Patents

Literature

31results about How to "Improve out-of-stock efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient denitrified integral catalyst of stationary source

InactiveCN101905156AWide operating temperatureImprove out-of-stock efficiencyCatalyst carriersDispersed particle separationIonMolecular sieve

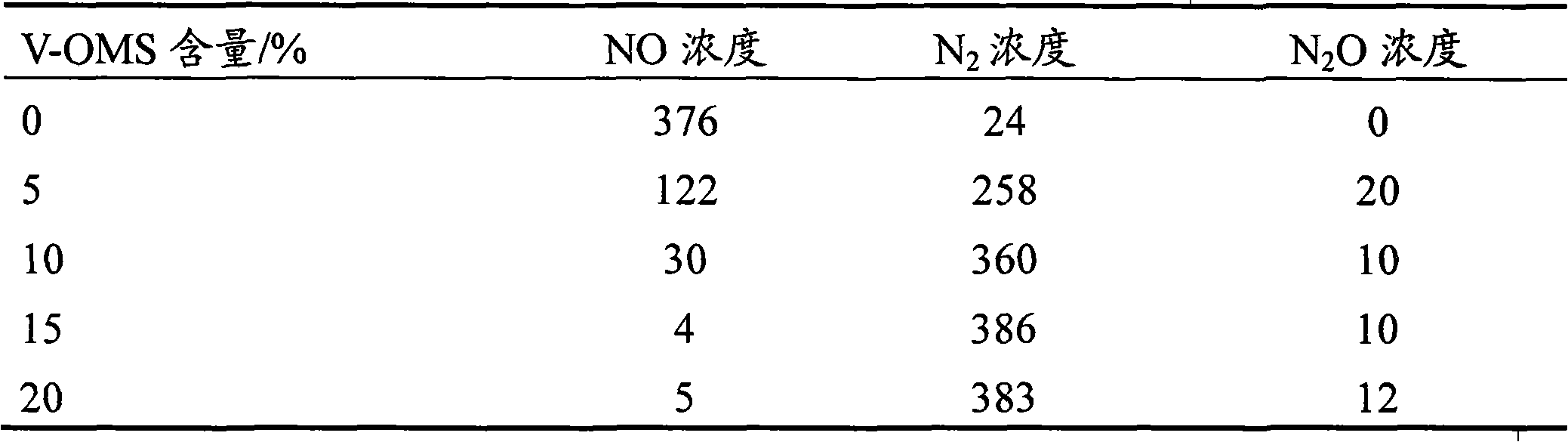

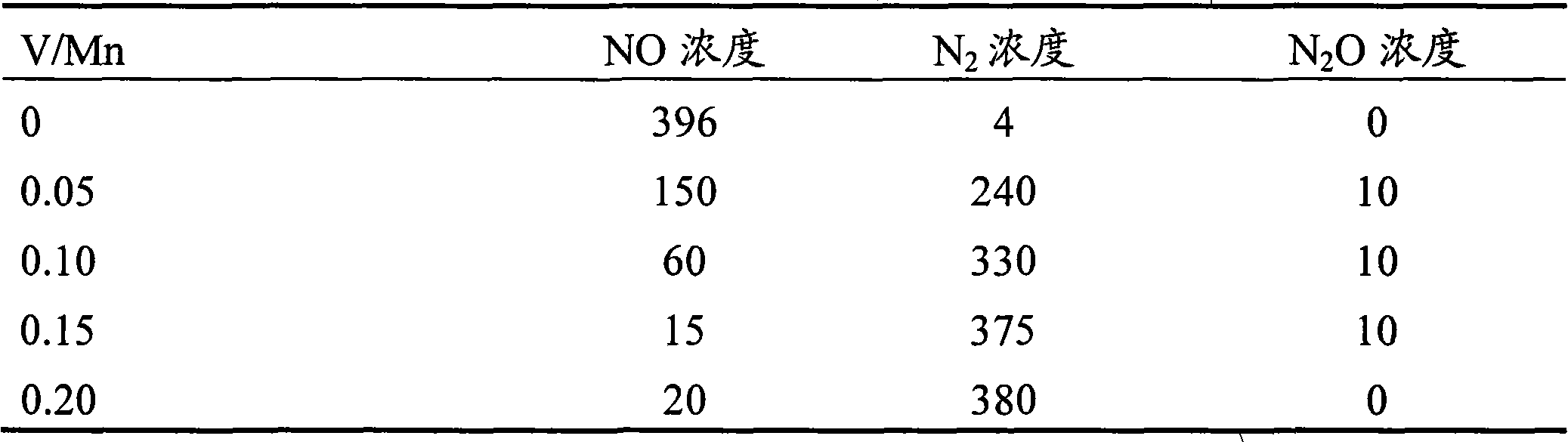

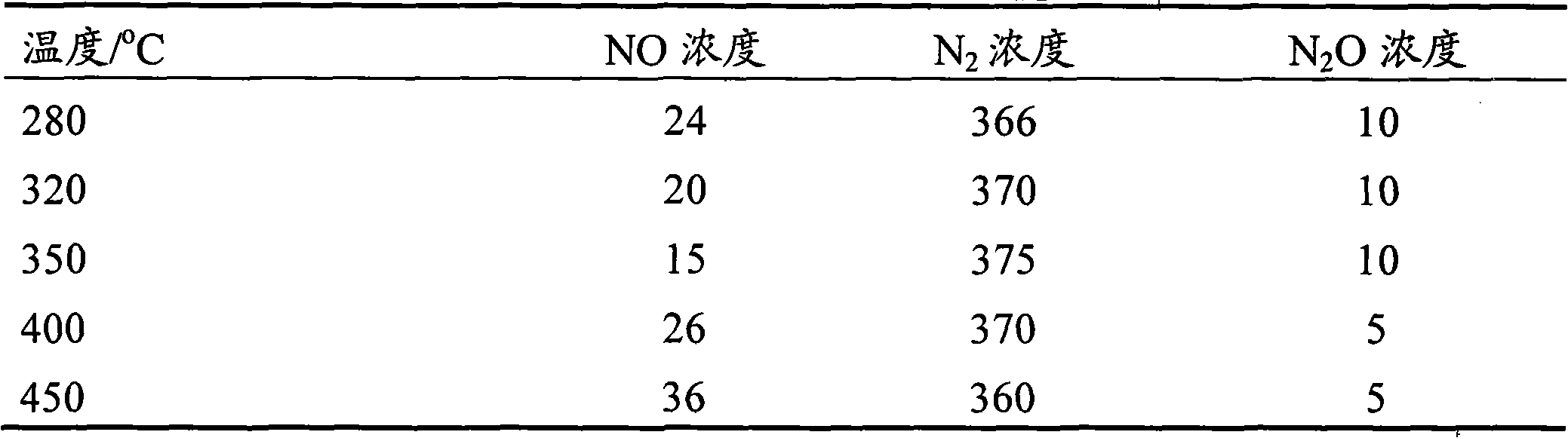

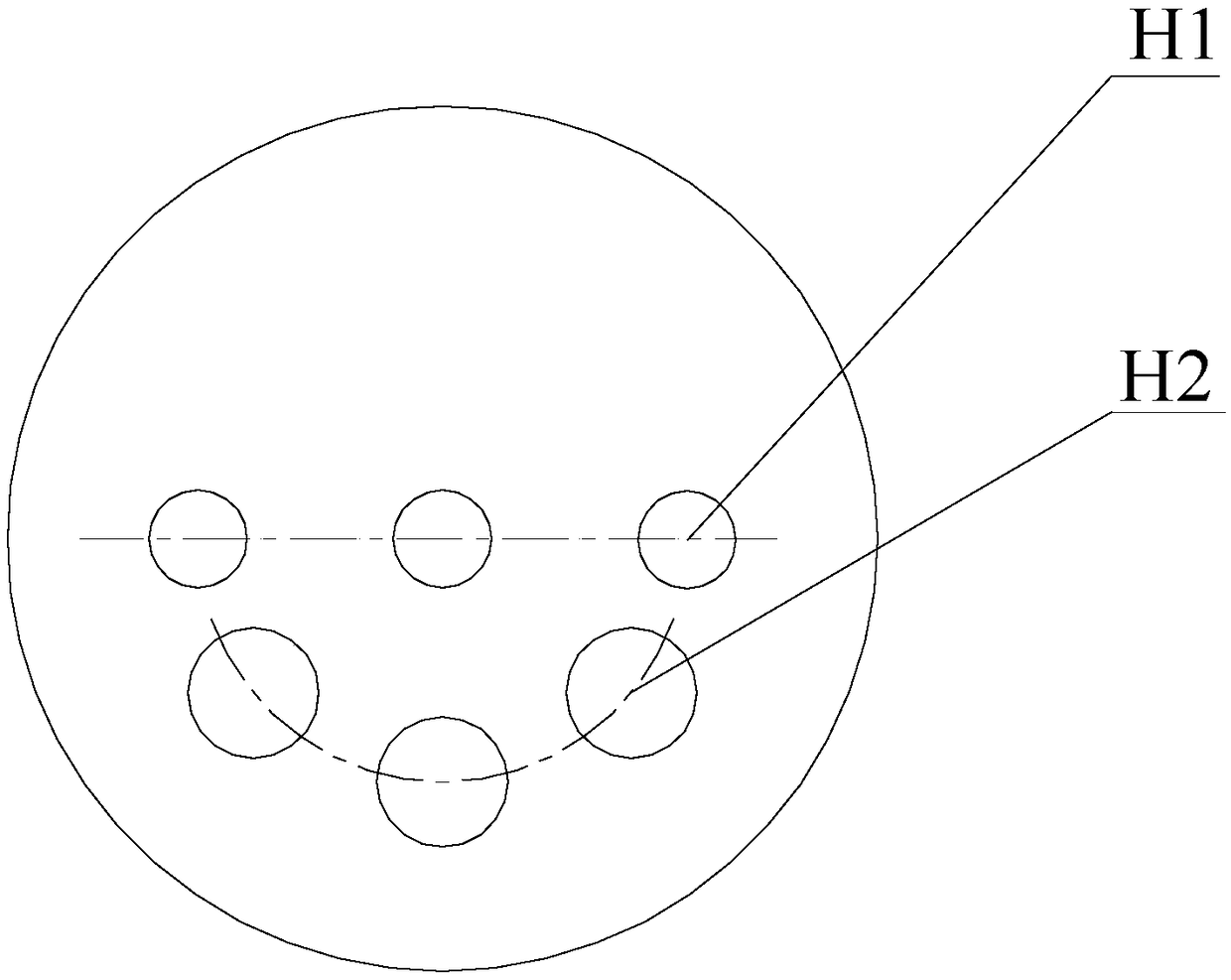

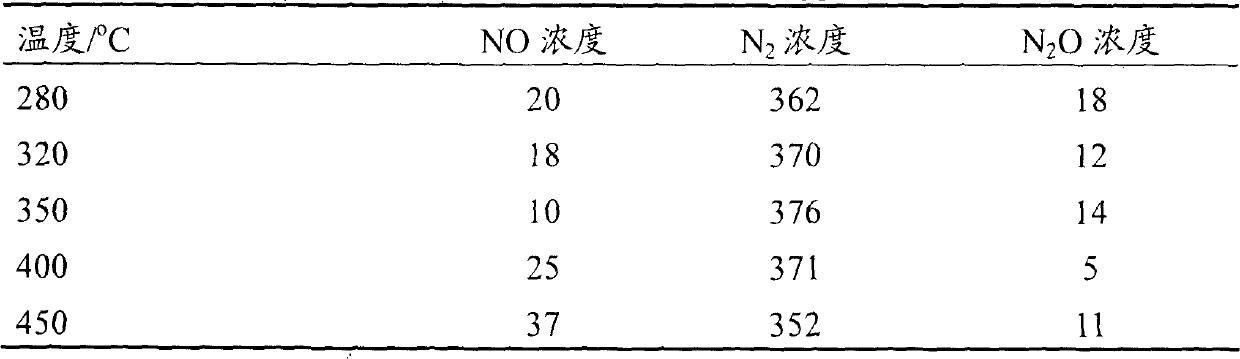

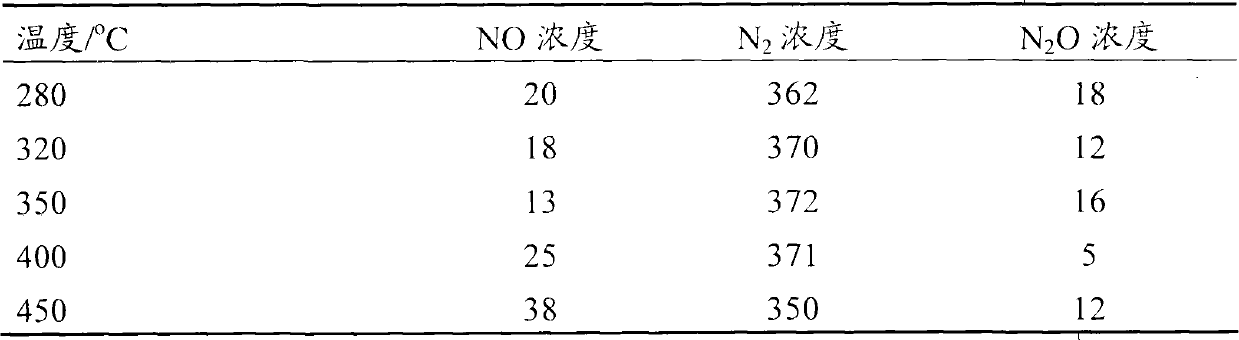

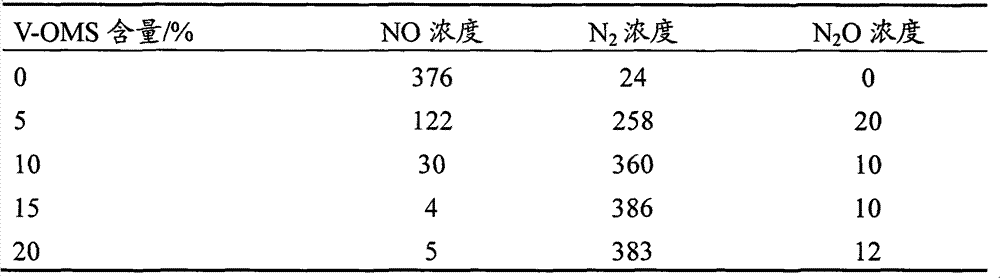

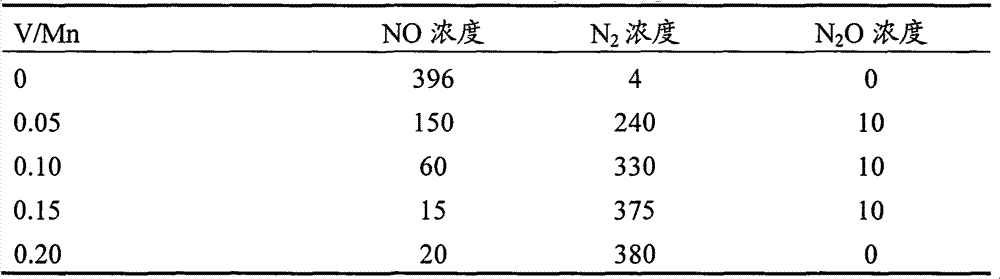

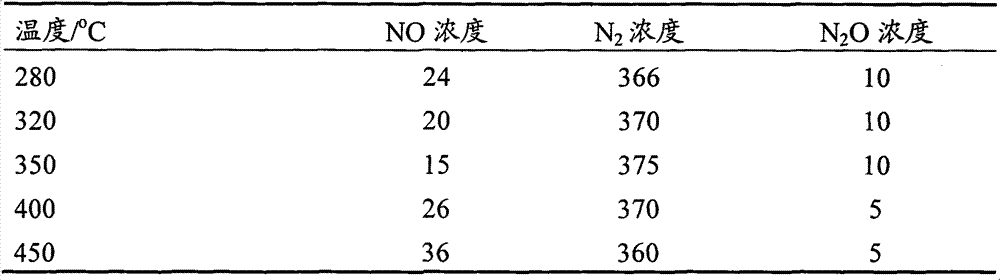

The invention discloses an efficient denitrified integral catalyst of a stationary source, which relates to a control technique of catalytic selective reducing nitric oxides (NOx) in the fields of catalyzation, environmental protection and energy saving and is characterized in that honeycomb cordierite ceramics are used as matrixes; gamma-Al2O3 is used as a first carrier; anatase crystal TiO2 is used as a second carrier; and a manganese oxide molecular sieve (V-OMS) of framework vanadium ions (V<5+>) is used as an active component, wherein contents of the gamma-Al2O3 and the TiO2 are respectively 5wt% to 15wt% and 5wt% to 15wt%; the content of the V-OMS is 5wt% to 20wt%; and the molar ratio of V to Mn is between 0 and 0.20. On a window with wide temperature of 80 DEG C to 450 DEG C, the conversion ratio of the NOx of the integral catalyst of the invention by using NH3 as a reducing agent is not less than 85%; and the selectivity of N2 is larger than 90%. The integral catalyst is suitable for controlling the discharge of nitrogen oxides of the stationary source (boiler).

Owner:唐幸福 +1

High-efficient denitration monolithic catalyst for titanium oxide carried vanadium-molybdenum composite oxide

ActiveCN102247832AImprove out-of-stock efficiencyHigh selectivityDispersed particle separationCatalyst activation/preparationComposite oxideTitanium oxide

The invention relates to a high-efficient denitration monolithic catalyst for titanium oxide carried vanadium-molybdenum composite oxide and a preparation method thereof, and relates to a technology for controlling selective catalytic reduction of nitrogen oxide (NOx) in the fields of catalysis, environmental protection and energy saving. The preparation method provided by the invention is characterized in that a honeycomb cordierite ceramic material is used as a matrix, gamma-Al2O3 is used as a first carrier, Anatase crystalline TiO2 is used as a second carrier, and active components containing V2O5-MoO3 composite oxide are used as the active components, wherein the contents of gamma-Al2O3 and TiO2 are respectively 5-15 wt% and 5-10 wt%, the content of V205-MoO3 is 1-10 wt%, and the mol ratio of V / Mo ranges from 0 to 0.20. The monolithic catalyst provided by the invention has a broad temperature window of 80-450 DEG C; with NH3 as a reducing agent, the transformation rate of NOx is not less than 85%; and the selectivity on N2 is greater than 90%.

Owner:上海复翼环保科技有限公司

TiO-supported vanadium-tungsten composite oxide monolithic catalyst for flue gas denitrification

InactiveCN102284283AWide operating temperatureStrong moisture resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsComposite oxideChemistry

The invention relates to a titanium oxide-supported vanadium-tungsten composite oxide high-efficiency denitration integral catalyst and a preparation method thereof, and relates to a control technology for catalytic selective reduction of nitrogen oxides (NOx) in the fields of catalysis, environmental protection and energy saving. It is characterized in that the honeycomb cordierite ceramic material is used as the matrix, γ-Al2O3 is used as the first carrier, the Anatase crystal TiO2 is used as the second carrier, and the active components include V2O5-WO3 composite oxides as the active components. The contents of γ-Al2O3 and TiO2 are respectively 5-15wt% and 5-10wt%, V2O5-WO3 is 1-10wt%, and the V / W molar ratio is between 0-0.20. The monolithic catalyst of the present invention has a wide temperature window of 80-450 DEG C, the conversion rate of NOx by using NH3 as a reducing agent is not less than 85%, and the selectivity to N2 is more than 90%.

Owner:SHANGHAI NIUYI NEW ENERGY TECH

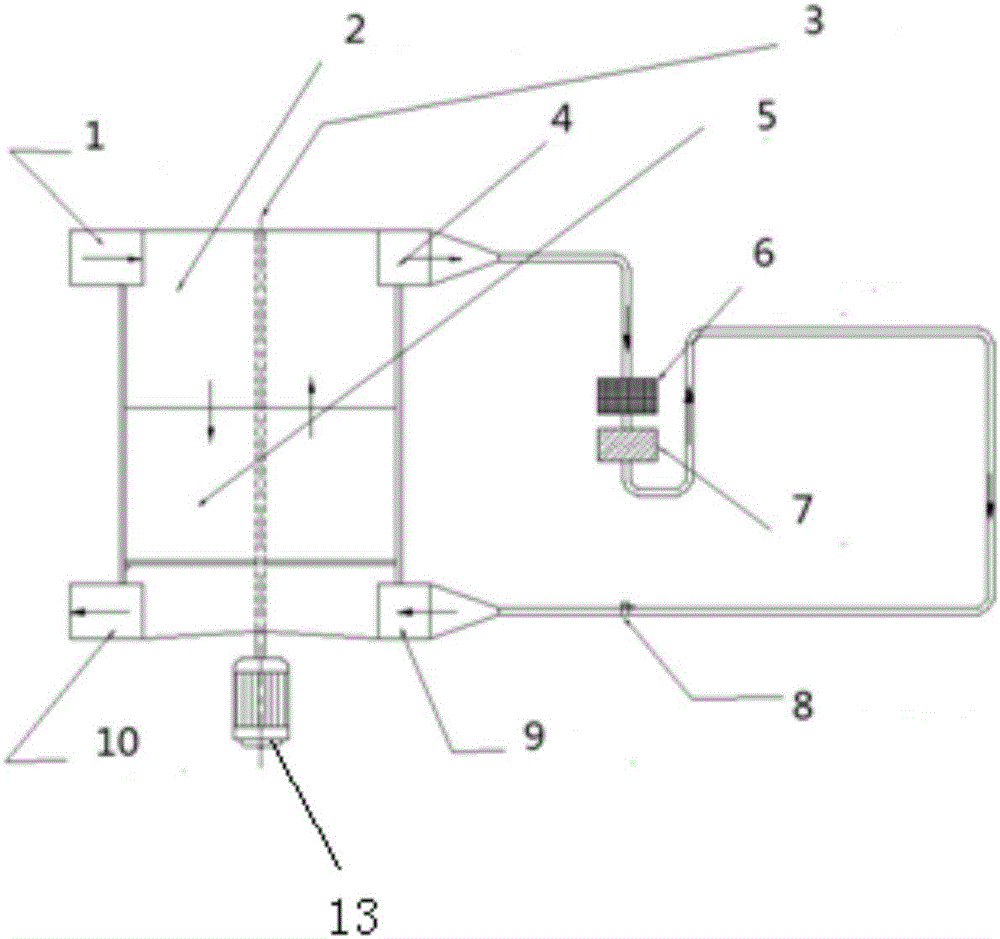

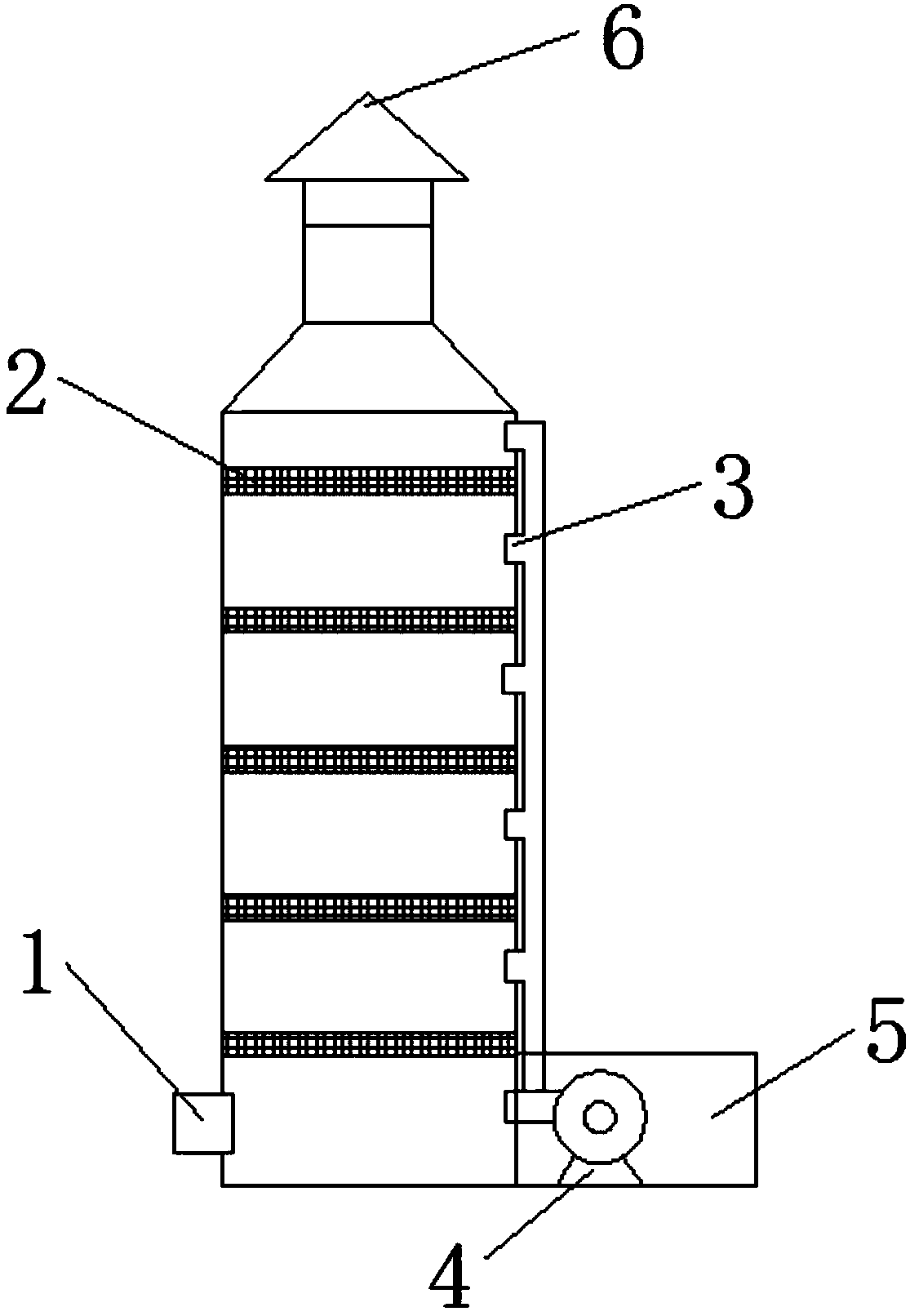

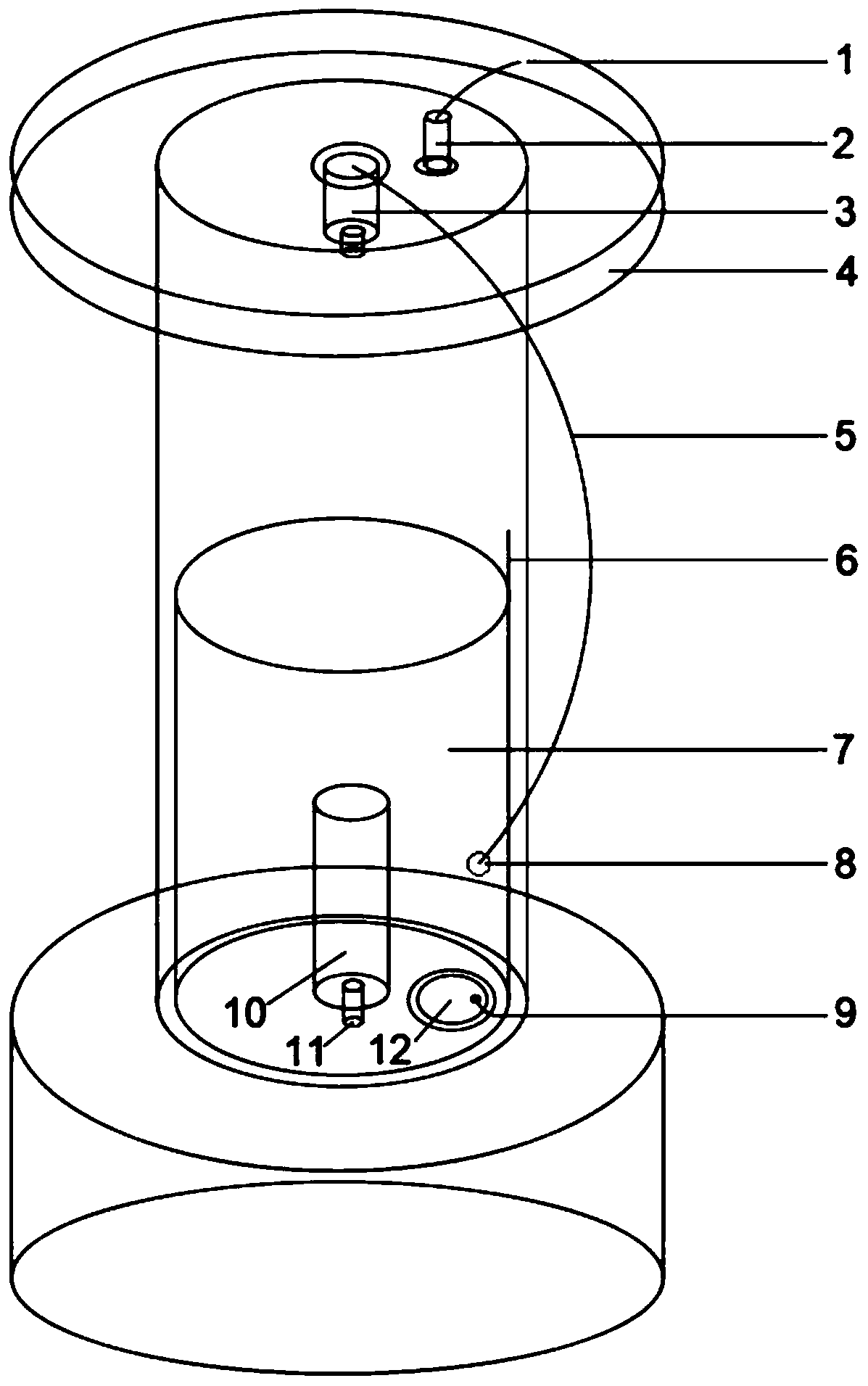

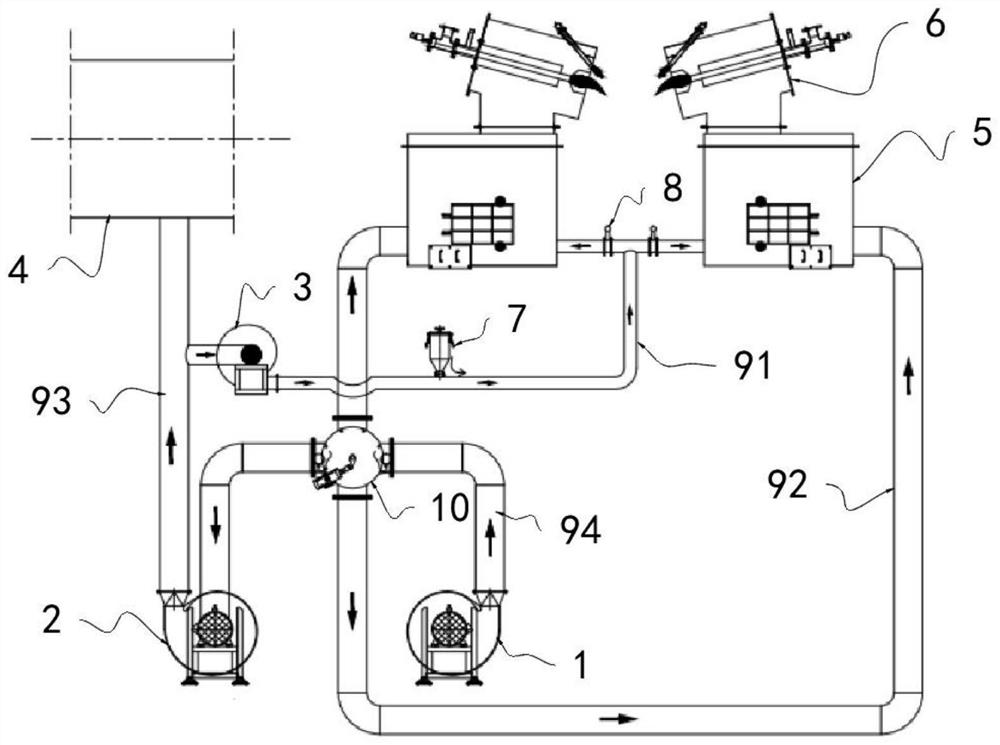

Low-temperature NOx enriching and removing system and method

InactiveCN104307363AReduce usageIncrease concentrationLighting and heating apparatusDispersed particle separationEngineeringEnergy consumption

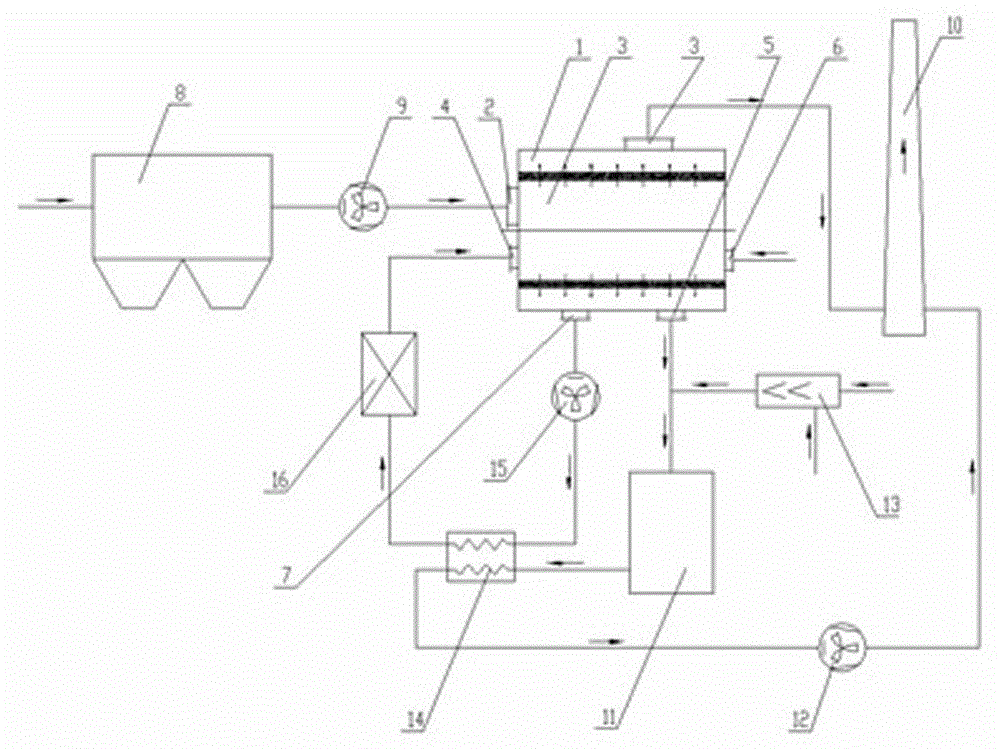

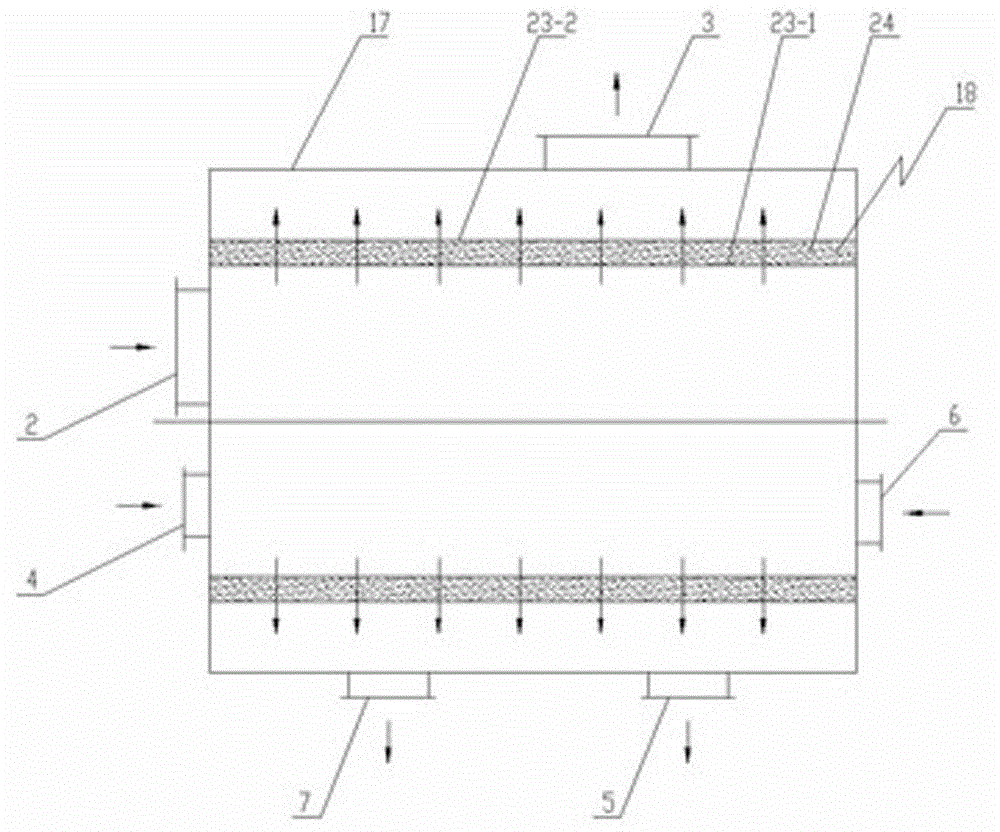

The invention provides a low-temperature NOx enriching and removing system, which is used for removing NOx in low-temperature smoke by adopting an intermediate-temperature SCR catalyst, reducing the heat required by heating NOx-containing smoke, greatly reducing the energy consumption and system operating cost, reducing the investment scale of equipment, meanwhile enriching NOx in smoke, improving the relative concentration of the NOx in the smoke, greatly reducing the treating amount of smoke of SCR denitration, solving the problem of low SCR denitration performance of the low-temperature smoke, and saving energy resources. The low-temperature NOx enriching and removing system is characterized by comprising an NOx enriching device, wherein the NOx enriching device comprises a smoke inlet, a smoke outlet, a heating medium inlet, a heating medium outlet, a cooling medium inlet and a cooling medium outlet; and the dust remover is connected with the smoke inlet through a smoke exhaust fan, the smoke outlet is connected with a chimney, the heating medium outlet is sequentially connected with an SCR reactor, an exhaust fan and the chimney, and an ammonia gas mixer is connected between the heating medium outlet and the SCR reactor. The invention meanwhile provides a low-temperature NOx enriching and removing method.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Integrated flue gas desulfurization and denitrification agent and application method thereof

ActiveCN106731783AImprove out-of-stock efficiencyIncrease chance of contactGas treatmentDispersed particle separationChemistryFlue gas

The invention relates to an integrated flue gas desulfurization and denitrification agent and an application method thereof. The invention is characterized in that the flue gas desulfurization and denitrification agent comprises the following ingredients: a desulfurizing agent, an iron-based denitration catalyst, an activator and a suspending agent. By using an alkaline substance as a desulfurizing agent, using the desulfurization product sulfite as a reducing agent and using the iron-based denitration catalyst as an active reaction factor, simultaneous removal of sulfur dioxide and nitrogen oxide in flue gas is realized in a the gas-liquid-solid three-phase homogenization suspension state, wherein NOx is reduced into nitrogen; and a reacted absorption liquid is activated by the use of an acid solution and a suspending agent is supplemented and then the mixture is sent by a circulating pump into a reaction tower for recycling. The method is simple to operate. By the method, desulphurization efficiency is 99% and above, denitration efficiency is 90% and above, and the desulfurization and denitrification effect is good. The materials are recycled, thus greatly reducing the operating cost of desulfurization and denitrification. The product has obvious economic advantages and can be used for treatment of flue gas or tail gas of various industrial boilers and industrial furnaces.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

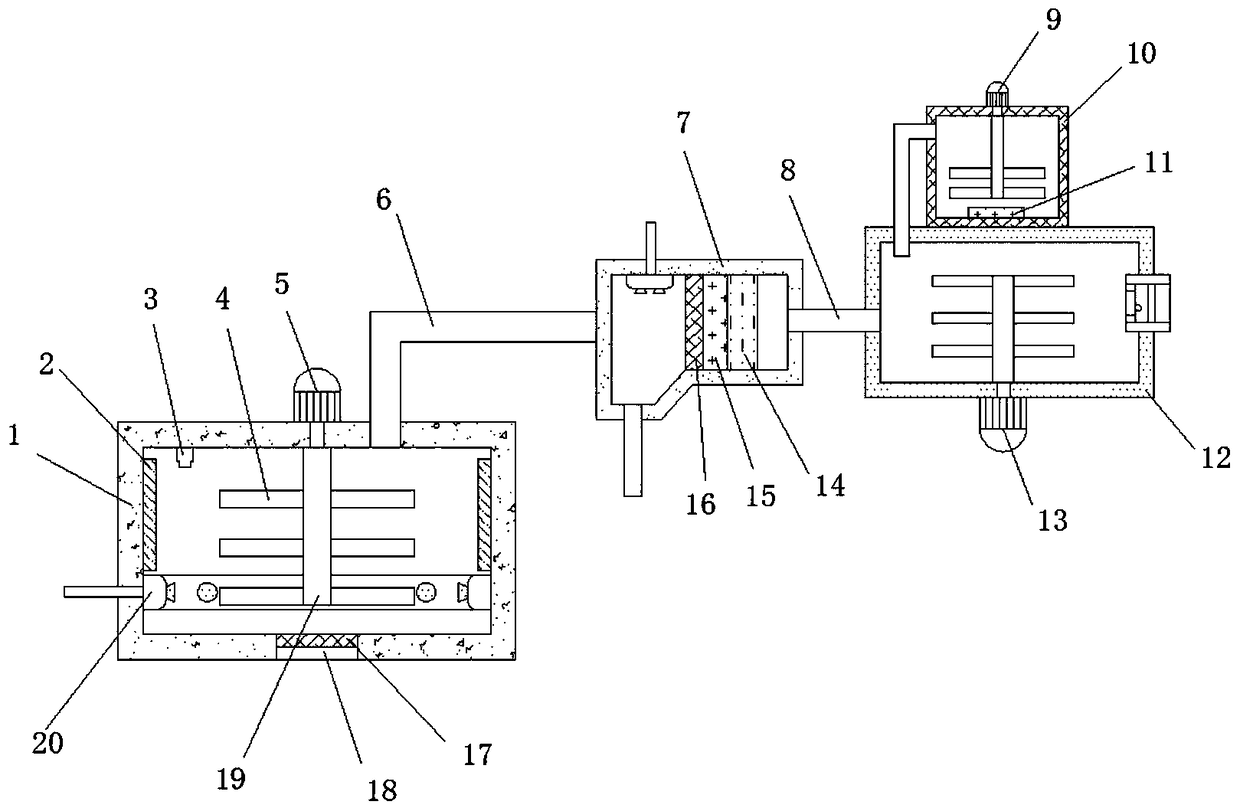

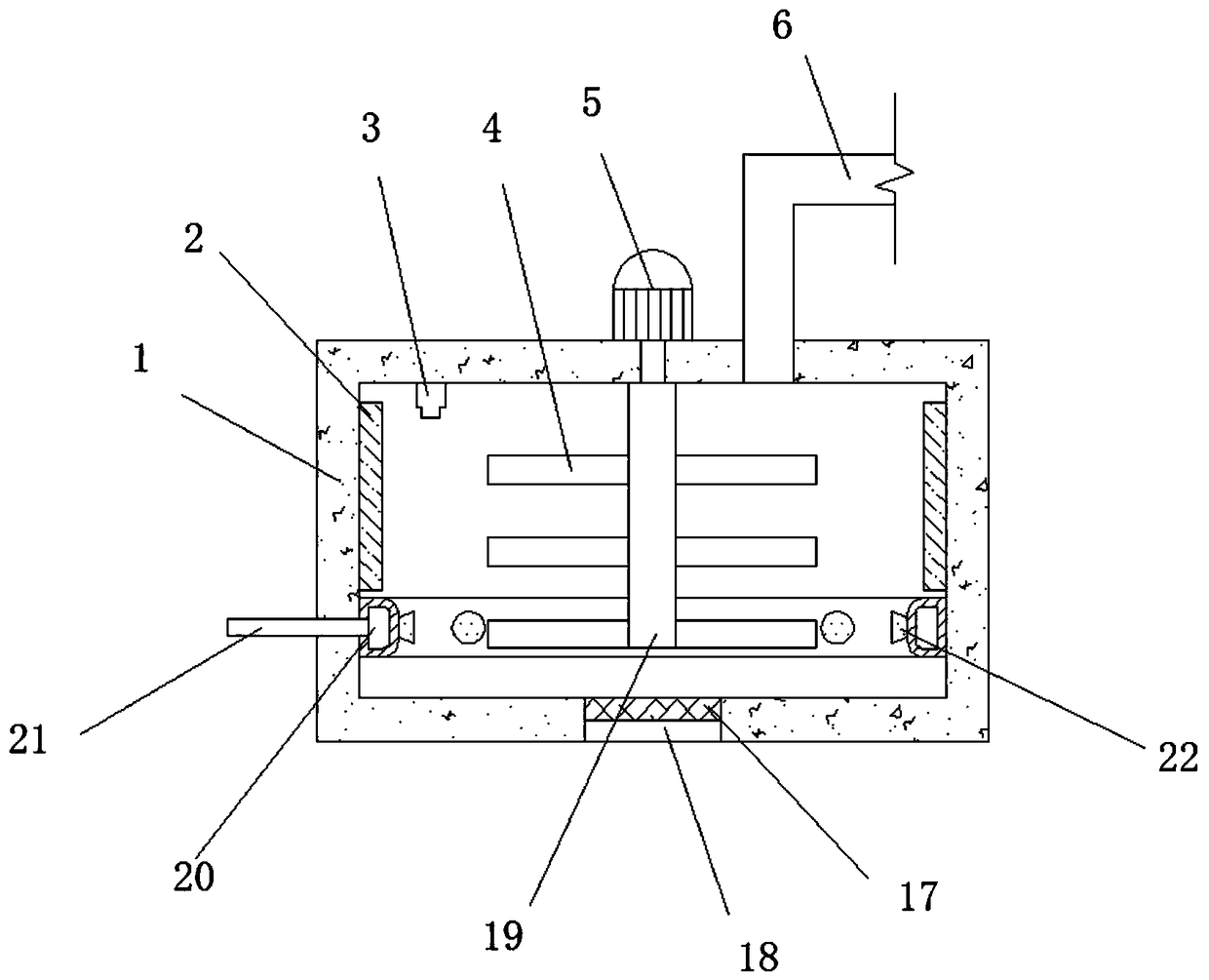

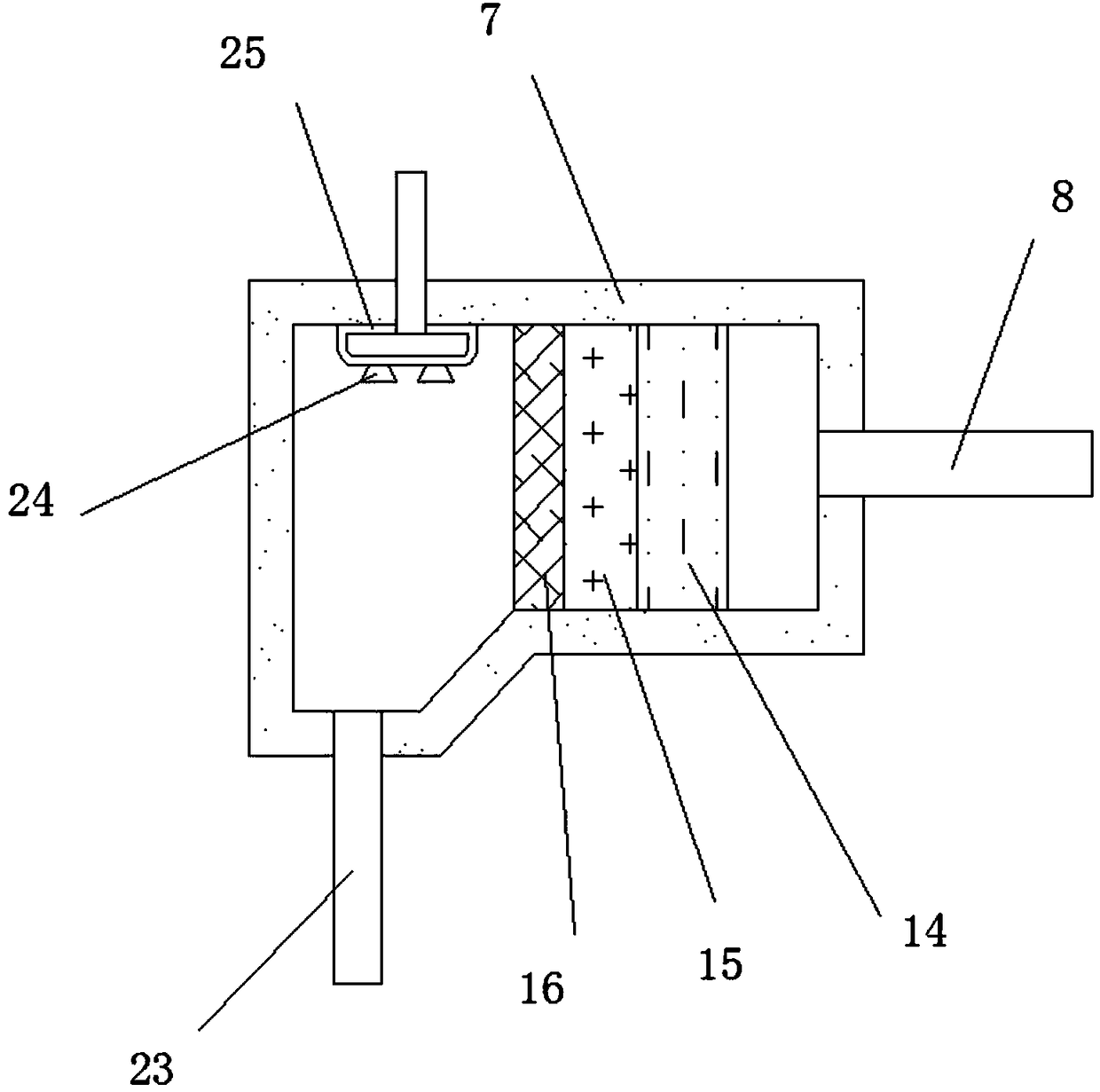

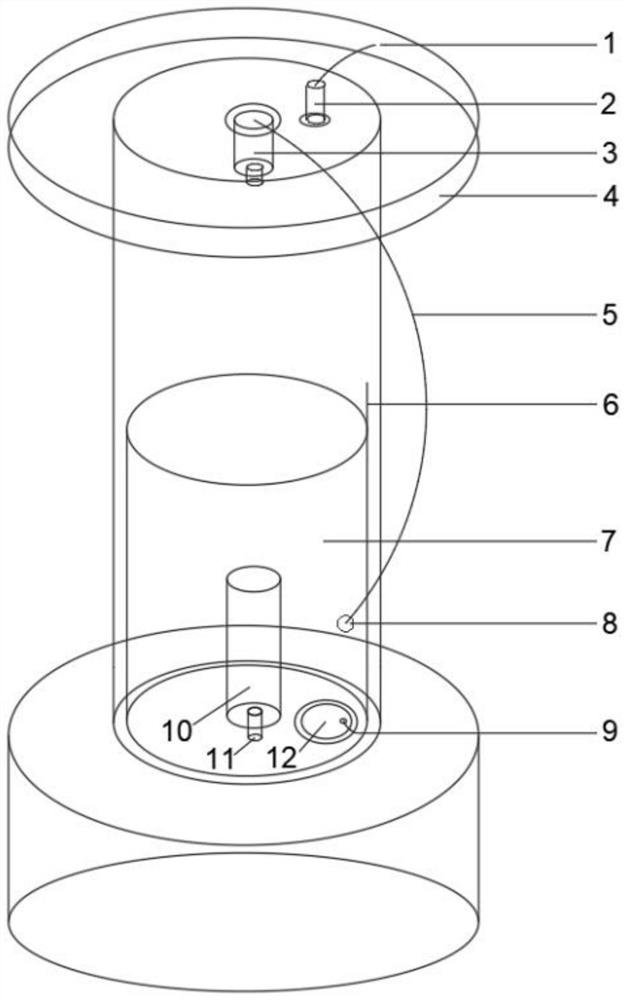

Rotary desulfurization and denitrification reactor and system

ActiveCN106345226AImprove out-of-stock efficiencyGood recyclingGas treatmentDispersed particle separationNitrogen oxideSmoke flow

The invention discloses a rotary desulfurization and denitrification reactor and a system. The reactor comprises a columnar shell, a rotary shaft and a clapboard, wherein the rotary shaft is mounted in the columnar shell, the clapboard is fixedly arranged on the rotary shaft to divide the columnar shell into at least two chambers, the chambers are filled with catalysts, an SO2 adsorbent is positioned above the nitrogen oxide catalyst, and the rotary shaft rotates under the driving of a motor; a smoke inlet and a reduction gas outlet are formed at the top of the columnar shell, the smoke inlet is arranged opposite to the reduction gas outlet, a smoke outlet and a reduction gas inlet are formed in the bottom of the columnar shell, the smoke outlet is positioned below the smoke inlet, and the reduction gas inlet is positioned below the reduction gas outlet. The two catalysts are overlapped vertically, and smoke flow from top to bottom, so as to realize simultaneous adsorption of SO2 and nitrogen oxide. due to adoption of the rotary reactor, the reduction gas flows from top to bottom, desorption and reaction of SO2 and nitrogen oxide are realized.

Owner:SHANDONG UNIV

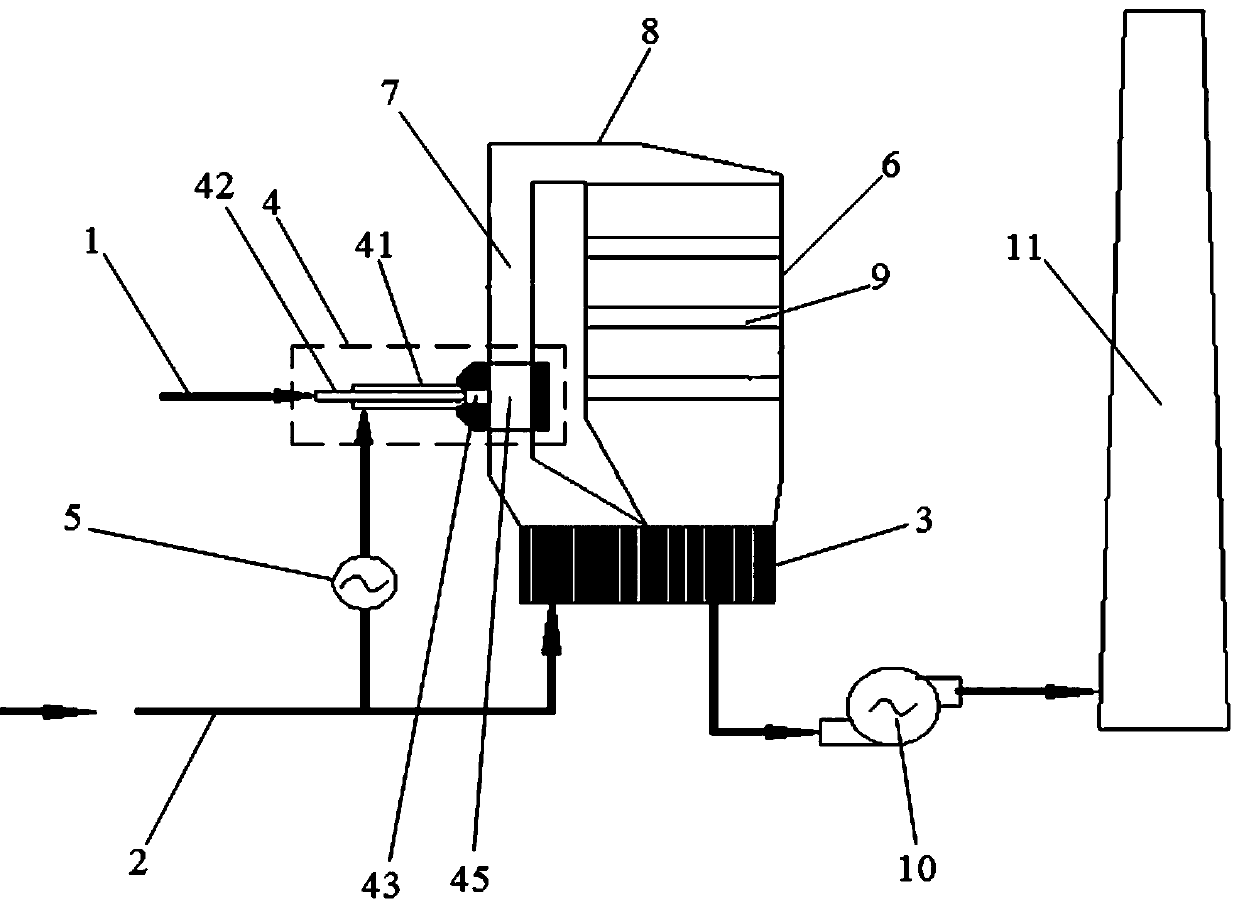

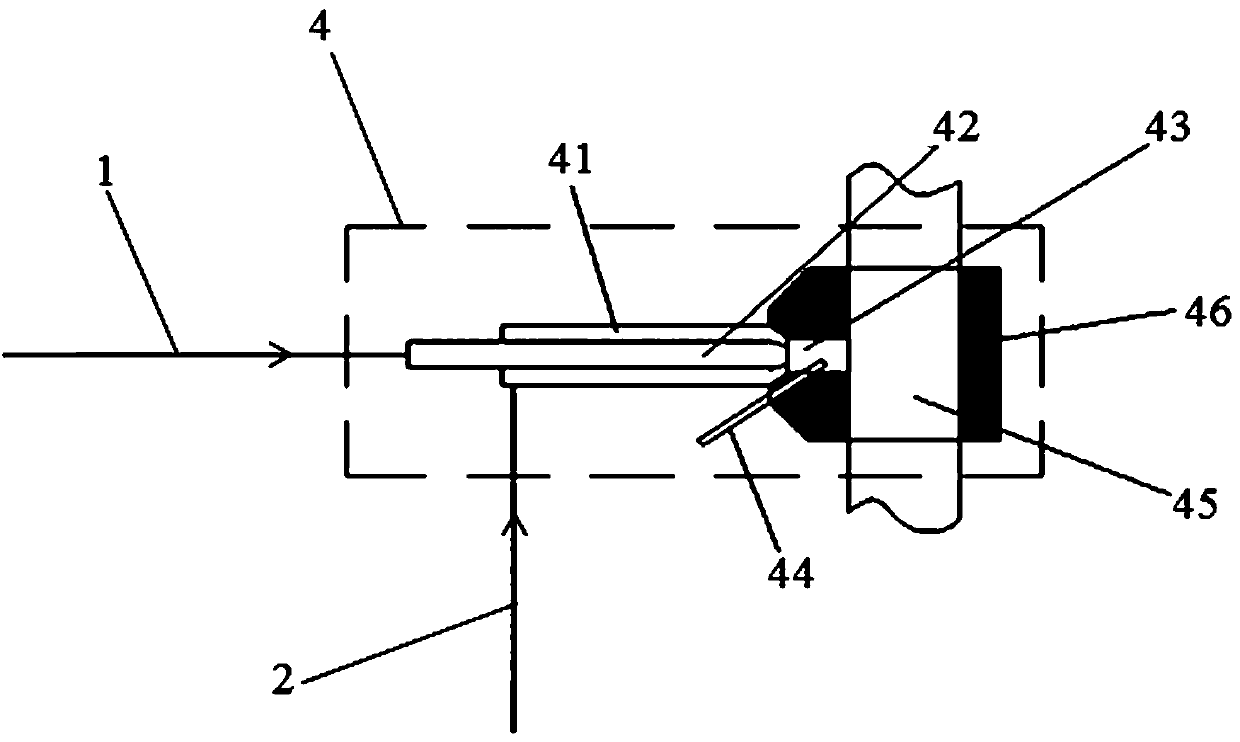

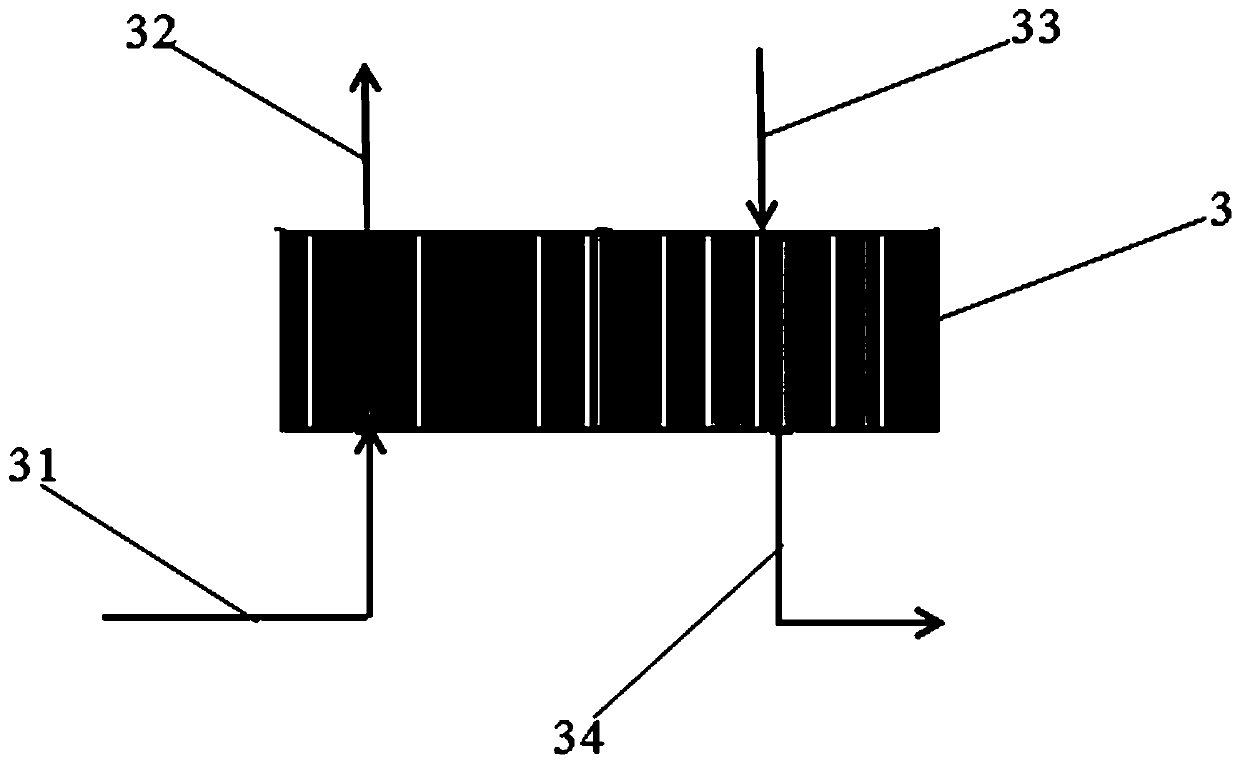

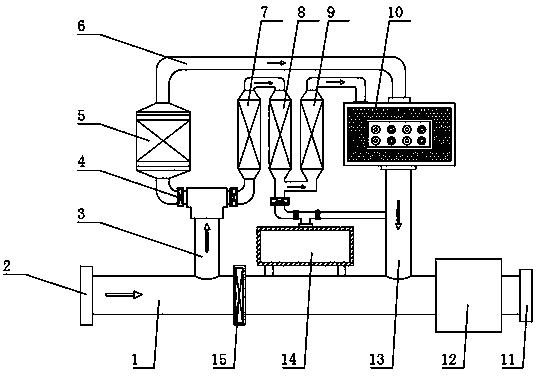

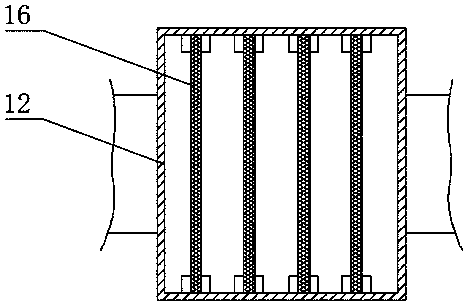

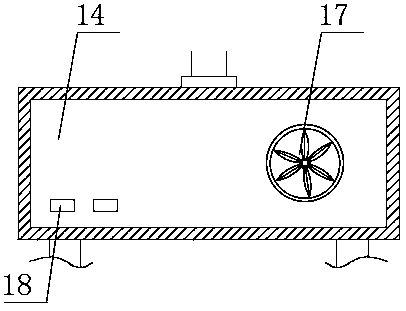

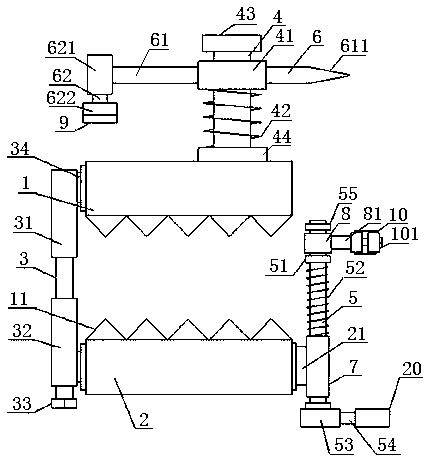

Sintering flue gas denitration direct-fired type heating device and method

PendingCN111306564AReduce CO contentEmission reductionEmission preventionIndirect carbon-dioxide mitigationPtru catalystCombustion chamber

The invention relates to a sintering flue gas denitration direct-fired type heating device. The sintering flue gas denitration direct-fired type heating device comprises a gas pipe (1) and a sinteringflue gas pipe (2), wherein the gas pipe and the sintering flue gas pipe are respectively connected with a gas chamber (42) and an oxidant gas chamber (41) of a direct-fired heating device body (4), and the oxidant gas chamber (41) and the gas chamber (42) are sequentially connected with a mixing combustion chamber (43) and a flue gas heating chamber (45), an inlet of flue gas heating chamber (45)is connected with a GGH heat exchanger (3), an outlet of the flue gas heating chamber (45)is connected with a denitration flue (7), an ammonia injection gird (8) is arranged above the denitration flue (7), a denitration catalyst (9) is arranged in a denitration reactor (6), the denitration reactor (6) is connected with the GGH heat exchanger (3), the GGH heat exchanger (3) is connected with an induced draft fan (10), and an outlet of the induced draft fan (10) is connected with one chimney (11). The sintering flue gas denitration direct-fired type heating device has the advantages of ensuringthe denitration efficiency, reducing CO content in flue gas and heated gas volume, and energy conservation and emission reduction.

Owner:NANJING JINHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Flue gas denitration agent and preparation method thereof

InactiveCN106178947AEasy to lockImprove out-of-stock efficiencyDispersed particle separationCarboxymethyl cellulosePyrolusite

The invention provides a flue gas denitrification agent and a preparation method thereof, which comprises the following raw materials according to weight percentage: 5-10% of urea, 5-10% of ganoderma acid, 1-3% of carboxymethyl cellulose sodium, pyrolusite Powder 20-40%, the balance is water. Preparation method: Weigh urea, ganoderma acid, sodium carboxymethylcellulose, pyrolusite powder and water according to the ratio, and then mix and stir until viscous material is formed. The denitrification agent has high desulfurization and denitrification efficiency and long operation time.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

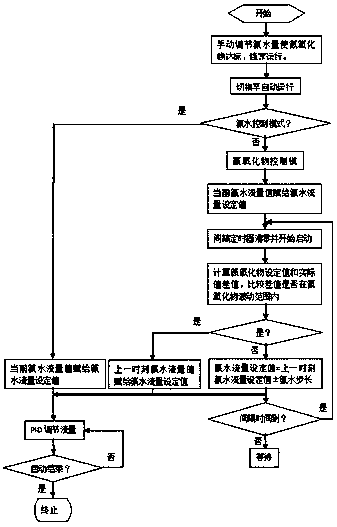

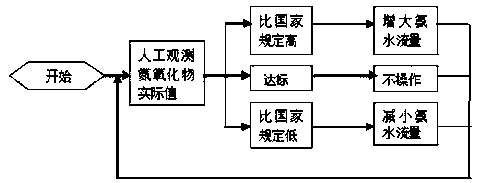

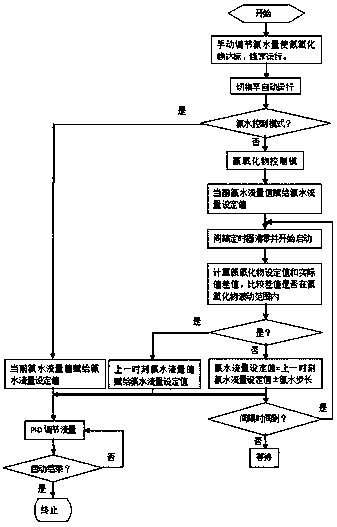

SNCR denitration automatic control method and system thereof

ActiveCN111135683AReduce workloadReduce manual interventionGas treatmentDispersed particle separationAutomatic controlNitrogen oxides

The invention discloses an SNCR denitration automatic control method and a system thereof. The method comprises the steps 1-5. The system comprises a control module, an ammonia water pump, a nitrogenoxide collection module and a PID function module, wherein the control module is internally provided with a timing module and a data processing module; full-automatic control of an SNCR system can beachieved; on the premise that nitric oxide is controlled to meet the environmental protection requirement, nitric oxide control does not exceed the standard and is not too low; an ammonia water control mode and a nitrogen oxide control mode can be automatically switched without disturbance; the ammonia water spraying amount is calculated according to the nitrogen oxide content and the formula thatthe ammonia water flow set value = the ammonia water flow set value at the last moment + / - the ammonia water step length, and the automatic tracking control of the nitrogen oxide is controlled by automatically adjusting the ammonia water spraying amount; manual intervention is reduced, the manual adjustment frequency is reduced, the workload of operators is reduced, and the working efficiency isimproved; the denitration efficiency is improved, the adjusting time is optimized, ammonia water is saved, and the defects caused by the prior art are overcome.

Owner:上海三融环保工程有限公司 +1

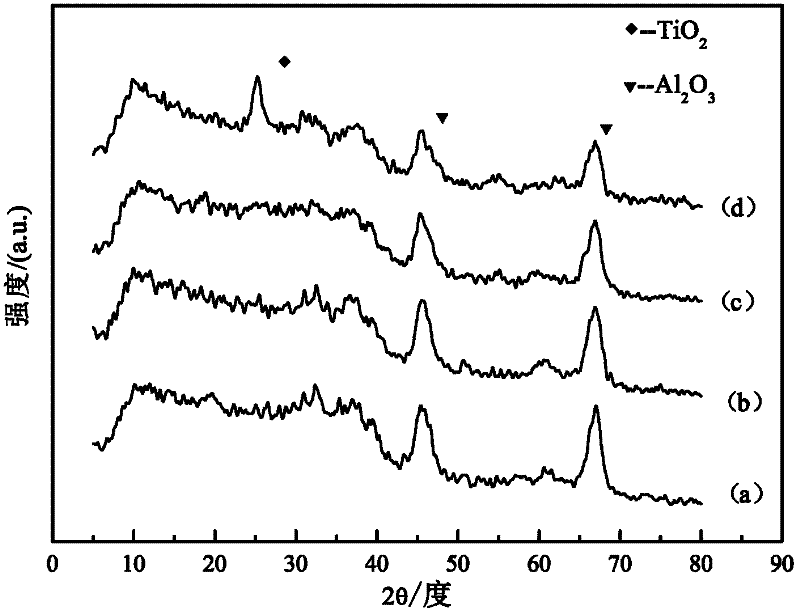

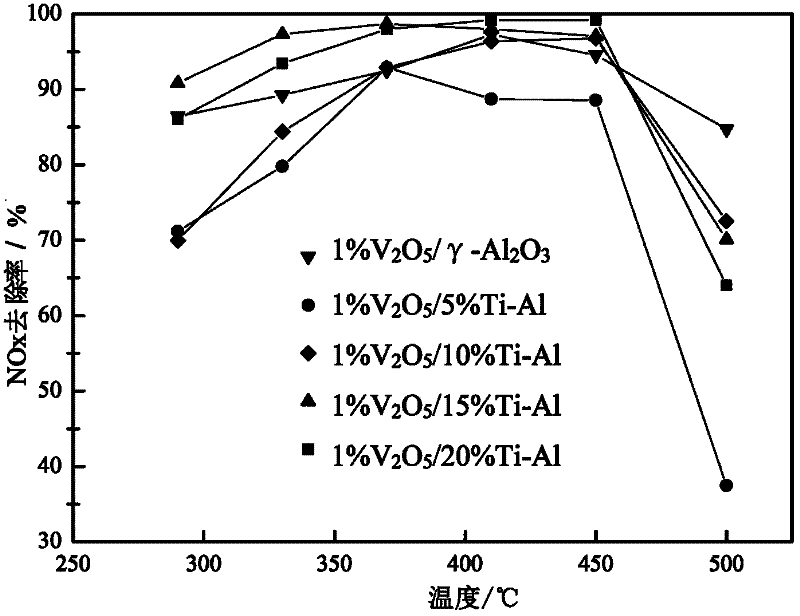

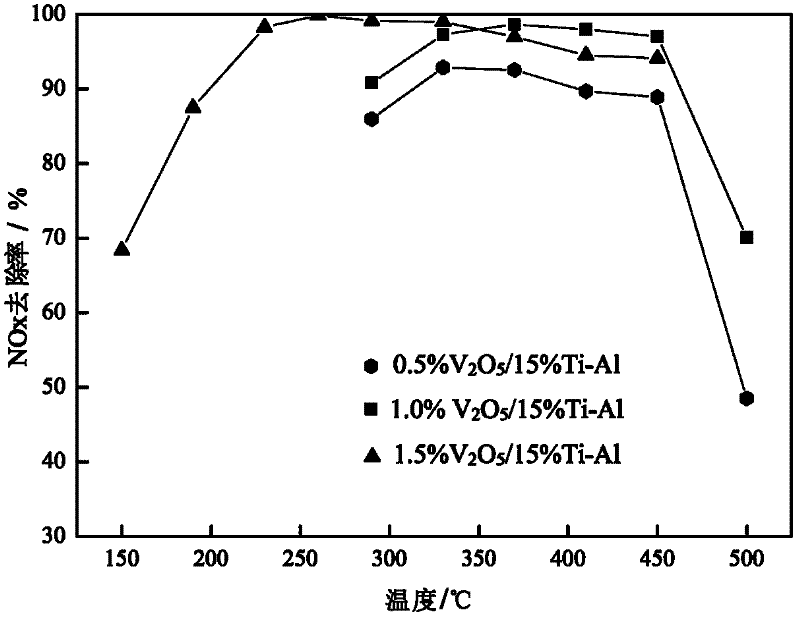

A kind of preparation method of vanadium-based supported denitration catalyst

InactiveCN102294235ALarge specific surface areaCrystal stableDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsAir atmosphere

The invention discloses a preparation method of a vanadium-based loaded denitration catalyst. Under the conditions of ice-water bath, N2 atmosphere protection and stirring, the n-butanol solution of butyl titanate is impregnated with γ-Al2O3 powder, and after aging, it is placed in an oil bath. Evaporate to dryness, and then dry in an oven. After the dried product is ground, it is roasted in an air atmosphere to obtain a titanium-aluminum composite carrier; add a titanium-aluminum composite carrier and ammonium metavanadate in deionized water, and stir at room temperature Dipping, evaporating to dryness in an oil bath, and drying in an oven. The dried product is ground and roasted in an air atmosphere to obtain a vanadium-based supported denitration catalyst. The vanadium-based supported denitration catalyst prepared by the method of the present invention has the following advantages: 1. The catalyst has a relatively large specific surface area, and at the same time, its crystal form is stable and has good surface properties. 2. It has a wider reaction window, and has a higher out-of-stock efficiency at a lower temperature, which is generally higher than that of simply using aluminum as a carrier.

Owner:SOUTHEAST UNIV

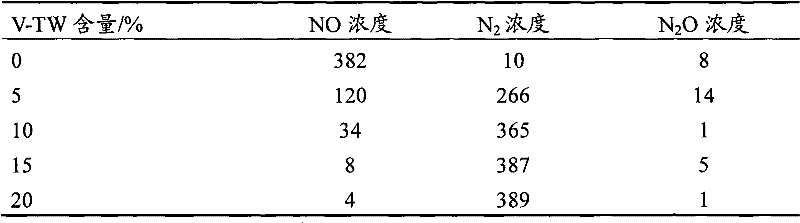

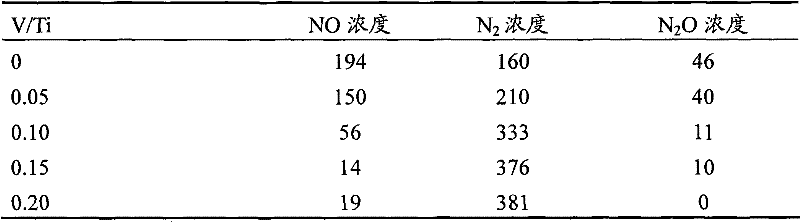

Titanium oxide molecular sieve monolithic catalyst for flue gas denitrification

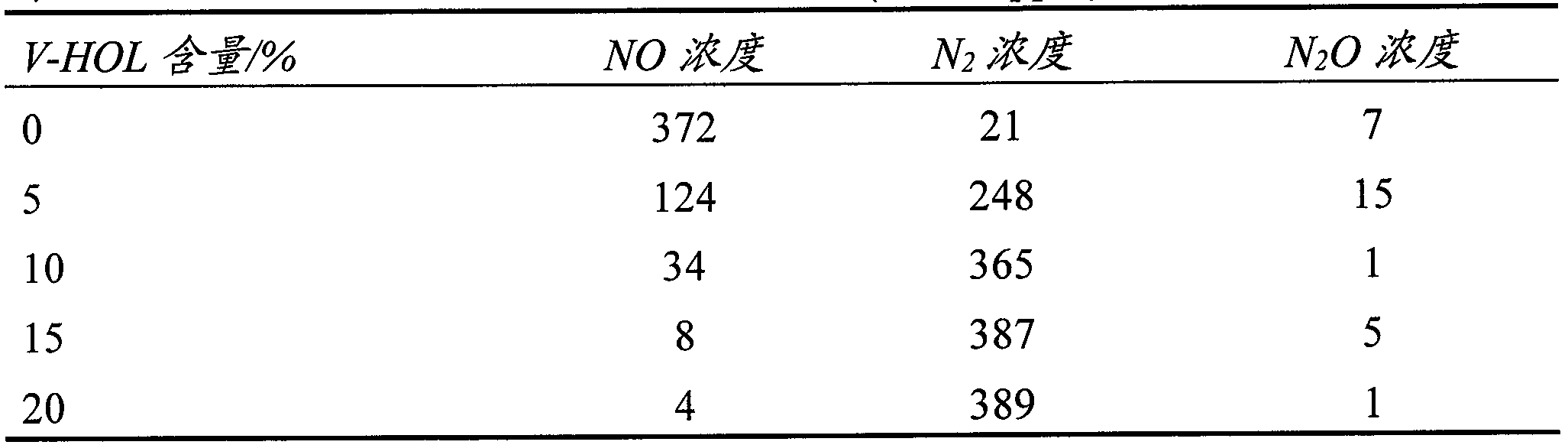

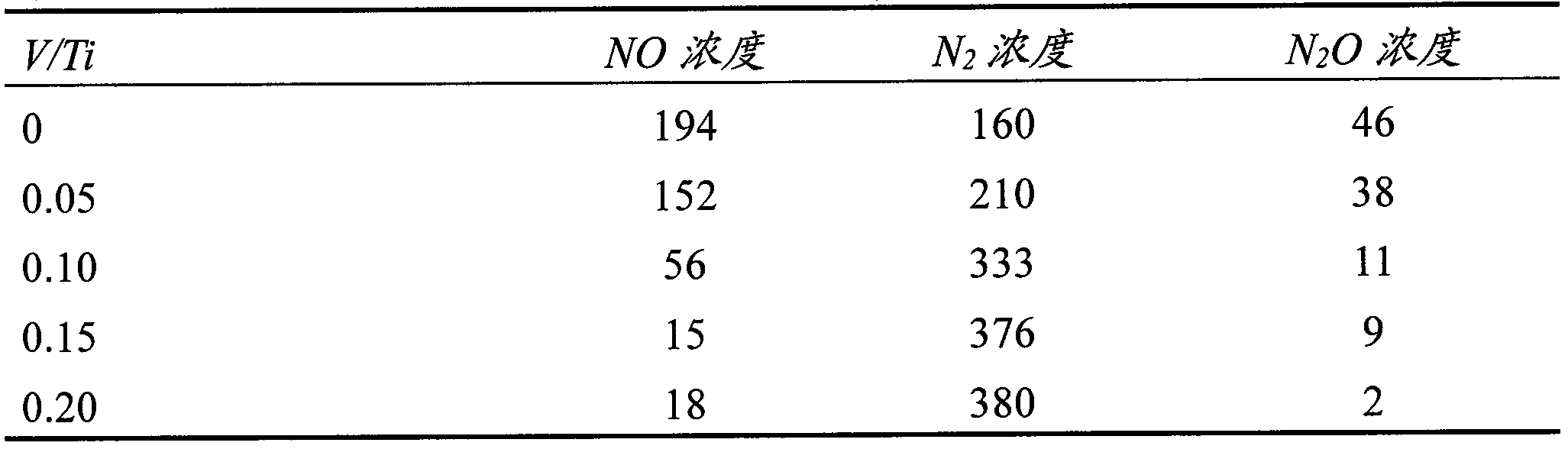

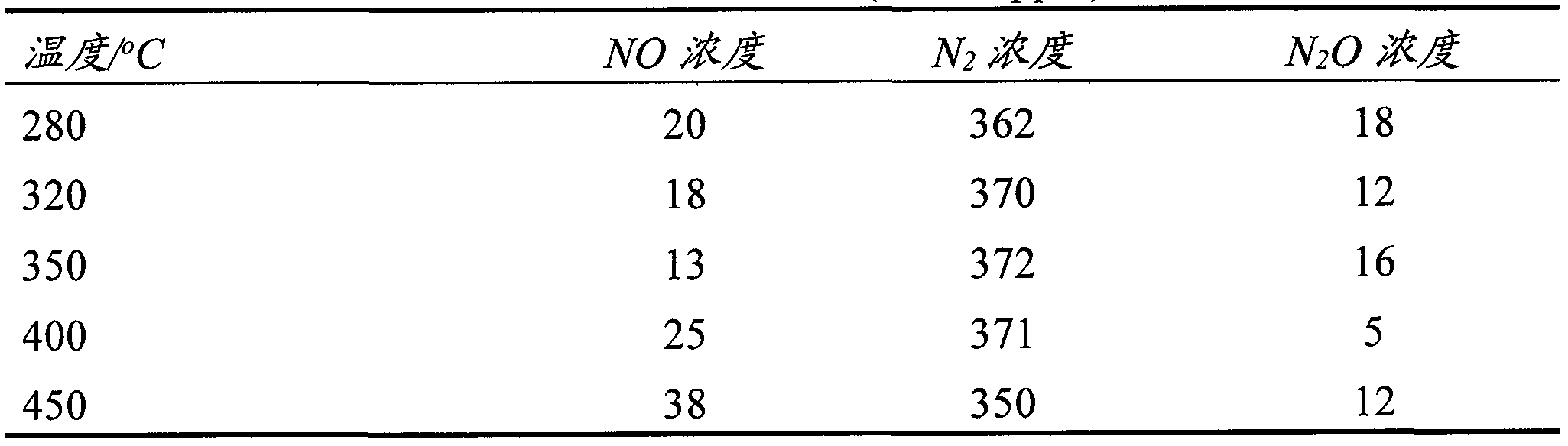

ActiveCN102284281AWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideCordierite

The invention provides a doped Hollandite type titanium oxide ammonia catalytic selective reduction nitrogen oxide (NH3-SCR) denitrified monolithic catalyst, and relates to the environmentally-friendly technology in the field of catalytic science and energy saving. The catalyst is characterized in that: a honeycomb cordierite ceramic material serving as a base material and gamma-Al2O3 serving as a carrier carry Anatase crystal TiO2 powder at first, and then carry Hollandite structured titanium oxide (V-HOL) of an active component framework vanadium ion (V5+), wherein the contents of gamma-Al2O3 and TiO2 are 5-15 weight percent and 5-10 weight percent respectively; the V-HOL is 5-20 weight percent; and the molar ratio of V / Ti is between 0 and 0.20. According to the monolithic catalyst, at a broad temperature window of between 100 and 450 DEG C, the conversion rate to NOx by using NH3 as a reducing agent is more than 85 percent, and the selectivity to N2 is more than 95 percent. The catalyst is suitable for controlling emission of nitric oxides.

Owner:上海复翼环保科技有限公司

Factory flue gas desulfurization and denitrification device for environment-friendly construction

InactiveCN108854523ATake advantage ofImprove contact efficiencyDispersed particle separationFlue gasSpray nozzle

The invention belongs to the technical field of environment-friendly construction and in particular relates to a factory flue gas desulfurization and denitrification device for the environment-friendly construction. Aiming at the problems that the design structure is simple, the denitrification efficiency is low and the desulfurization efficiency is low, the invention provides the following scheme: the factory flue gas desulfurization and denitrification device comprises a denitrification chamber, wherein a gas inlet is formed in the middle position of a bottom outer wall of the denitrification chamber; the top of a peripheral inner wall of the gas inlet is connected with a second filtering screen plate through a fastening bolt; the bottoms of inner walls at four sides of the denitrification chamber are connected with a transition pipe through fastening bolts; ammonia gas spraying nozzles, which are distributed at an equal distance, are connected with the outer wall at one side, far away from the denitrification chamber, of the transition pipe through fastening bolts. According to the factory flue gas desulfurization and denitrification device for the environment-friendly construction, the contact efficiency between ammonia gas and flue gas is improved, a catalyst is sufficiently utilized and the denitrification efficiency is improved; the ammonia gas which does not react completely is effectively filtered and subsequent equipment is prevented from being damaged by the ammonia gas; a condition that the deposition concentration of Ca(OH)2 slurry is not uniform is effectivelyavoided; sufficient mixing and contact of ammonia gas and the flue gas is ensured and the desulfurization efficiency is improved.

Owner:上海帅腾环保科技有限公司

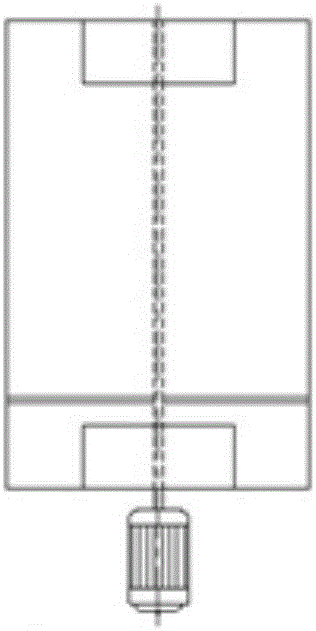

Coal-fired boiler high-temperature ammonia spraying denitration system based on biomass pyrolysis and method thereof

PendingCN113083009AReasonable designImprove out-of-stock efficiencyDispersed particle separationCombustorNitrogen oxides

The invention relates to a coal-fired boiler high-temperature ammonia spraying denitration system based on biomass pyrolysis and a method thereof, a biomass pyrolysis device and an amino reducing agent spraying device are connected to a boiler main combustion area, and high-temperature flue gas obtained after a high-temperature superheater is extracted is connected with the high-temperature flue gas inlet end of the biomass pyrolysis device; biomass fuel is subjected to multi-stage heating pyrolysis to generate mixed gas, and the mixed gas and an amino reducing agent are sequentially introduced into a main combustion area of the boiler; an air staged combustion mode is adopted, and the excess air coefficient of a main combustion area is reduced by utilizing a low-nitrogen combustor and an SOFA air nozzle; an SOFA nozzle is additionally arranged, so that a main combustion area is in a reducing atmosphere; an amino reducing agent is sprayed into the main combustion area, the amino reducing agent can be subjected to a reduction reaction with nitric oxide in flue gas in a high-temperature reducing atmosphere, and the concentration of the nitric oxide at a hearth outlet is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

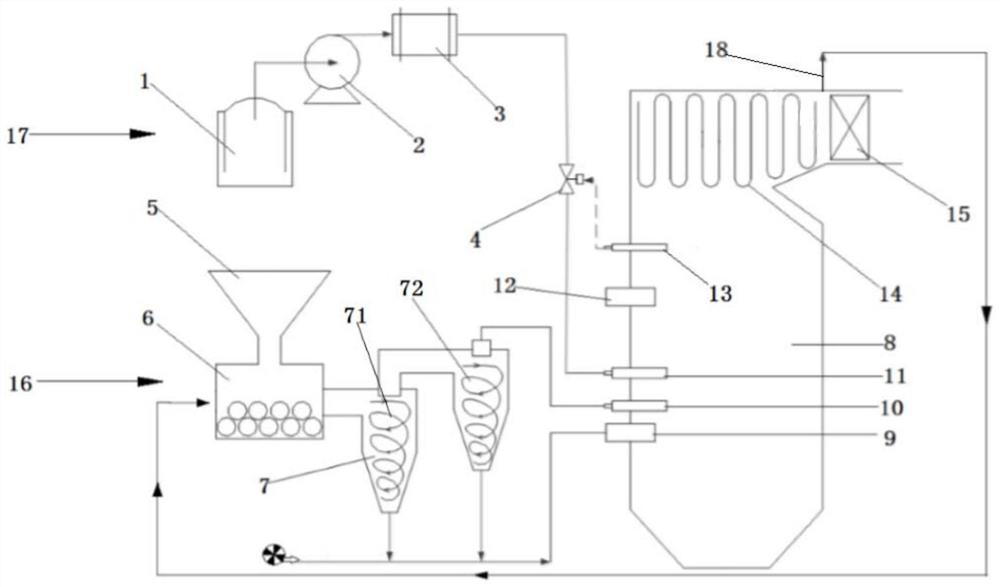

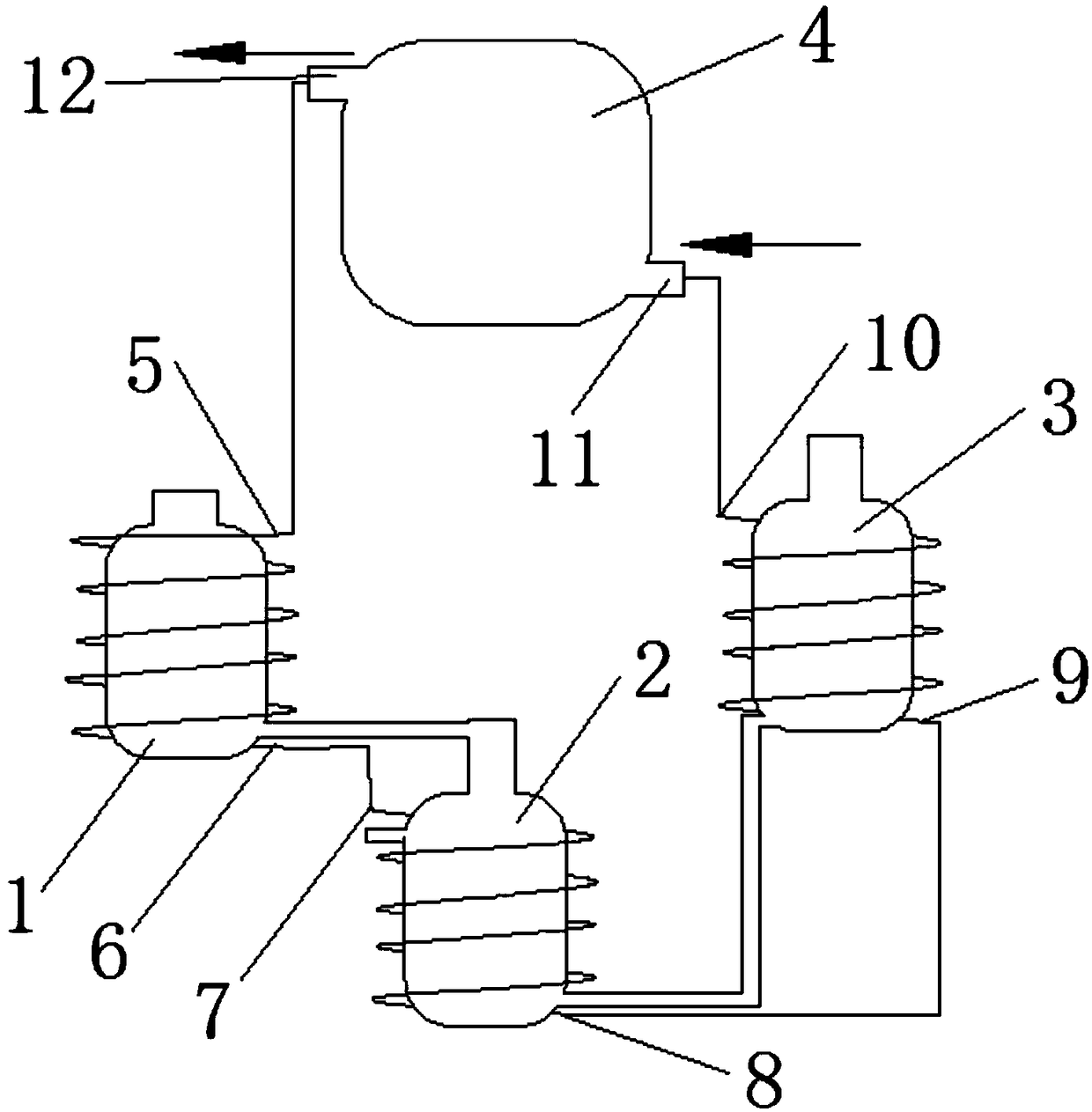

A system and method for desulfurization and denitrification of sintering flue gas

ActiveCN104006673BReduce pollutionIncrease incomeDispersed particle separationWaste heat treatmentExhaust pipeAmmonium sulfate

A desulfurization and denitrification system and method for sintering flue gas, including a mixing and granulating device, a main smoke exhaust pipeline, an electrostatic precipitator, a ring cooler, a bypass valve, an activated carbon absorption tower, a bag filter, and an activated carbon storage bin and chimneys. Add an induced draft fan, heat recovery cover and hot air pipe above the ring cooler, and add a urea solution tank on the mixing and granulating device. Mix the urea solution into the sintering mixture at a ratio of 0.5 to 3%, and the NH produced by thermal decomposition of urea 3 and SO in the sintering flue gas 2 The reaction produces ammonium sulfate, and the excess NH 3 with SO 2 On the contrary, it is discharged along the main exhaust pipe; the induced draft fan transfers the recovered waste heat of the annular cooler into the pipeline between the electrostatic precipitator and the activated carbon absorption tower through the hot air pipe, and heats the sintering flue gas to above 150°C to accelerate the NH 3 Reaction efficiency with NOx in sintering flue gas. The invention can greatly improve the destocking efficiency, realize simultaneous desulfurization and denitrification of sintering flue gas, and make the concentration of nitrogen oxides in the outlet flue gas less than 300mg / m 3 .

Owner:ANGANG STEEL CO LTD

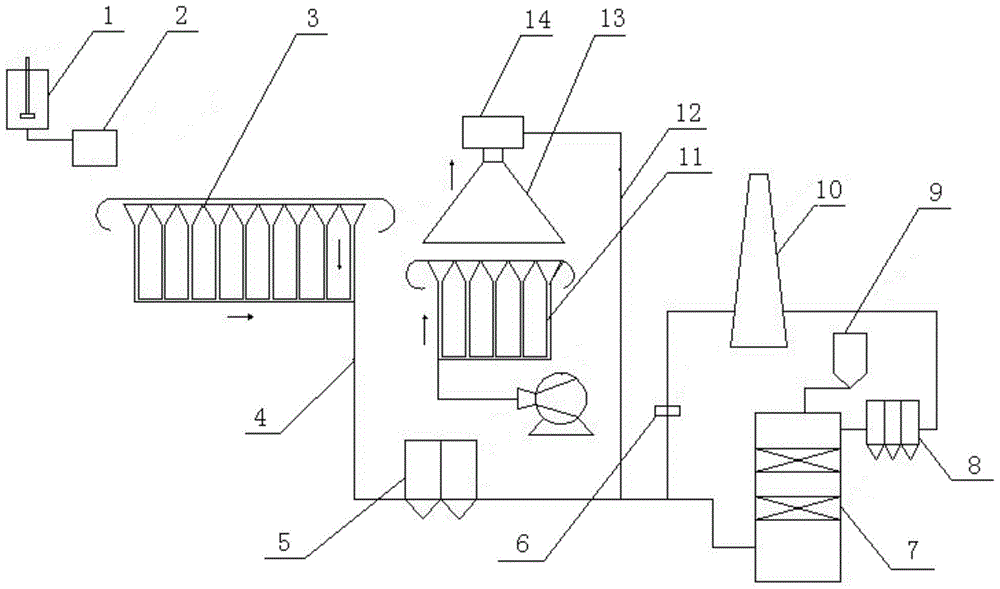

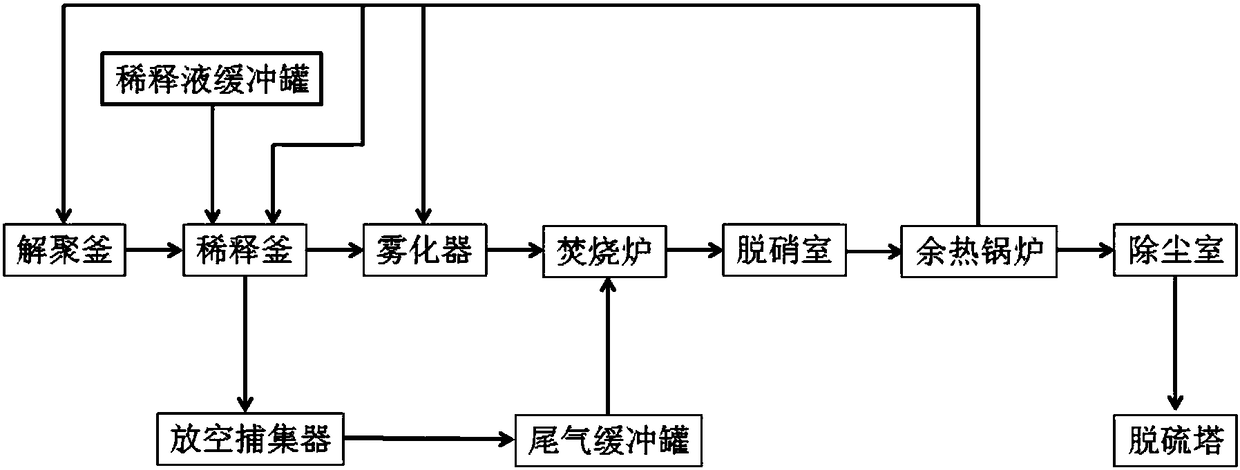

Treatment system and method for acrylic acid and ester waste oil of acrylic acid

PendingCN108413413ALow viscosityImprove combustion effectCombination devicesLiquid fuel feeder/distributionEmission standardWaste oil

The invention discloses a treatment system and method for acrylic acid and ester waste oil of the acrylic acid. The treatment system comprises a depolymerizing kettle, a diluent buffer tank, a diluting kettle, an emptying and trapping machine, a tail gas buffer tank, an atomizer, an incinerator, a denitrating tower, a waste heat boiler, a dust removal chamber and a desulfurization tower. The treatment method is characterized in that organic waste acid is used for diluting the acrylic acid and the ester waste oil of the acrylic acid so as to reduce the viscosity of the acrylic acid and the ester waste oil of the acrylic acid, then the acrylic acid and the ester waste oil of the acrylic acid are thoroughly treated after undergoing atomization, incineration, denitration, waste heat recovery,dust removal and desulfuration and can meet the national emission standards, and meanwhile, steam which is generated through burning heat of the acrylic acid and the ester waste oil of the acrylic acid is returned to a production line for recycling. According to the treatment system and method, the breakthrough design concept of using waste to treat waste is adopted, pretreatment, atomization, incineration, denitration, waste heat recovery, dust removal and desulfuration of the acrylic acid and the ester waste oil of the acrylic acid are integrated, various flue gas emission indexes are far lower than the national environmental protection emission standards, so that remarkable practicability and economic benefits are achieved.

Owner:JIANGSU XINDONGFENG CHEM TECH

Titanium oxide molecular sieve monolithic catalyst for flue gas denitrification

ActiveCN102284281BWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCordieriteNitric oxide

The invention provides a doped Hollandite type titanium oxide ammonia catalytic selective reduction nitrogen oxide (NH3-SCR) denitrified monolithic catalyst, and relates to the environmentally-friendly technology in the field of catalytic science and energy saving. The catalyst is characterized in that: a honeycomb cordierite ceramic material serving as a base material and gamma-Al2O3 serving as a carrier carry Anatase crystal TiO2 powder at first, and then carry Hollandite structured titanium oxide (V-HOL) of an active component framework vanadium ion (V5+), wherein the contents of gamma-Al2O3 and TiO2 are 5-15 weight percent and 5-10 weight percent respectively; the V-HOL is 5-20 weight percent; and the molar ratio of V / Ti is between 0 and 0.20. According to the monolithic catalyst, at a broad temperature window of between 100 and 450 DEG C, the conversion rate to NOx by using NH3 as a reducing agent is more than 85 percent, and the selectivity to N2 is more than 95 percent. The catalyst is suitable for controlling emission of nitric oxides.

Owner:上海复翼环保科技有限公司

Novel cathode and anode electro-catalysis synergistic flue gas denitration method

ActiveCN111514712AImprove out-of-stock efficiencyLow costGas treatmentDispersed particle separationElectrolysisNitrogen gas

The invention discloses a novel cathode and anode electro-catalysis synergistic flue gas denitration method, which belongs to the technical field of atmospheric treatment. According to the method disclosed by the invention, NO in the flue gas is oxidized into high-valence NOx which is easily dissolved in a water body by utilizing active matters generated by anodic oxidation; NOx absorbed by the water phase is converted into nitrite and nitrate, meanwhile, dissolved nitrate nitrogen can be converted into nitrogen or ammonium on the cathode through the catalytic reduction effect, and the generated ammonium can be finally oxidized into nitrogen by hypochlorous acid generated by anode electrolysis. According to the system, the solution is lifted to the top of the reaction device through the lifting pump and forms spray through the spraying device, so that the contact time and the contact area of NO and the solution are further increased, and the treatment efficiency is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Temperature adjustable three-way pipe boiler SCR denitration equipment

InactiveCN110354678AIncrease temperatureReduce the temperatureGas treatmentLighting and heating apparatusFlue gasEngineering

The invention discloses temperature adjustable three-way pipe boiler SCR denitration equipment, which comprises a flue gas channel, wherein the surface of the flue gas channel is provided with a gas inlet pipe, a three-way pipe is installed on the top end of the gas inlet pipe, one end of the three-way pipe is connected to a steam heater through a pipeline, and one side of the steam heater is provided with an electromagnetic valve. According to the present invention, one side of the flue gas channel is provided with the steam heater through the gas inlet pipe, and when the temperature of the gas in the flue gas channel does not achieve a specified temperature value, the electromagnetic valve on one side of the steam heater is opened to allow the flue gas to enter the steam heater, such that the flue gas is treated by the steam heater to increase the temperature of the flue gas, and the temperature of the flue gas is increased to the temperature range required for the denitration so asto improve the flue gas denitration efficiency; and the first flue gas heat exchanger, the second flue gas heat exchanger and the third flue gas heat exchanger are arranged on one end of the steam heater, such that the flue gas denitration efficiency can be accelerated when the flue gas temperature is higher than a specified temperature region.

Owner:郑州林大环保科技有限公司

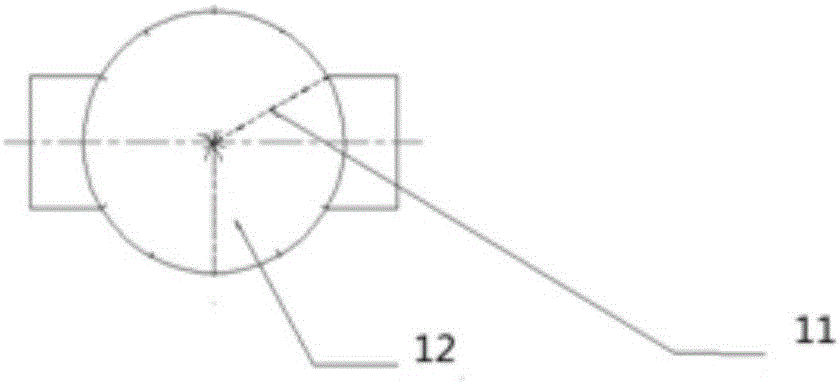

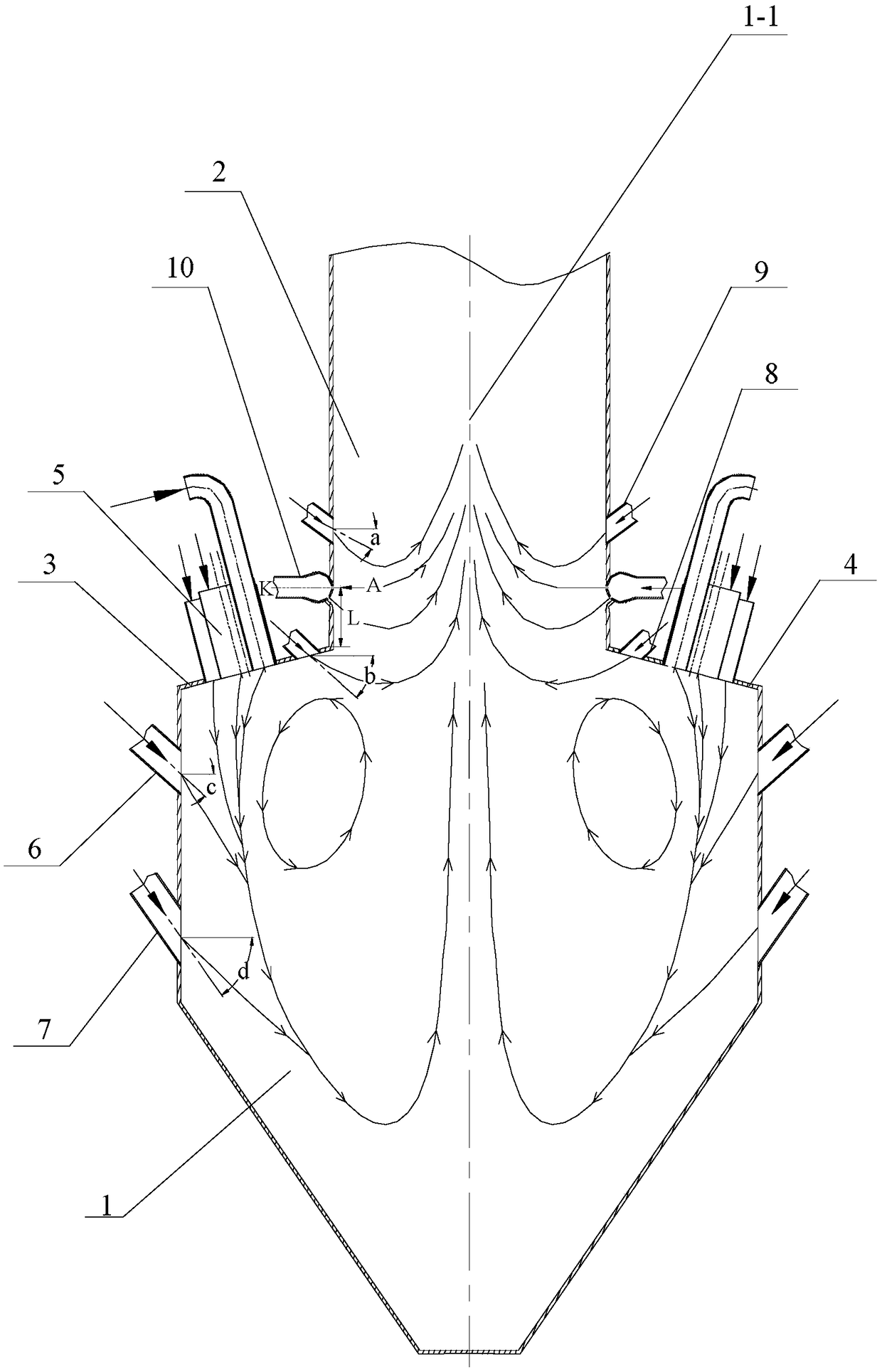

Porous Ammonia Injection Device Used in High Temperature Reduction Zone of W Flame Boiler

ActiveCN107543148BReduce escapeWiden the temperature windowCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSpray nozzleEngineering

The invention discloses a porous ammonia spraying device used for a W-flame boiler high-temperature reduction zone and relates to porous ammonia spraying devices. The problems that an existing turbulent burner W-flame boiler is high in NOx emission and low in denitration efficiency are solved. The porous ammonia spraying devices are hollow spheres; a plurality of swinging exhaust air spraying nozzles are sequentially arranged on the upper portion of the front side wall of a lower hearth in the horizontal direction; a plurality of swinging graded air spraying nozzles are sequentially arranged in the middle of the front side wall of the lower hearth in the horizontal direction; a plurality of swinging first-grade overfire air spraying nozzles are arranged on a rear boiler arch in the horizontal direction; a plurality of swinging second-grade overfire air spraying nozzles are sequentially arranged in the middle of an upper hearth in the circumferential direction; the multiple porous ammonia spraying devices are sequentially arranged on the lower portion of the upper hearth in the circumferential direction and are the hollow spheres; and a plurality of round holes are machined in the positions, below the center faces K of the porous ammonia spraying devices, of the spheres, so that multi-azimuth and multi-angle direct ammonia spraying is formed. The porous ammonia spraying device is used for ammonia spraying on the W-flame boiler high-temperature reduction zone.

Owner:HARBIN INST OF TECH

Pin removal device for semi-trailer tractor and use method of device

A pin removal device for a semi-trailer tractor comprises a tractor side clamping upper part, a tractor side clamping lower part, a clamping ring, a stepping block, a transverse rod or a magnet, a first spiral spring and a sleeve, wherein the tractor side clamping upper part and the tractor side clamping lower part are used for fixing the pin removal device; the clamping ring is in sealed fit withthe bottom of a traction pin; the stepping block drives the clamping ring to collide with a positioning screw of the traction pin to release positioning; the transverse rod or the magnet is used forfixing the top of the traction pin; the first spring and the sleeve drive the traction pin to move upwards to achieve pin removal. When the device is used, the tractor side clamping upper part and thetractor side clamping lower part are used for clamping the tractor side, then the clamping ring is in sealed fit with the bottom of the traction pin, then the top of the traction pin is fixed, the stepping block is treaded, so that the clamping ring collides with the positioning screw at the tip of the traction pin till positioning is released, finally, the first spiral spring pushes the sleeve to slide upwards under the action of elastic force of the first spiral spring, and the traction pin is driven to move upwards to achieve pin removal. By means of the design, removal of traction pins, different in structure, of the semi-trailer tractor can be achieved.

Owner:DONGFENG COMML VEHICLE CO LTD

High-efficient denitration monolithic catalyst for titanium oxide carried vanadium-molybdenum composite oxide

ActiveCN102247832BWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationCatalyst activation/preparationPtru catalystNitrogen oxides

The invention relates to a titanium oxide-loaded vanadium-molybdenum composite oxide high-efficiency denitrification monolithic catalyst and a preparation method thereof, and relates to a control technology for catalytic selective reduction of nitrogen oxides (NOx) in the fields of catalysis, environmental protection and energy saving. It is characterized in that the honeycomb cordierite ceramic material is used as the matrix, the γ-Al2O3 is used as the first carrier, the Anatase crystal form TiO2 is used as the second carrier, and the active component includes V2O5-MoO3 composite oxide as the active component. Wherein the contents of γ-Al2O3 and TiO2 are respectively 5-15wt% and 5-10wt%, V2O5-MoO3 is 1-10wt%, and the molar ratio of V / Mo is between 0-0.20. In the wide temperature window of 80-450 DEG C, the monolithic catalyst of the present invention uses NH3 as the reducing agent to convert NOx to not less than 85%, and the selectivity to N2 is greater than 90%.

Owner:上海复翼环保科技有限公司

Integrated flue gas desulfurization and denitrification agent and its application method

ActiveCN106731783BEfficient reductionImprove out-of-stock efficiencyGas treatmentDispersed particle separationPtru catalystSulfite salt

The invention relates to an integrated flue gas desulfurization and denitrification agent and an application method thereof. The invention is characterized in that the flue gas desulfurization and denitrification agent comprises the following ingredients: a desulfurizing agent, an iron-based denitration catalyst, an activator and a suspending agent. By using an alkaline substance as a desulfurizing agent, using the desulfurization product sulfite as a reducing agent and using the iron-based denitration catalyst as an active reaction factor, simultaneous removal of sulfur dioxide and nitrogen oxide in flue gas is realized in a the gas-liquid-solid three-phase homogenization suspension state, wherein NOx is reduced into nitrogen; and a reacted absorption liquid is activated by the use of an acid solution and a suspending agent is supplemented and then the mixture is sent by a circulating pump into a reaction tower for recycling. The method is simple to operate. By the method, desulphurization efficiency is 99% and above, denitration efficiency is 90% and above, and the desulfurization and denitrification effect is good. The materials are recycled, thus greatly reducing the operating cost of desulfurization and denitrification. The product has obvious economic advantages and can be used for treatment of flue gas or tail gas of various industrial boilers and industrial furnaces.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

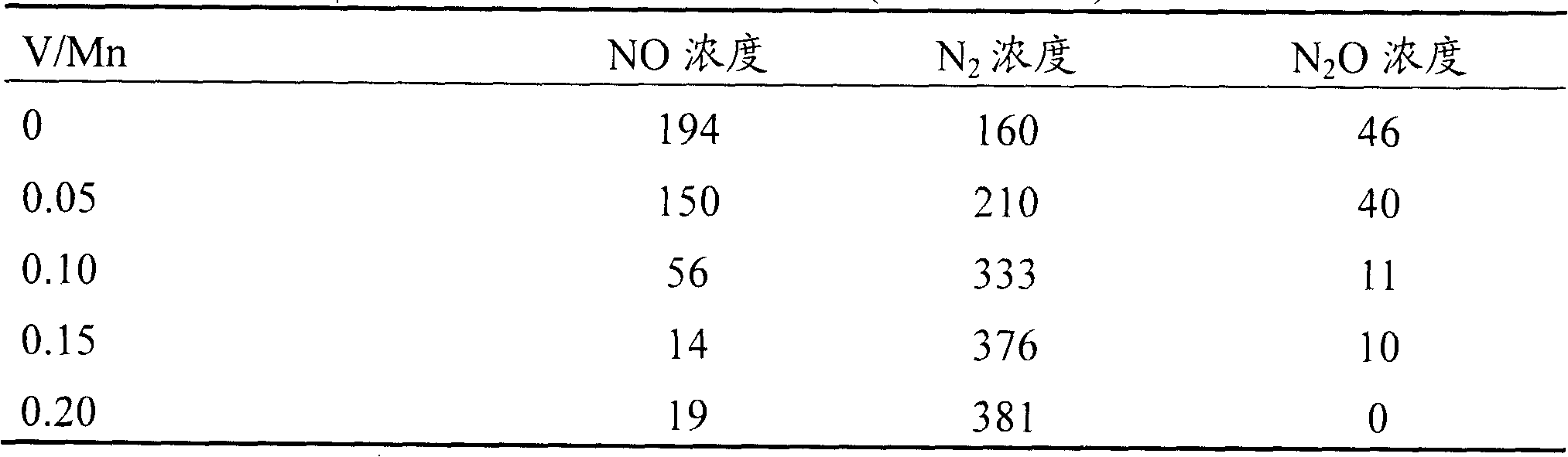

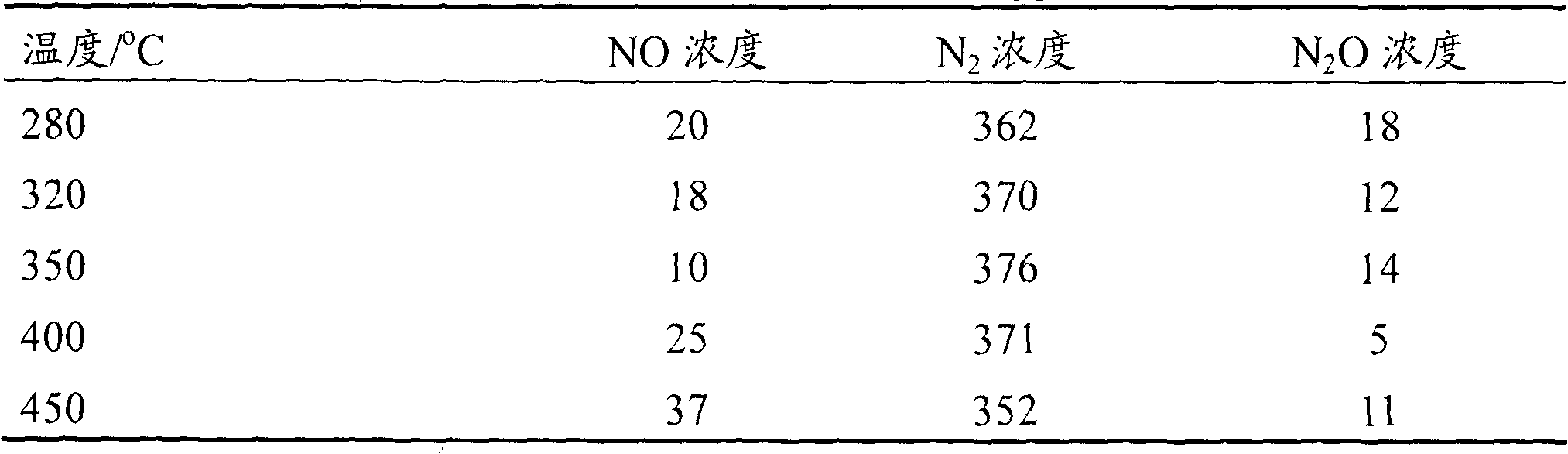

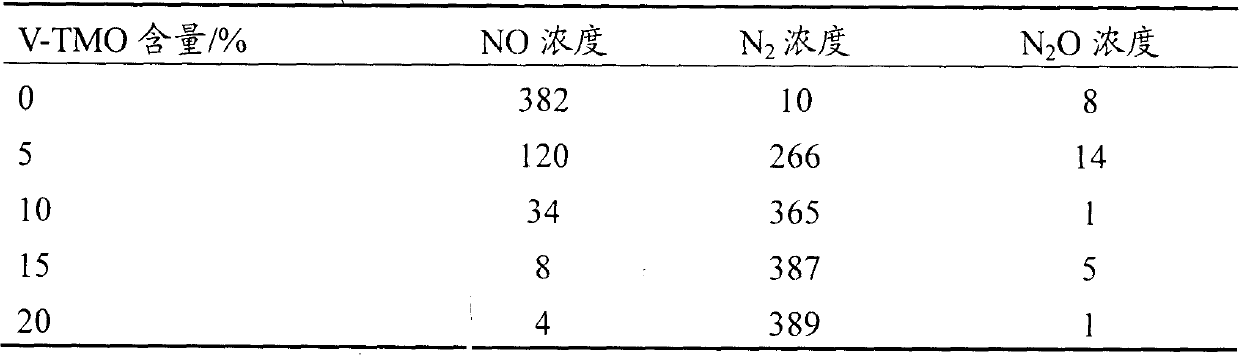

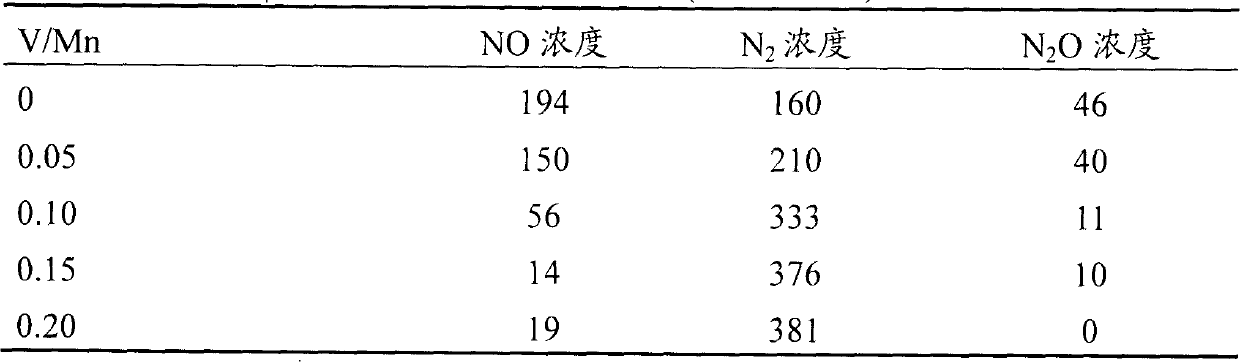

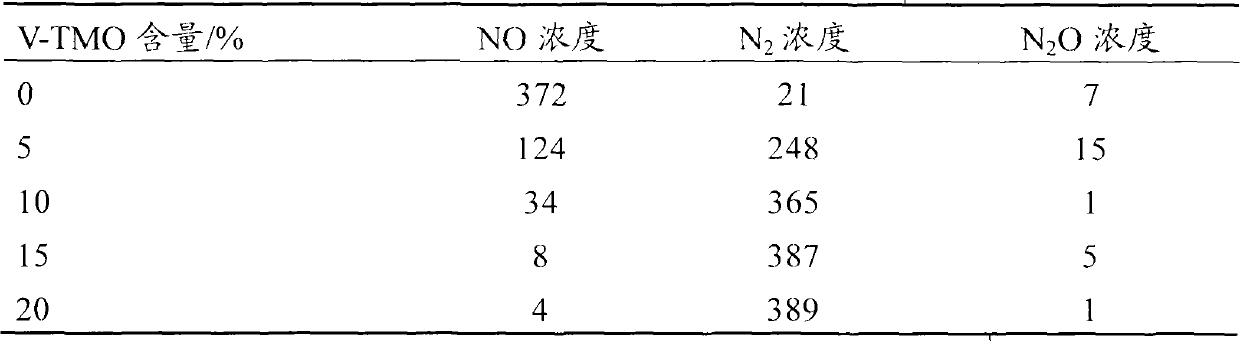

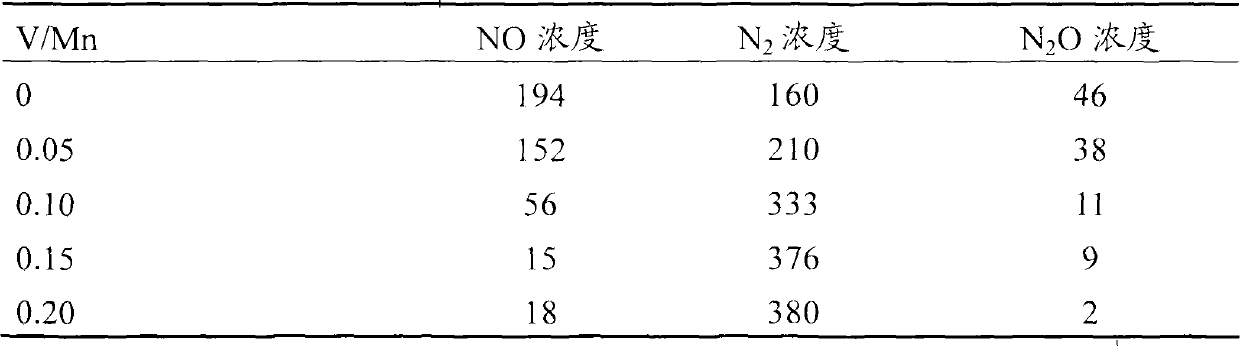

Doped todorokite-type manganese oxide denitration integral catalyst

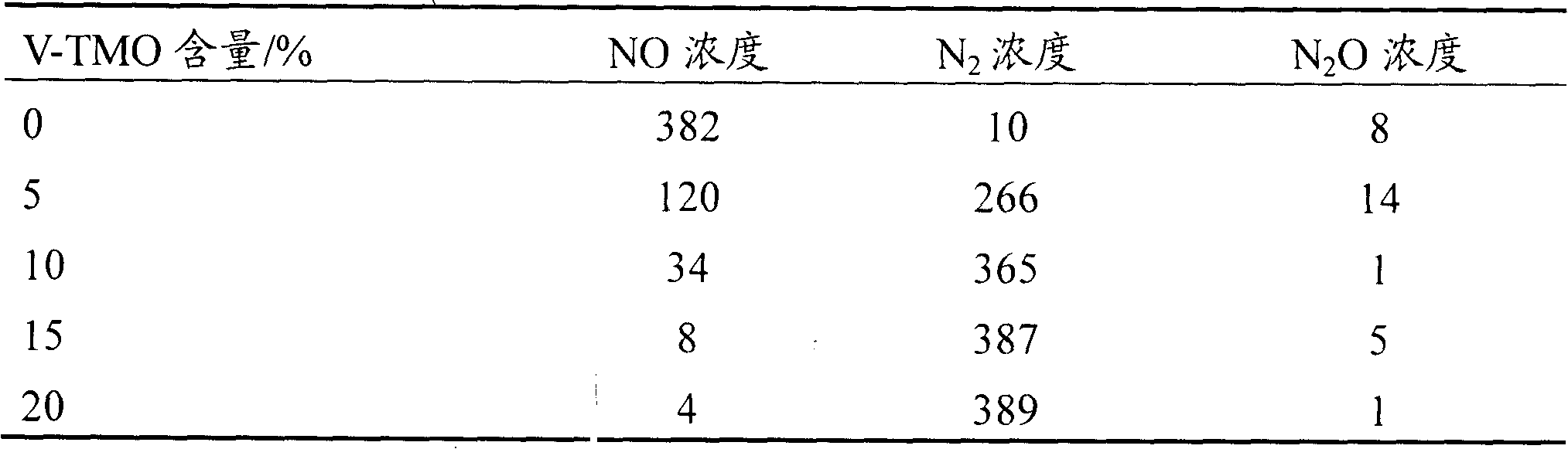

ActiveCN102247835BWide operating temperatureImprove out-of-stock efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHoneycombNitrogen oxide

Relating to the catalytic science and environmental protection technology in the field of energy saving, the invention provides a doped todorokite-type manganese oxide denitration integral catalyst for selective catalytic reduction of NOx by ammonia (NH3-SCR). The catalyst is characterized by taking honeycomb cordierite ceramic material as the matrix and gamma-A1203 as the carrier. The ceramic material is firstly loaded with anatase crystal TiO2 powder, and then loaded with the active component of skeleton vanadium ion (V<5+>) todorokite-structured manganese oxide (V-TMO). Wherein, the contents of gamma-A1203 and TiO2 are 5-15wt% and 5-10wt% respectively, V-TMO accounts for 5-20wt%, and the mol ratio of V to Mn ranges from 0-0.20. The integral catalyst of the invention, at a broad temperature window ranging from 100-450DEG C, can transform NOx at a rate of more than 85% with NH3 as the reducing agent, and has a selectivity of over 95% for N2. The integral catalyst provided in the invention is suitable for controlling the discharge of nitrogen oxides.

Owner:上海复翼环保科技有限公司

Flue gas self-circulation low-nitrogen heat storage burner control method and device

PendingCN114484430AAvoid local low temperature of the flameSpray state remains consistentEmission preventionIndirect carbon-dioxide mitigationNitric oxideNitrogen oxides

The invention discloses a flue gas self-circulation low-nitrogen heat storage burner control method and device, and belongs to the field of heat storage burners, the flue gas self-circulation low-nitrogen heat storage burner control method comprises the following steps that S1, fuel gas is ignited at the ignition end of one burner and forms flames in a hearth; the air blower is started, and combustion-supporting air enters the heat storage box body from the air pipe through the four-way valve to support combustion of flames; s2, an induced draft fan is started, flue gas generated by combustion in the hearth in the step S1 is led out through a four-way valve, a high-pressure induced draft fan is started to lead part of the led-out flue gas into a mixing pipeline, the flue gas enters a heat storage box through regulation and control of an air valve and is mixed into combustion-supporting air, oxygen-deficient combustion of a burner is achieved, and nitric oxide generated in the combustion process is reduced; smoke with carbon dioxide and nitrogen as main components is introduced and mixed into combustion-supporting air, generation of nitric oxide is restrained in the combustion process by reducing the oxygen content in the combustion-supporting air, and oxygen-deficient combustion of the burner is achieved.

Owner:衢州市荣胜环保科技有限公司

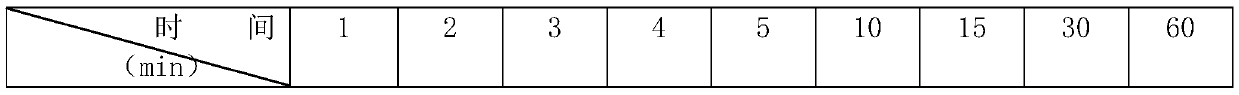

A kind of modified urea denitration agent and preparation method thereof

ActiveCN107115773BImprove out-of-stock efficiencyLow costGas treatmentDispersed particle separationPolyvinyl alcoholPolyethylene glycol

The invention discloses a modified urea denitration agent which is prepared from the following three parts: (1) 100.0 parts by mass of urea; (2) 0.5-10.0 parts by mass of high polymers such as polyethylene glycol, polyacrylic acid, sodium polyacrylate and polyvinyl alcohol; and (3) 0.1-10.0 parts by mass of a modified component. The modified component is a silicon dioxide microcapsule loading titanyl sulfate or titanyl sulfate and zinc sulfate or manganese sulfate and / or aluminum sulfate. The denitration rate of the denitration agent at 750-1050 DEG C can reach 83.2%-99.0%. The compound denitration agent is simple in preparation method, and can be widely applied to high temperature gas denitration in a thermal power plant, a waste incineration plant, etc.

Owner:SHENZHEN HUAMING ENVIRONMENTAL PROTECTION TECH CO LTD

A new cathodic and anode electrocatalytic synergistic flue gas denitrification method

ActiveCN111514712BImprove out-of-stock efficiencyLow costGas treatmentDispersed particle separationElectrolysisNitrogen gas

The invention discloses a novel cathode-anode electrocatalysis cooperative flue gas denitrification method, which belongs to the technical field of atmospheric treatment. The method of the present invention utilizes the active matter produced by anodic oxidation to oxidize NO in the flue gas into high-valence NOx that is easily soluble in water, and the NOx absorbed by the water phase is converted into nitrite and nitrate, and the dissolved nitrate nitrogen can be It is converted to nitrogen or ammonium by catalytic reduction on the cathode, and the ammonium produced can be finally oxidized to nitrogen by the hypochlorous acid generated by electrolysis at the anode. The system uses a lifting pump to lift the solution to the top of the reaction device, and forms a spray through the spray device, which further increases the contact time and contact area between NO and the solution, and improves the treatment efficiency.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

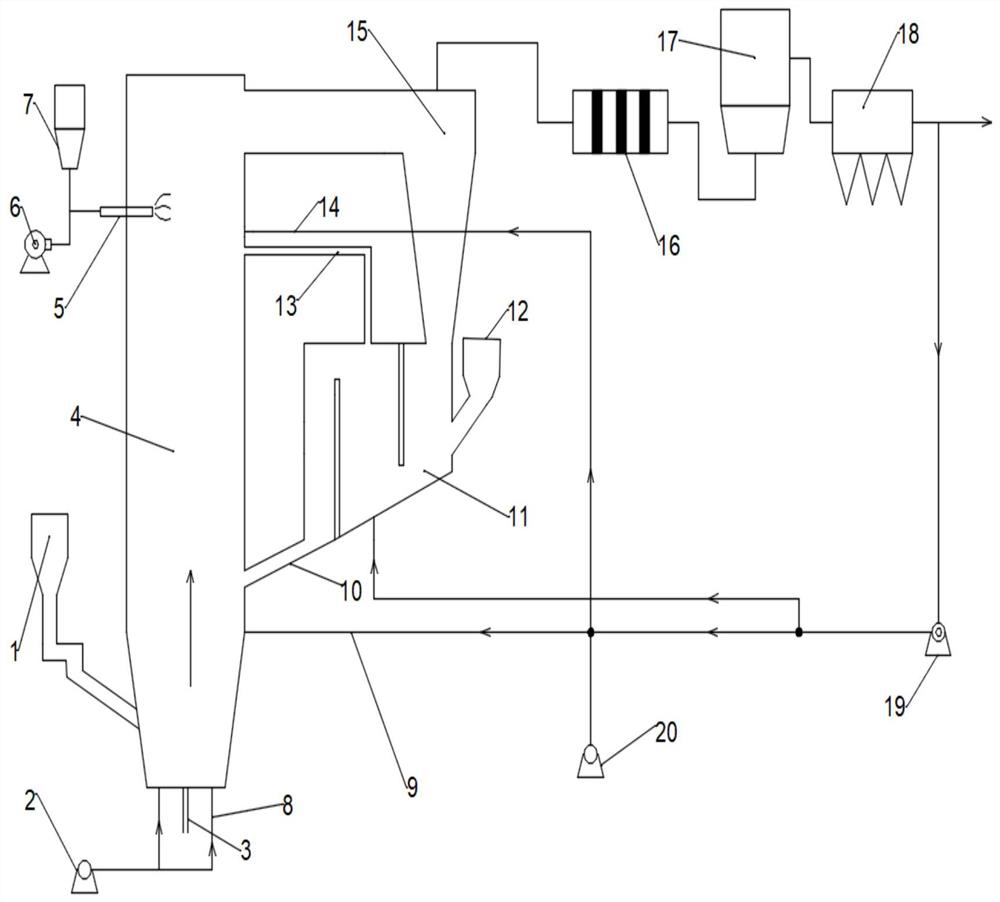

A biomass fluidized bed direct combustion system and denitrification method thereof

ActiveCN111006207BAchievement of denitrification efficiencyEmission reductionFluidized bed combustionNon-combustible gases/liquids supplyDirect combustionFlue gas

The invention belongs to the field of biomass fluidized bed combustion, and specifically discloses a biomass fluidized bed direct combustion system and a denitrification method thereof, which includes a biomass fluidized bed boiler, a cyclone separator, a feeding reactor, and a waste heat boiler , flue gas purification device and air distribution device, the lower end of the biomass fluidized bed boiler is provided with a first feeder and slag discharge pipe, and the upper side is provided with a denitrification device; the cyclone separator is arranged at the upper end of the biomass fluidized bed boiler, and It is connected with the feeding reactor; the upper end of the feeding reactor is provided with an exhaust pipe, and the lower end is provided with a feeding pipe. Both the exhaust pipe and the feeding pipe are connected with the biomass fluidized bed boiler, and the feeding reactor is also provided with The second feeder; one end of the waste heat boiler is connected to the cyclone separator, and the other end is connected to the flue gas purification device; the air distribution device is used to supply air to the biomass fluidized bed boiler. The invention optimizes the problem of low denitrification efficiency in the traditional biomass combustion boiler, has high denitrification efficiency, and reduces operating costs at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

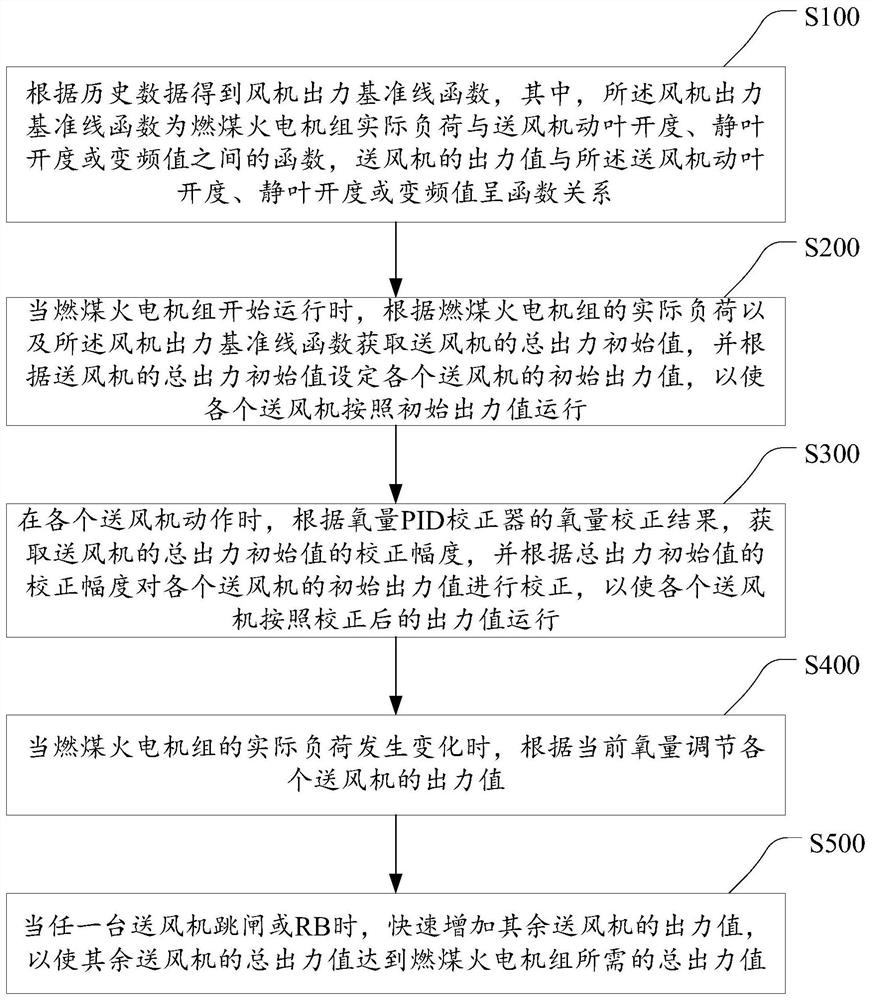

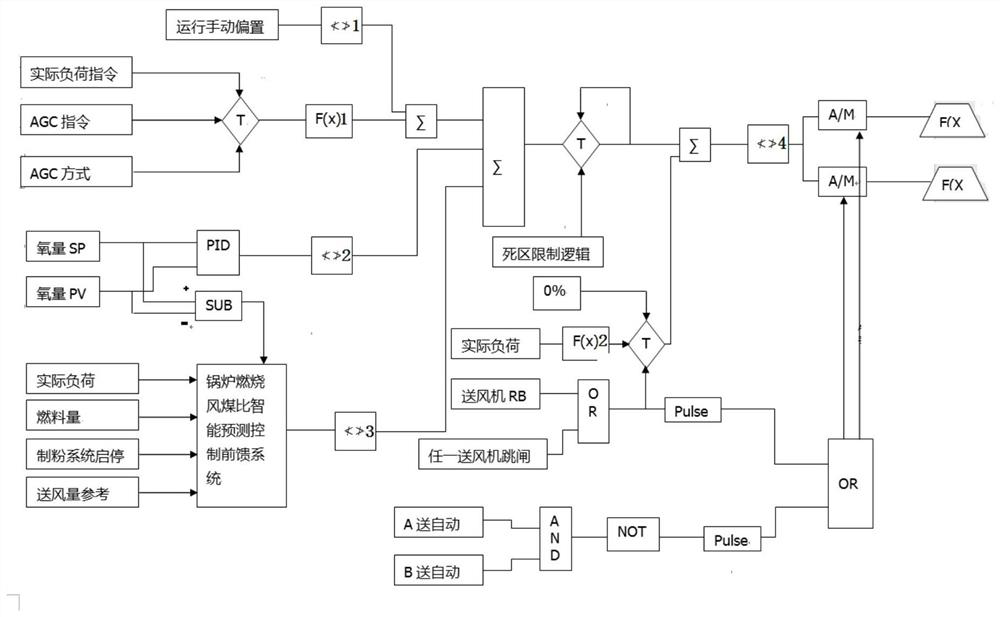

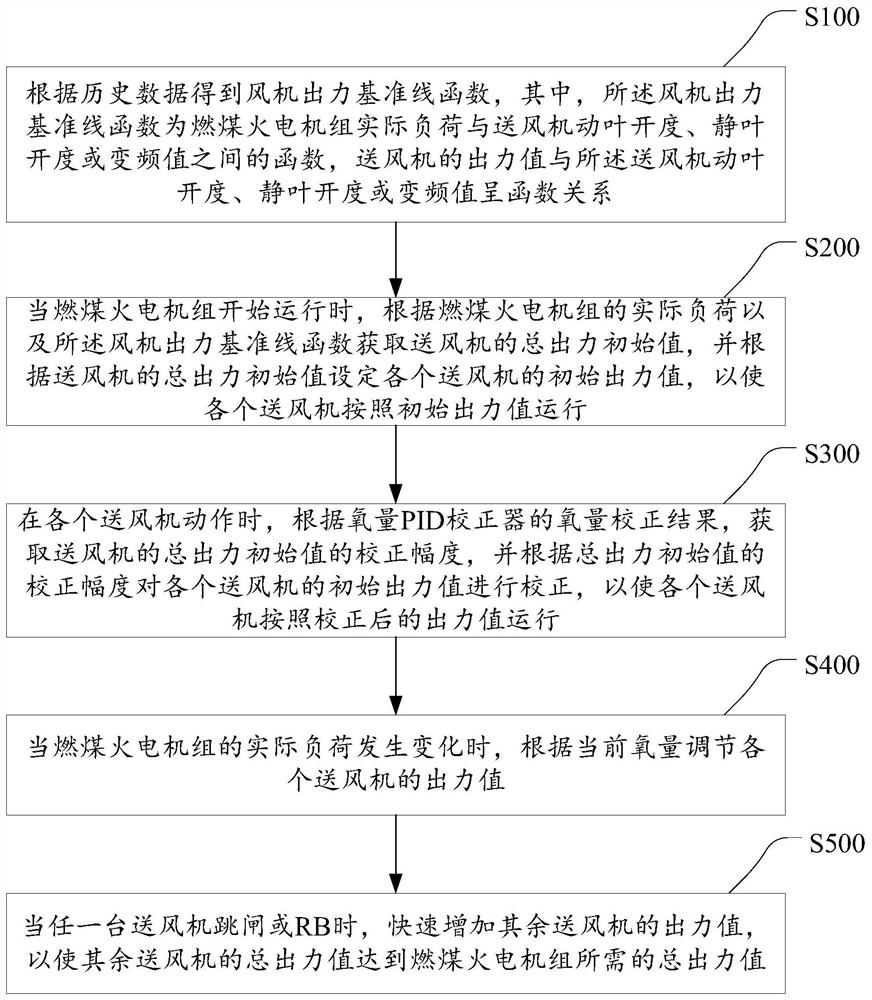

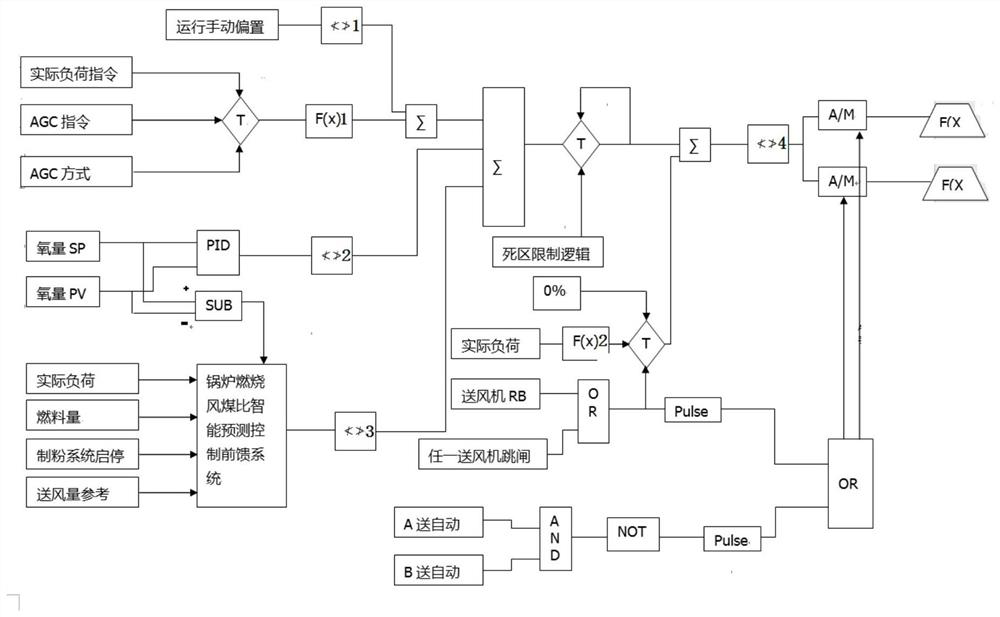

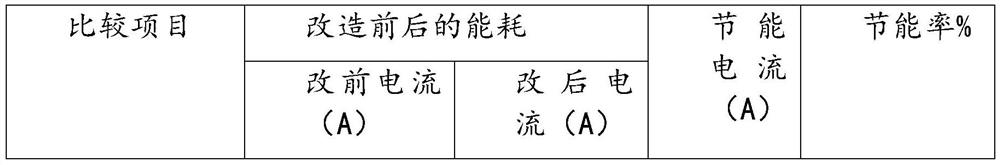

An intelligent air supply control method, device and storage medium

ActiveCN112797437BSmooth changeImprove energy savingAir supply regulationAir volumeProcess engineering

The invention relates to an intelligent air supply control method, equipment and storage medium. The method includes: analyzing historical data and obtaining a fan output baseline function through actual load dynamic tests; according to the actual load of coal-fired thermal power units and the fan output baseline function Obtain the initial value of the total output of the blower, and set the initial output value of each blower according to the initial value of the total output of the blower, so that each blower operates according to the initial output value; according to the oxygen amount calibration result of the oxygen amount PID calibrator, obtain the blower's The correction range of the initial value of the total output, and correct the initial output value of each blower according to the correction range of the initial value of the total output, so that each blower operates according to the corrected output value; when the actual load of the coal-fired thermal power unit changes , adjust the output value of each blower according to the current oxygen amount. The invention solves the problem of inaccurate measurement of air volume due to the air supply control strategy of the coal-fired thermal power unit, which is unsafe and uneconomical.

Owner:HUANENG WUHAN POWER GENERATION CO LTD

Efficient denitrified integral catalyst of stationary source

InactiveCN101905156BWide operating temperatureImprove out-of-stock efficiencyCatalyst carriersDispersed particle separationNitric oxideCordierite

The invention discloses an efficient denitrified integral catalyst of a stationary source, which relates to a control technique of catalytic selective reducing nitric oxides (NOx) in the fields of catalyzation, environmental protection and energy saving and is characterized in that honeycomb cordierite ceramics are used as matrixes; gamma-Al2O3 is used as a first carrier; anatase crystal TiO2 is used as a second carrier; and a manganese oxide molecular sieve (V-OMS) of framework vanadium ions (V<5+>) is used as an active component, wherein contents of the gamma-Al2O3 and the TiO2 are respectively 5wt% to 15wt% and 5wt% to 15wt%; the content of the V-OMS is 5wt% to 20wt%; and the molar ratio of V to Mn is between 0 and 0.20. On a window with wide temperature of 80 DEG C to 450 DEG C, the conversion ratio of the NOx of the integral catalyst of the invention by using NH3 as a reducing agent is not less than 85%; and the selectivity of N2 is larger than 90%. The integral catalyst is suitable for controlling the discharge of nitrogen oxides of the stationary source (boiler).

Owner:唐幸福 +1

Intelligent air supply control method and device and storage medium

The invention relates to an intelligent air supply control method and device and a storage medium. The method comprises the steps: analyzing historical data, and obtaining a fan output reference line function through an actual load dynamic test. According to the actual load of a coal-fired thermal power generating unit and a fan output reference line function, the total output initial value of air blowers is obtained, and according to the total output initial value of the air blowers, the initial output value of each air blower is set, so that each air blower operates according to the initial output value. According to an oxygen amount correction result of the oxygen amount PID corrector, the correction amplitude of the total output initial value of the air blowers is obtained, and the initial output value of each air blower is corrected according to the correction amplitude of the total output initial value, so that each air blower operates according to the corrected output value. When the actual load of the coal-fired thermal power generating unit changes, the output value of each air blower is adjusted according to the current oxygen amount. The method solves the problem that the air quantity measurement of the air supply control strategy of the coal-fired thermal power generating unit is not accurate, so that the method is unsafe and uneconomical.

Owner:HUANENG WUHAN POWER GENERATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com