Low-temperature NOx enriching and removing system and method

A low-temperature flue gas and enrichment technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of reducing the amount of SCR denitrification flue gas treatment, low economic performance of SCR denitrification technology, and reducing equipment investment scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

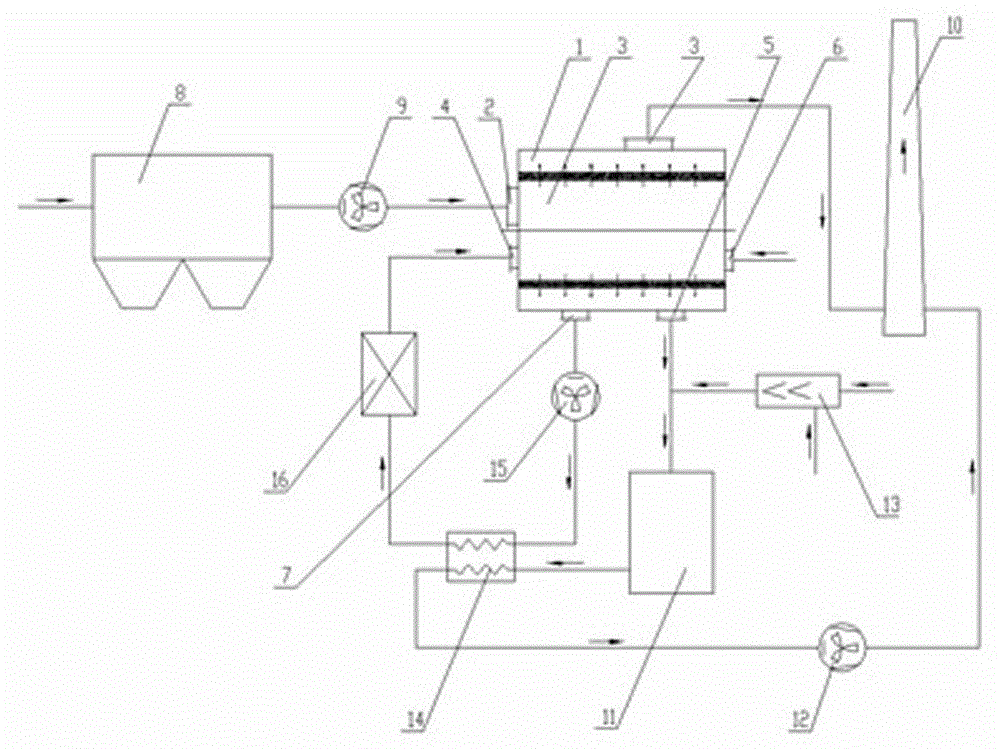

[0020] See figure 1 ,

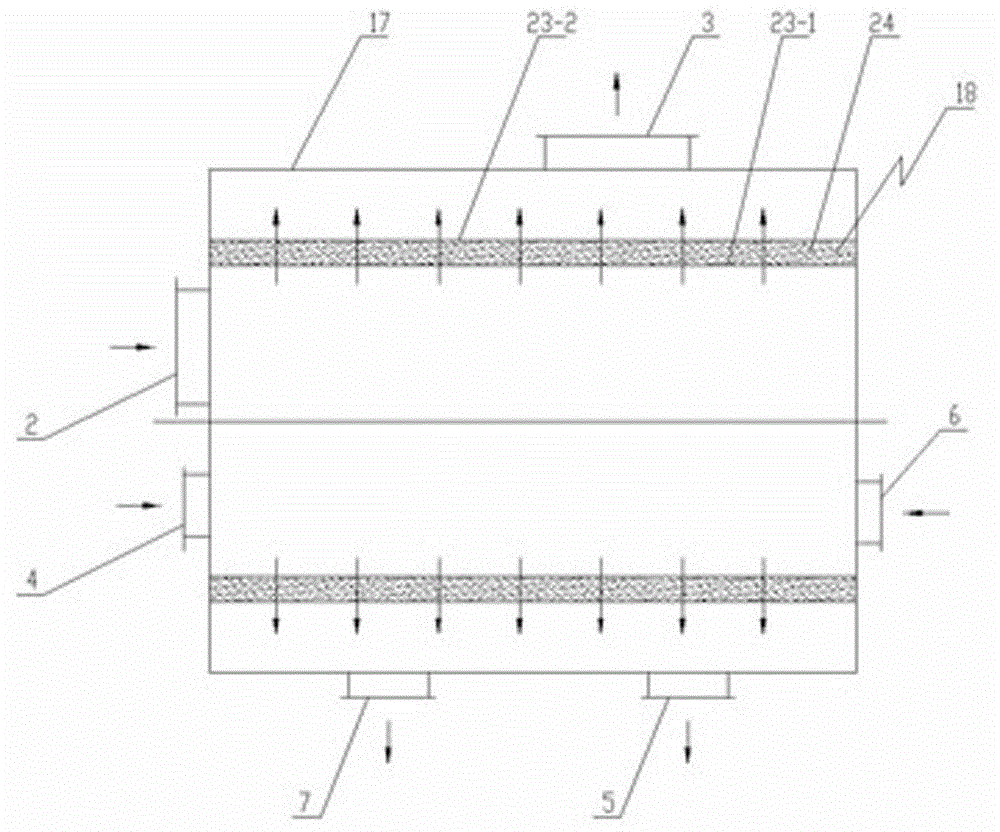

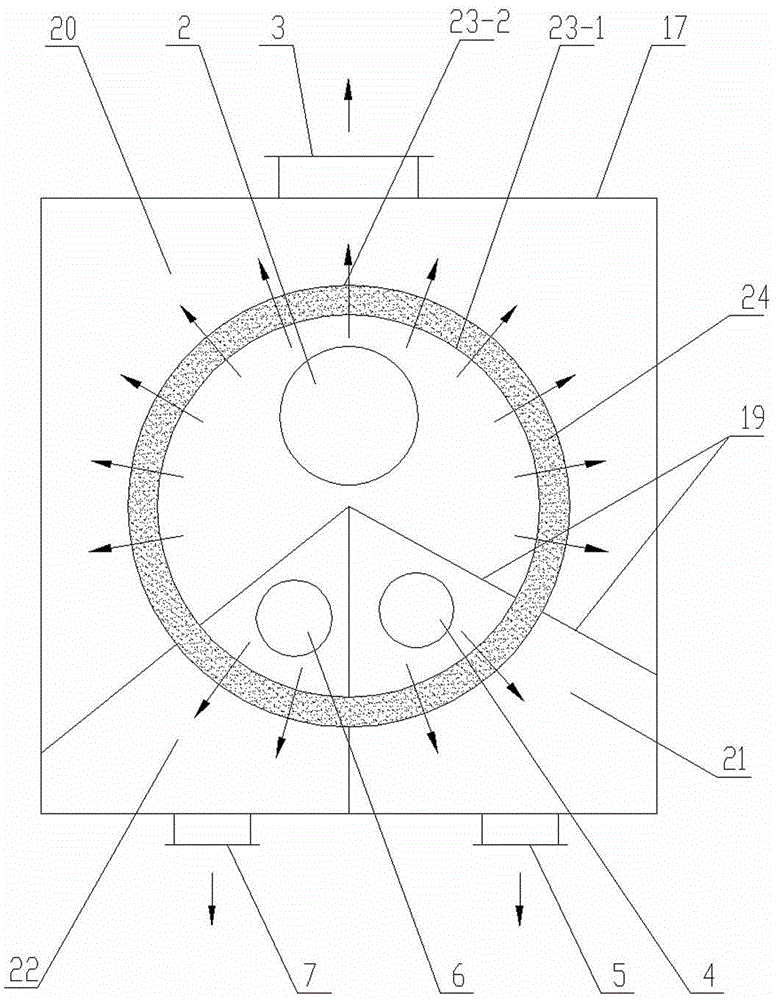

[0021] A low temperature flue gas NO X Enrichment removal system, which includes NO X Enrichment device 1, NO X The enrichment device 1 includes a flue gas inlet 2, a flue gas outlet 3, a heating medium inlet 4, a heating medium outlet 5, a cooling medium inlet 6, and a cooling medium outlet 7. The dust collector 8 is connected to the flue gas inlet 2 through a smoke exhaust fan 9, and the flue gas The gas outlet 3 is connected to the chimney 10, the heating medium outlet 5 is connected to the SCR reactor 11, the exhaust fan 12, and the chimney 10 in turn, and the heating medium outlet 5 and the SCR reactor 11 are connected to the ammonia gas mixer 13;

[0022] The cooling medium outlet 7 is connected to the heating medium inlet 4, and the cooling gas is in the NO X After the temperature rises in the enrichment device 1, the heated cooling gas is used as the source gas of the heating gas, forming a circulation of cold and hot media, increasing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com