Fluidized bed heat energy center of low-heat-value fuel for combustion and using method of fluidized bed heat energy center

A fluidized bed, low calorific value technology, used in combustion methods, fluidized bed combustion equipment, and fuel burning in a molten state, etc., can solve the problems of large equipment footprint, high fuel cost, and many operators, and achieve combustion Long time, lower NOX emissions, simple and convenient system adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

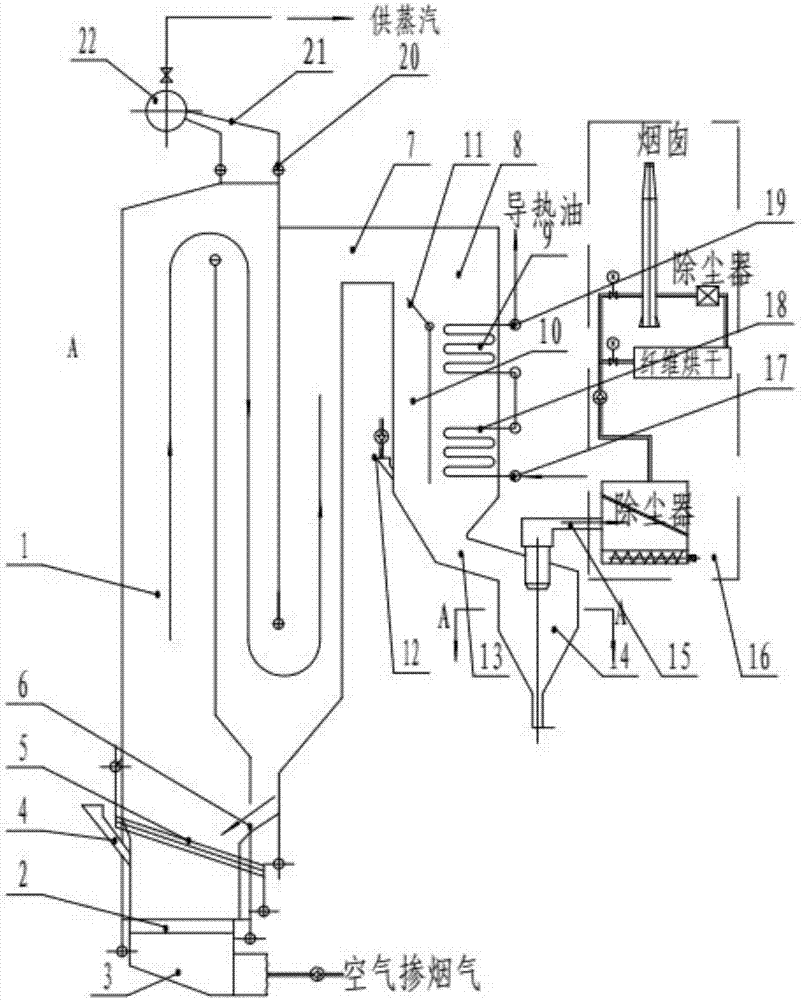

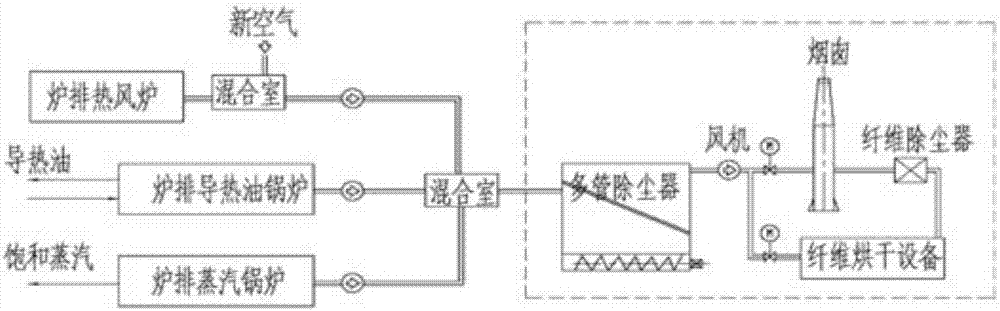

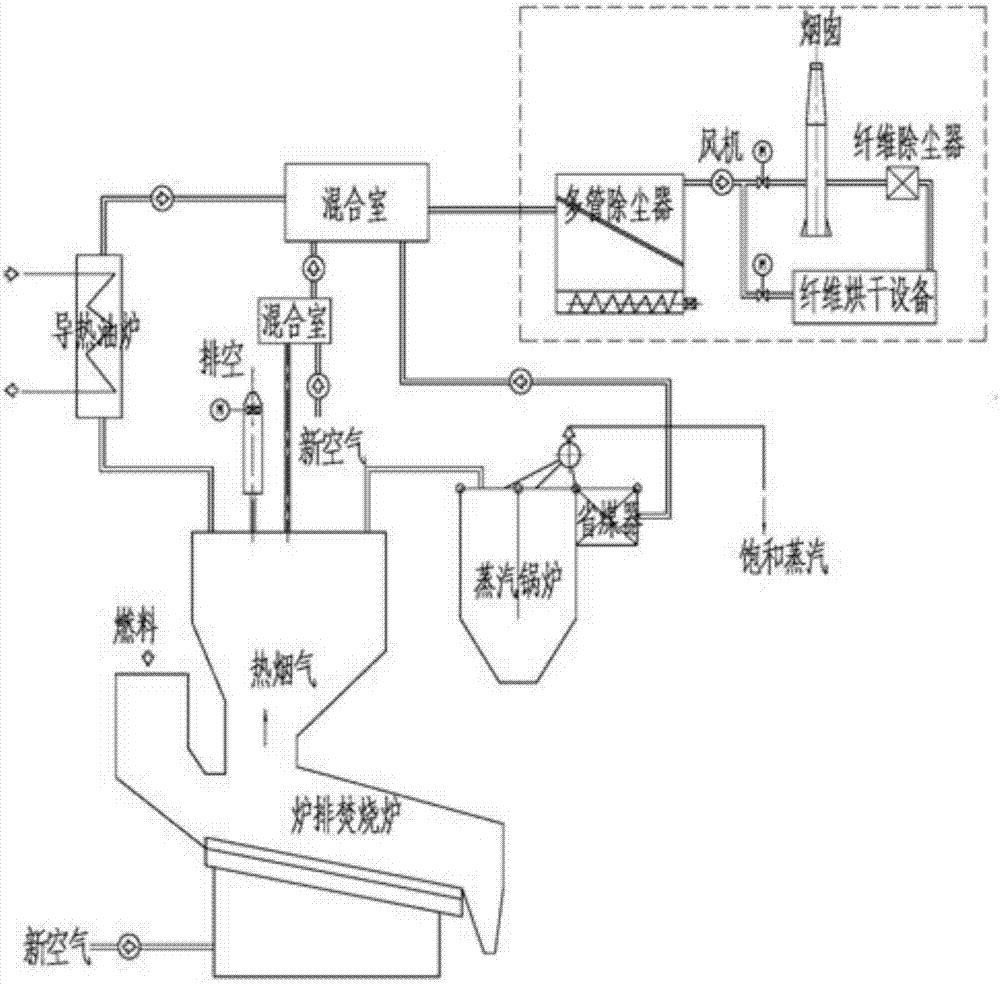

[0035] Example 1: Such as Figure 1-4 As shown, a fluidized bed thermal energy center that uses low-calorific value fuels includes a three-pass furnace 1. The lower part of the three-pass furnace 1 is connected to an equal pressure air chamber 3 through a small hood air distribution plate 2, and the lower part of the three-pass furnace 1 is equipped with feed Pipe 4, high-level buried pipe 5, return material port 6, three-pass furnace 1 is provided with a water-wall upper header 20 on the top of the water-cooled wall upper header 20 is connected to the drum 22 through the steam guide 21, and the outlet of the three-pass furnace 1 passes through the horizontal The flue 7 turns and connects to the tail shaft 8. The tail shaft 8 is arranged vertically in parallel with the heat conduction oil heating device 9 and the bypass flue 10. The inlet of the bypass flue 10 is equipped with a regulating baffle 11, the outlet is connected to the fresh air device 12, and the tail shaft 8 is low...

Embodiment 2

[0042] Embodiment 2: A method for using a fluidized bed thermal energy center that uses low-calorific value fuel, the method includes the following steps:

[0043] (1) An equal pressure air chamber 3 is set under the three-pass furnace 1, and the inlet medium of the equal pressure air chamber is a mixture of natural fresh air and 0-30% of the tail flue gas;

[0044] (2) Blending low-calorific value coal with low-calorific value biomass sawdust waste, bark, and wood powder to form a fuel whose particle diameter is ≤8mm, biomass particles ≤50mm, and the calorific value after mixing is less than 2500Kcal / kg,

[0045] (3) The mixed fuel is added to the small hood air distribution plate 2 under the fluidized bed;

[0046] (4) By controlling the bed pressure of the fluidized bed, the coarse and heavy particles burn in the dense phase zone of the furnace, and the light and fine particles enter the upper low-velocity and long-flow furnace for combustion. The flow rate is controlled to 3.5-6m / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com