Device and method for cooling clinker by liquid oxygen and liquid nitrogen of cement kiln

A technology of cement kiln and liquid oxygen, which is applied to the device for strengthening the combustion of the preheating decomposition system of the rotary kiln, and the device for cooling the clinker by using liquid oxygen and liquid nitrogen in the cement kiln. It can solve the problem of unstable cooling effect, affecting the quality of cement products, Large cooling energy consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

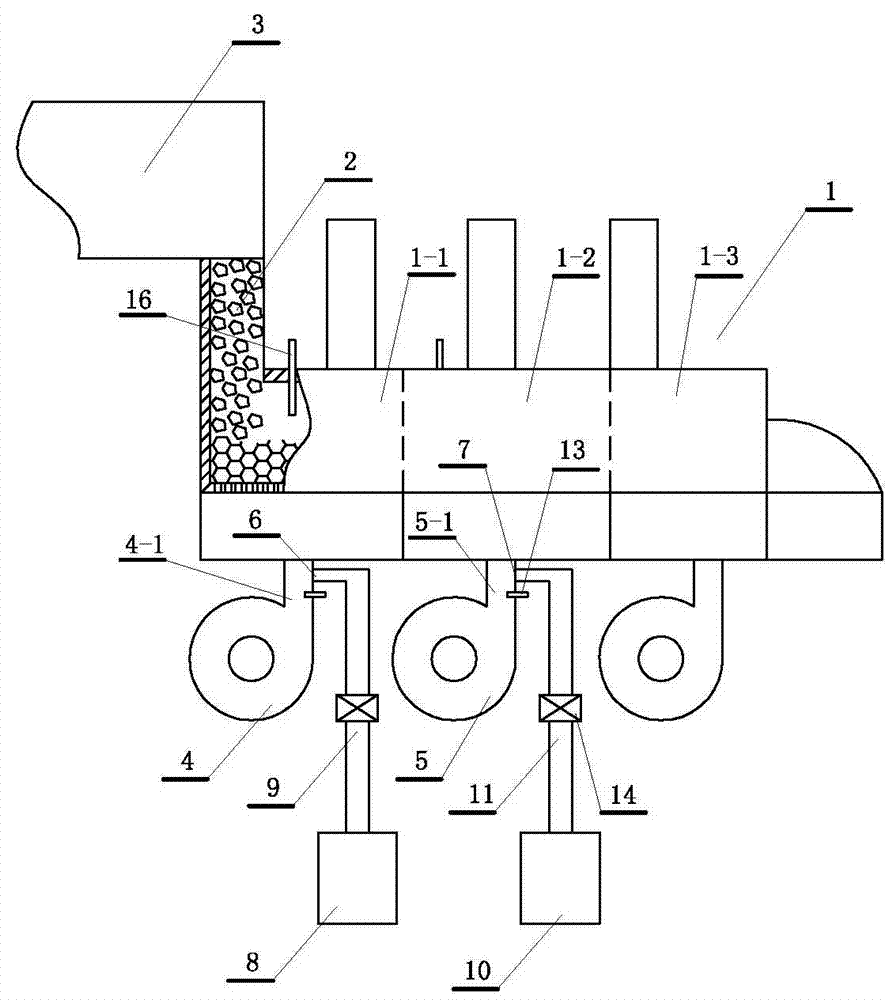

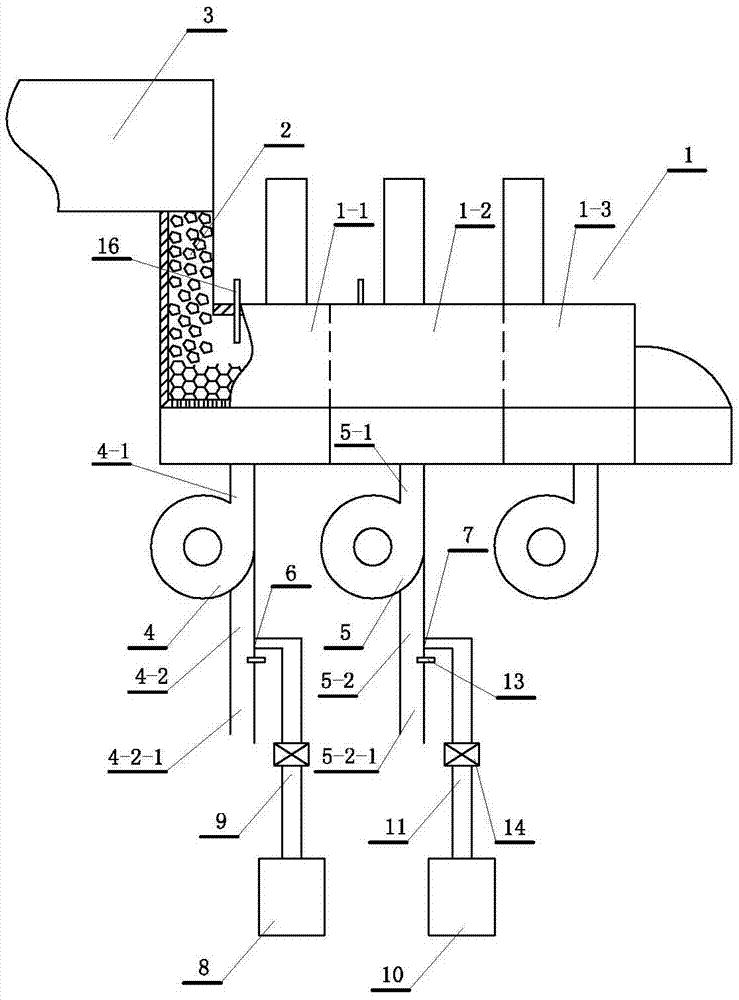

[0031] A device for cooling clinker in a cement kiln using liquid oxygen and liquid nitrogen, such as figure 1 and figure 2 As shown, the cement kiln grate cooler 1 is included, and the high-temperature clinker 2 of the cement kiln falls into the cement kiln grate cooler after coming out of the rotary kiln 3. The cement kiln grate cooler is sequentially provided with a high temperature cooling zone 1-1, a medium temperature Cooling zone 1-2 and low-temperature cooling zone 1-3, the high-temperature clinker is transferred to the next process section after passing through the high-temperature cooling zone, medium-temperature cooling zone and low-temperature cooling zone. Zones are respectively provided with air-cooled blowers 4 and 5, on the output pipeline 4-1 of the air-cooled blower in the high-temperature cooling zone, a liquid oxygen input interface 6 is arranged, and in the output pipeline 5-1 of the air-cooled blower in the medium-temperature cooling zone A liquid nitro...

Embodiment 2

[0039] A method for cooling clinker by using liquid oxygen and liquid nitrogen in a cement kiln is a method for cooling clinker by using liquid oxygen and liquid nitrogen based on the device described in Example 1, and the method is in the high temperature section of the cement kiln grate cooler The cooling air sent by the blower contains liquid oxygen of 1% to 12% of the total air volume, and the cooling air sent by the blower in the middle temperature section of the cement kiln grate cooler contains liquid nitrogen of 1% to 45% of the total air volume.

[0040] In an embodiment, the method further includes:

[0041] a. After the cement kiln is running normally, open the liquid oxygen delivery channel. In the middle of the high temperature section of the grate cooler, when the gas temperature is higher than 1150°C, increase the cooling air flow sent by the blower, and the cold air flow contains total Air volume of 1% to 12% liquid oxygen, adjust the content of liquid oxygen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com