Patents

Literature

76results about How to "Reduce Excess Air Coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

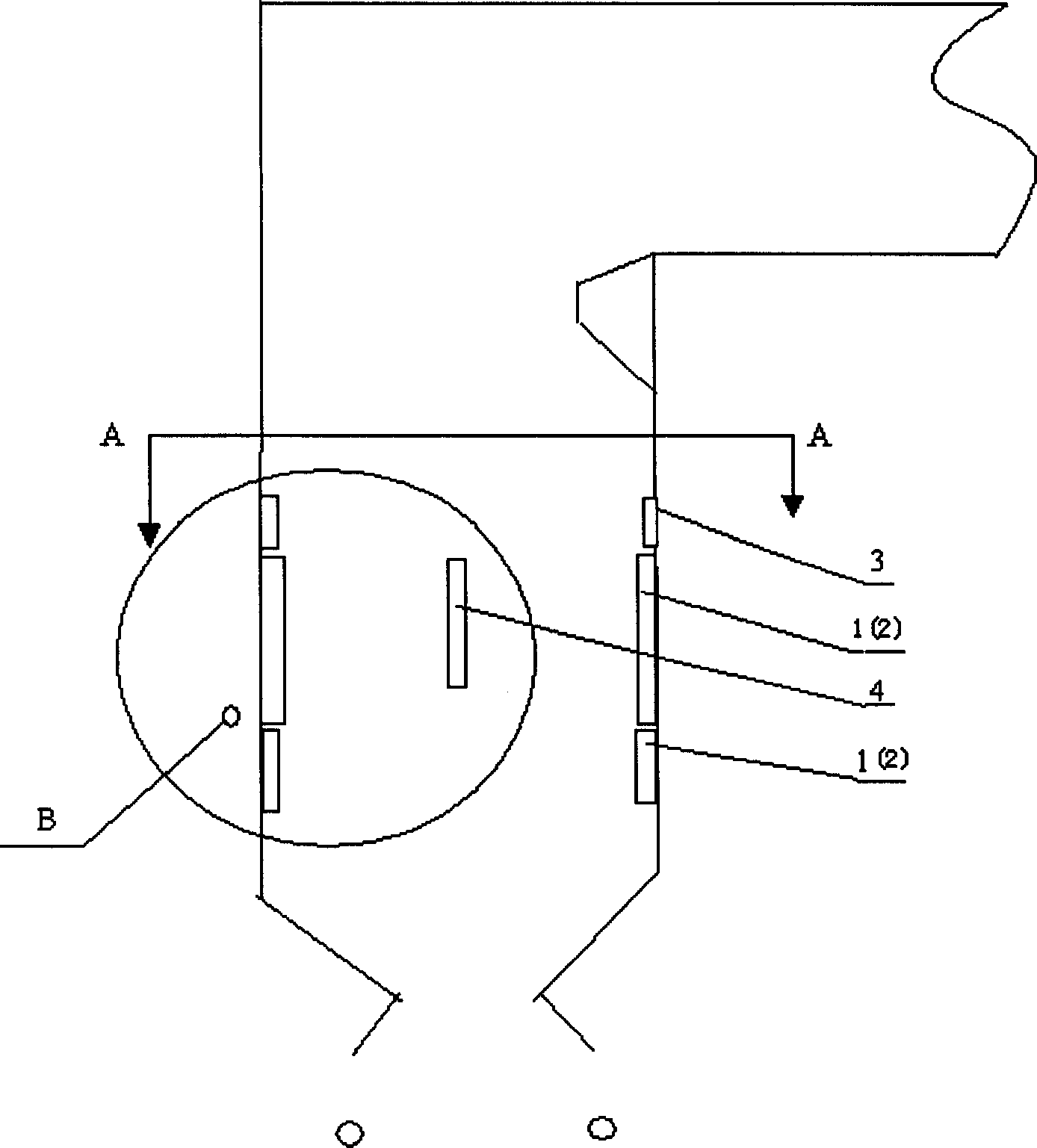

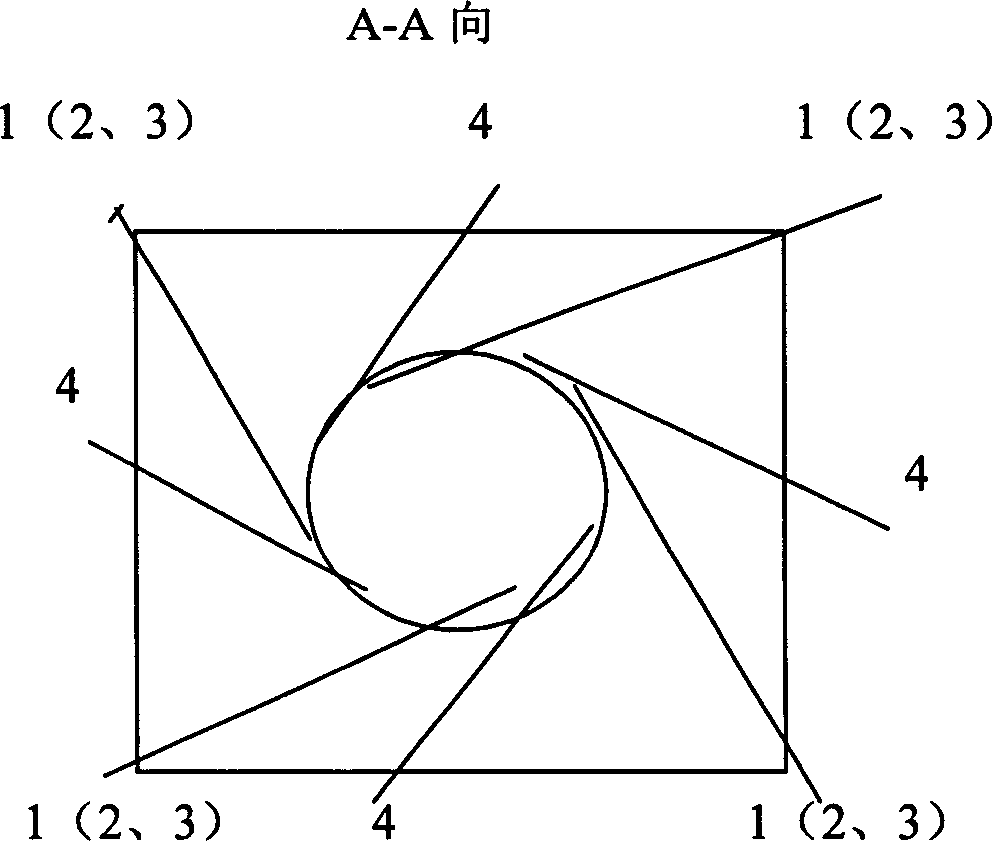

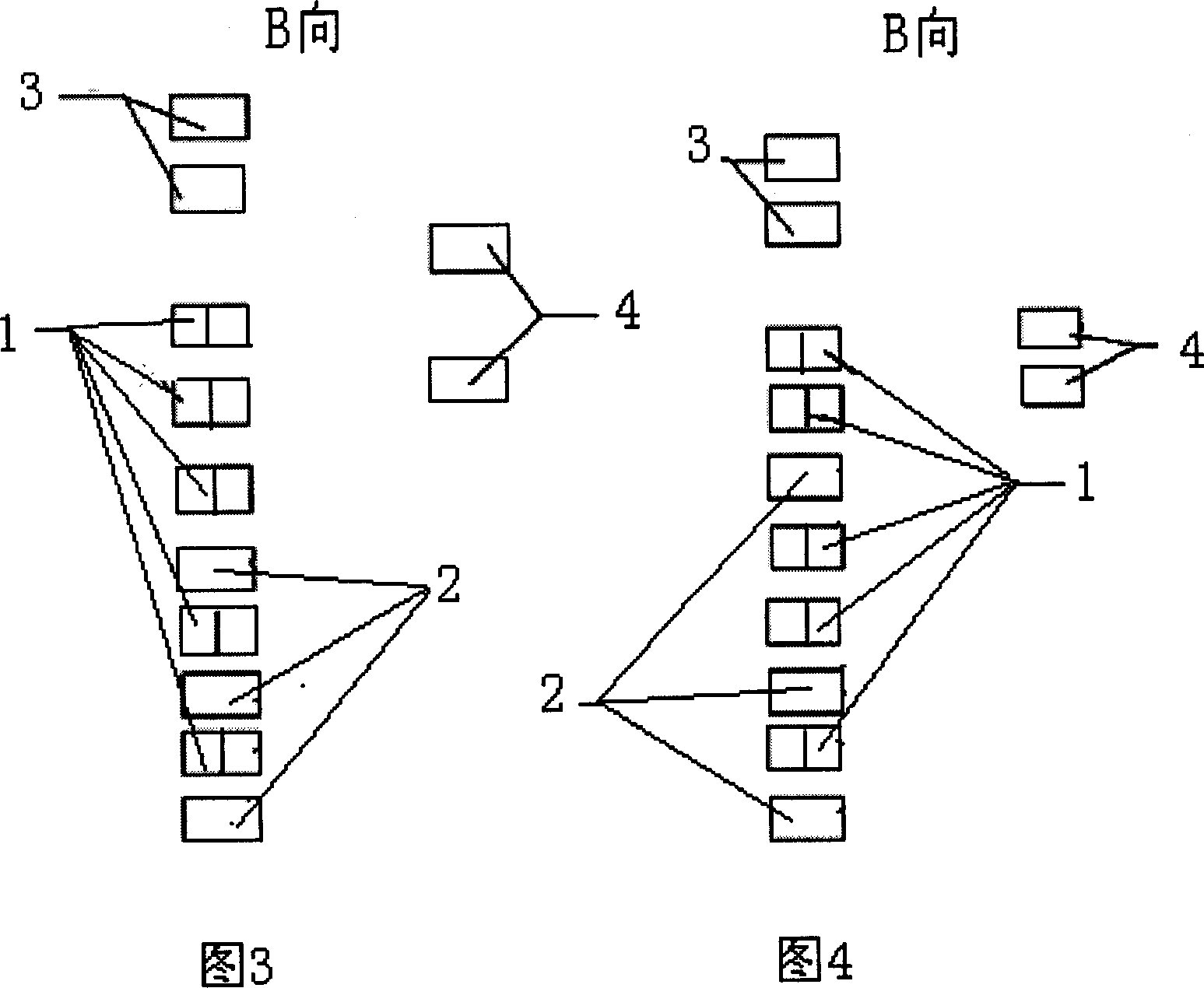

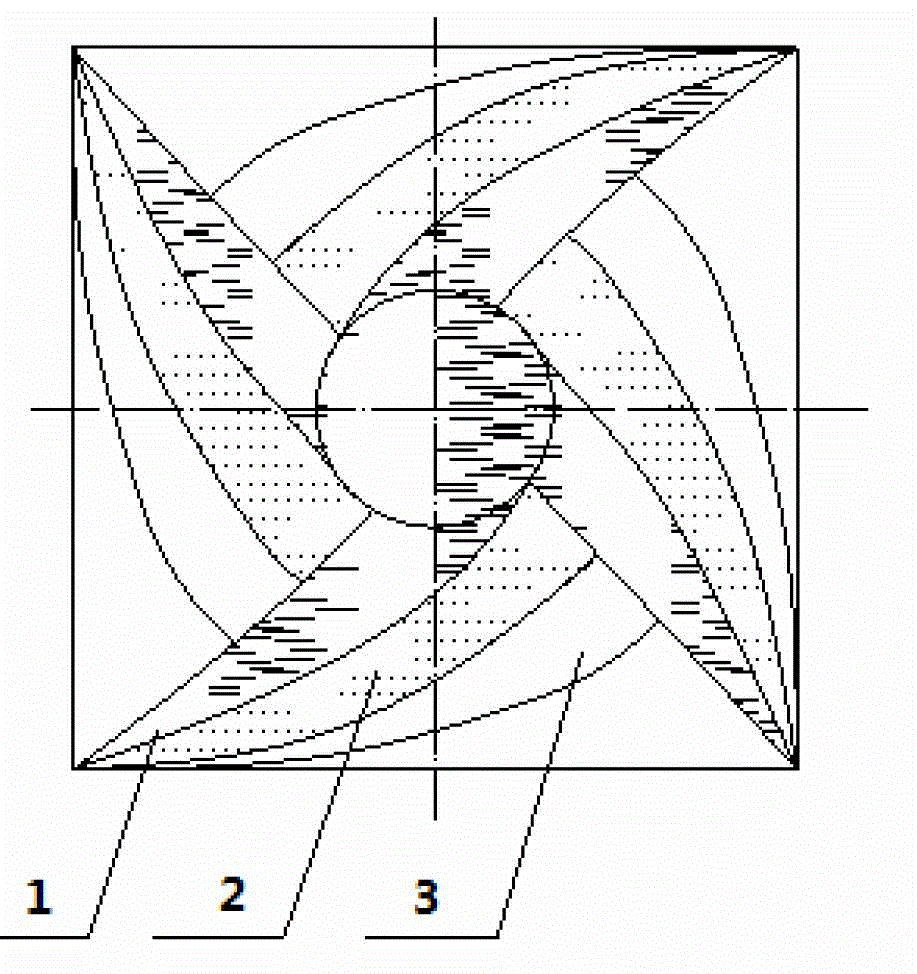

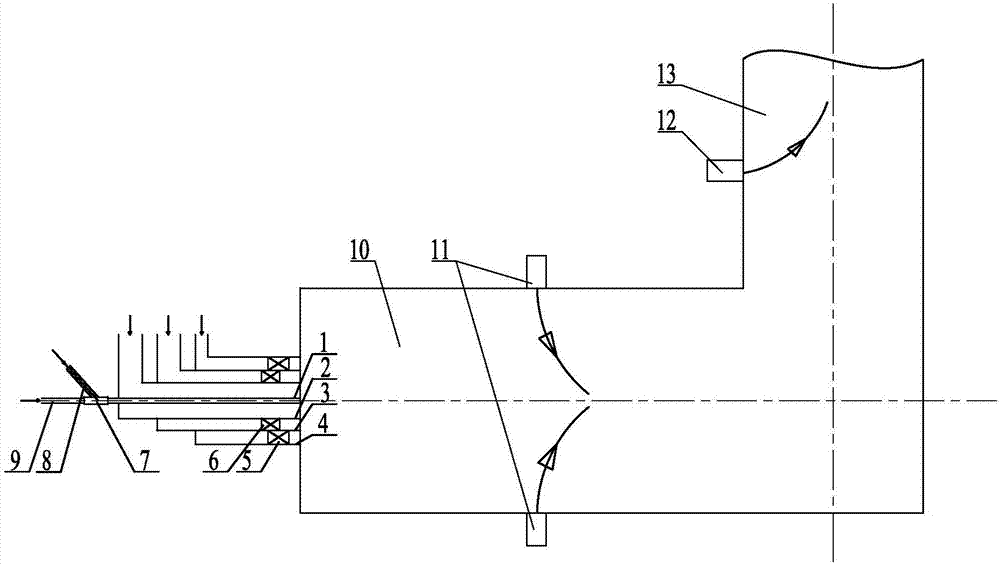

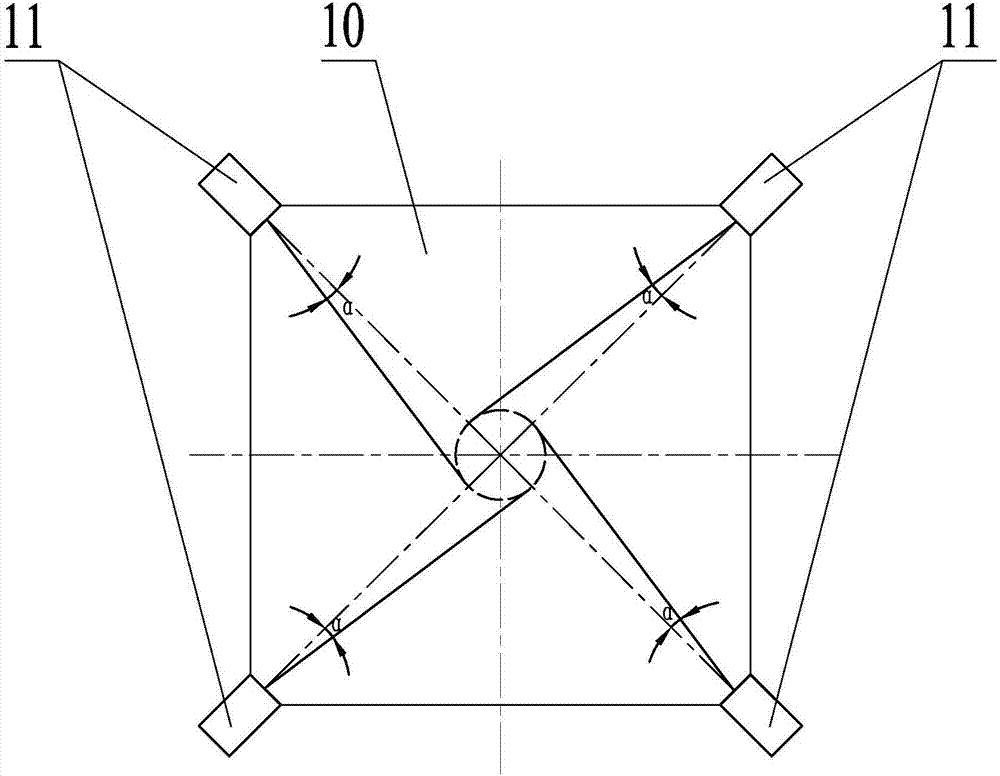

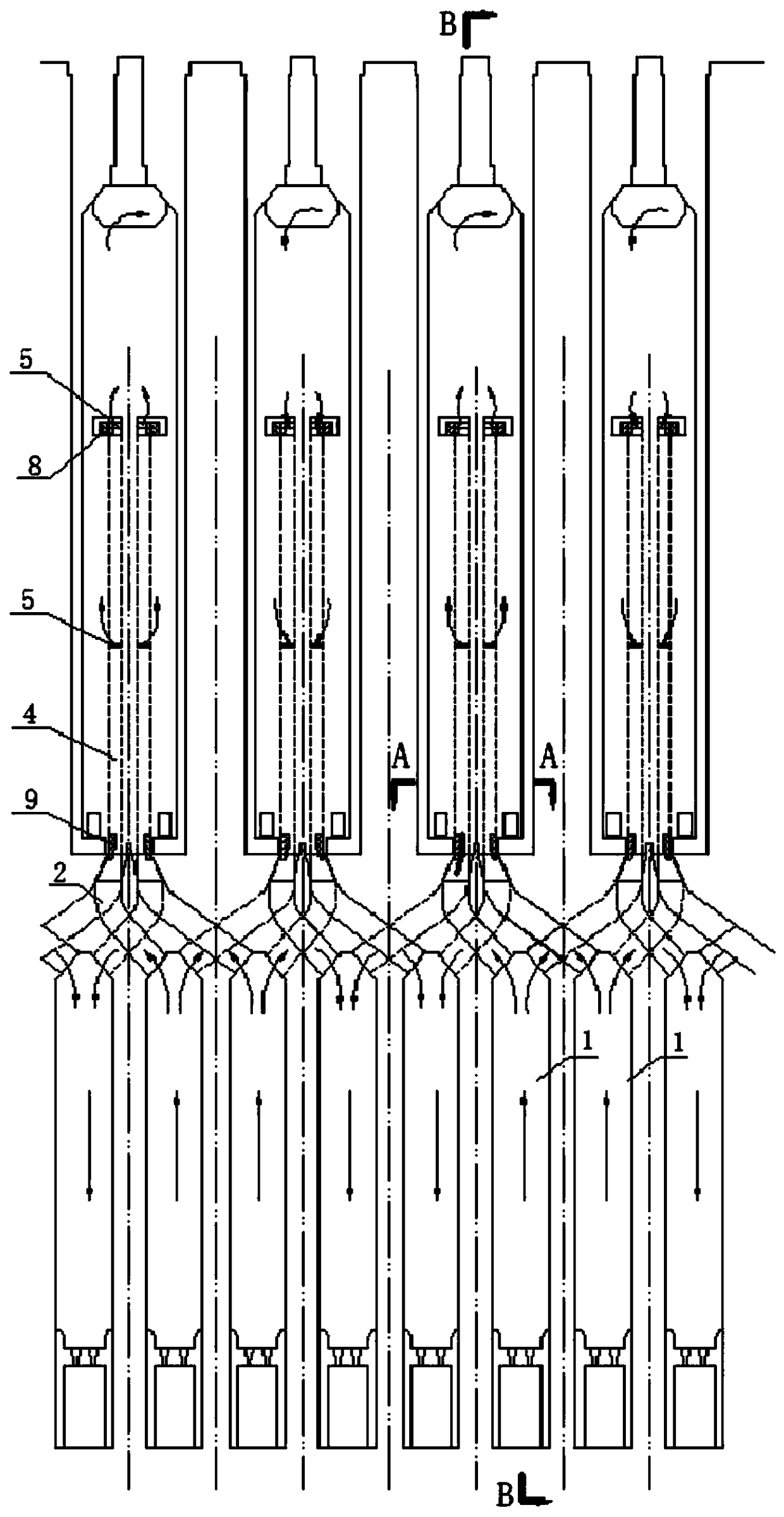

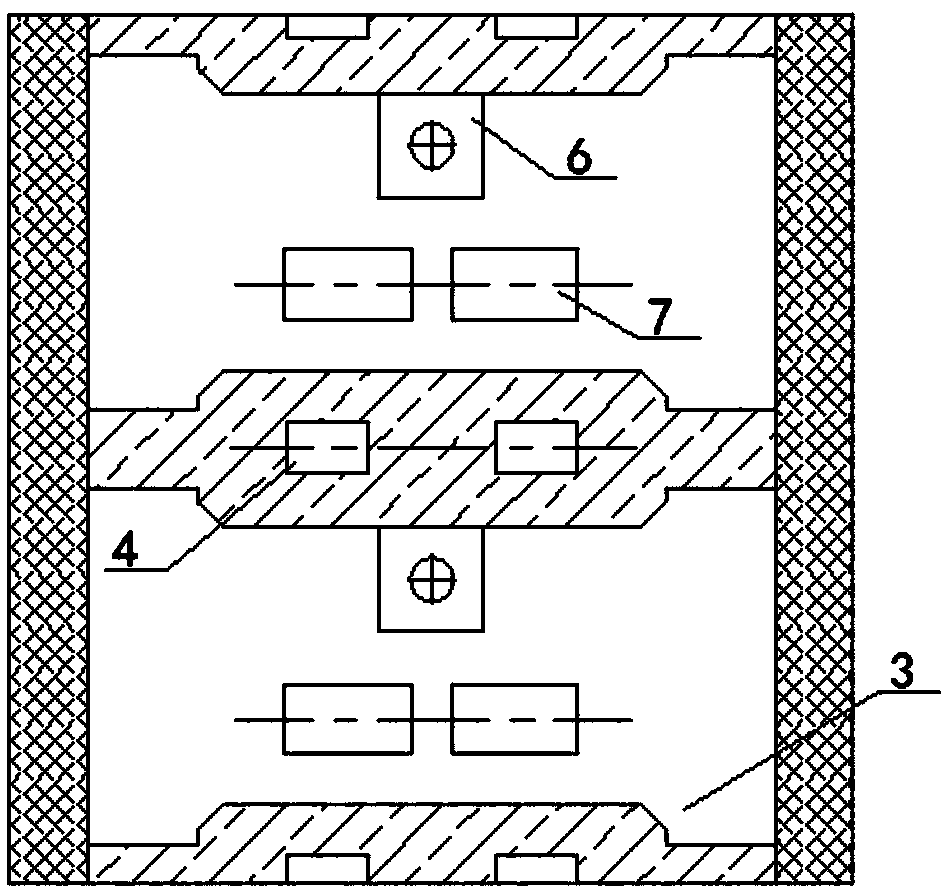

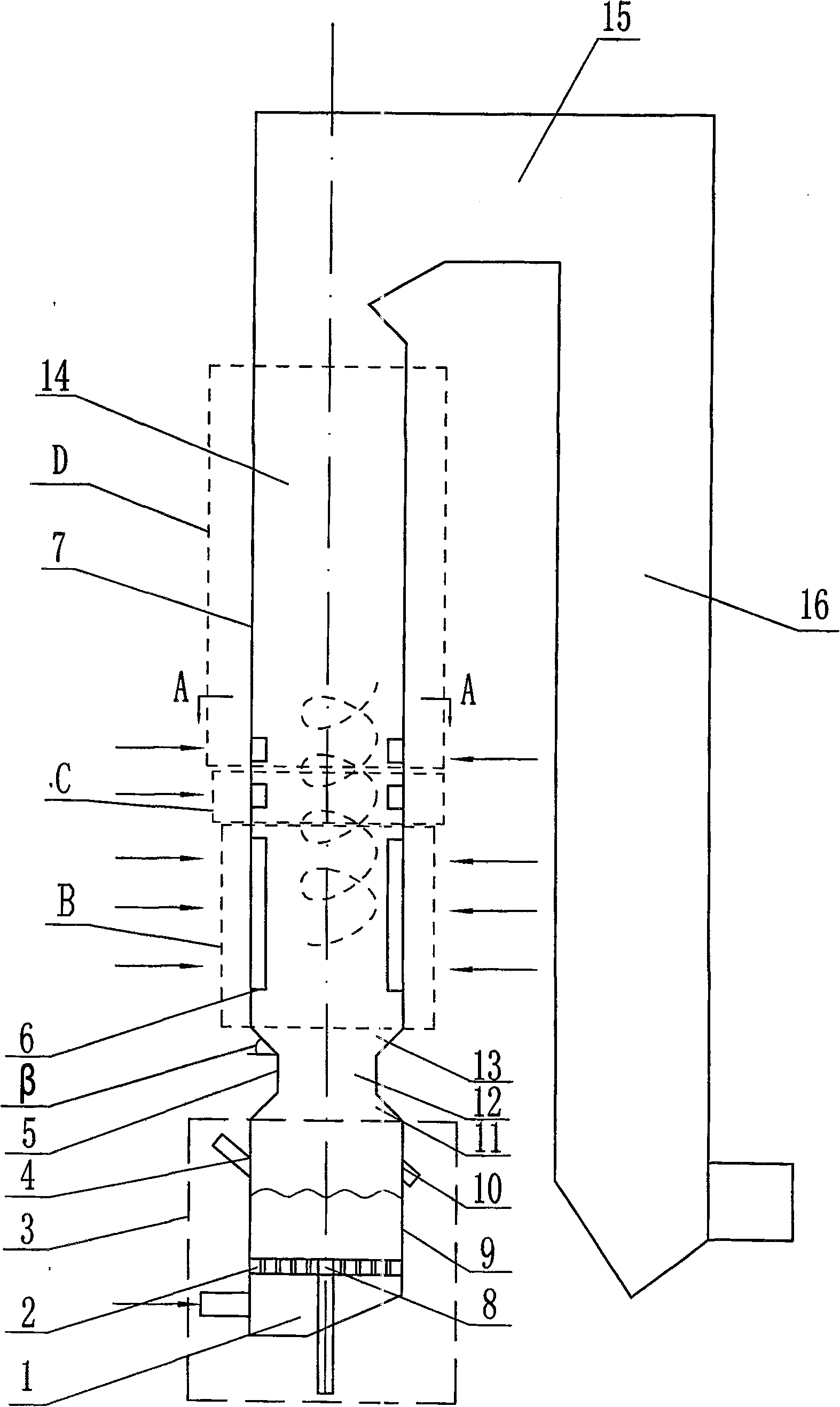

Spliting arranging method for new three area burner of tangential circle boiler

InactiveCN1786564AEmission reductionBurnout has little effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal dustEngineering

The invention discloses tangential firing boiler new three zones burner split arrangement type. The includes the following steps: dividing combustion process into three zones that stable combustion zone, combustion and reducing zone, and full combustion zone by gas coal type arrangement plus once wind centralizing arrangement plus fission OFA plus top OFA arrangement type; complementing combustion air in time by fission OFA arrangement; the deep hypoxia cryogenic combustion of the initial stage coal dust air flow and the deep fuel of the combustion and reducing zone are fractional combustion. This successfully solves the abuse that the current low NOx combustion technique denitrifying effect is bad. Secondary burn-out wind complementing type can greatly reduce the influence of the new three zones burner fission arrangement type on the combustion efficiency. Thus this can successfully solves the problem of taking account of the current NOx combustion technique and the combustion efficiency at the same time. It is the burner arrangement type with better denitrifying effect.

Owner:XIAN THERMAL POWER RES INST CO LTD

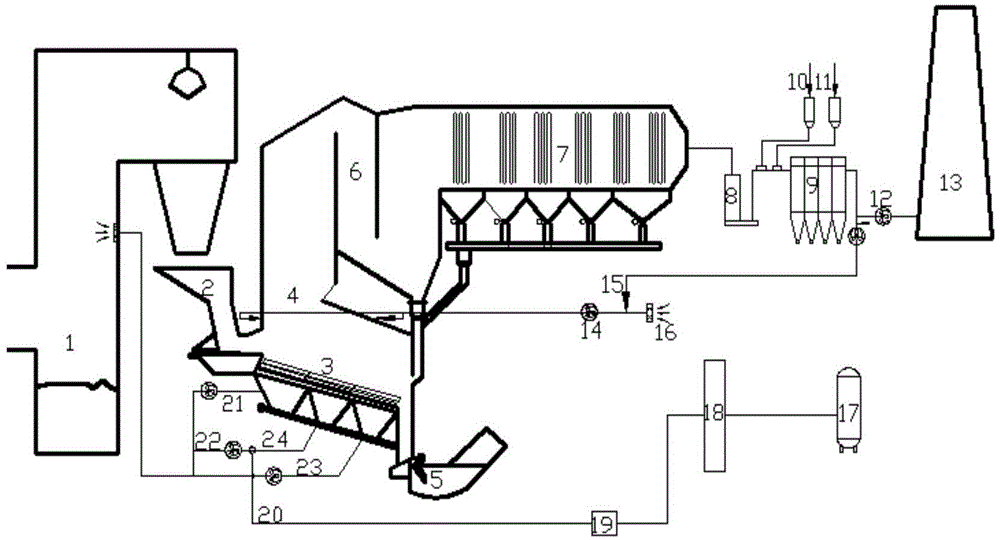

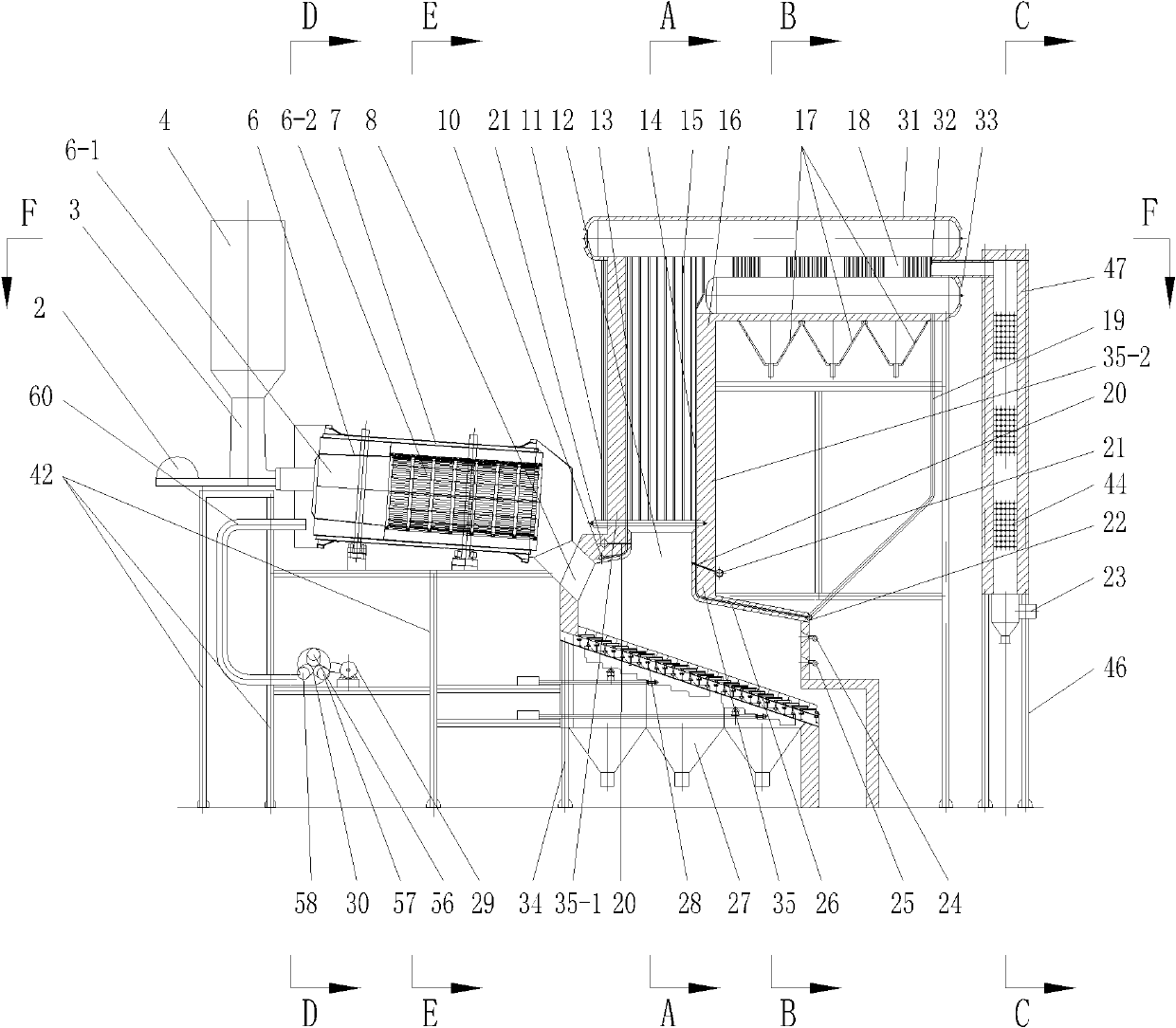

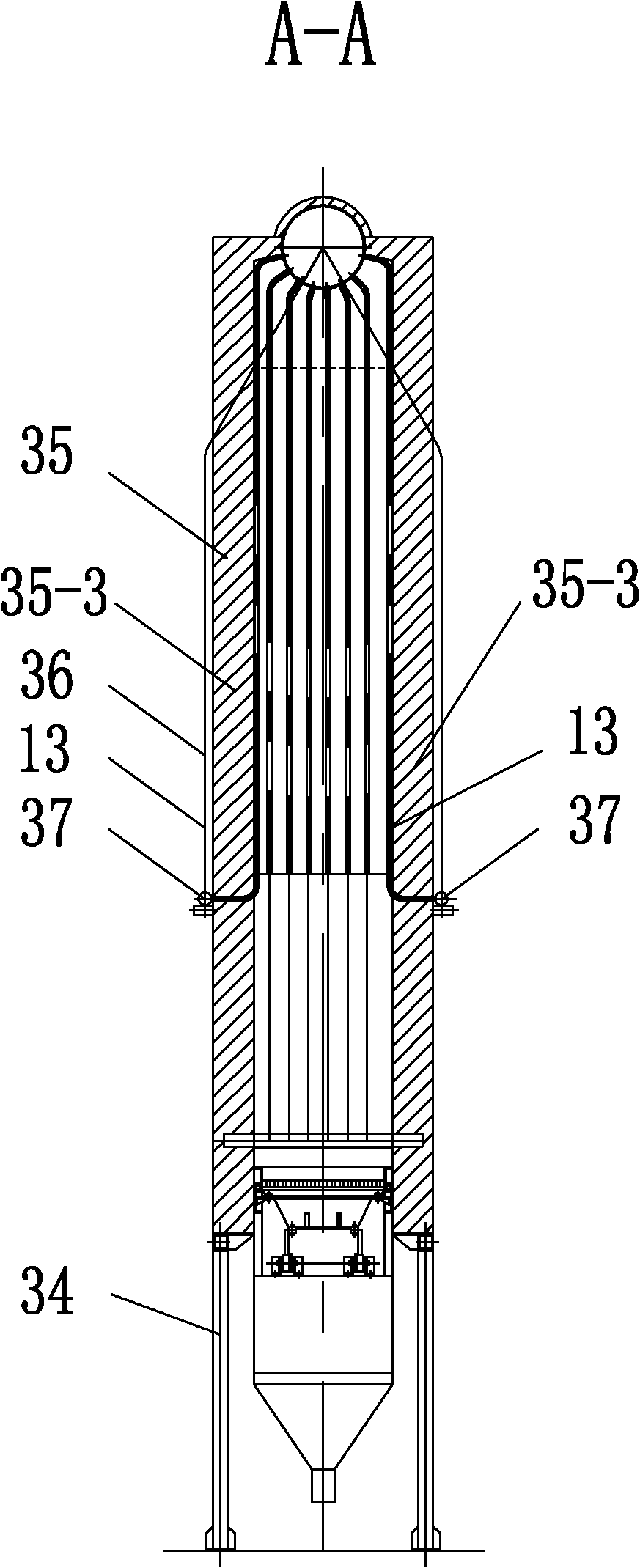

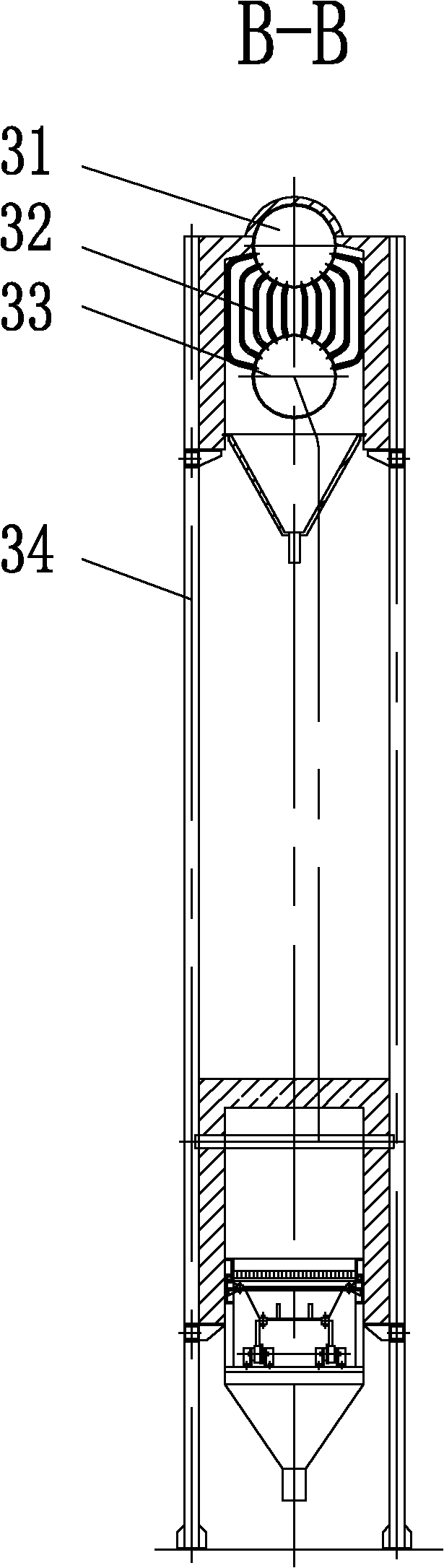

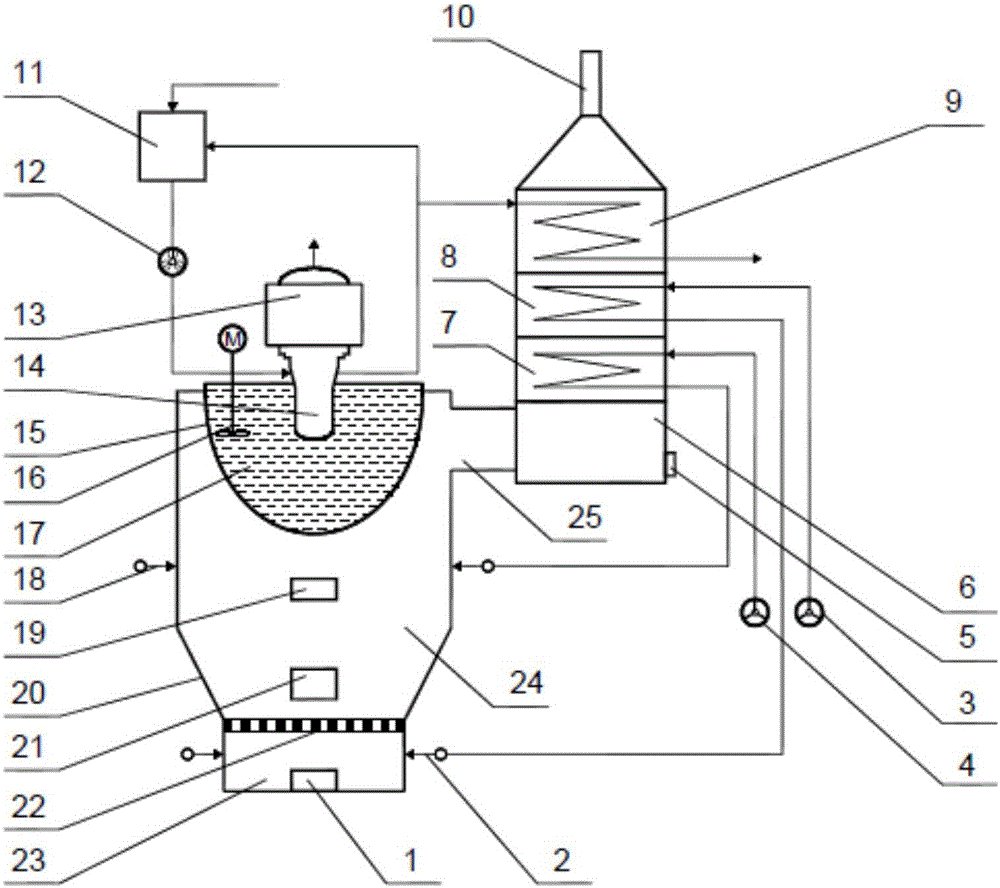

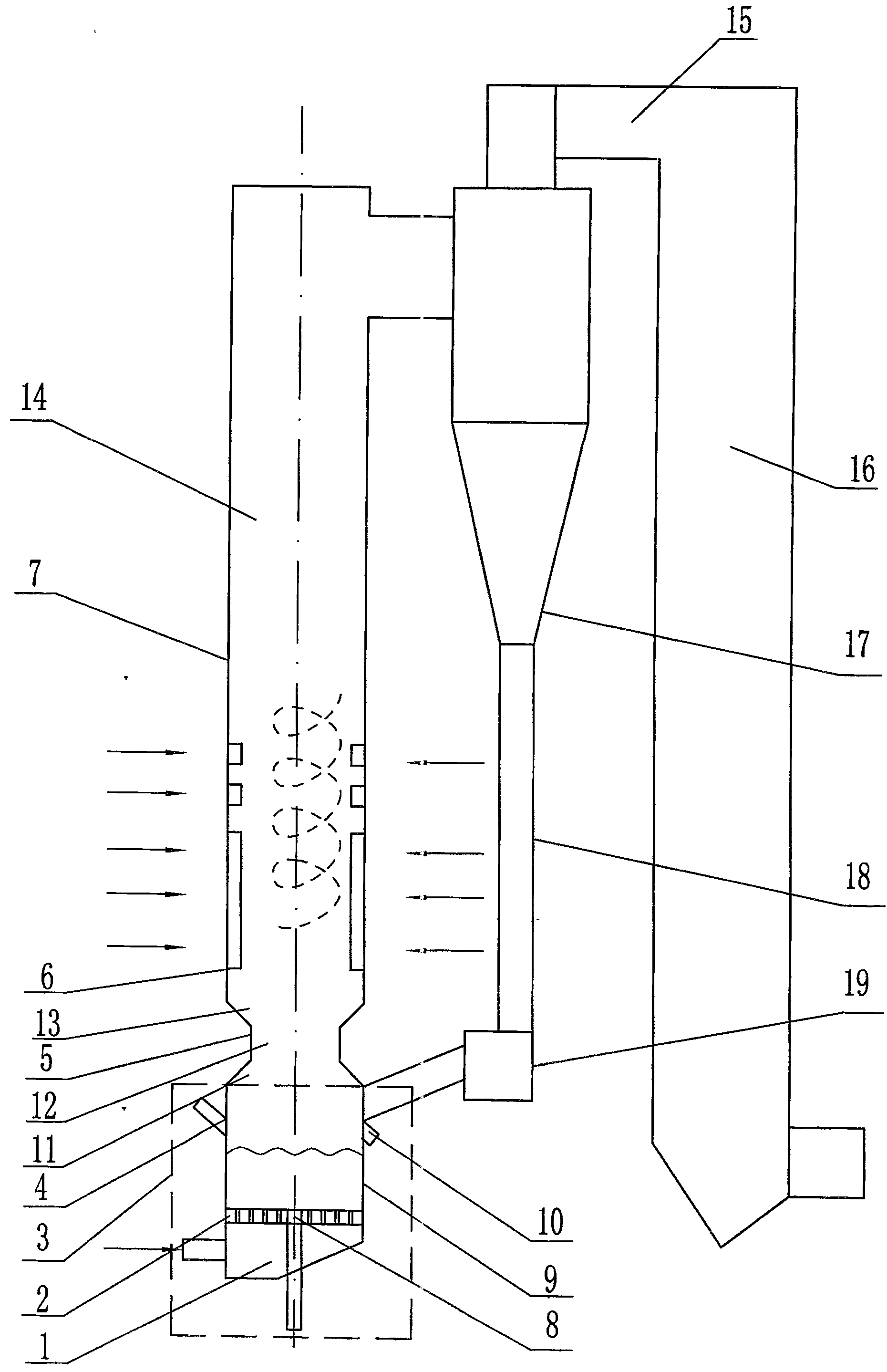

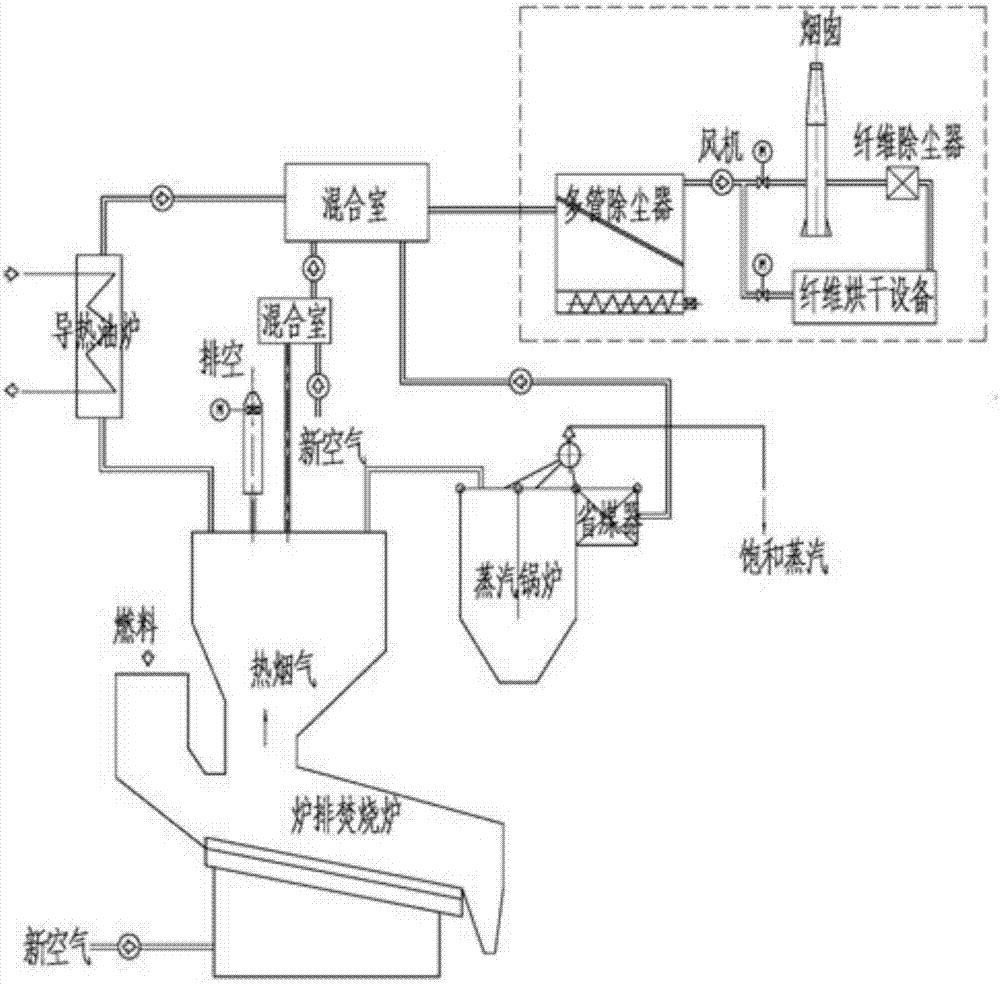

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

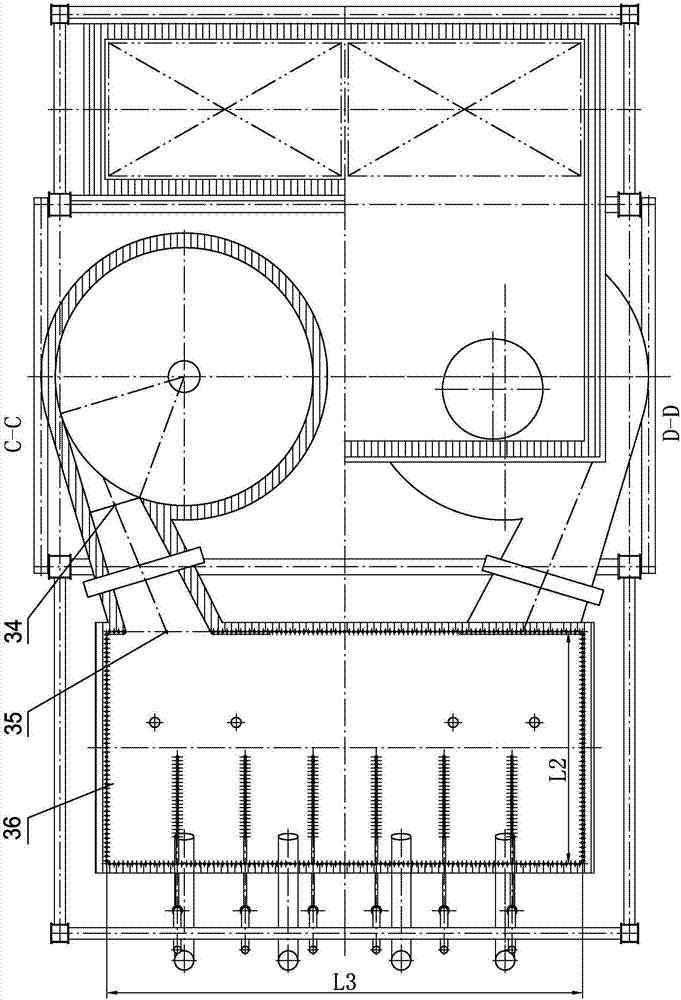

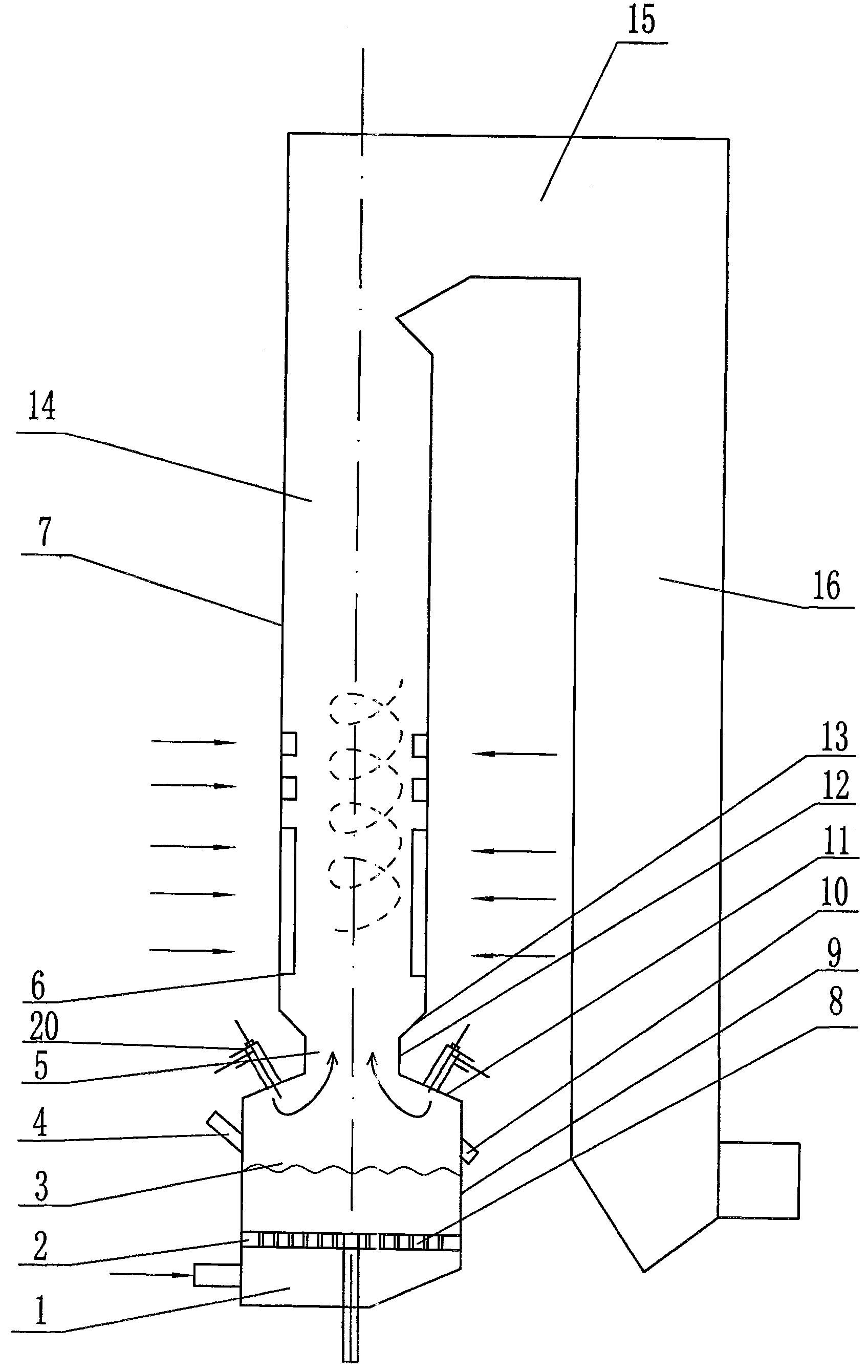

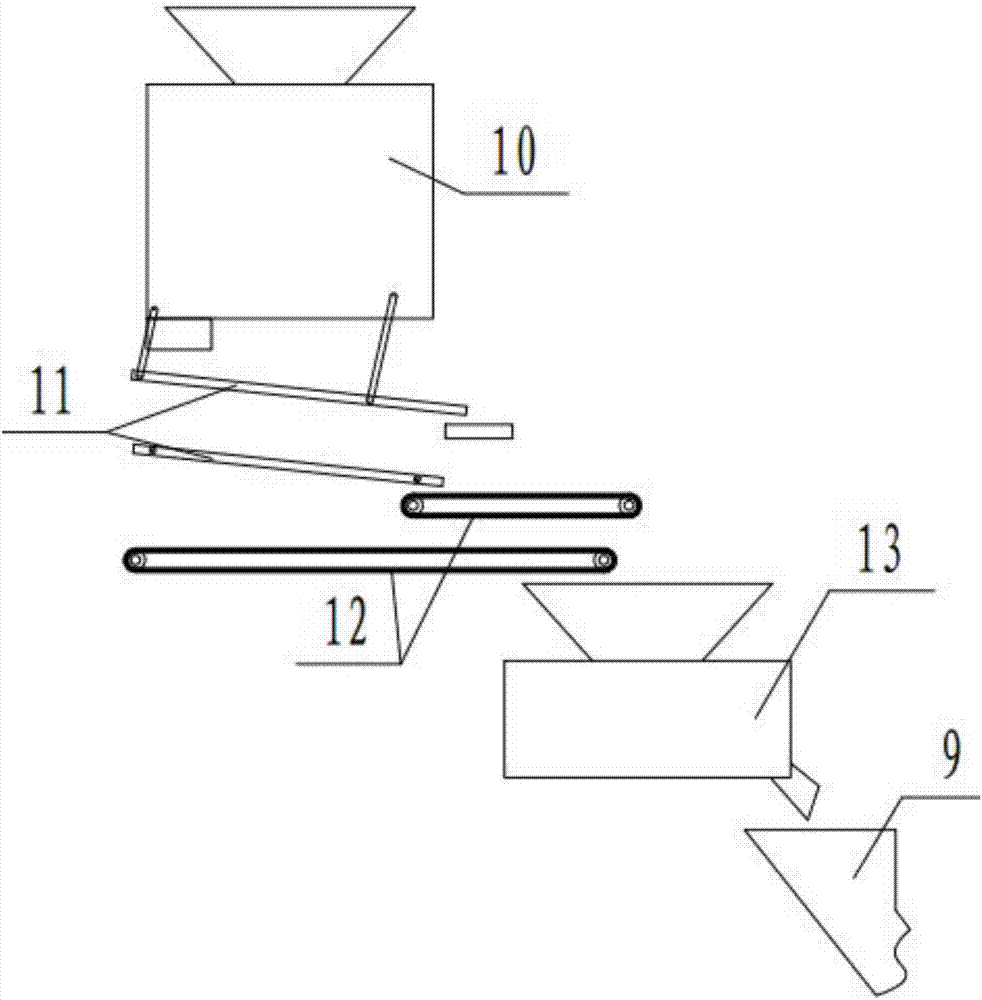

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

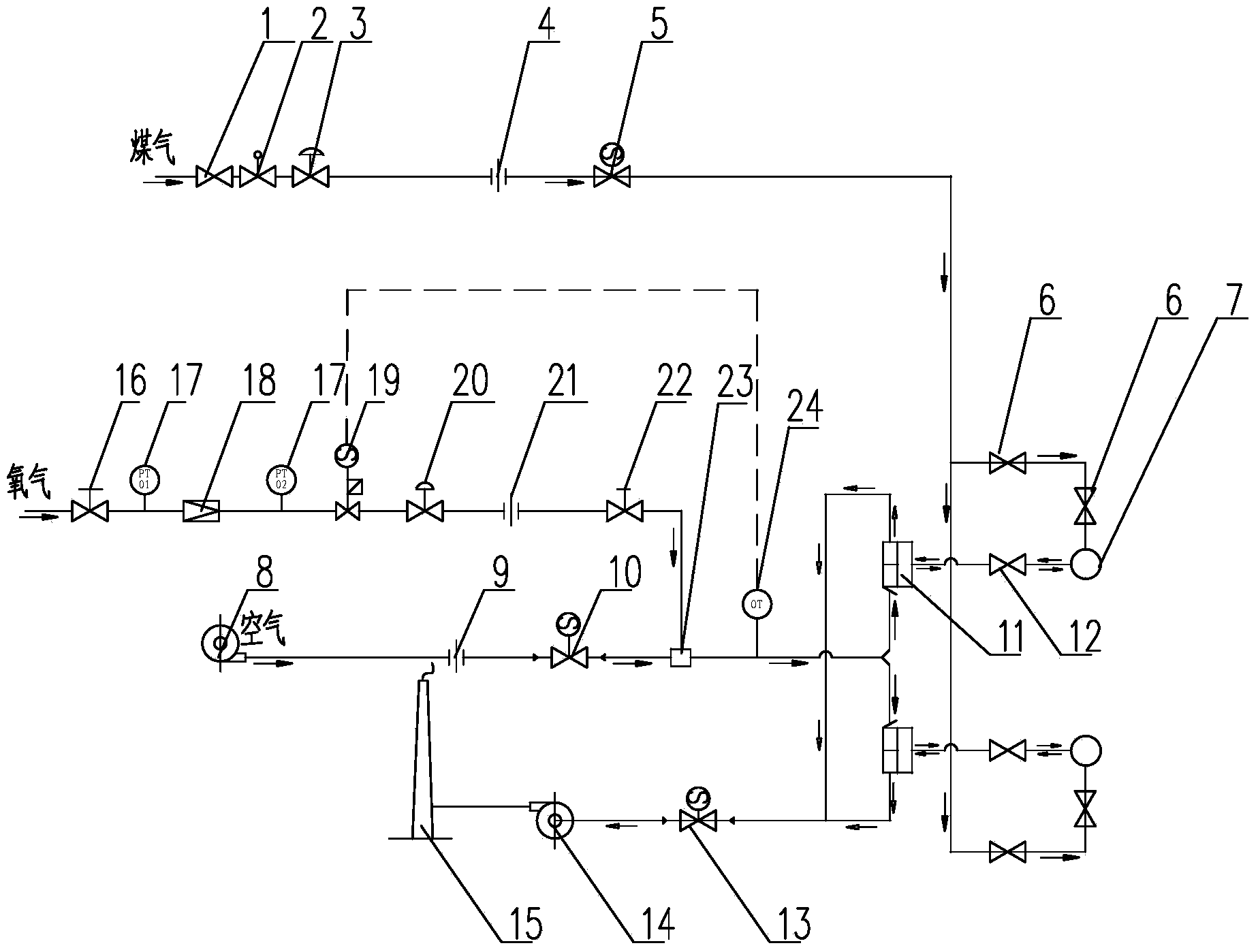

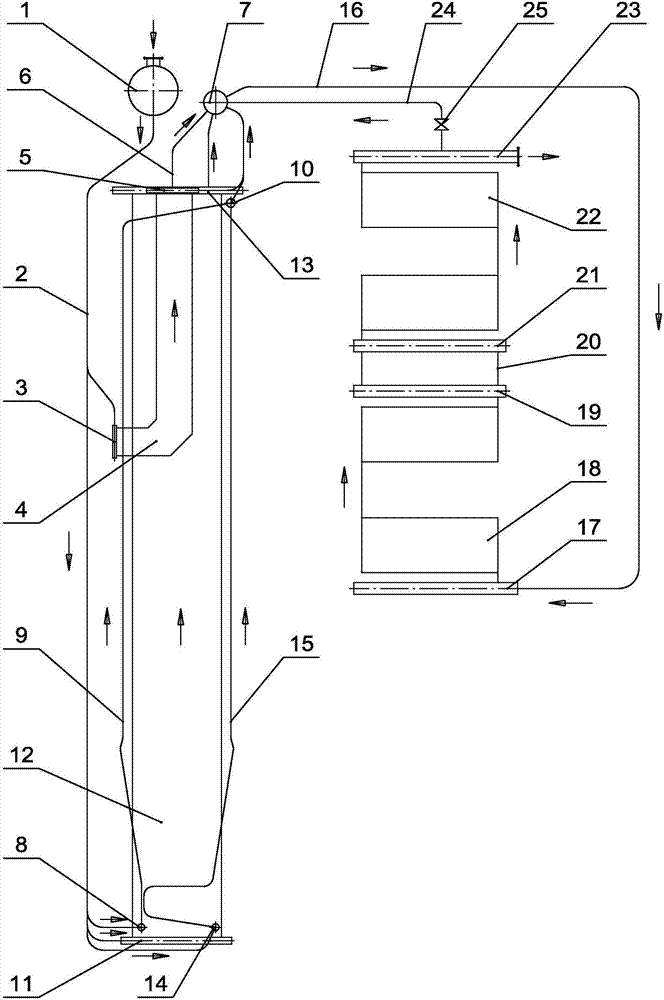

Cold crude gas heat accumulating type oxygen-enriched combustion method and cold crude gas heat accumulating type oxygen-enriched combustion system

InactiveCN103953920AReduce generationPromote environmental protectionDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemOxygen system

The invention relates to a cold crude gas heat accumulating type oxygen-enriched combustion method and a cold crude gas heat accumulating type oxygen-enriched combustion system. The combustion method comprises the steps of transmitting cold crude gas, generating and transmitting mixed oxygen-enriched air, reversing the oxygen-enriched air by an air-smoke reversing valve, heating the reversed oxygen-enriched air in a heat accumulating type burner, mixing the oxygen-enriched air with gas for burning, discharging smoke, and the like; the combustion system comprises a gas system, an air-smoke system and an oxygen system, wherein the tail end of a pipeline of the oxygen system is connected with a dynamic mixer of the air-smoke system; the tail end of a branch behind the air-smoke reversing valve in the air-smoke system is connected with the heat accumulating type burner of the gas system. Compared with the prior art, the method and the system have the beneficial effects that (1) the burning velocity is increased, the tempering is avoided, and the combustion safety is improved; (2) the ignition temperature of fuel and the burn out time are reduced; (3) the excess air coefficient is reduced, and the amount of the smoke after combustion can be reduced; (4) the production of CO2 and NOX can be effectively reduced, so that the environmental protection can be better realized; (5) the system is simple in structure, convenient to operate and high in degree of automation.

Owner:辽宁向导科技发展有限公司

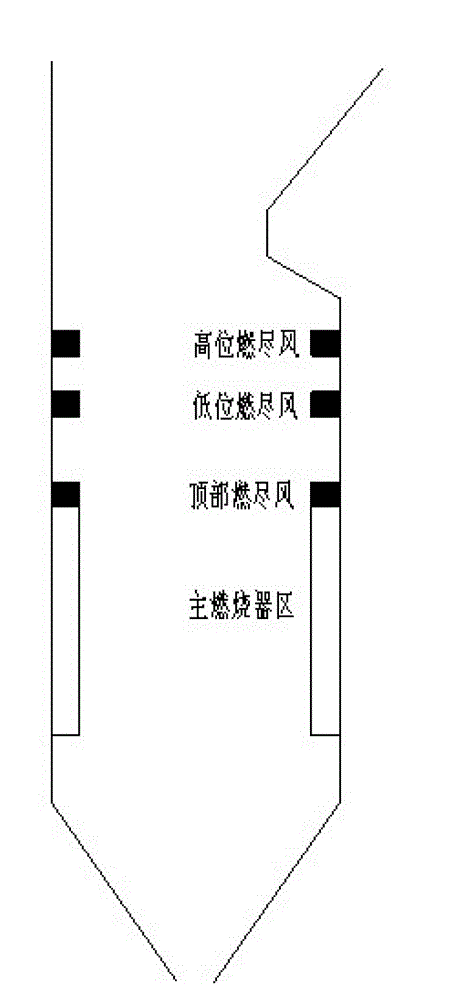

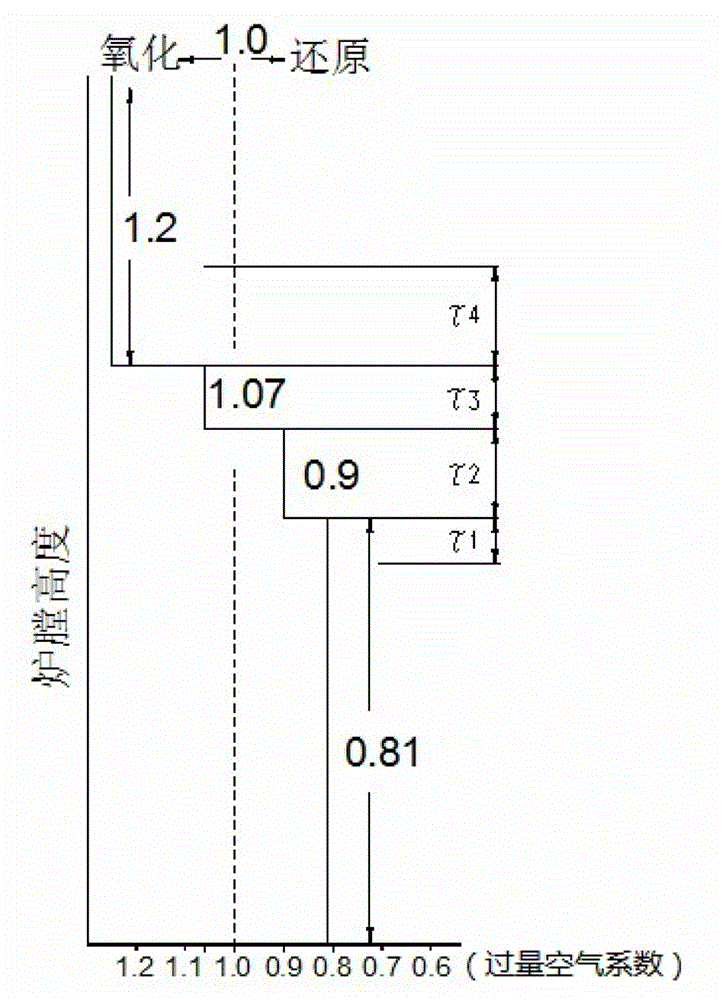

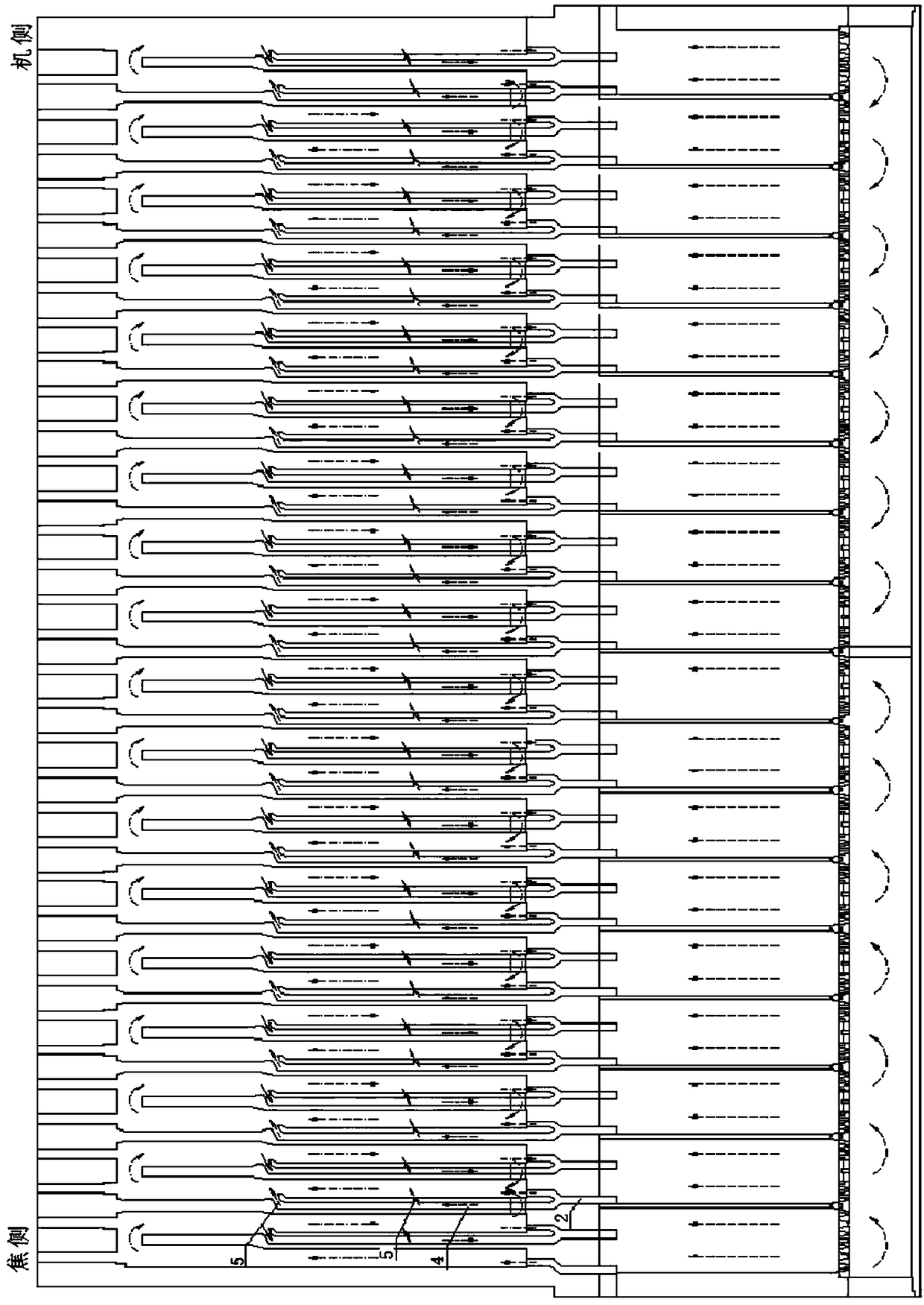

4D multidimensional low-nitrogen combustor

InactiveCN105090940AReduce Excess Air CoefficientDelay mixingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorBoiler furnace

The invention relates to a 4D multidimensional low-nitrogen combustor. The combustor comprises a boiler furnace. Along the vertical direction of the boiler furnace, the air for combustion is divided into four grades: the first grade is a main combustor area, the second grade is over fire air next to the top of the main combustor, the third grade is low-position over fire air, which is higher than the main combustor, and the fourth grade is high-position over fire air, which is higher than the low-position over fire air. In the vertical direction, the air is combusted in three grades. Along the horizontal cross section direction of furnace, from inner to outer, the air flow is divided into condensed coal powder air flow, diluted coal powder air flow, and flow of air close to the wall; and in the horizontal direction, the air is combusted in two grades. At the same time, the reduction and burn-out time of flue gas in the combustion area in furnace are controlled so as to reduce the discharge of oxynitride and minimize the influence on boiler burning efficiency. The provided combustor can solve the problem of limitation influence of combustion air mode, effectively reduce the discharge of oxynitride in coal-fired boiler by 50% or more, and effectively reduce the discharge of oxynitride in old boiler improvement.

Owner:WUHAN TIANHE TECH

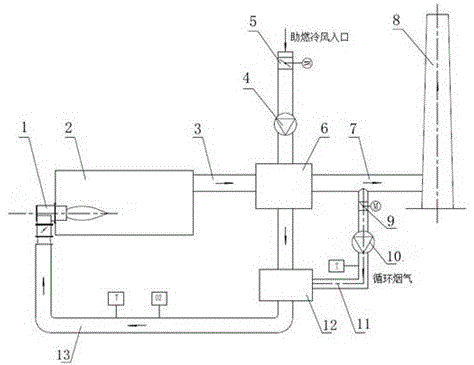

Smoke recirculator for boiler

InactiveCN105588135AReduce emission concentrationLower combustion temperatureIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyEngineeringOxygen

The invention relates to the technical field of boiler burning, in particular to a smoke recirculator for a boiler. According to a conventional smoke recirculator, auxiliary equipment is needed, a system is complicated, the investment is large, and it is quite difficult to stably lowering the oxygen concentration to the degree which is low enough in the true sense on most occasions. According to the smoke recirculator for the boiler, recirculating smoke and air are mixed, so that the burning temperature is decreased, the oxygen concentration is lowered, the smoke heat exchange coefficient is increased, and the overall efficiency of the boiler is improved; by arranging a smoke and air mixing chamber and optimizing the structure of a flue system, a complicated flue structure is simpler and more reasonable, and the stability and safety of the whole system are improved.

Owner:TAIJUNE BOILER IND KUSN

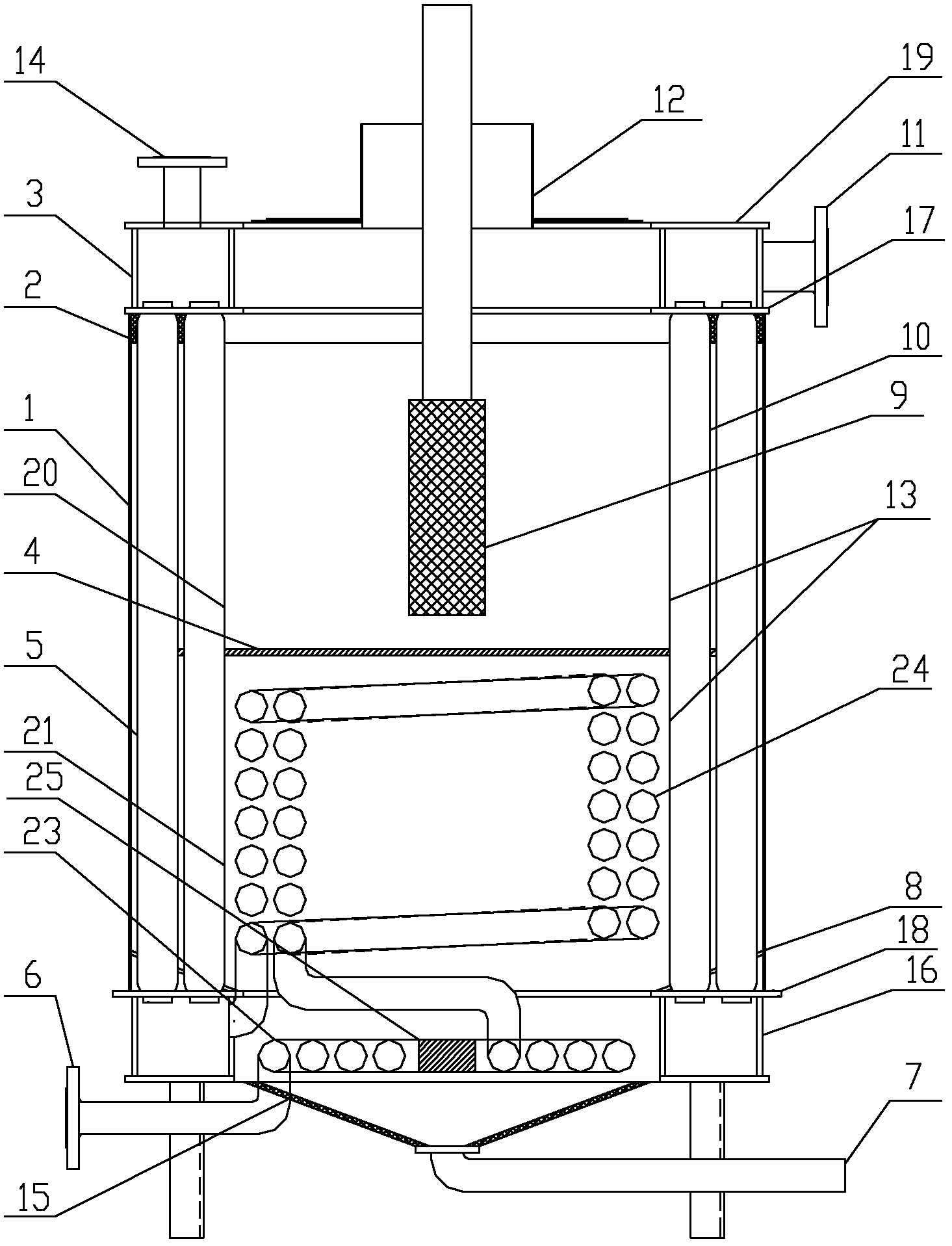

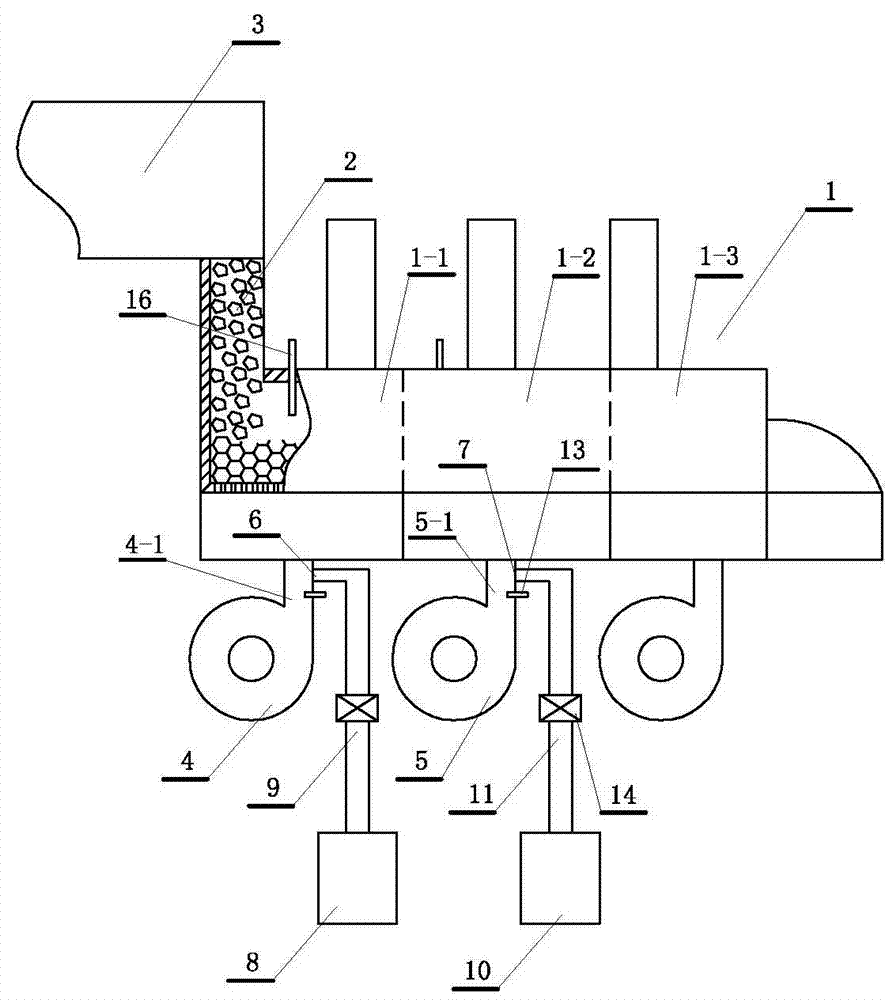

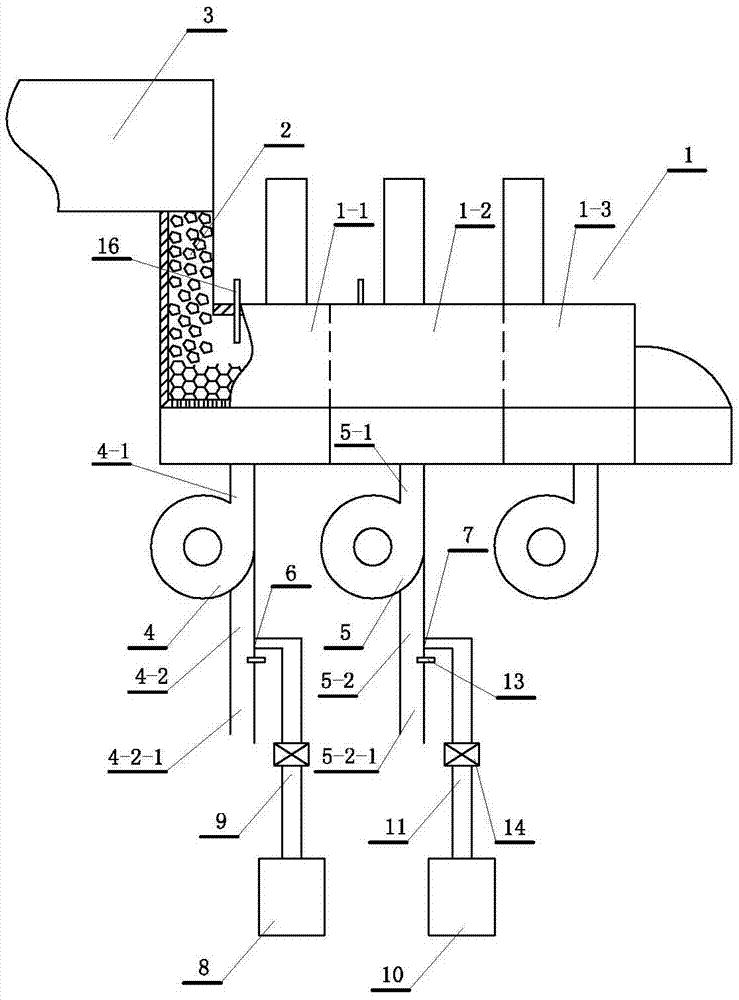

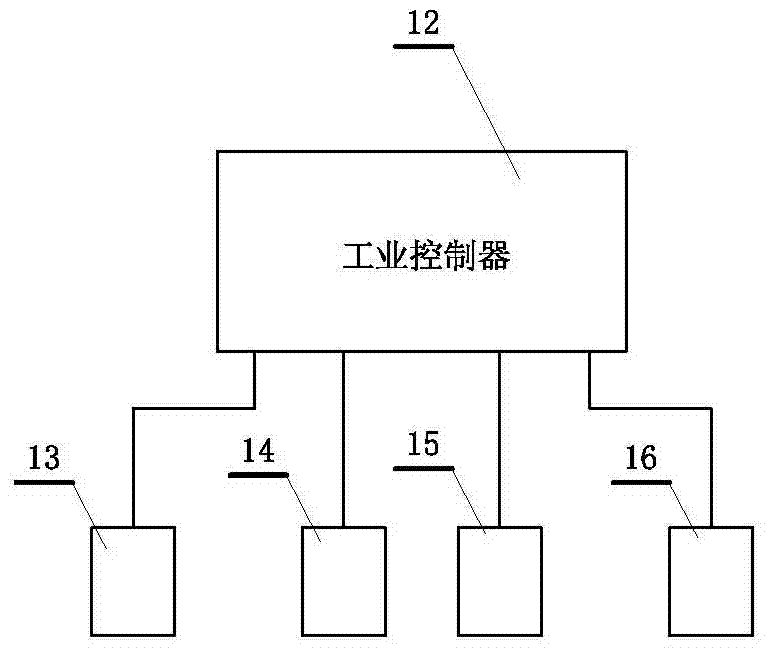

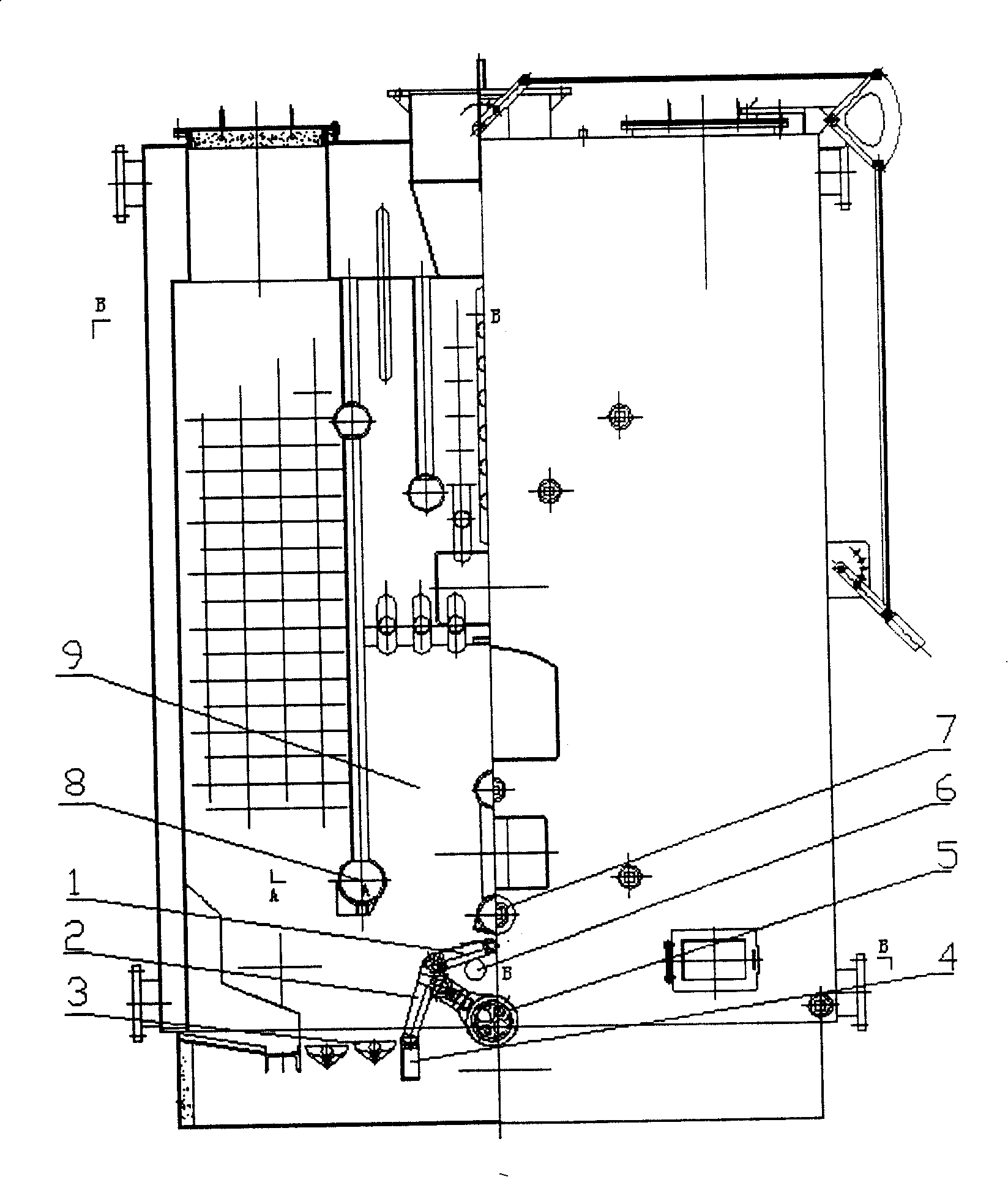

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

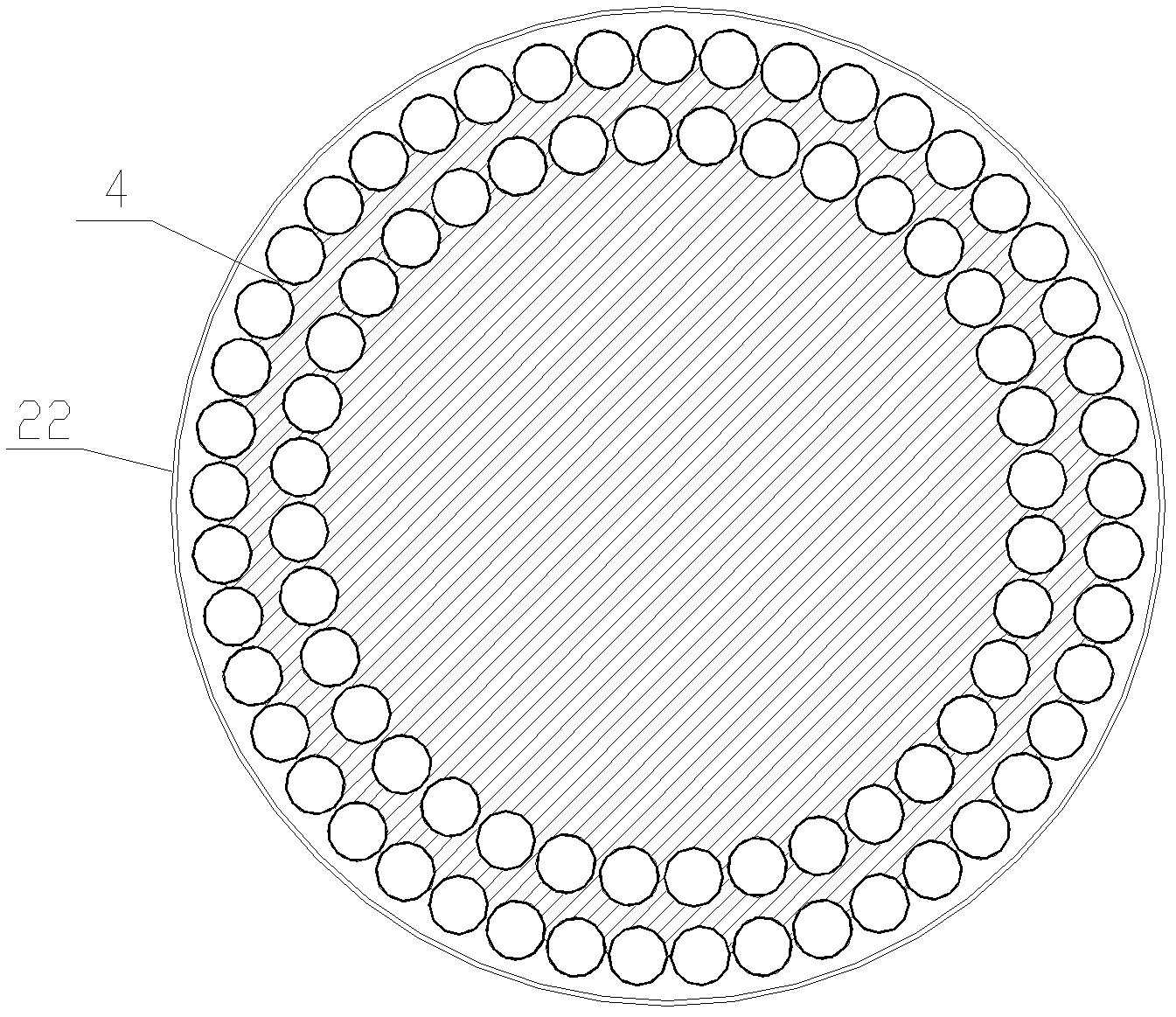

Through-flow type narrow-clearance integral condensation hot-water boiler

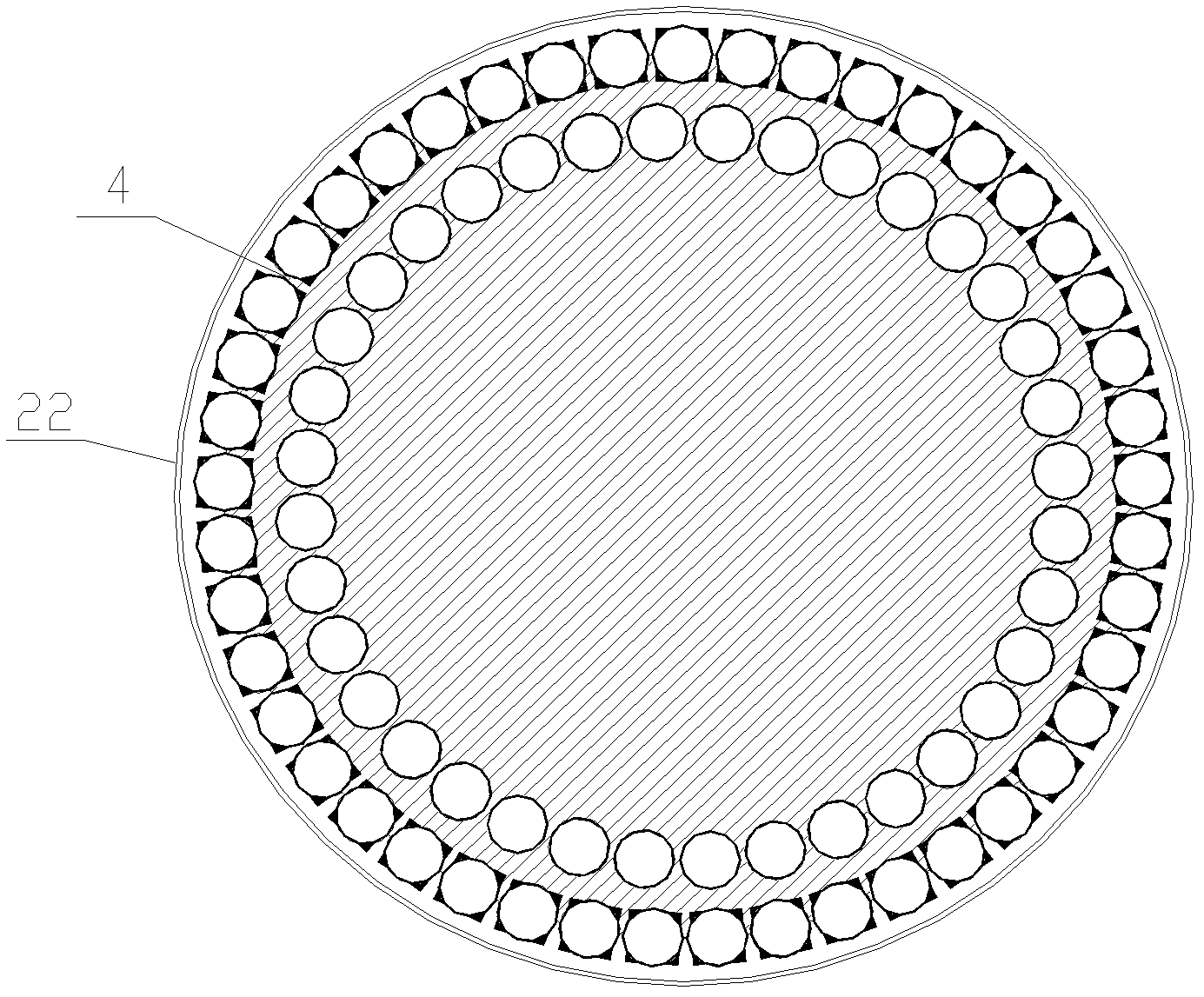

InactiveCN102635945ALow investment costAvoid uneven temperature distributionAir heatersSustainable buildingsCombustorEngineering

A through-flow type narrow-clearance integral condensation hot-water boiler comprises a shell. An annular water outlet header is arranged on the upper portion of the shell, an annular water feeding header is arranged on the lower portion of the shell, a deep condensation heat exchange tube bundle and a V-shaped condensation collecting device with a condensate neutralizing treatment device are arranged below the annular water feeding header, an all-premixing metal fiber combustor is arranged on a top plate of a boiler, a metal fiber head of the all-premixing metal fiber combustor penetrates into a radiation heat exchange space so as to realize the characteristic of high radiation heat exchange capacity of the metal fiber head, the annular water outlet header is communicated with the annular water feeding header via inner and outer circles of annular water cooling walls consisting of a plurality of vertical water tubes, a clearance with the size of 1-2mm is reserved between each two adjacent vertical water tubes and is used as a smoke circulation channel, smoke realizes convection heat exchange and condensation heat exchange when flowing among the vertical water tubes, heat is transmitted to working medium water in the vertical water tubes, the deep condensation heat exchange tube bundle deeply cools the smoke, and efficiency of the boiler is improved. In addition, the through-flow type narrow-clearance integral condensation hot-water boiler is simple in structure and convenient in manufacture, and can effectively avoid the harm that tubes are easy to be exploded due to uneven heat load distribution of a traditional through-flow boiler.

Owner:XI AN JIAOTONG UNIV

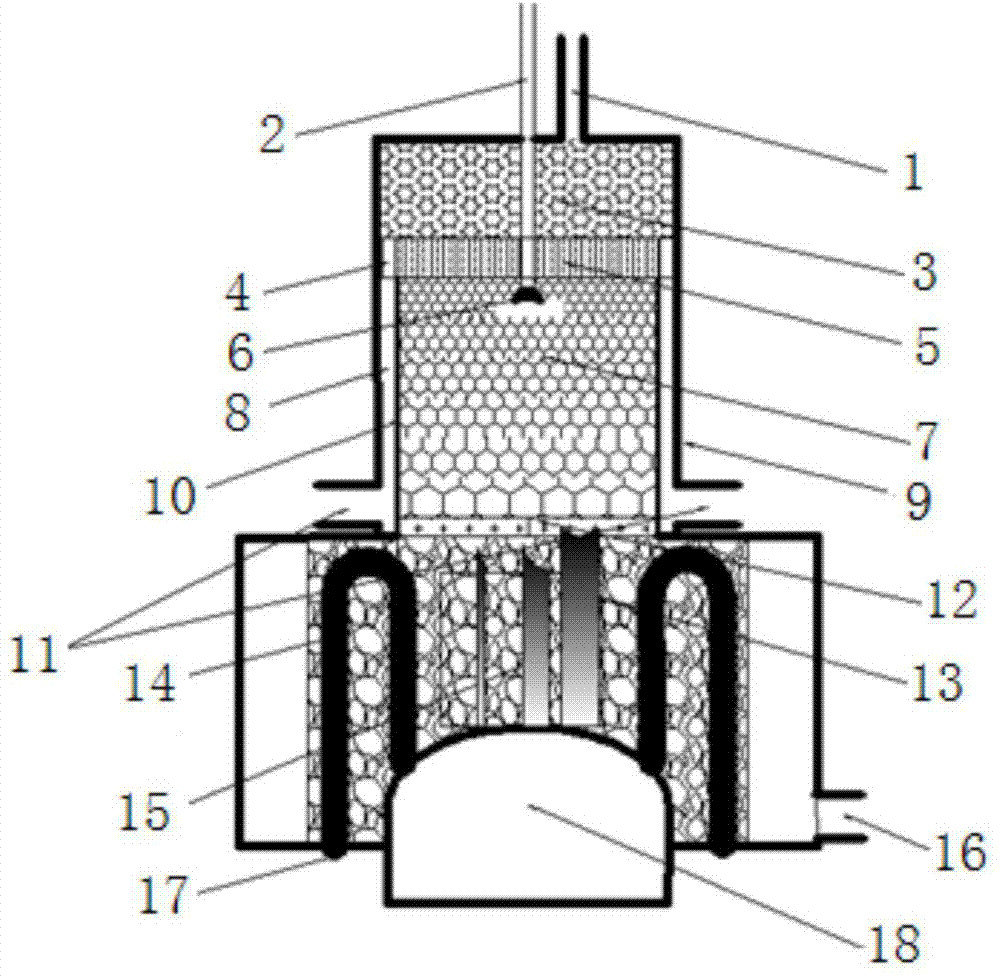

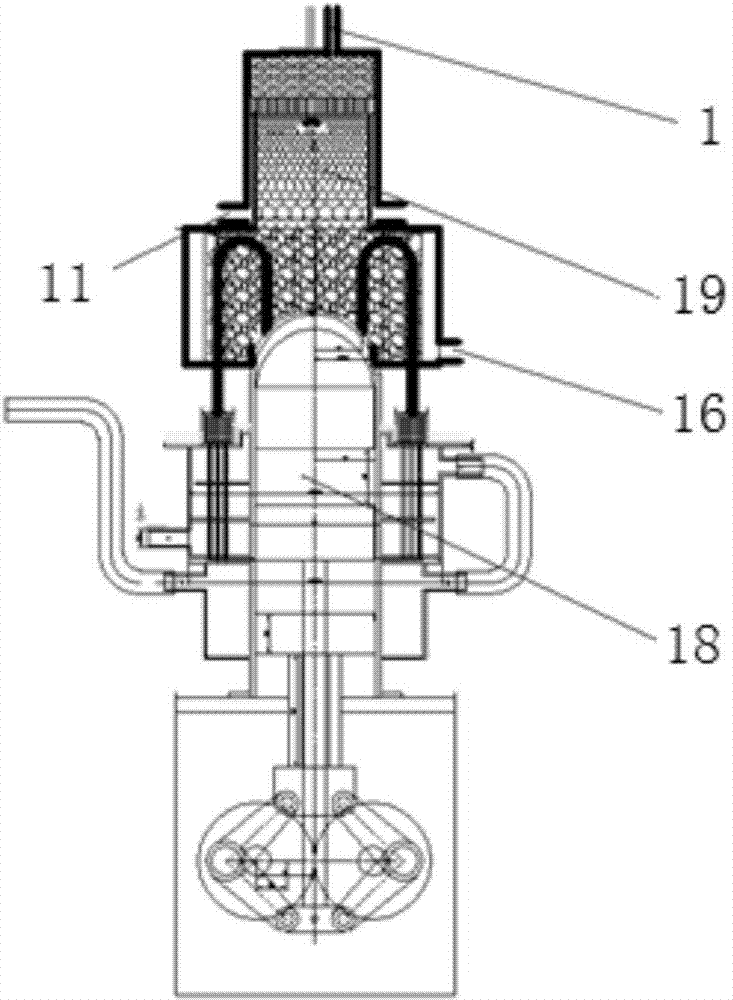

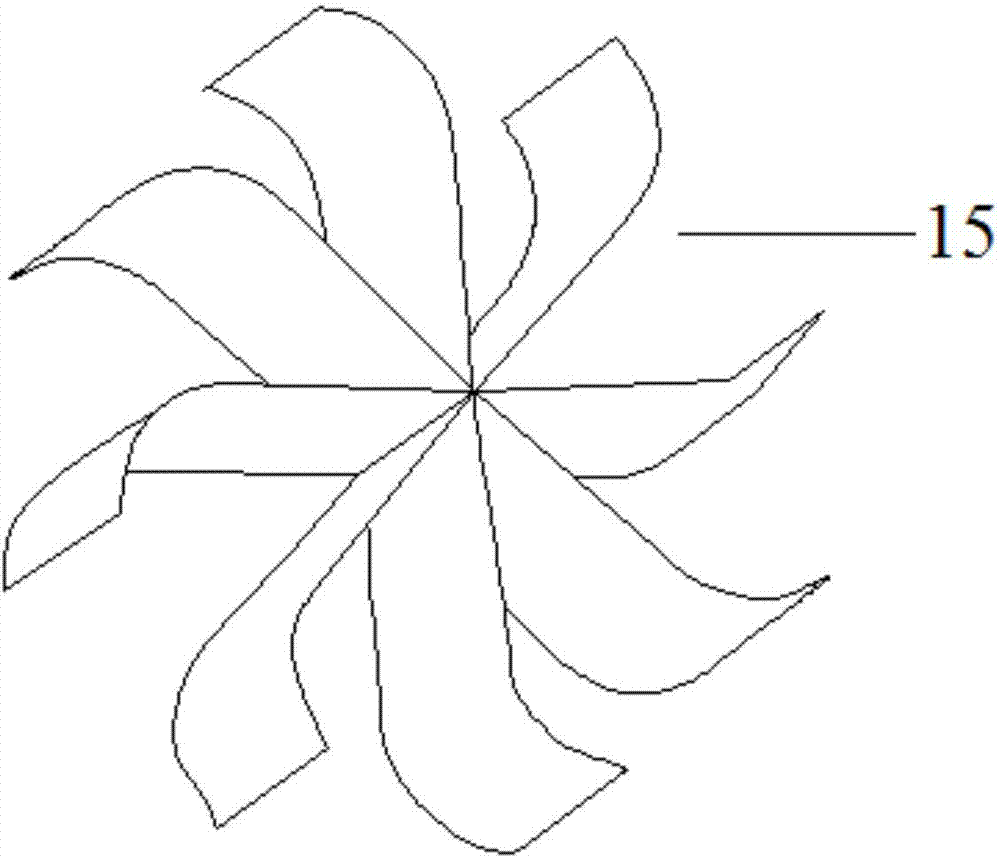

Combustion heating system for Stirling engine

ActiveCN104727976AProtection from being burnedReduce startup timeHot gas positive displacement engine plantsCombustorPorous medium

The invention relates to a combustion heating system for a Stirling engine. The combustion heating system for the Stirling engine is composed of a straight-shaped gradient lapped type porous medium combustor and a fill type porous medium combustor, which are arranged up and down, wherein the straight-shaped gradient lapped type porous medium combustor comprises a shell, a fuel gas inlet, a pre-mixing chamber, an axial thermal insulating layer, a flame igniter leading wire protective tube, an igniter, a gradient ceramic porous medium layer and a catalyst layer, wherein the fuel gas inlet, the pre-mixing chamber, the axial thermal insulating layer, the flame igniter leading wire protective tube, the igniter, the gradient ceramic porous medium layer and the catalyst layer are arranged in the shell in sequence form top to bottom, the fill type porous medium combustor comprises an external insulating layer, a metal net cylinder arranged in the insulating layer and heating tubes arranged in the metal net cylinder in a central symmetry mode, and the gaps of the heating tubes are filled with metal wires. The combustion heating system for the Stirling engine has the advantages of being stable in combustion, high in combustion efficiency, good in heat transfer performance, good in heat storage performance, stable in working, wide in load regulation range, easy to regulate and less in pollutant discharge, and the effect on improving the fuel gas type Stirling engine working efficiency is remarkable.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

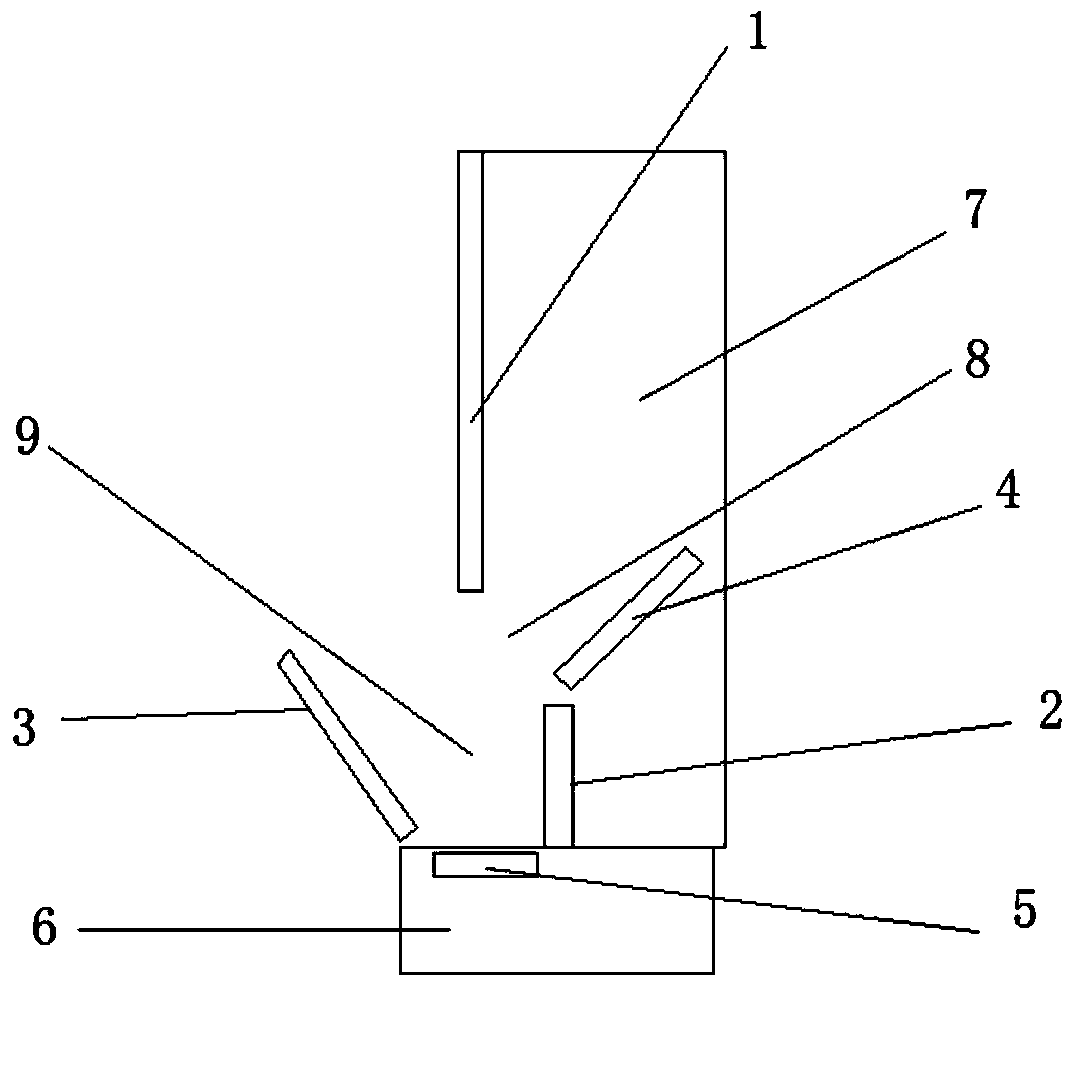

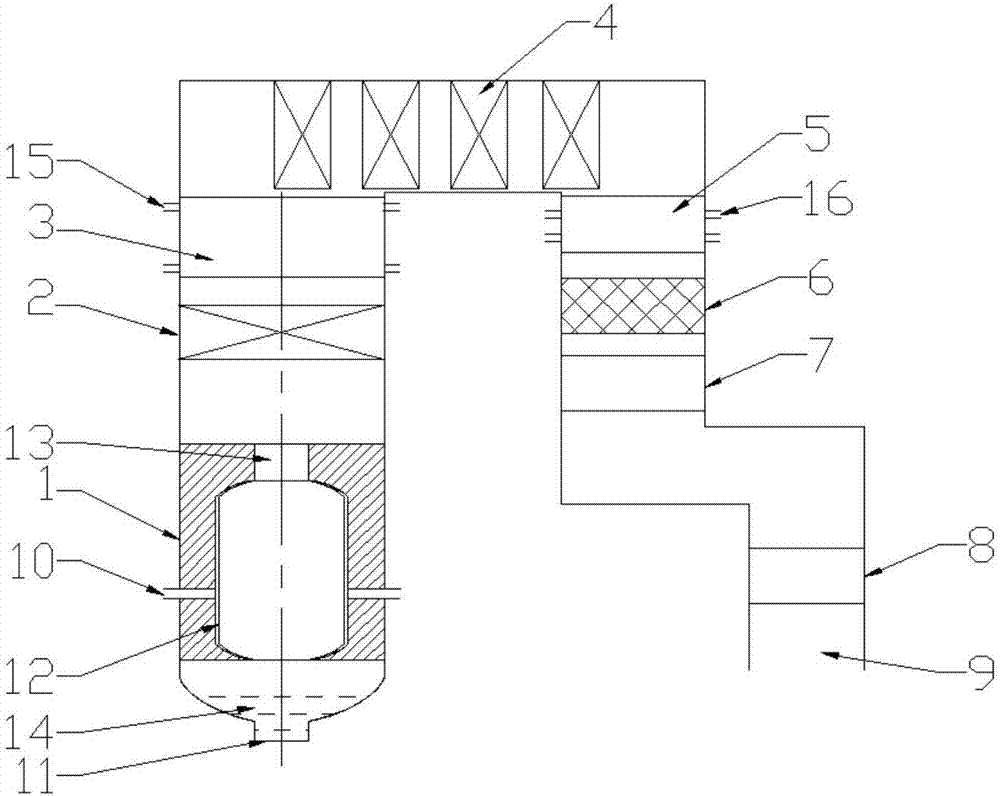

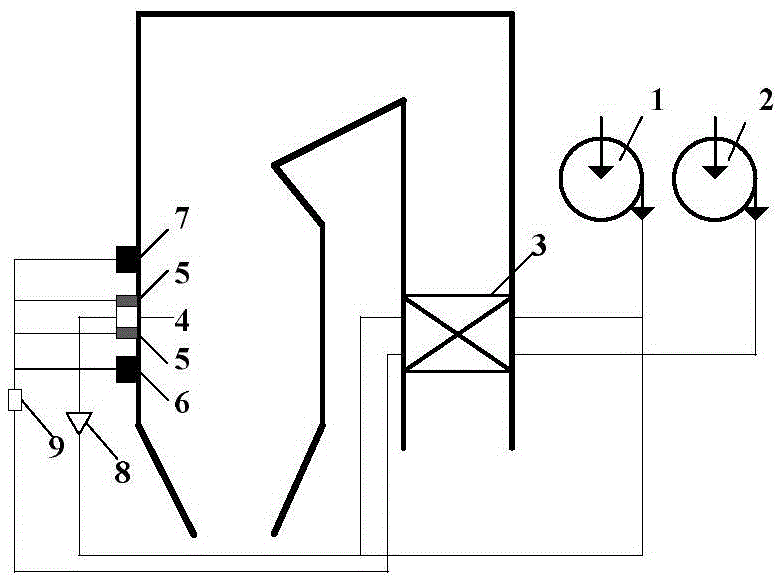

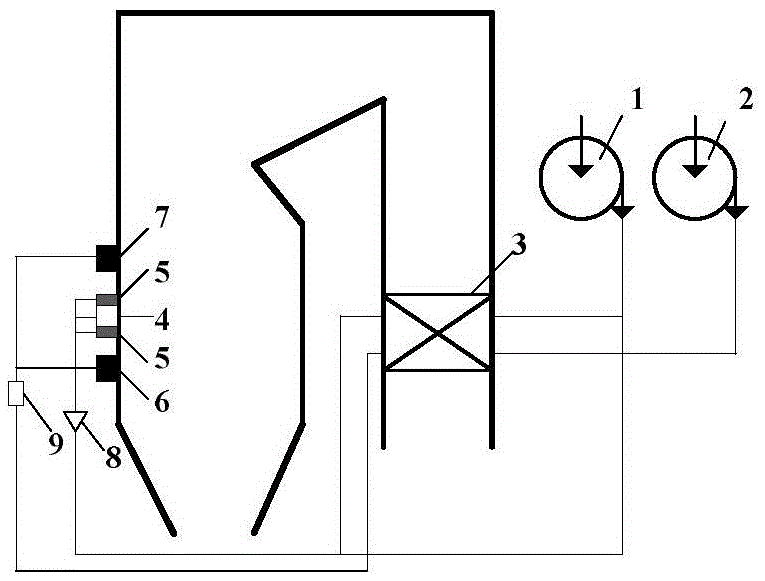

Coal-fired decoupling combustion apparatus and combustion method

ActiveCN103471089AReduce harmful air leakageFully burnt outSolid fuel combustionIndirect carbon-dioxide mitigationCombustionStructural engineering

The invention belongs to the field of raw-coal combustion equipment, and particularly relates to a coal-fired decoupling combustion apparatus and a combustion method. The coal-fired decoupling combustion apparatus comprises a furnace and an air chamber (6) positioned below the furnace; the furnace comprises an upper partition wall (1), a first lower partition wall (2) and a second lower partition wall (3), the first lower condition wall (2) and the second lower partition wall (3) are respectively arranged below the inner lower side and the outer side of the upper partition wall (1), a first grate (4) is erected between the top of the inner first lower partition wall (2) and a side wall of the furnace, and a second grate (5) is arranged between the bottom of the first lower partition wall (2) and the bottom of the second lower partition wall (3); a gasification pyrolysis zone (7) and a semi-coke zone (8) are formed between space above the first grate (4) and the upper partition wall (1), and the semi-coke zone (8) is positioned below the gasification pyrolysis zone (7); a coke zone (9) is formed by the first lower partition wall (2) and the second lower partition wall (3). The coal-fired decoupling combustion apparatus and the combustion method have the advantages that a rate of harmful air leakage and an excess air coefficient can be reduced; the harmful air leakage in the semi-coke zone can be effectively reduced, and the capacity and the efficiency of a boiler can be guaranteed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Combustion device for upper spraying, combustion, exhumation and outflow of premixed annular airflow

InactiveCN101793396ASimple structureReduce productionFluid heatersGaseous fuel burnerCombustion chamberEngineering

The invention relates to a combustion device for upper spraying, combustion, exhumation and outflow of premixed annular airflow, which effectively solves the problems that gas and blasting air rapidly combust in the combustion chamber after flowing into the premixing loop and the gas flow in the flue flow field is uniform and stable. The combustion device is a combustion chamber which consists of a dome cylinder type lower opening, a cylinder type wall body and a semi-spherical dome and is used for flow and combustion of premixed gas flow, a gas loop and an air loop are separately arranged along the vertical direction in the inner wall of the cylinder type wall body, the periphery of the inner side of the gas loop is uniformly provided with gas nozzles with rectangular sections, and the periphery of the inner side of the air loop is uniformly provided with air nozzles with rectangular sections; the outer sides of the gas loop and the air loop are respectively connected with a gas inlet pipe and an air inlet pipe; the spouts of the gas nozzles and the air nozzles are vertically communicated with the outer side of a premixing loop; and the premixing loop is an annular loop with the upper opening on the rectangular section of the combustion chamber and is tightly and coaxially connected with the inner wall of the combustion chamber. The invention has the advantages of low manufacturing and installation difficulty and high stability, and can reduce the excess air coefficient, enhance the combustion intensity and increase the combustion temperature.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Device and method for cooling clinker by liquid oxygen and liquid nitrogen of cement kiln

ActiveCN103968671ASpeed up heat exchangeImprove stabilityDomestic cooling apparatusHandling discharged materialDecompositionNitrogen

The invention discloses a device and a method for cooling clinker by liquid oxygen and liquid nitrogen of a cement kiln. The device is characterized in that a high-temperature cooling region of a grate cooler of the cement kiln is provided with a liquid oxygen input connector, and a middle-temperature cooling region of the grate cooler is provided with a liquid nitrogen input connector. The method comprises the steps of adding liquid oxygen the volume of which is 1%-12% of the total volume of cooling air fed by an air blower of a high temperature section of the grate cooler of the cement kiln, and adding liquid nitrogen the volume of which is 1%-45% of the total volume of cooling air fed by an air blower of a middle temperature section of the grate cooler of the cement kiln. The device and the method provided by the invention have the advantages that the cooling rate of clinker is improved by inputting liquid oxygen, and high-temperature clinker is cooled suddenly, so that the decomposition of D3S at 1250 DEG C is prevented or alleviated, the crystallization of MgO is prevented or alleviated, and the stability of the clinker is improved; a C3S crystal is prevented from growing, and thus the grindability of clinker is improved; the C2S crystal transfer is effectively prevented or alleviated by introduced liquid nitrogen.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method

ActiveCN107975782AEfficient emissionsReduce pollutionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberSlag

The invention discloses a slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method. The slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system comprises a lean-oxygen combustion chamber and a carbon monoxide catalytic oxidation device. A cavity is contained in the lean-oxygen combustion chamber. The upper end of the lean-oxygen combustion chamber is provided with a smoke outlet. A secondary combustion chamber is arranged on the downstream side of the smoke outlet of the lean-oxygen combustion chamber. A smoke inlet of the secondary combustion chamber communicates with the smoke outlet of the lean-oxygen combustion chamber. An air supplementation chamber is arranged on the downstream side of the smoke outlet of the secondary combustion chamber. A smoke inlet of the air supplementation chamber communicates with a smoke outlet of the secondary combustion chamber. The downstream side of the smoke outlet of the air supplementation chamber is provided with the carbon monoxide catalytic oxidation device. The smoke inlet of the carbon monoxide catalytic oxidation device communicates with a smoke outlet of the air supplementation chamber. According to the slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method, through staged combustion of coal, high efficiency and low emission of NOx can be achieved, and atmospheric pollution is lowered; a SCR denitration device is not arranged, so that the catalyst optimum temperature limitation problem, the ammonia injection mixing evenness problem, the catalyst waste treatment problem and other serious problems in the denitration process can be avoided.

Owner:XI AN JIAOTONG UNIV

Surrounding air method for reducing NOx emission concentration of power station pulverized coal powder plant boiler

InactiveCN105605606AThe total air volume remains unchangedReduce Excess Air CoefficientFuel supply regulationAir supply regulationMomentumAir volume

The invention provides a surrounding air method for reducing the NOx emission concentration of a power station pulverized coal powder plant boiler. The method includes the specific step of replacing existing secondary air with primary air high in wind pressure under the condition that it is ensured that the total air volume of a hearth is not changed, wherein the primary air is used as surrounding air of a cooling pulverized coal spray nozzle. Because the wind pressure of primary air is higher than the wind pressure of secondary air, after the existing surrounding air is replaced with primary air, the flowing speed of surrounding air is increased. It is ensured that the momentum of surrounding air is constant before and after replacement, and therefore the mass flow rate of surrounding air is correspondingly decreased after replacement. Because the momentum of surrounding air is not changed, the cooling effect the same as that of a combustor can be achieved, and rigidity of the pulverized coal jet flow is also ensured. Meanwhile, the mass flow rate of surrounding air is decreased, and therefore the excess air coefficient of the initial combustion period of pulverized coal is decreased, NO generation in the initial period of combustion is restrained, and therefore the NO emission concentration during running of the boiler is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

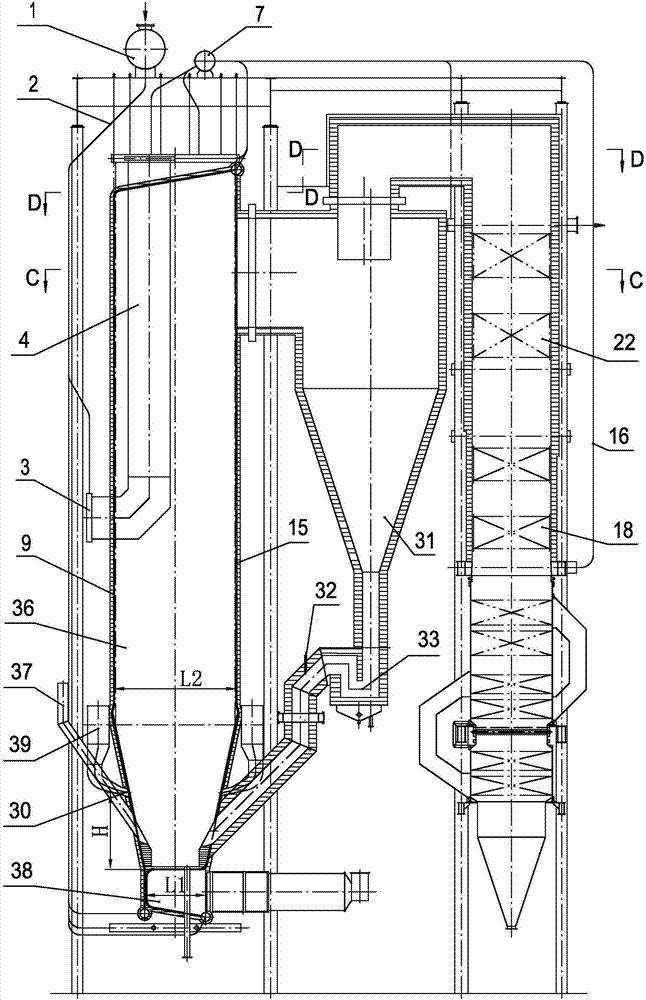

Low emission type circulating fluidized bed boiler

ActiveCN107345660AImprove environmental performanceEmission reductionFluidized bed combustionEmission preventionCombustionFluidized bed

The invention discloses a low emission type circulating fluidized bed boiler and relates to a circulating fluidized bed boiler, in particular to a low emission type circulating fluidized bed boiler adopting an in-furnace desulfurization and low nitrogen combustion technology in order to solve the problems than in an out-furnace environment-friendly device of an existing circulating fluidized bed boiler, desulfurization and denitration equipment is in low removal efficiency, high in running cost and large in floor space. The low emission type circulating fluidized bed boiler comprises a separator, a refeeder, a hearth, a coal feeding device, a primary air chamber, a secondary air bellow, a high temperature coal economizer and a low temperature coal economizer; the coal feeding device and the secondary air bellow are installed on the lower portion of the hearth; the primary air chamber is arranged at the bottom of the hearth; in a tail flue, the high temperature coal economizer and the low temperature coal economizer are sequentially arranged from top to bottom; and the ratio of the width of the primary air chamber to the width of the hearth is 0.4-0.5. According to the low emission type circulating fluidized bed boiler, the initial super-low emission of the boiler is adopted by adopting the in-furnace desulfurization and low nitrogen combustion technology, 'out-furnace treatment' is converted into 'in-furnace emission reduction', and pollutant generation is controlled from the source.

Owner:哈尔滨红光锅炉总厂有限责任公司

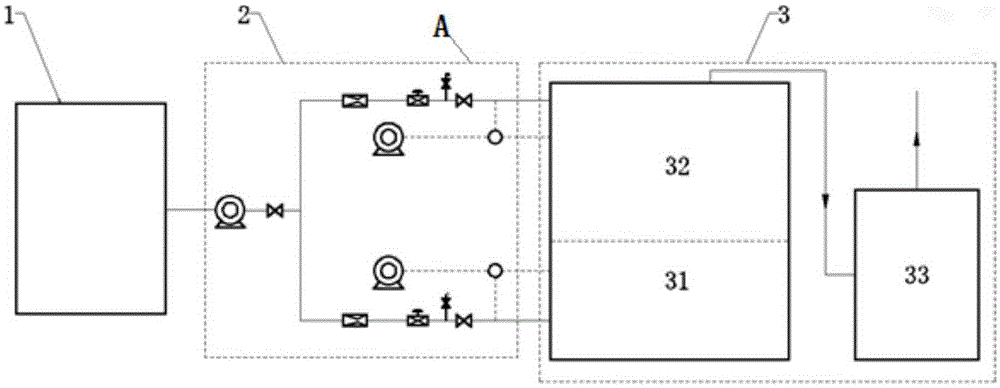

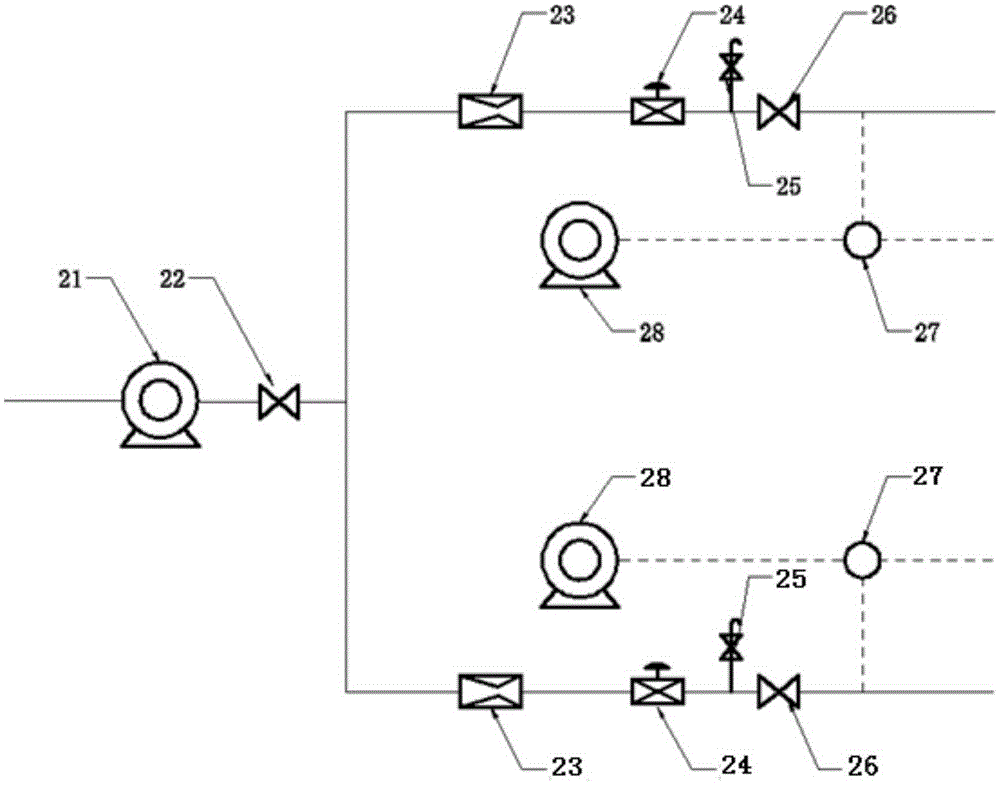

Pyrolysis and gasification garbage incinerator adopting oxygen enriched combustion technique

ActiveCN105351942AHigh calorific valueImprove combustion conditionsIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberOxygen enrichment

The invention discloses a pyrolysis and gasification garbage incinerator adopting an oxygen enriched combustion technique. The pyrolysis and gasification garbage incinerator comprises an oxygen preparation unit, an oxygen injection unit and an incinerator main body unit, wherein the oxygen injection unit is connected with the oxygen preparation unit and the incinerator main body unit, the oxygen injection unit comprises a booster fan, a shutoff valve and two oxygen flow control devices, and each oxygen flow control device comprises a flow meter, a regulating valve, a stop valve, a mixer and an air supply fan; the shutoff valve is connected with the flow meters; the incinerator main body unit comprises an incinerator body and a smoke purification device, and the incinerator body comprises a first combustion chamber, a second combustion chamber and a partition. According to the pyrolysis and gasification garbage incinerator, the problems of low combustion temperature and combustion efficiency, substandard pollutant discharge and the like caused by low oxygen content of air or low garbage calorific value can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Power and heat co-supply system based on Stirling engine and power and heat co-supply method of system

ActiveCN106351765AReduce manufacturing costReduce commercializationCombustion processStorage heatersEngineeringEconomizer

The invention discloses a power and heat co-supply system based on a Stirling engine and a power and heat co-supply method of the system. Grids cannot be laid in a great majority of families in mountainous areas and underdevelopment areas. Biomass combusts in a combustion furnace, molten salt in a heat storage pot is heated, and the high-temperature molten salt heats a hot end of the Stirling engine to drive the Stirling engine to generate power; a circulating water system for cooling a cold end of the Stirling engine flows through the cold end of the Stirling engine and an economizer, waste heat of the two parts is recovered, and hot water at 50-100 DEG C is finally obtained. With the adoption of the system and the method, the problems that the Stirling engine causes severe ash accumulation and coking at the hot end when applied to a biomass direct-combustion power generation boiler and the power generation efficiency is decreased are solved; gradient utilization of energy is realized and the thermal efficiency of the system is high; power and heat co-supply is realized and the energy saving effect is remarkable; the power output quality is stable, the system is very suitable for energy storage and release, and a way is provided for solving the problem about power in power islands in remote areas.

Owner:马加德

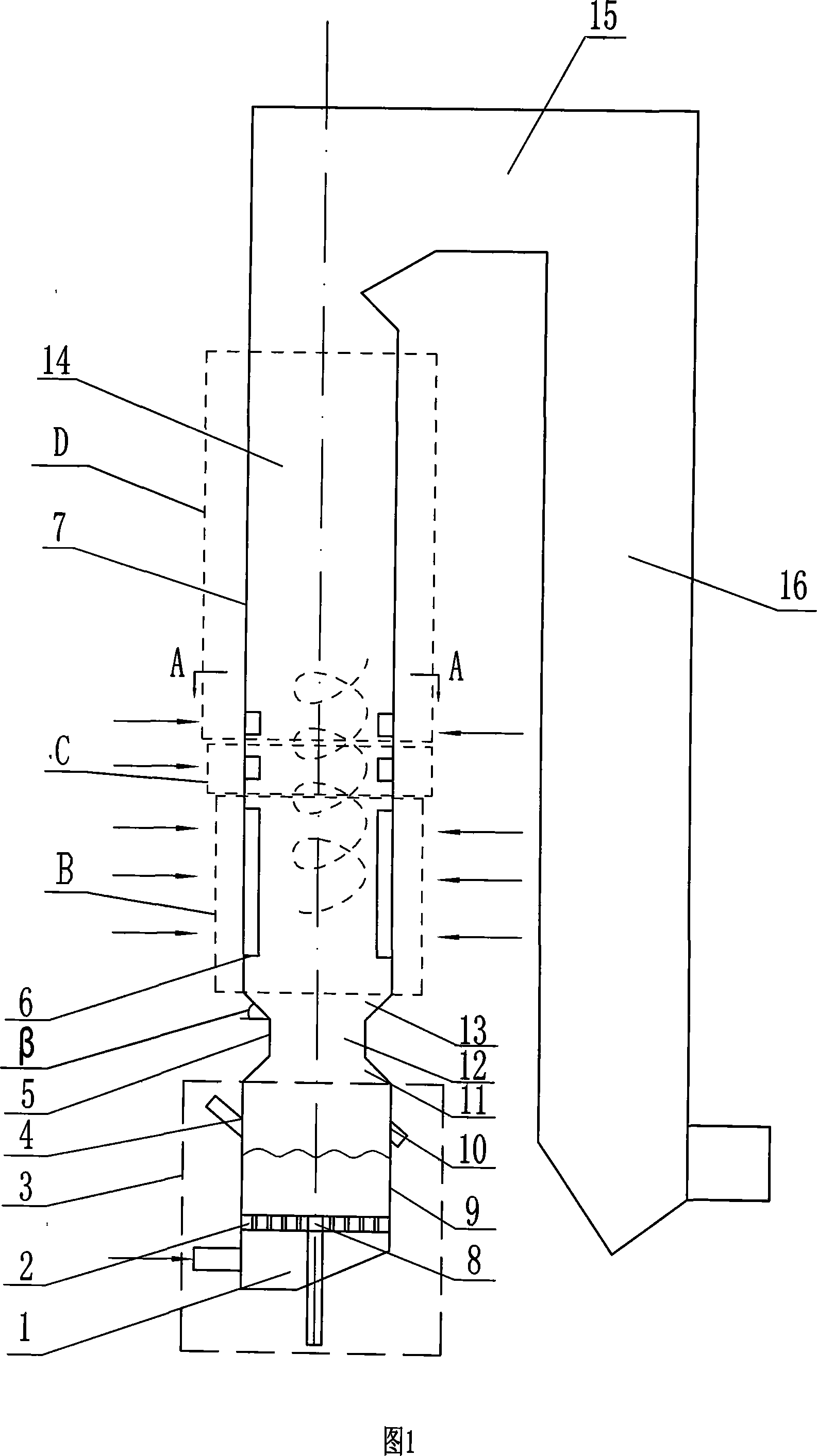

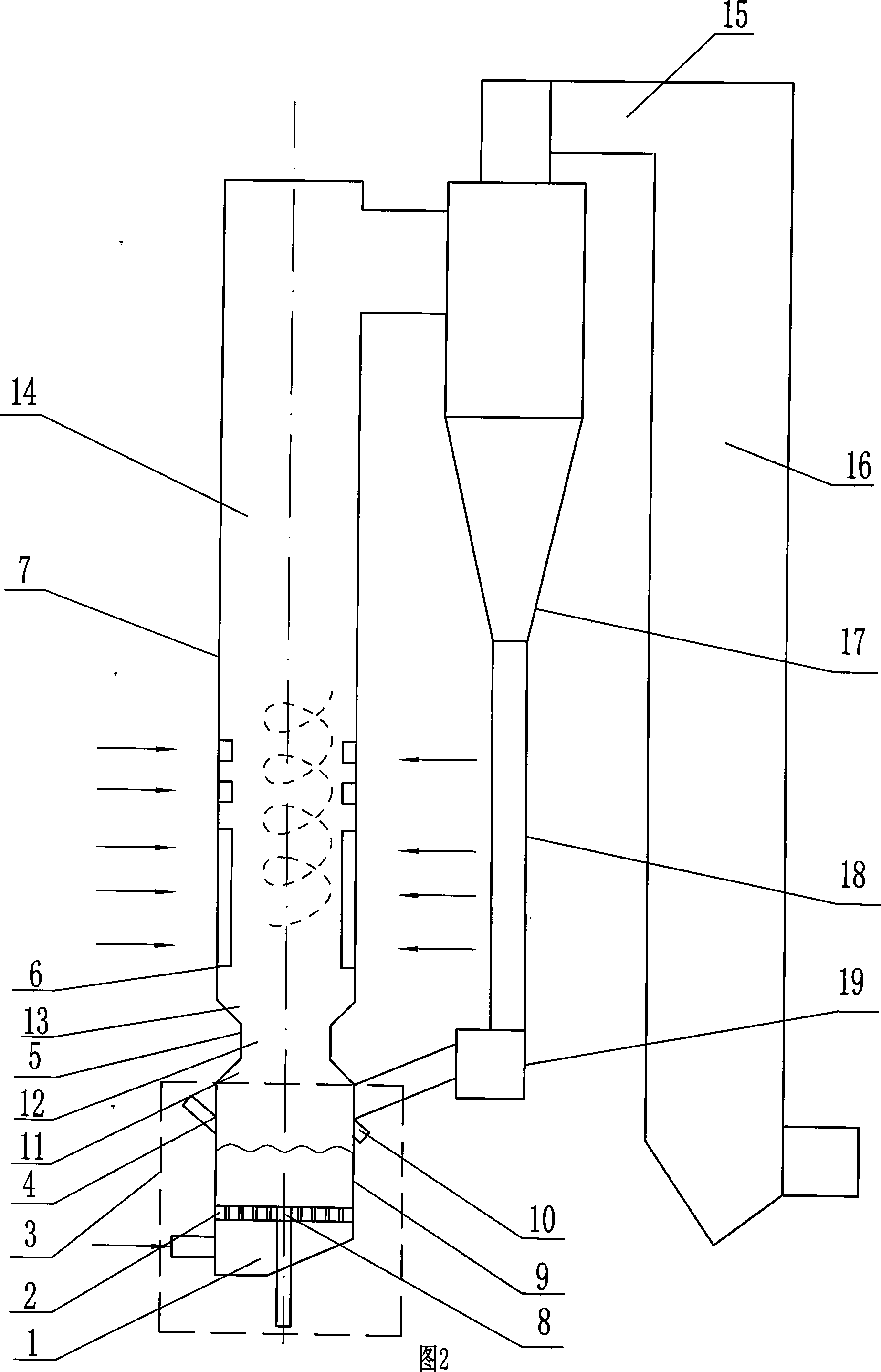

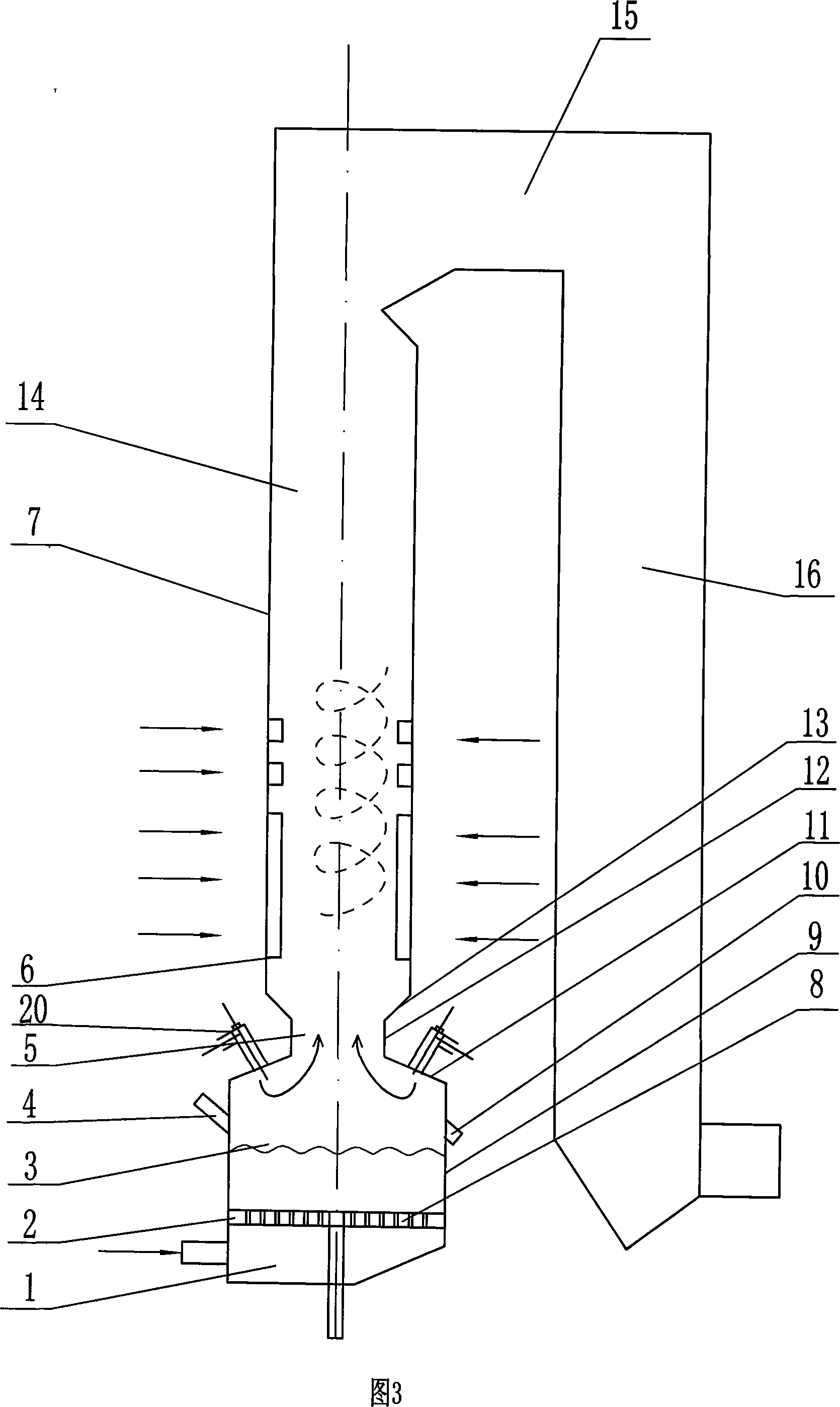

Fluidization-suspending two-stage type compound combustion device

InactiveCN101196294AReduce generationReduce volatilityFluidized bed combustionCombustion chambersCombustion chamberSolid fuel

A fluidizing and suspension type compound burning device is provided, which relates to a burning device. The invention resolves the problem as mutual heat influence and mutual flow influence of a bubbling fluidized bed firebox and a suspension firebox of the existing burning device for the two are integrated, thus incapable of symmetrically burning two solid fuels with different grain diameters and burning activities sufficiently in one burning device. The invention comprises a bubbling fluidized bed low temperature firebox (3), a high temperature swirl suspension firebox (7) and a transition section chamber body (5); wherein, the high temperature swirl suspension firebox (7) is located over the bubbling fluidized bed low temperature firebox (3), which is communicated with upper end of the bubbling fluidized bed low temperature firebox (3) through the transition section chamber body (5) with lower end. The invention has the advantages of high burning efficiency and sufficient burning, which realizes the sufficient burning of two solid fuels of different burning grain diameters and burning activities symmetrically in one burning device.

Owner:HARBIN INST OF TECH

Low nitrogen emission coke-oven heating system adopting rich gas heating and adjustment method thereof

PendingCN108728127AReduce the area of high temperature zoneReduce the formation of nitrogen oxidesCombustible gas coke oven heatingFlueNitrogen oxides

The invention relates to a low nitrogen emission coke-oven heating system adopting rich gas heating and adjustment method thereof. The coke-oven heating system comprises a small flue, a heat exchangepassage, a combustion-supporting gas passage and a combustion chamber. The heat exchange passage comprises a heat exchange passage for gas supply at the bottom of a vertical flue and a heat exchange passage for gas supply at the section of the vertical flue; a small flue connecting pipe corresponding to the heat exchange passage for gas supply at the bottom of the vertical flue is provided with agas supply hole at the bottom of the vertical flue and a gas intake flow adjustment device I, and the heat exchange passage for gas supply at the bottom of the vertical flue is communicated with the outlet of the combustion-supporting gas at the bottom of the vertical flue through the combustion-supporting gas passage; the small flue connecting pipe corresponding to the heat exchange passage for gas supply at the section of the vertical flue is provided with the gas supply hole at the section of the vertical flue and a gas intake flow adjustment device II at the section of the vertical flue, and the heat exchange passage for gas supply at the section of the vertical flue is communicated with the outlet of the combustion-supporting gas in the partition of the vertical flue through the combustion-supporting gas passage. According to the low nitrogen emission coke-oven heating system, the amount of combustion-supporting air entering the bottom, middle, and upper parts of the vertical fluecan be independently and quantitatively adjusted, and the formation of nitrogen oxides can be effectively reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

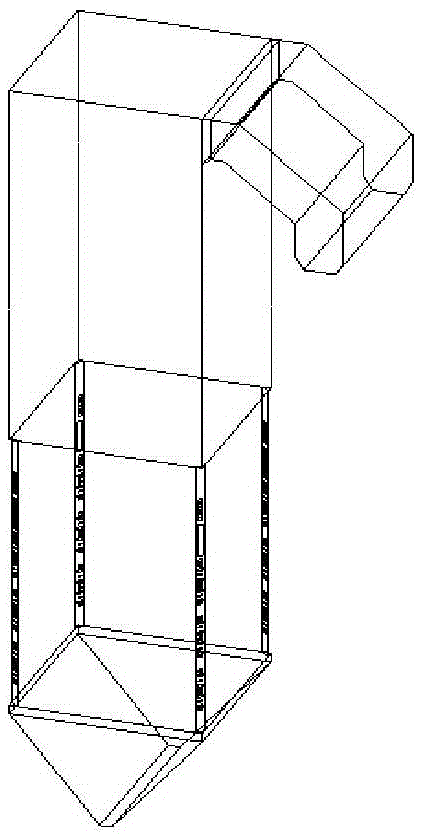

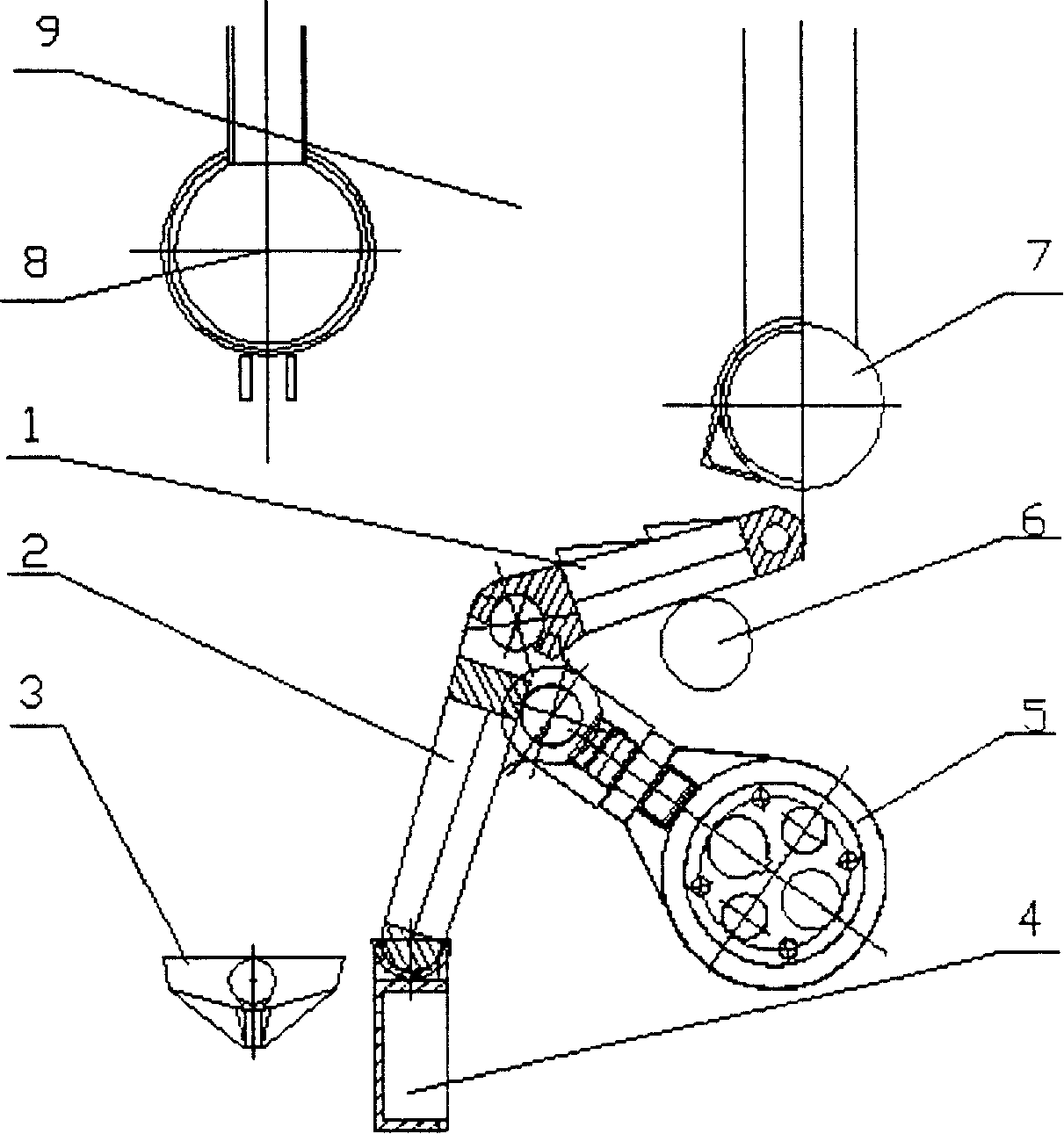

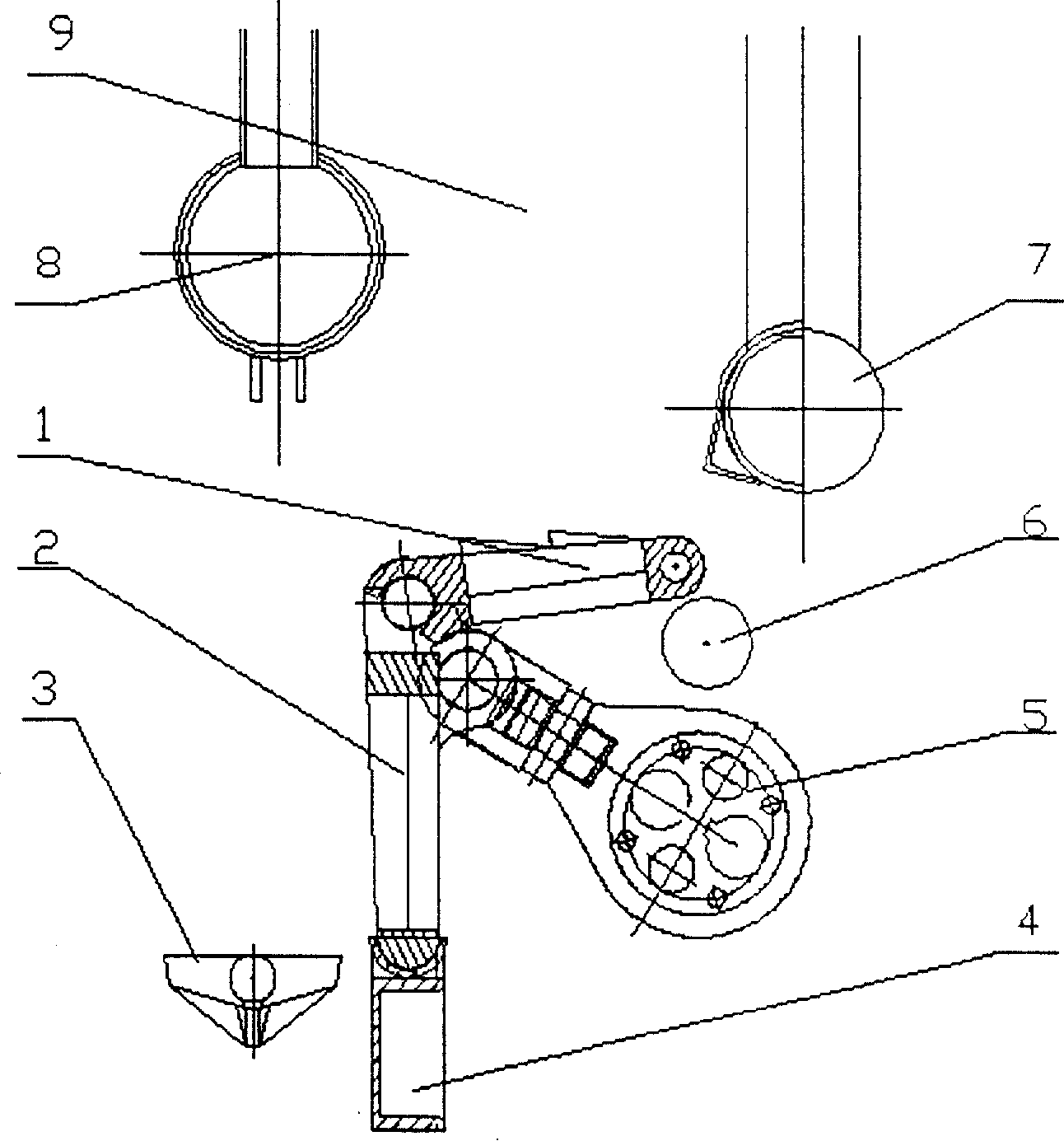

Oscillating mechanical fire grate used for lamellated decoupling burning furnace

InactiveCN101210681AImprove efficiencyPromote environmental protectionRevolving grateRocking grateEngineeringLarge size

The invention relates to a reciprocating-oscillation type mechanical grate used with a layered decoupling burning furnace, which comprises a reciprocating-type upper grate with a grid structure, and an oscillating type lower grate, and a lower grate. The left end of the reciprocating-type upper grate is overlapped with the upper end of the oscillating type lower grate. The right end of the reciprocating-type upper grate is supported by and connected with a supporting rod. The lower end of the oscillating type lower grate is supported by and connected with a supporting beam. The lower end surface of the oscillating type lower grate is connected with a transmission mechanism. Under the drive of the transmission mechanism, the oscillating type lower grate oscillates reciprocatingly and alternately in clockwise and counterclockwise directions, around the upper part of the supporting beam as a center, with an oscillation included angle of 10-40 degrees. The grate realizes the mechanical automation of layered decoupling burning furnaces with various specifications, increases the efficiency and environment-friendly performance, and solves the problems of the prior layered decoupling burning furnace with large capacity (above 700kw), such as large size, uneasy operation, and poor stability in environmental protection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

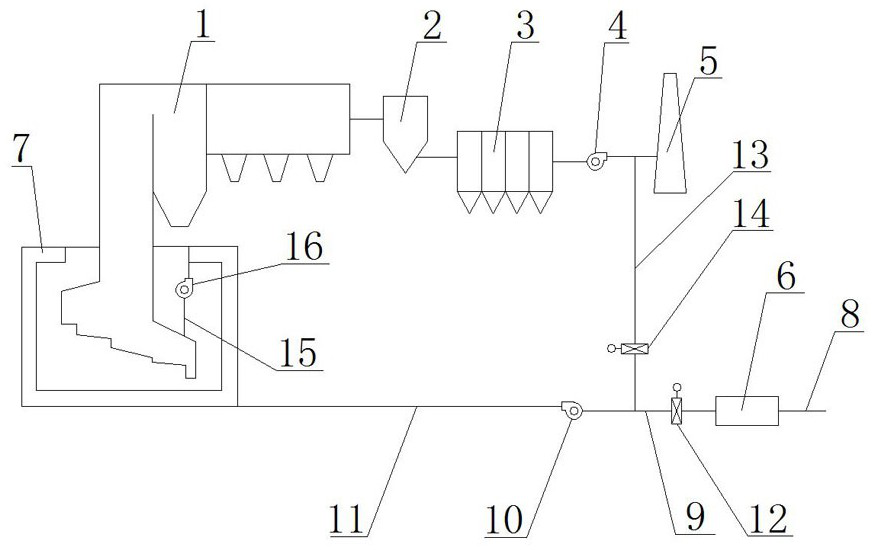

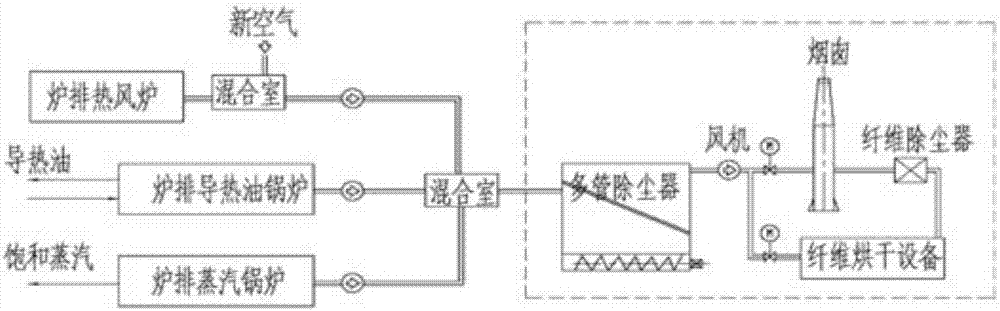

Flue gas recirculation system of household garbage incineration power plant

PendingCN113280351AIncreased inert gas contentSuppress generationEmission preventionIndirect carbon-dioxide mitigationAir preheaterInert gas

The invention discloses a flue gas recirculation system of a household garbage incineration power plant. The flue gas recirculation system comprises an incinerator, a reaction tower, a dust remover, an induced draft fan, a chimney and an air preheater, a flue gas outlet of the incinerator is connected with an inlet of the reaction tower, an outlet of the reaction tower is connected with one end of the dust remover, and the other end of the dust remover is connected with one end of the induced draft fan. The other end of the induced draft fan is connected with the chimney, air is introduced into one end of the air preheater, and the other end of the air preheater and the other end of the induced draft fan are connected with a secondary air chamber of the incinerator. According to the flue gas recirculation system of the household garbage incineration power plant, recycled flue gas replaces part of secondary air, so that the content of inert gas in a combustion area is increased, the flue gas absorbs heat, the concentration of oxygen is reduced, the flue gas and combustion-supporting air spread and combust in a high-temperature and low-oxygen atmosphere, the flame volume is multiplied, a local high-temperature area is reduced, temperature distribution is more uniform, generation of thermal NOx is inhibited, the coking problem of a hearth can be solved, and the heat efficiency and the generating capacity are improved.

Owner:CHINA TIANYING +1

Novel environment-friendly methanol diesel fuel and preparation method thereof

InactiveCN108913224AGood solubilityGood compatibilityBiofuelsLiquid carbonaceous fuelsSolventChemistry

The invention discloses novel environment-friendly methanol diesel fuel and a preparation method thereof. The novel environment-friendly methanol diesel fuel is prepared from the following raw materials in parts by weight: 30 to 50 parts of biodiesel, 20 to 30 parts of methanol, 15 to 20 parts of petroleum diesel, 5 to 7 parts of methylal and 3 to 5 parts of an additive, wherein the additive is prepared from the following assistants in parts by weight: 0.3 to 0.5 part of a mutual solvent, 0.3 to 0.5 part of a combustion improver, 0.1 to 0.3 part of a purification dispersant, 0.01 to 0.03 partof an anti-seismic detonation inhibitor and 0.01 to 0.05 part of an antioxidant. According to the novel environment-friendly methanol diesel fuel disclosed by the invention, by utilizing and combiningabandoned illegal cooking oil in catering in and by utilizing a modernized ultrasonic emulsifying technology, the novel environment-friendly methanol diesel fuel is produced, a safe and environment-friendly reproducible alternative energy source is provided, the problems that carbon deposition is generated during combustion of previous diesel, the ignition is poor, cold boot is difficult, cylinder knocking is prevented from being generated during rapid combustion and the like are overcome, emission of tail gas is reduced, and pollution to the environment is reduced.

Owner:广西隆昌德民生态农业发展有限公司

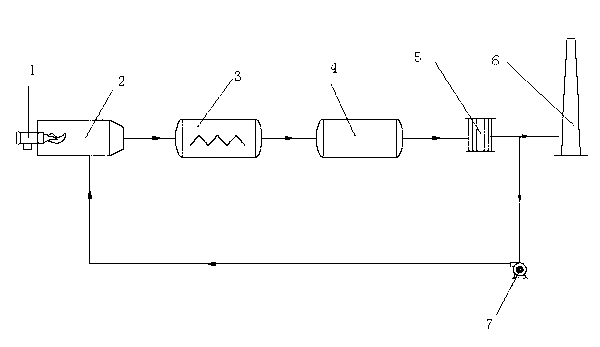

Flue gas recirculating waste heat utilization process

ActiveCN103017556AReduce lossesHigh thermal efficiencyCombustion processIncreasing energy efficiencyCombustorFlue gas

The invention relates to a flue gas waste heat utilization technology, in particular to a flue gas waste heat utilization process. The provided flue gas waste heat utilization process comprises the following steps: the flue gas generated after the combined firing of fuel and air in a burner (1) enters a heating furnace (2); the high-temperature flue gas from the heating furnace enters a low-temperature heat exchange device (5) after the heat exchange through a high-temperature heat exchange device (3) and a medium-temperature heat exchange device (4); and the combustion-supporting air is preheated in the low-temperature heat exchange device (5) via process medium or medium-temperature steam, and the temperature of the flue gas and the heated combustion-supporting air is decreased to about 150-200 DEG C. According to the invention, the flue gas waste heat is utilized to the utmost extent, the heat loss carried away by the flue gas and discharged in the atmosphere is reduced, the thermal efficiency of the heating furnace is improved, and the energy consumption of the whole process flow is reduced.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

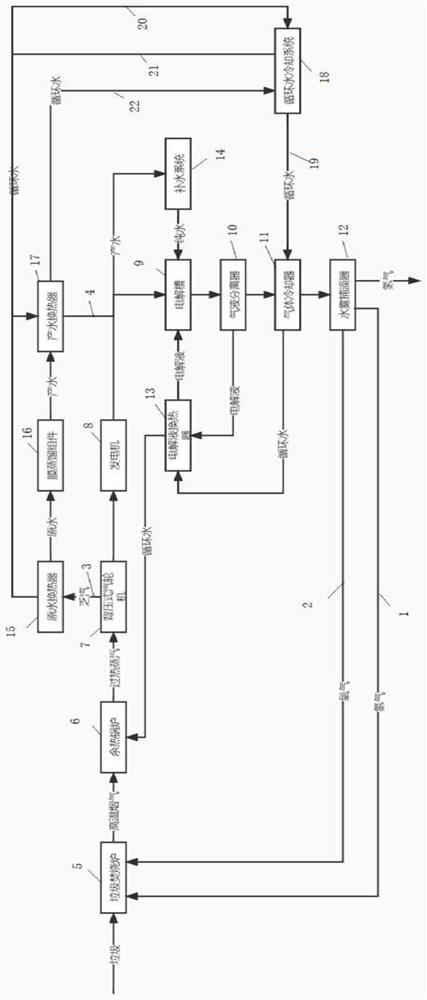

Waste incineration power generation coupled water electrolysis hydrogen production system

PendingCN114277391ASolve technical problemsReduce energy consumptionCellsIndirect carbon-dioxide mitigationProcess engineeringHydrogen production

The invention provides a waste incineration power generation and water electrolysis hydrogen production coupled system which comprises a waste incineration power generation mechanism and a water electrolysis hydrogen production mechanism, and the waste incineration power generation mechanism is used for supplying power to the water electrolysis hydrogen production mechanism. The water electrolysis hydrogen production mechanism supplies hydrogen and oxygen to the waste incineration power generation mechanism through a first pipeline and a second pipeline correspondingly, and the pure water preparation mechanism is connected with the waste incineration power generation mechanism through a third pipeline and used for introducing dead steam. According to the water electrolysis hydrogen production system, the waste incineration power generation system is coupled with the water electrolysis hydrogen production system, waste heat generated in the waste incineration power generation process serves as a heat source in the membrane distillation process, pure water needed by water electrolysis hydrogen production is prepared, and the water electrolysis hydrogen production system has the advantages that the waste incineration power generation system is coupled with the water electrolysis hydrogen production system; the energy consumption required by pure water preparation is reduced, and the energy conversion efficiency of waste incineration power generation is improved.

Owner:HUANENG CLEAN ENERGY RES INST +9

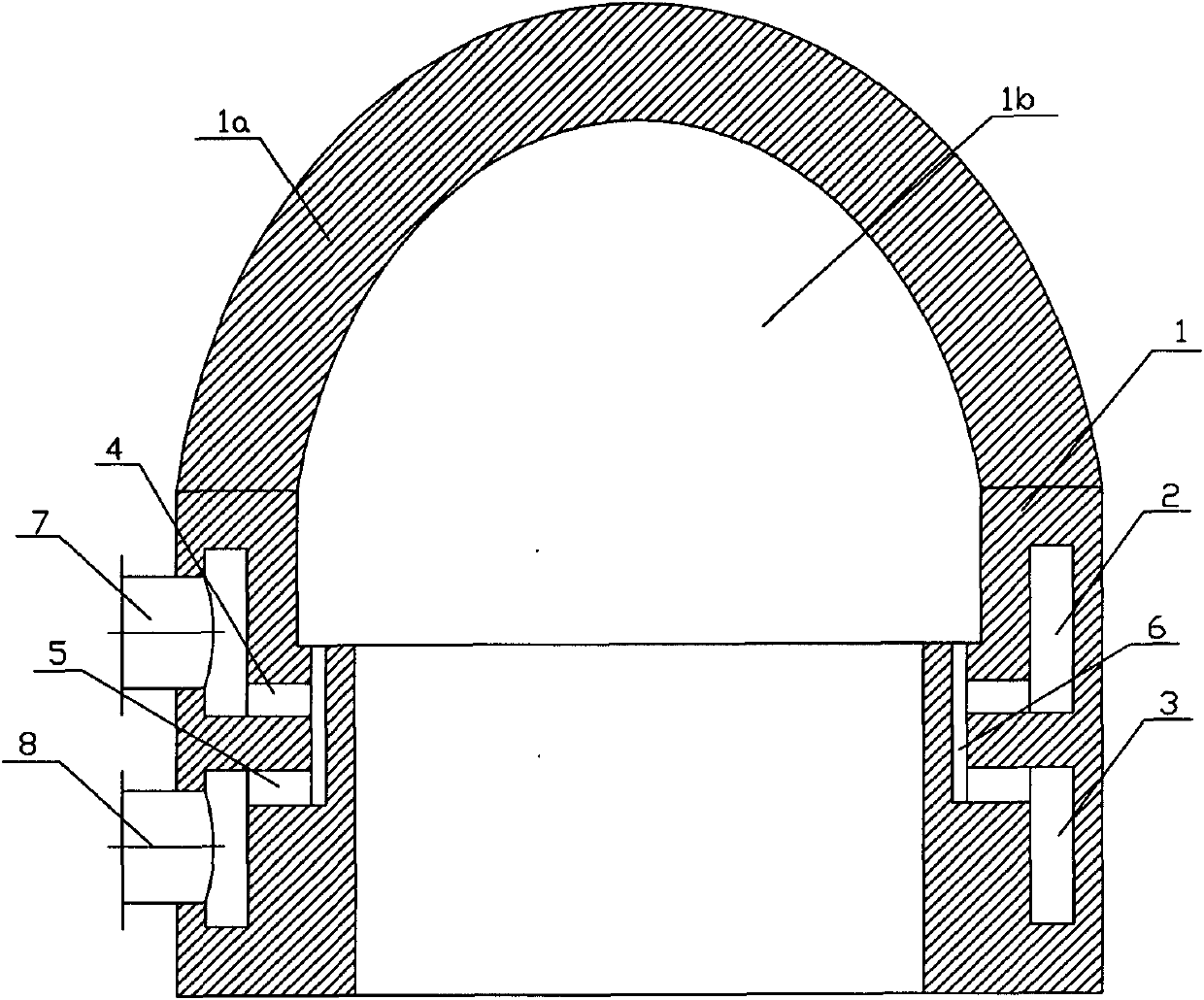

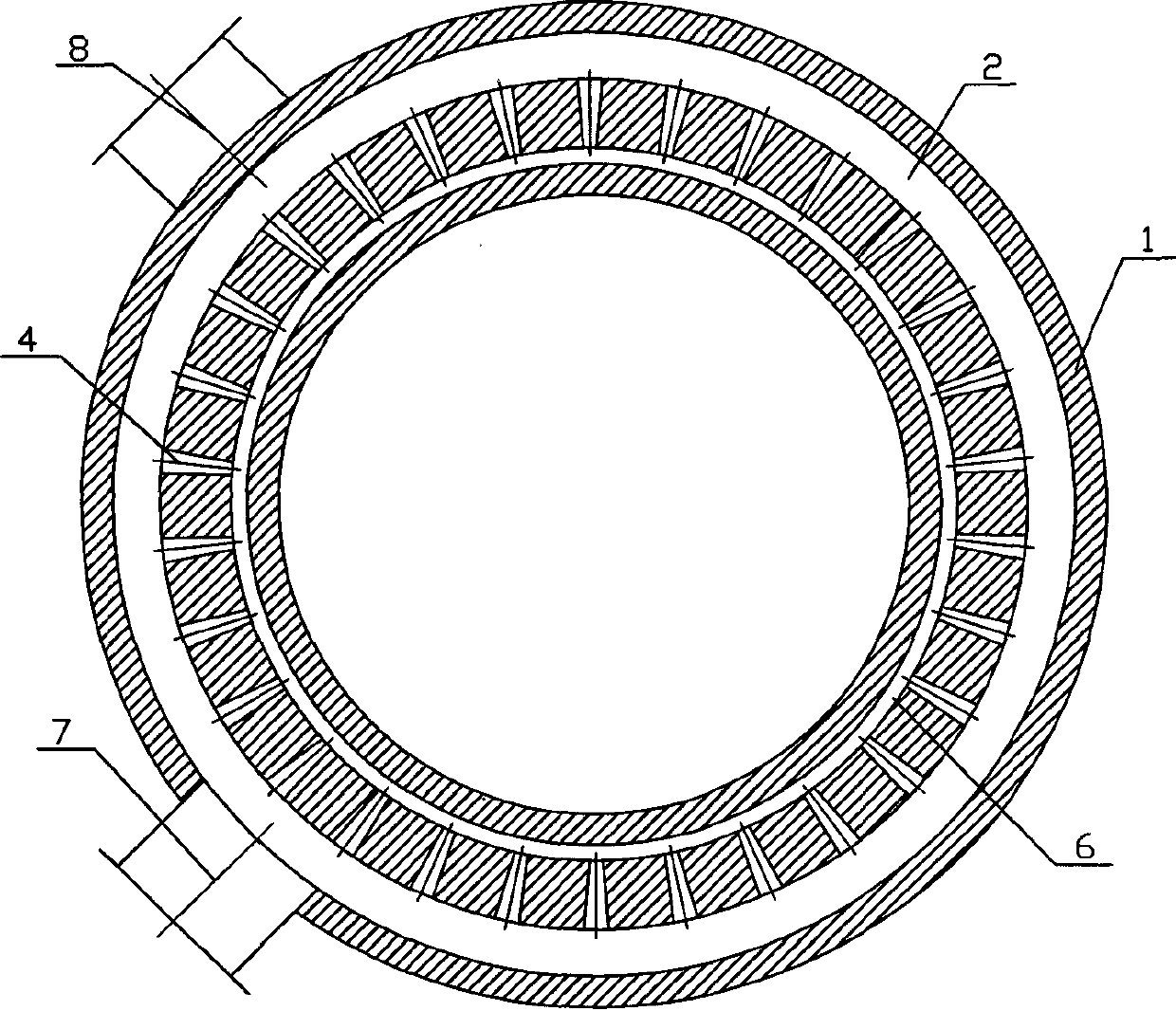

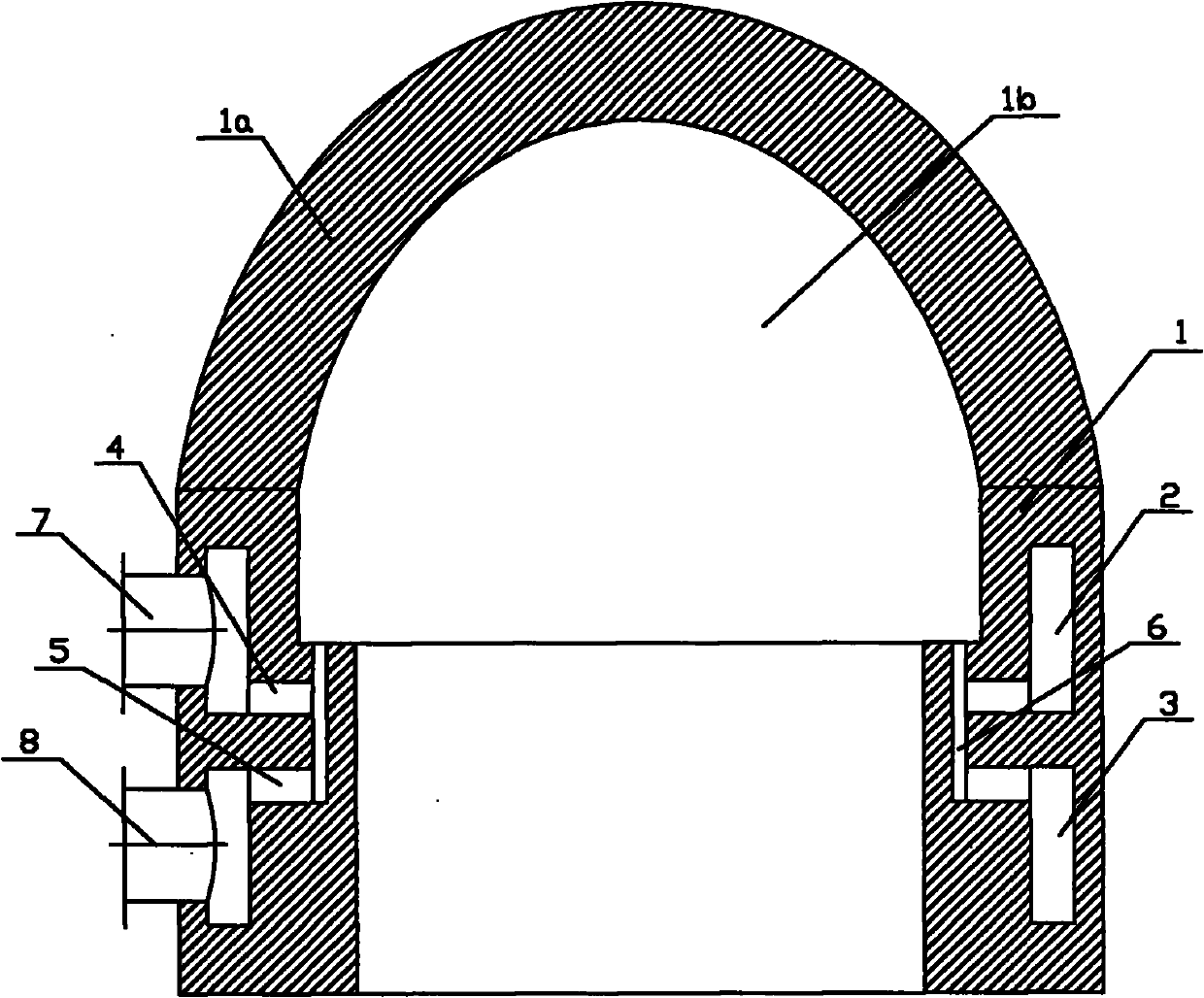

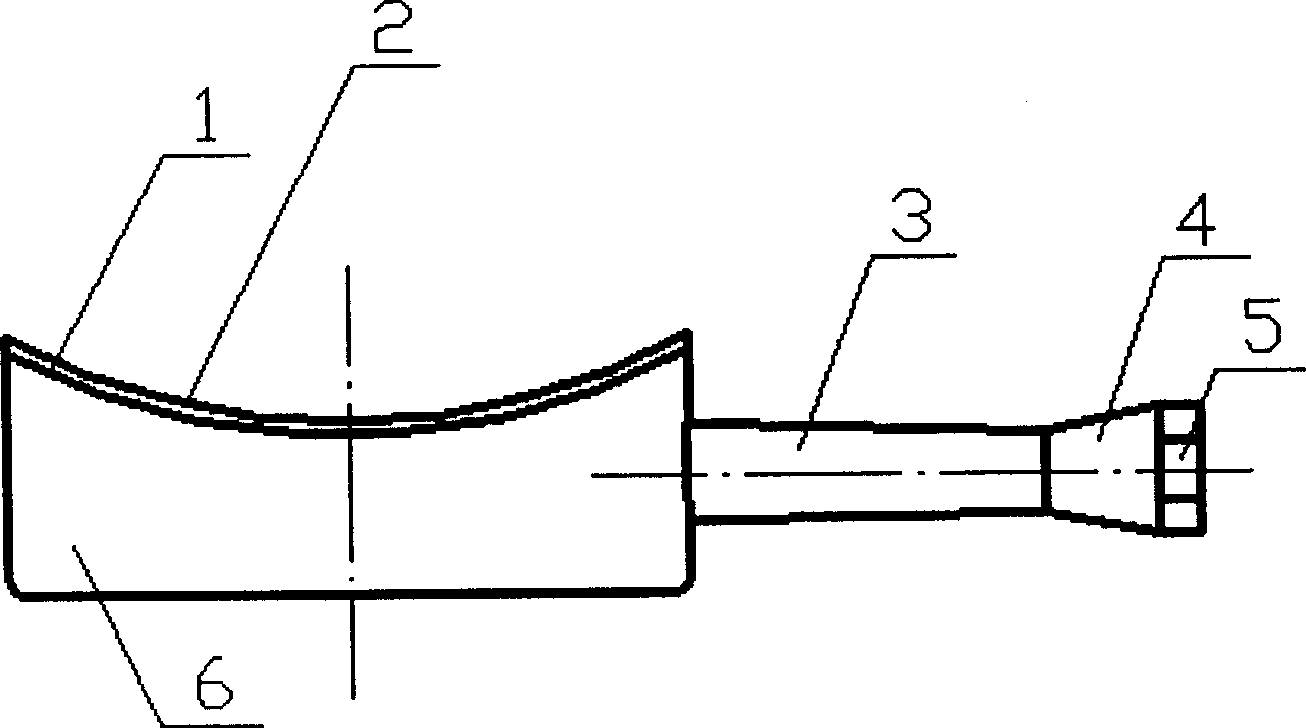

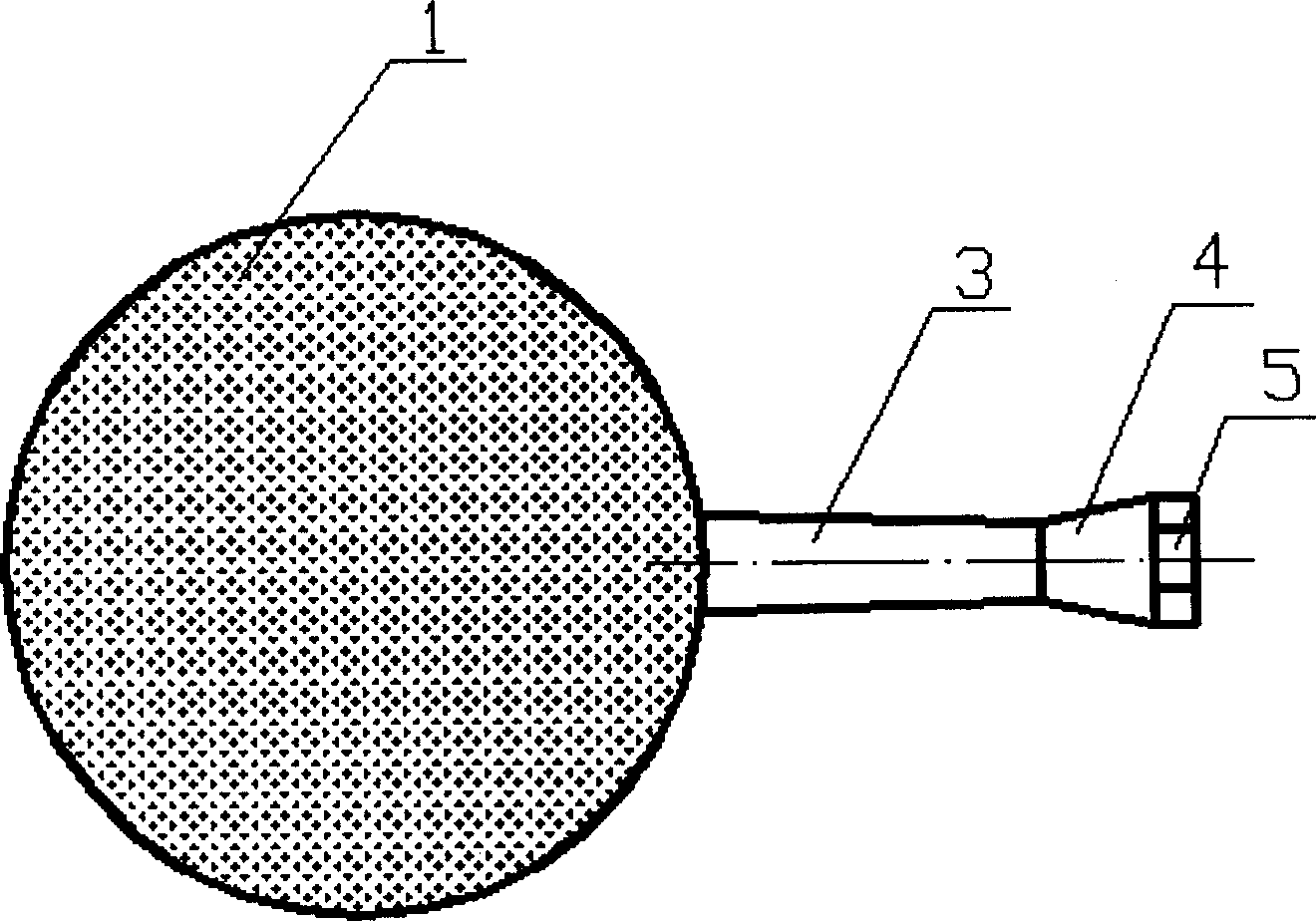

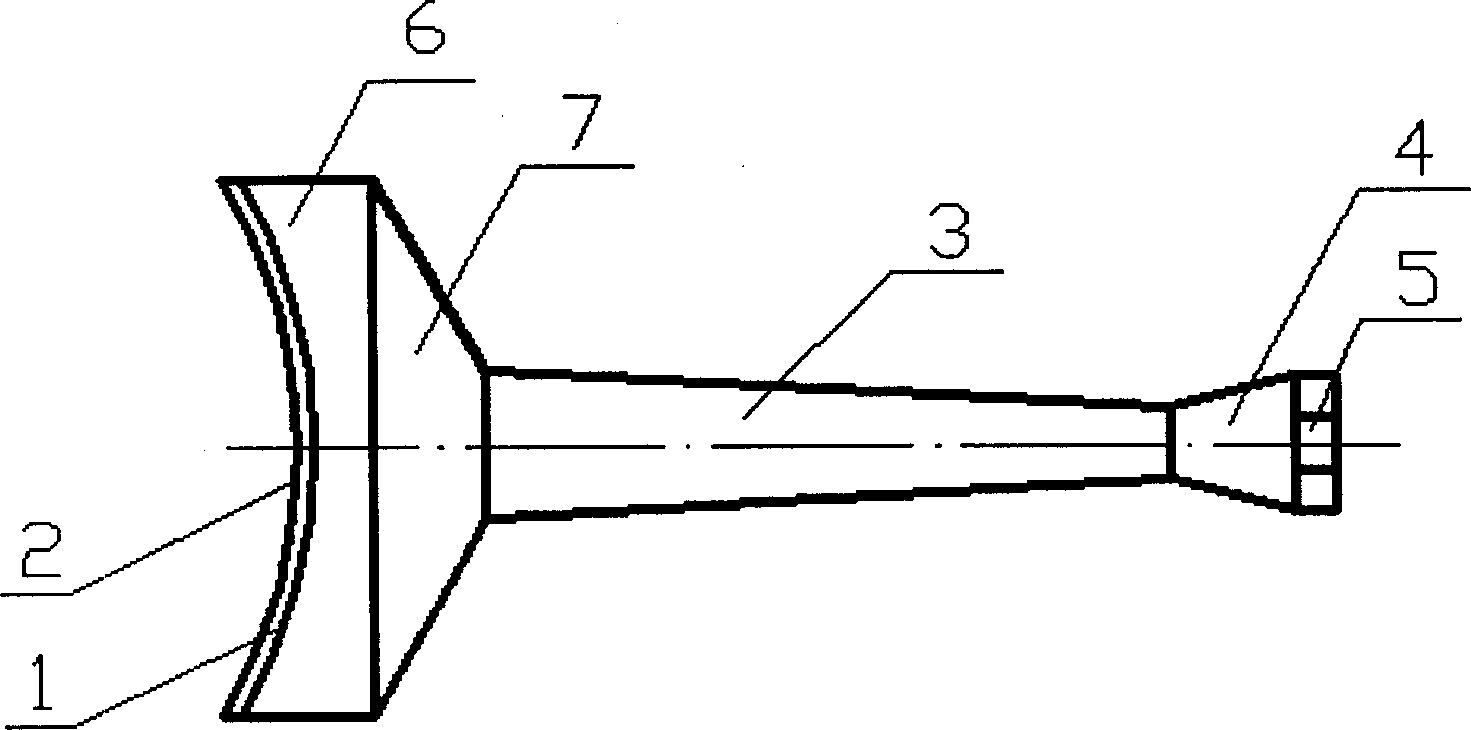

Spherieal radiation gas fuel burner

The invention relates to partial premixing type flue gas burner. Face of fire layer is in spherical surface prepared by splicing one or more cambered fireproof honeycomb panel. Angle between tangent of point, which is cutting point between faces of fire layer and mixing chamber, and horizontal line is 5-10 degrees. In the invention, particular surface shape reduces too large radiation heat dissipation from face of fire layer, raises thermal efficiency 20% higher than efficiency of traditional burner. Central temperature is higher than 900deg.C. Discharge of carbon monoxide and Nox is less than traditional burner.

Owner:TSINGHUA UNIV

Fluidization-suspending two-stage type compound combustion device

InactiveCN100549517CReduce generationReduce volatilityFluidized bed combustionCombustion chambersCombustion chamberCombustor

A fluidized-suspension two-stage composite combustion device relates to a combustion device. The invention solves the problem that the bubbling fluidized bed combustion chamber and the suspension combustion chamber of the existing combustion device are integrated so that the two have mutual thermal influence and flow influence, and it is impossible to fully burn the particle size at the same time in the same combustion device. Or the problem of burning two solid fuels with different reactivity. The invention includes a bubbling fluidized bed low-temperature combustion chamber, a high-temperature vortex suspension combustion chamber, and a variable-diameter chamber body. The upper end of the low-temperature combustion chamber of the bubbling fluidized bed communicates with the chamber body through the variable diameter section; the multi-layer direct-flow burners are evenly distributed on the side wall of the suspension furnace body. The invention has the advantages of high combustion efficiency and sufficient combustion, and realizes that two solid fuels with different particle diameters or different combustion activities can be fully burned simultaneously in the same combustion device.

Owner:HARBIN INST OF TECH

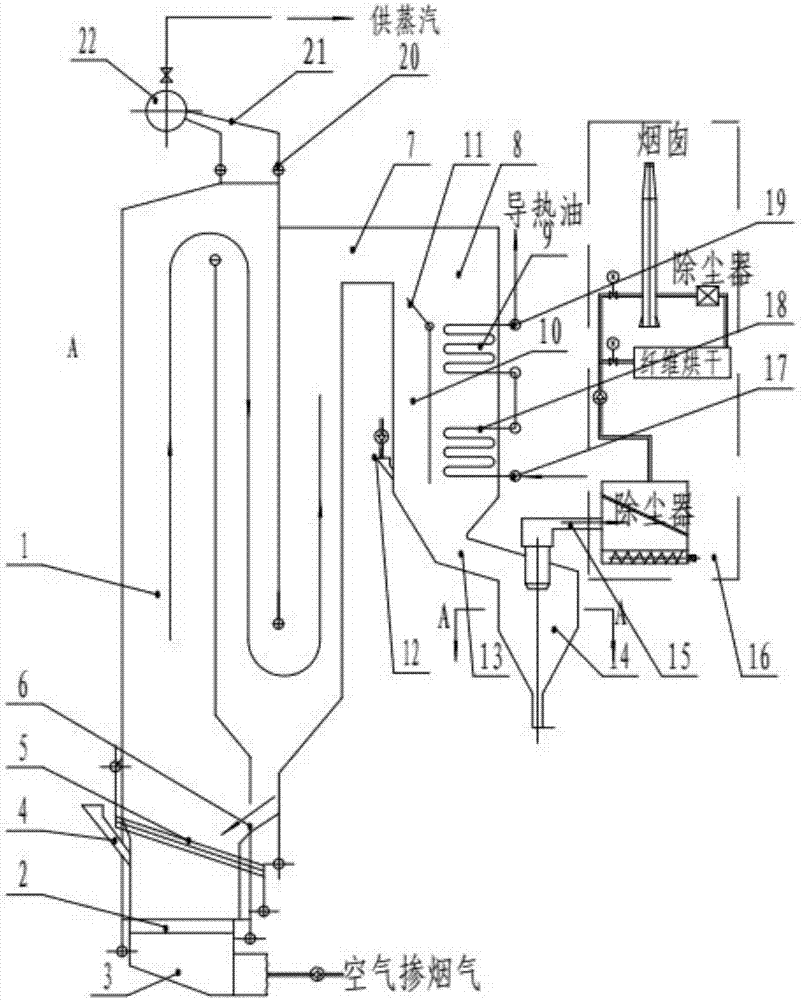

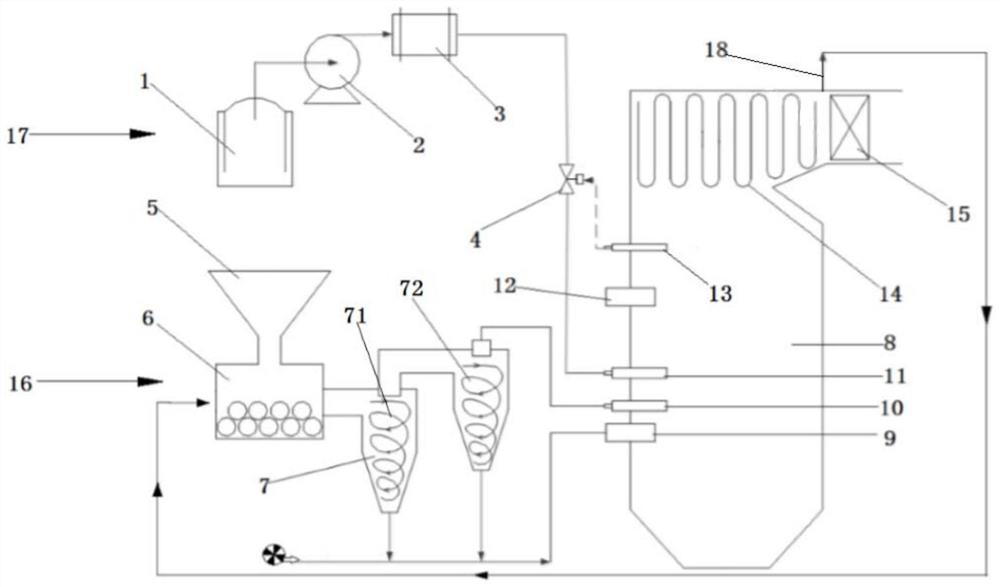

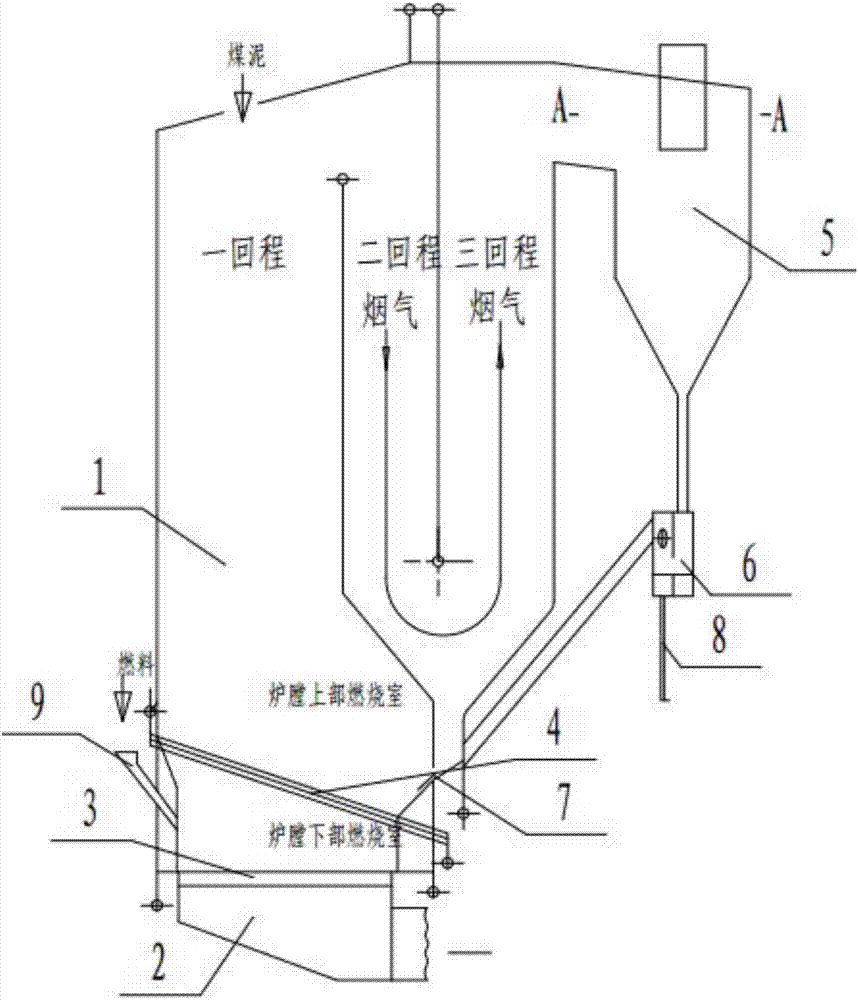

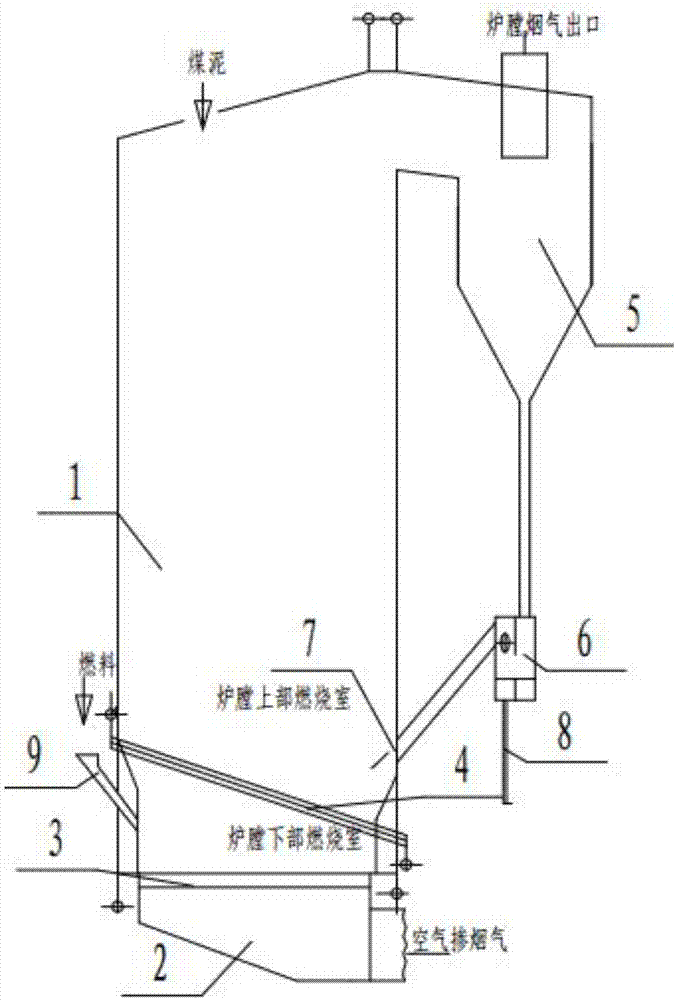

Fluidized bed heat energy center of low-heat-value fuel for combustion and using method of fluidized bed heat energy center

PendingCN107965773ASmall footprintEasy to operateFluidized bed combustionStorage heatersProduction lineCombustion

The invention discloses a fluidized bed heat energy center of low-heat-value fuel for combustion and a using method of the fluidized bed heat energy center. The fluidized bed heat energy center comprises a three-return-stroke hearth; the bottom of the three-return-stroke hearth is connected with an isobaric air chamber through a small hood air distribution plate; the lower portion of the three-return-stroke hearth is provided with a feeding pipe, a high-position buried pipe and a material return opening; the top of the three-return-stroke hearth is provided with a water cooling wall upper header which communicates with a boiler barrel through a steam guide pipe; an outlet of the three-return-stroke hearth communicates with a tail vertical shaft through a horizontal flue bent; a conductionoil heating device and a bypass flue are vertically and parallelly distributed on the tail vertical shaft; an inlet of the bypass flue is provided with an adjusting baffle, and an outlet of the bypassflue is connected with a fresh air device; a lower outlet of the tail vertical shaft communicates with a volute separator through a downdip flue; and an outlet of the volute separator communicates with a drying production line through a connection flue. Through the fluidized bed heat energy center of the low-heat-value fuel for combustion and the using method of the fluidized bed heat energy center, the equipment investment and operation cost can be reduced, system adjusting is easy, convenient, safe and reliable, original NOX emission of equipment is low, and the flue gas up-to-standard discharge environmental protection operating cost is reduced.

Owner:贵州新能源开发投资股份有限公司

Coal-fired boiler high-temperature ammonia spraying denitration system based on biomass pyrolysis and method thereof

PendingCN113083009AReasonable designImprove out-of-stock efficiencyDispersed particle separationCombustorNitrogen oxides

The invention relates to a coal-fired boiler high-temperature ammonia spraying denitration system based on biomass pyrolysis and a method thereof, a biomass pyrolysis device and an amino reducing agent spraying device are connected to a boiler main combustion area, and high-temperature flue gas obtained after a high-temperature superheater is extracted is connected with the high-temperature flue gas inlet end of the biomass pyrolysis device; biomass fuel is subjected to multi-stage heating pyrolysis to generate mixed gas, and the mixed gas and an amino reducing agent are sequentially introduced into a main combustion area of the boiler; an air staged combustion mode is adopted, and the excess air coefficient of a main combustion area is reduced by utilizing a low-nitrogen combustor and an SOFA air nozzle; an SOFA nozzle is additionally arranged, so that a main combustion area is in a reducing atmosphere; an amino reducing agent is sprayed into the main combustion area, the amino reducing agent can be subjected to a reduction reaction with nitric oxide in flue gas in a high-temperature reducing atmosphere, and the concentration of the nitric oxide at a hearth outlet is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

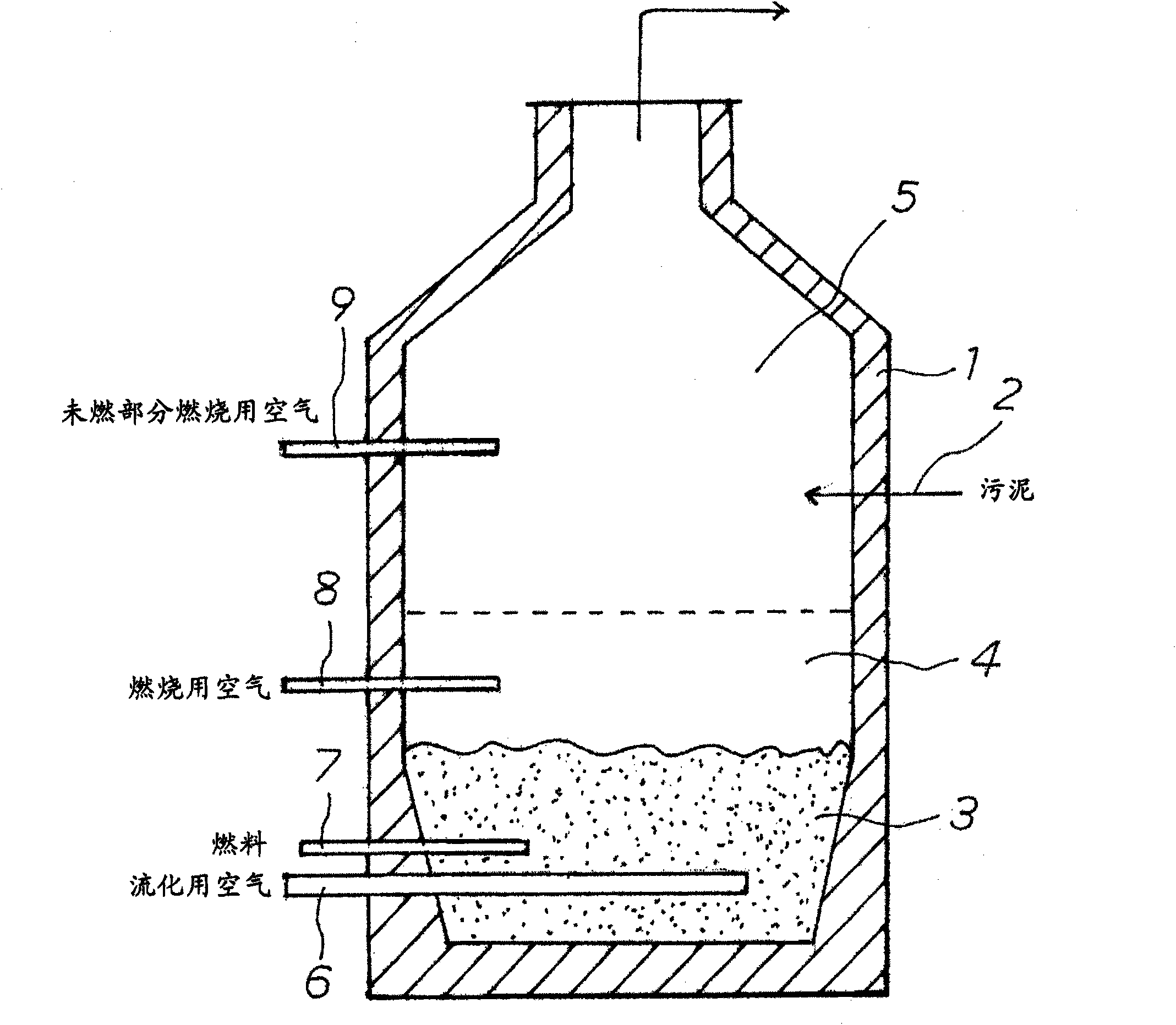

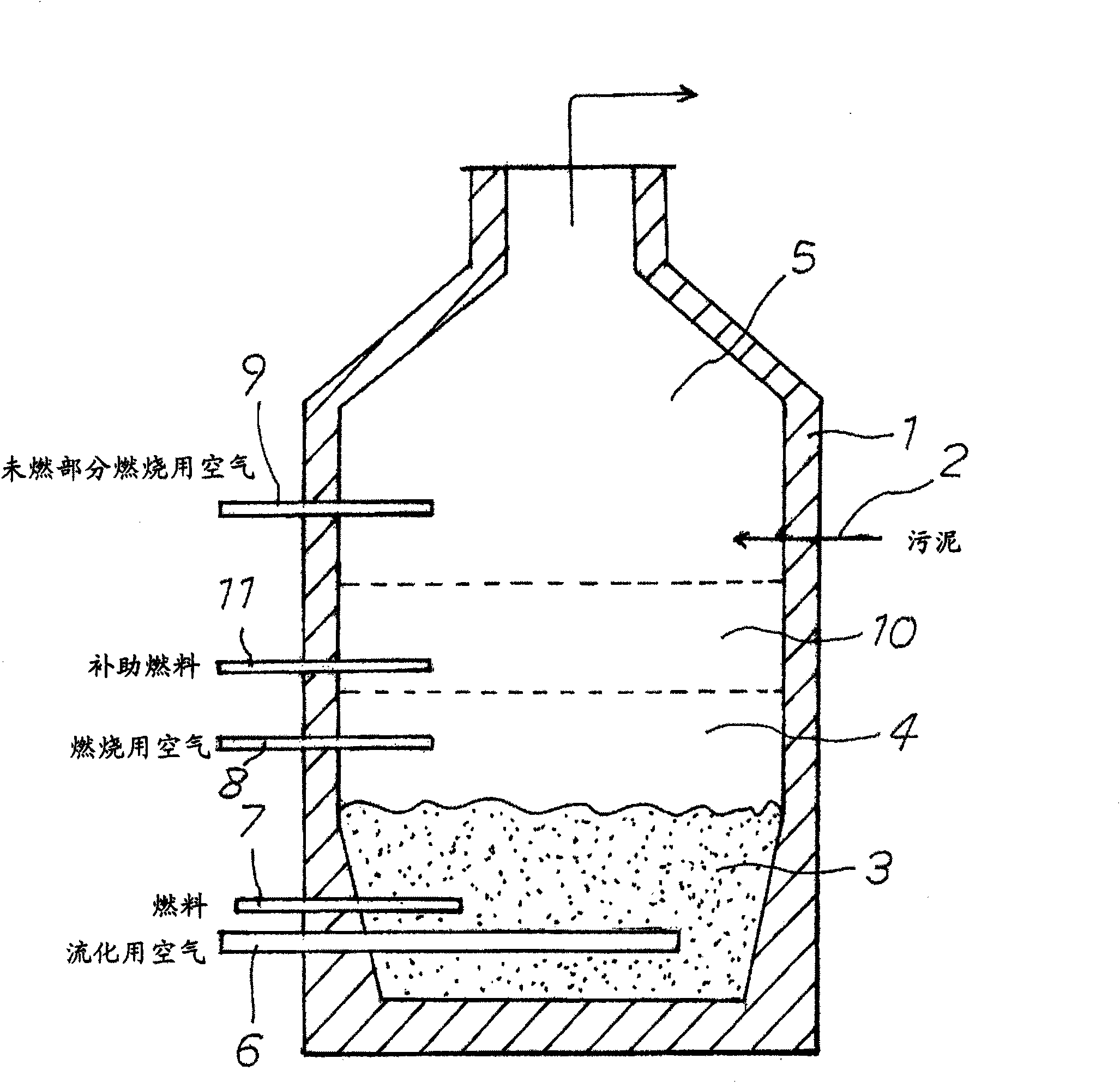

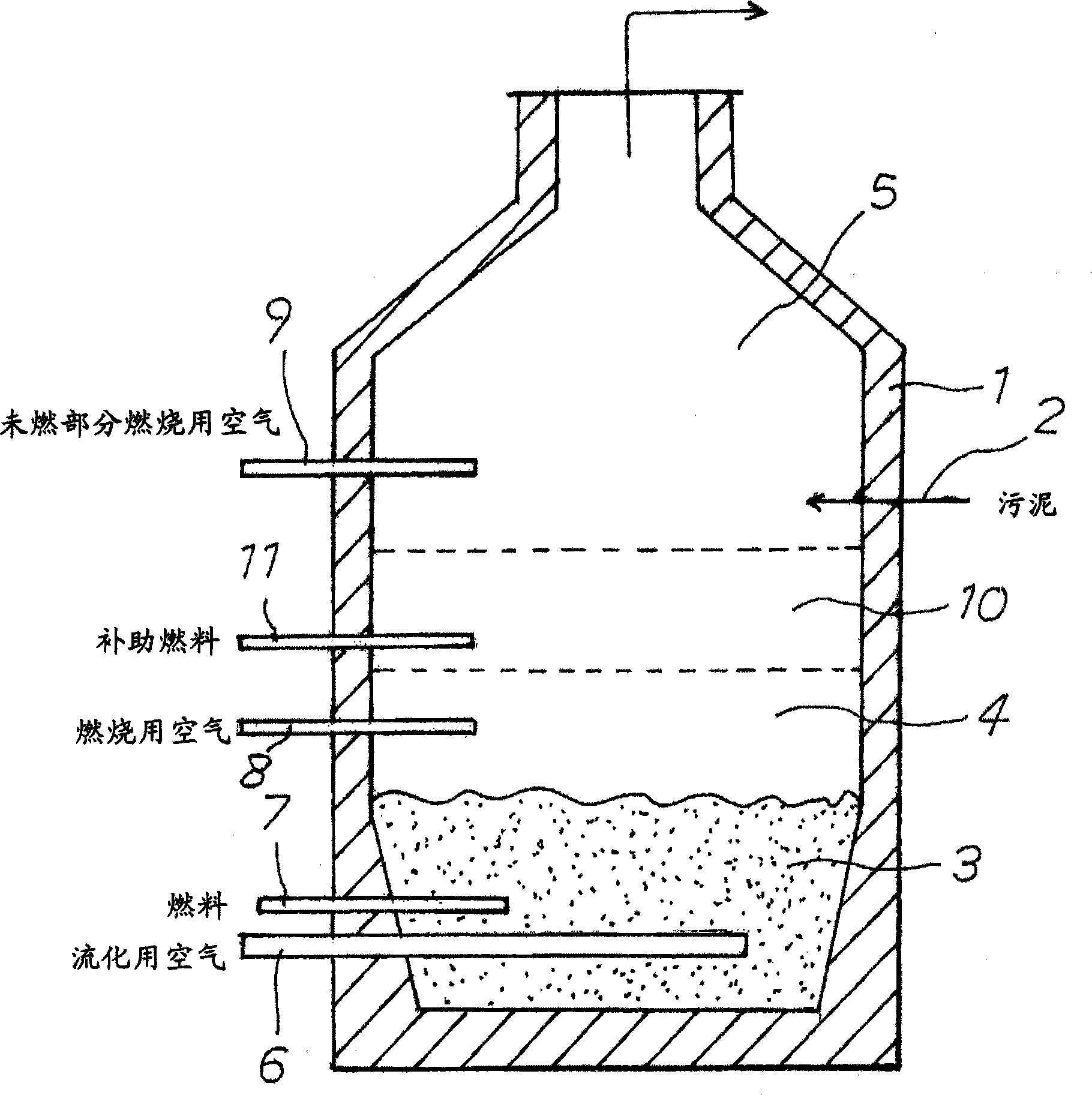

Fluidized-bed incinerator and method of fluidized-bed incineration of sludge with the same

ActiveCN101849140ASuppress generationFully thermally decomposedFluidized bed combustionEmission preventionCombustionReaction zone

The inside of a furnace body (1) into which a sludge is introduced is divided in the height direction into the following: a lower part which serves as a pyrolysis zone (3) in which air for fluidization having an air ratio of 1.1 or lower is supplied together with a fuel to burn the fuel and pyrolyze the sludge while fluidizing the sludge; a part right over the zone (3), the part serving as an on-layer combustion zone (4) in which only air for combustion having an air ratio of 0.1-0.3 is supplied to thereby form a local high-temperature field to decompose N2O; and an uppermost part of the furnace body, the part serving as a complete combustion zone (5) in which an unburned matter is completely burned. The amount of N2O generating during sludge incineration can be considerably reduced while maintaining the amount of a supplemental fuel to be used on the same level as in conventional incineration methods. A supplemental-fuel reaction zone (10) in which only the supplemental fuel is fed to decompose N2O may be formed between the pyrolysis zone (3) and the on-layer combustion zone (4). This constitution can further reduce the amount of N2O to be generated.

Owner:METAWATER CO LTD

Low bed pressure recombination fluidized bed burning fuel with ultralow heat value and using method thereof

PendingCN106979514AImprove ash forming performanceReduce wearFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

The invention discloses a low bed pressure recombination fluidized bed burning fuel with ultralow heat value and a using method thereof. The low bed pressure recombination fluidized bed comprises a hearth, wherein an isobaric air chamber is formed below the hearth; the hearth communicates with the isobaric air chamber through a small hood air distributing plate; a high-position buried pipe is arranged above the hearth; a volute separator is arranged at an exhaust outlet and is connected with a hearth returning charge opening through a selective U-shaped return feeder; an emptying pipe is further arranged on one side of the selective U-shaped return feeder; a crushing device is arranged at a feeding hole of the hearth; an outlet of the crushing device is provided with an upper-layer screen plate and a lower-layer screen plate; the pore diameters of meshes of the upper-layer screen plate and the lower-layer screen plate are 6 mm and 4 mm; an outlet of the lower-layer screen plate and the lower part of the lower-layer screen plate are connected into a stirrer through two weighing belt feeder; and a stirrer outlet communicates with the feeding hole. The low bed pressure recombination fluidized bed greatly improves the ash forming performance of gangue and furnace slag and reduces energy consumption of a pressure head of a fluidization fan and abrasion of a combustion chamber; and fluidization in the bed is uniform and stable, the coefficient of excessive air is small, and NOx is reduced.

Owner:贵州新能源开发投资股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com