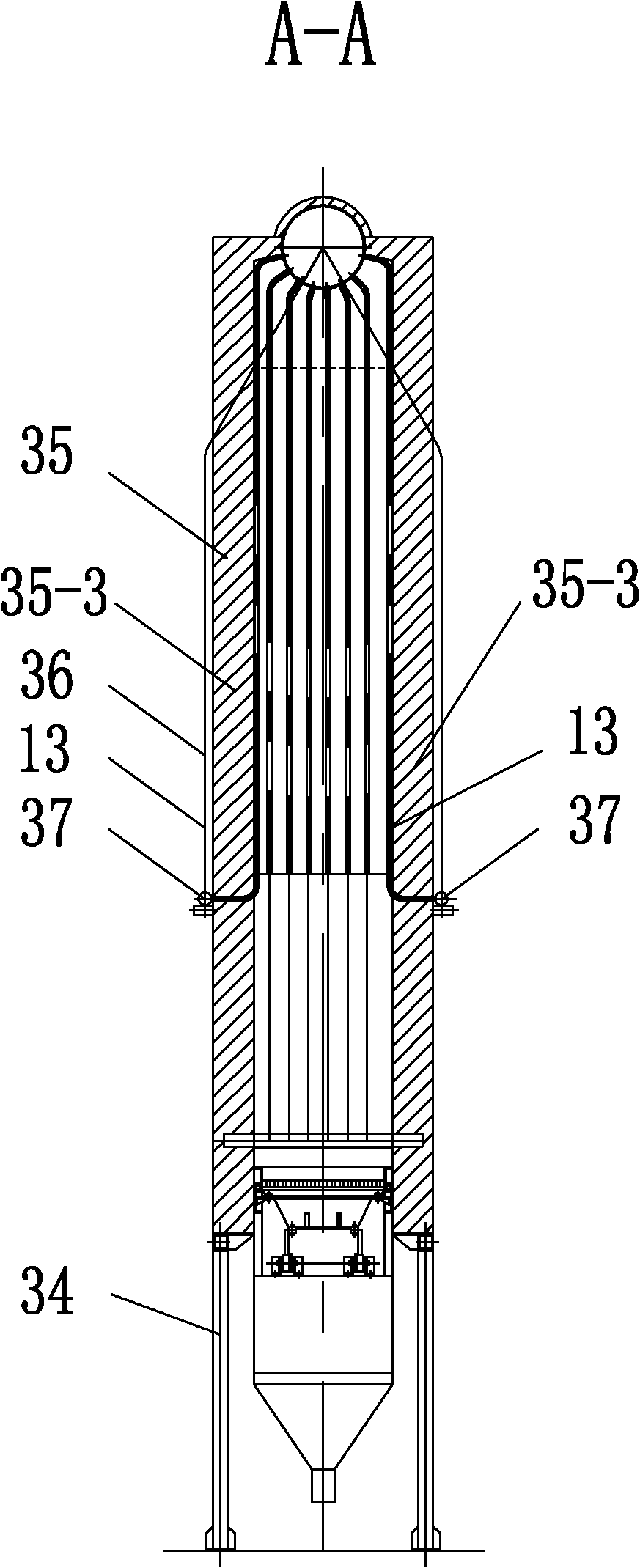

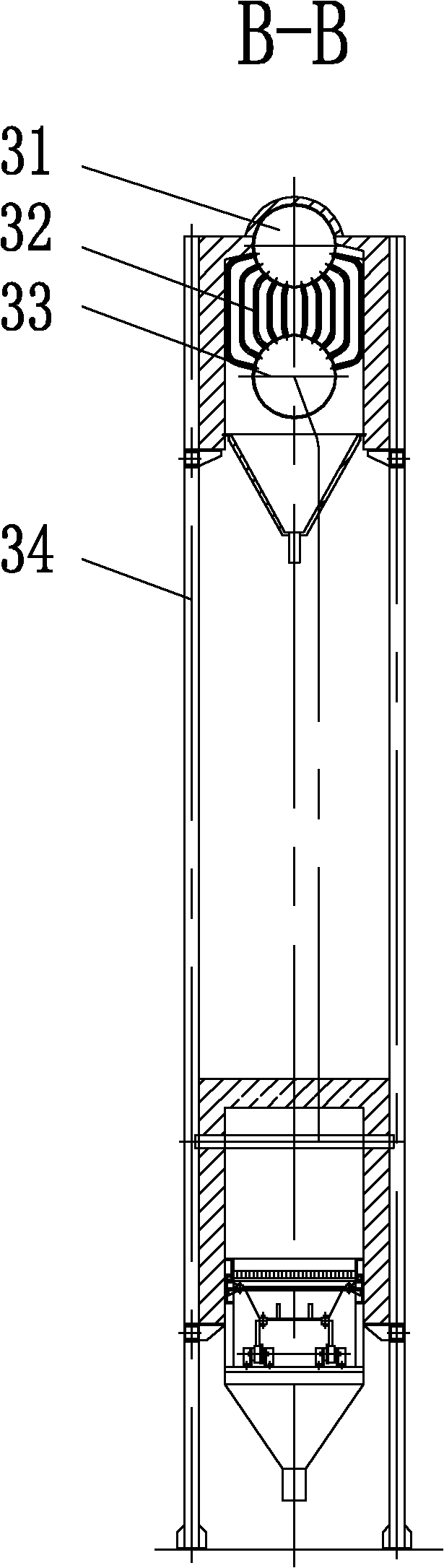

[0020] Specific implementation mode one: combine Figure 1-7 Description, the three-dimensional graded air supply combined waste incineration device of the present embodiment consists of a feeding device 3, a rotary drying and pyrolysis device 7, a first support 42, a grate type incineration device 16, a pyrolysis gas conveying fan 29, a thermal Decomposition gas distribution device 30 and a plurality of pipelines 60, one end of the rotary dry pyrolysis device 7 is provided with a feed port 38, an oil combustion nozzle 39, an air inlet 40 and a lye nozzle 41, the upper The lower end of the feeding device 3 communicates with the feed port 38 of the rotary drying pyrolysis device 7, and the other end of the rotary drying pyrolysis device 7 communicates with the grate type incineration device 16, and the feeding device 3 and the rotary drying heat The solution device 7 is all fixedly installed on the first support 42;

[0021] The grate type incineration device 16 includes a gra...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 and Figure 6 Explain that the rotary drying and pyrolysis device 7 described in this embodiment is composed of a transmission device 51, an outer cylinder 53, an inner cylinder 6, an insulating layer 50, and an outer shell 52, and the inner cylinder 6 is located in the outer cylinder 53 And the two ends of the inner cylinder 6 are installed on the side walls of the two ends of the outer cylinder 53, the inner cylinder 6 and the outer cylinder 53 are arranged coaxially, and the outer walls of the outer cylinder 53 are wrapped with an insulating layer 50, An outer shell 52 is set on the outer wall of the insulation layer 50, the inner cylinder 6 is composed of a front cylinder 6-1 and a rear cylinder 6-2, and the rear cylinder 6-2 is uniformly processed with The grate hole 49, the front cylinder body 6-1 is provided with a feed inlet 38, a fuel combustion nozzle 39 and a lye nozzle 41, and the transmission device 51...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 Explanation, in this embodiment, the feeding device 3 in this embodiment is composed of a hopper 4 and a pusher 2 , the pusher 2 is located at the lower end of the hopper 4 and the pusher 2 is connected to a rotary drying and pyrolysis device 7 . With such a design, the waste can be pushed into the rotary drying and pyrolysis device 7 by the pusher 2 . Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com