Titanium oxide molecular sieve monolithic catalyst for flue gas denitrification

A titanium oxide and catalyst technology, which is applied to the control of catalytic selective reduction of nitrogen oxides, the above catalyst is applied to or mobile source denitrification, and the preparation field of the above catalyst achieves strong sulfur resistance, strong humidity resistance, and wide service temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

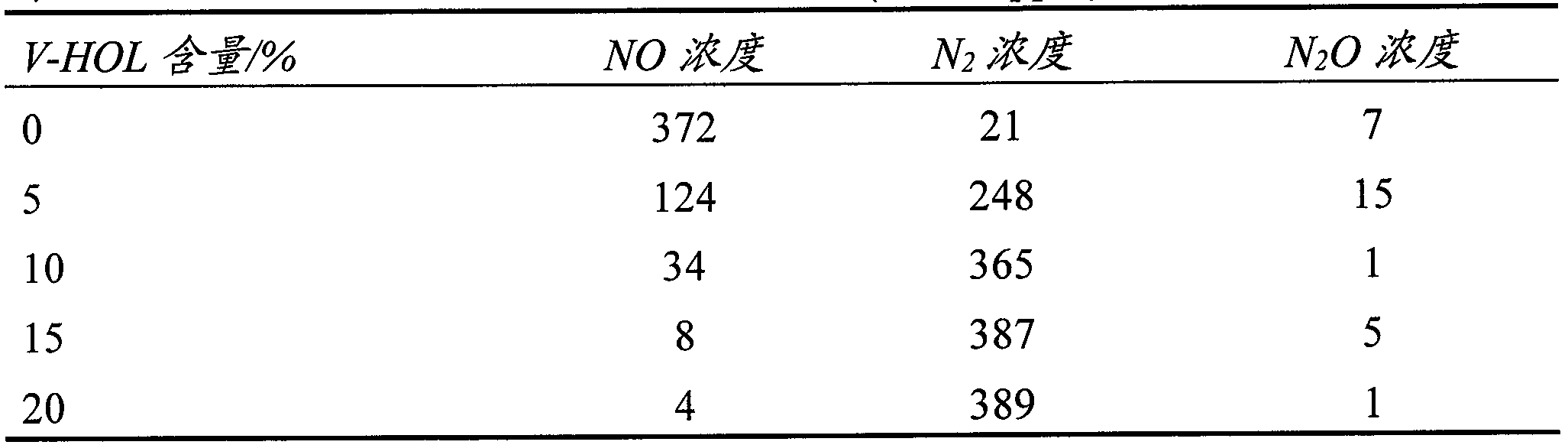

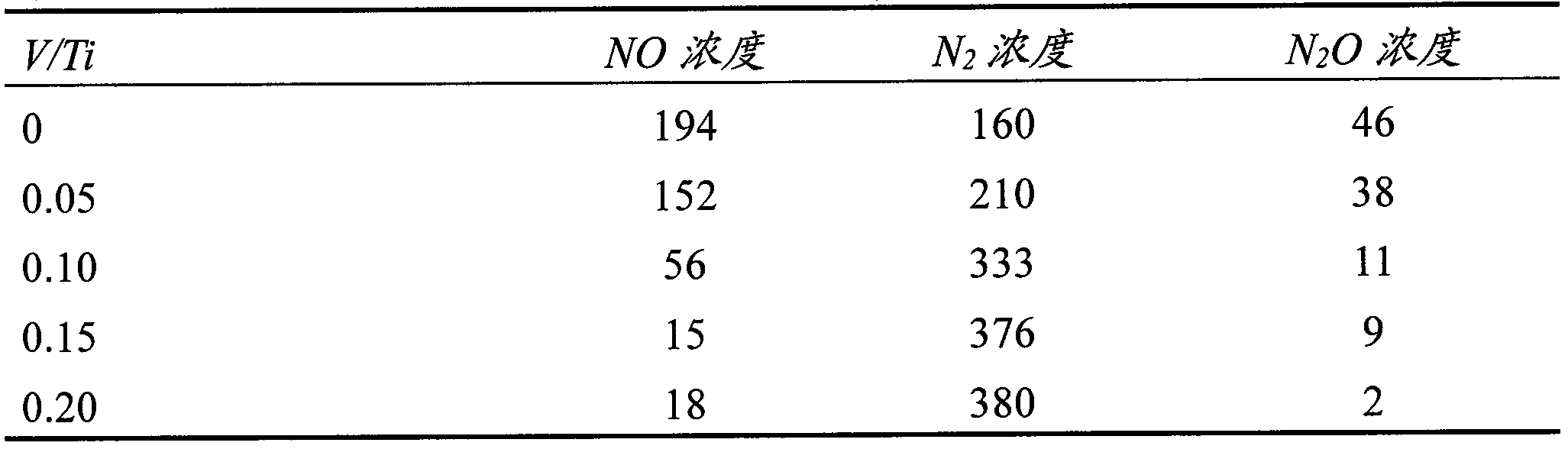

[0030] Monolithic catalysts for denitrification with varying active composition.

[0031] Contains γ-Al 2 o 3 Preparation of cordierite honeycomb ceramics. Weigh a certain amount of diaspore, add a certain proportion of urea or ammonia water, dissolve it with a certain concentration of nitric acid solution, stir it evenly, and ball mill it for 1 to 5 hours to obtain a certain concentration of γ-Al 2 o 3 slurry. The pre-treated cordierite honeycomb ceramics were impregnated in the prepared γ-Al 2 o 3 In the slurry, take it out after immersing for 1-5 minutes, blow off the residual liquid in the channel, dry in the shade and dry at 80-130°C for 2-10 hours, and then bake at 500°C for 2-8 hours to obtain 10% γ-Al loading 2 o 3 cordierite honeycomb ceramic samples.

[0032] Loaded γ-Al 2 o 3and TiO 2 Preparation of cordierite honeycomb ceramics. Dissolve a certain amount of tetrabutyl titanate or titanium ethoxide in absolute ethanol, stir for 1 to 30 minutes, add a cer...

Embodiment 2

[0037] The preparation method of the catalyst is the same as in Example 1. γ-Al 2 o 3 and TiO 2 The content of V-HOL is changed in the range of 5-15wt% and 5-10wt%, respectively, and the content of V-HOL of the monolithic depinning catalyst is 15%, and the molar ratio of V / Ti is 0.15.

[0038] The catalytic activity test is the same as in Example 1. The results showed that the content changes of the two supports had little effect on the overall catalytic performance.

Embodiment 3

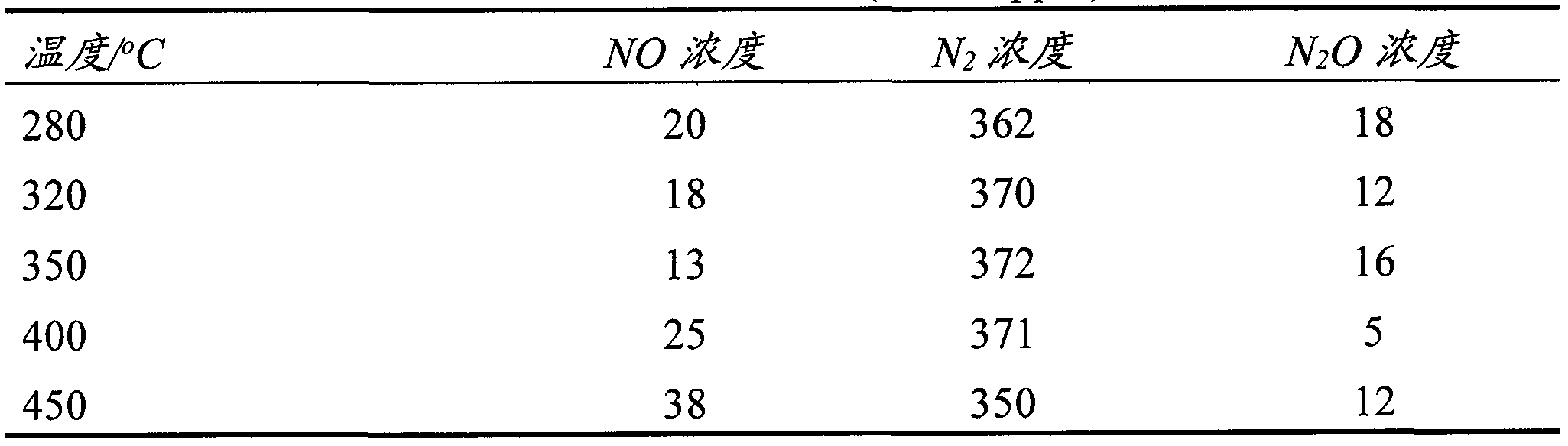

[0040] The preparation method of the catalyst is the same as in Example 1. γ-Al 2 o 3 and TiO 2 The content of V-HOL is adjusted to 10wt%, the content of V-HOL is 15wt%, and the molar ratio of V / Ti is 0.15.

[0041] The catalytic activity test was the same as in Example 1, and the reaction temperature was 150°C. Concentration of reaction tail gas: 35ppTiO, 0ppTi 2 O and 365ppTi 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com