Coal-fired boiler high-temperature ammonia spraying denitration system based on biomass pyrolysis and method thereof

A technology for biomass pyrolysis and coal-fired boilers, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

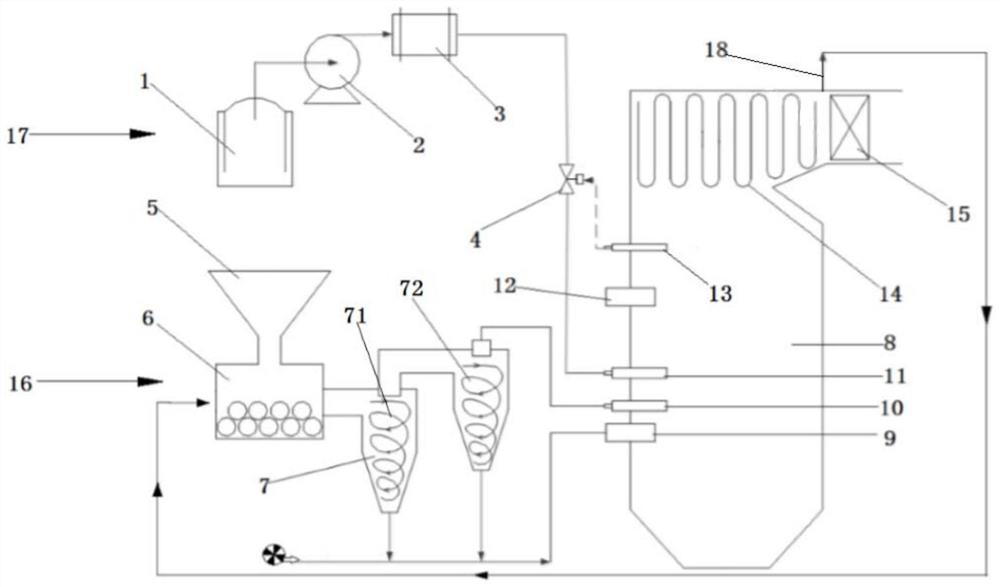

[0028] A high-temperature ammonia injection denitrification system for coal-fired boilers based on biomass pyrolysis, such as figure 1 As shown, it includes a boiler 8, a biomass pyrolysis device 16 and an amino reducing agent injection device 17; the side wall of the boiler 8 has a low-nitrogen burner 9, a biomass pyrolysis gas nozzle 10, and an amino reducing agent spray gun 11 in sequence along the height direction and SOFA air nozzle 12; the bottom of the boiler 8 is the main combustion zone, and the middle part is the burnout zone; the low-nitrogen burner 9, the biomass pyrolysis gas nozzle 10 and the amino reducing agent spray gun 11 are in the main combustion zone, and the SOFA air nozzle 12 is set in the burnout zone.

[0029] There is a panel superheater 14 and a high-temperature su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com