Cold crude gas heat accumulating type oxygen-enriched combustion method and cold crude gas heat accumulating type oxygen-enriched combustion system

A gas heat storage and oxygen-enriched combustion technology, applied in the field of combustion, can solve problems such as reducing the thermal efficiency of furnaces and kilns, and achieve the effects of high degree of automation, reduction of CO2 and NOX, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

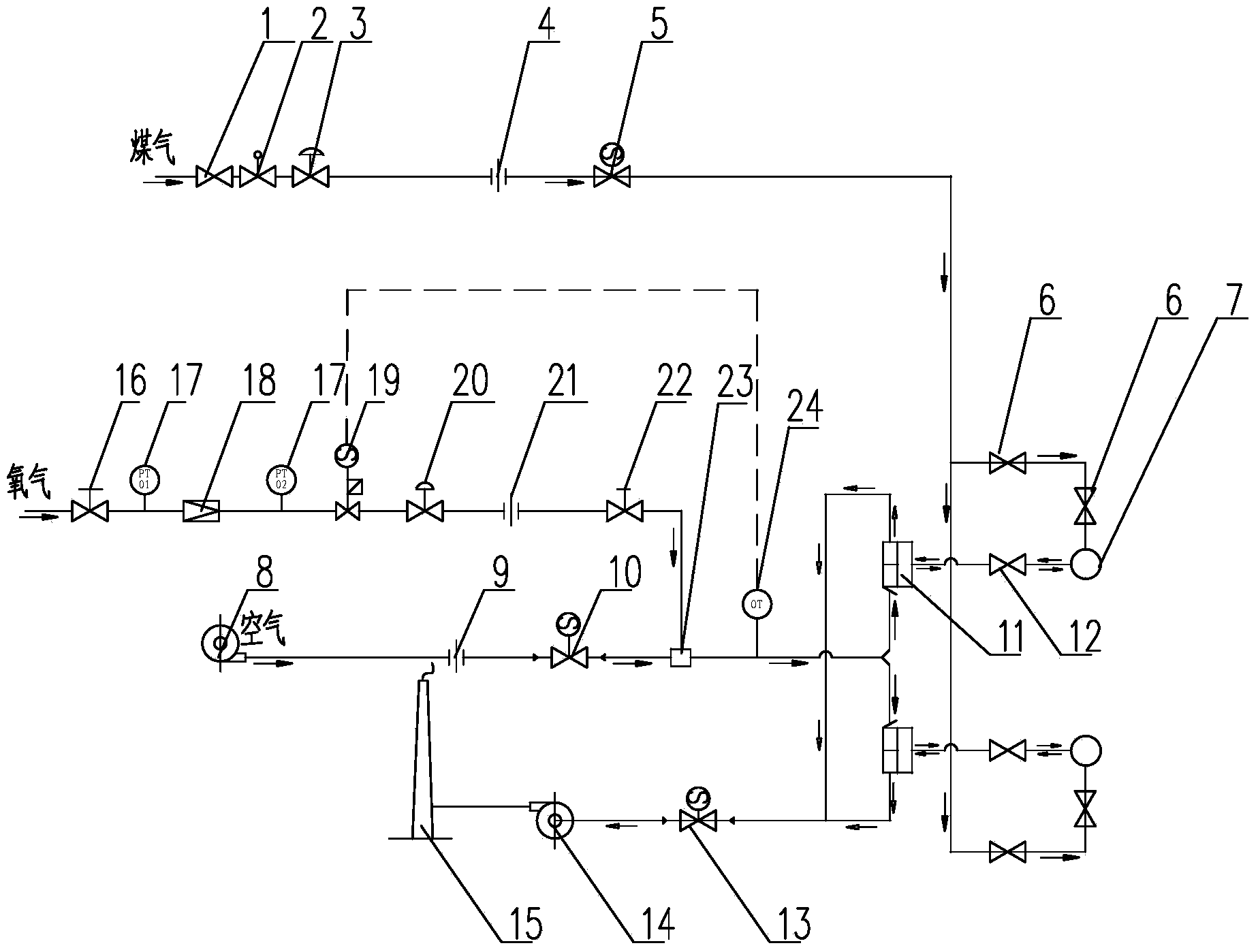

[0047] [Example 1] A specific application of a cold dirty gas regenerative oxygen-enriched combustion method and combustion system of the present invention

[0048] The cold dirty gas regenerative oxygen-enriched combustion process of this embodiment includes the following steps:

[0049] The blast furnace cold dirty gas at room temperature enters the gas system pipeline with a flow rate of 2400m 3 / h, after metering and adjustment, it finally enters two regenerative burners 7.

[0050] The pressure value of oxygen is reduced to 0.1MPa through the self-operated pressure reducing valve 18, and the flow rate is 156m 3 / h, after adjustment and metering, it enters the dynamic mixer 23 to mix with the combustion-supporting air, detects the online oxygen concentration through the oxygen detector 24 and automatically adjusts the opening of the oxygen electric regulating valve 19 to reach an oxygen-enriched concentration of 26%. .

[0051] After the air is blasted by the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com