System and method for vehicle-used battery thermal management

A technology for battery thermal management and vehicle use, which is applied to secondary batteries, battery pack components, circuits, etc. It can solve problems such as inability to dissipate heat from the battery, waste energy, and affect the performance of the power battery, so as to save layout space and reduce heat dissipation time , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

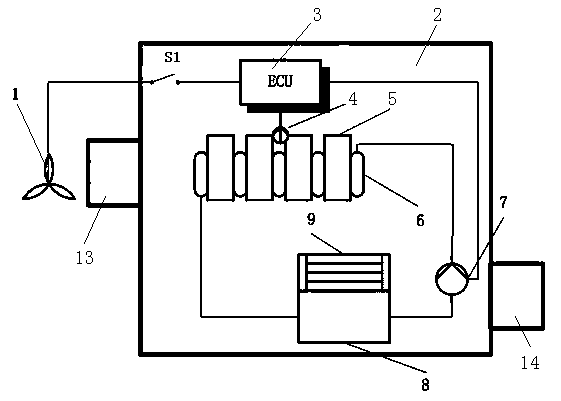

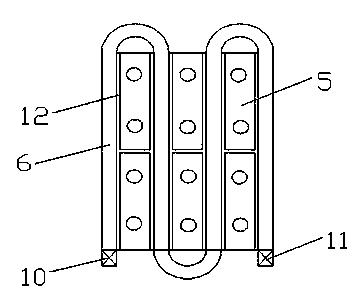

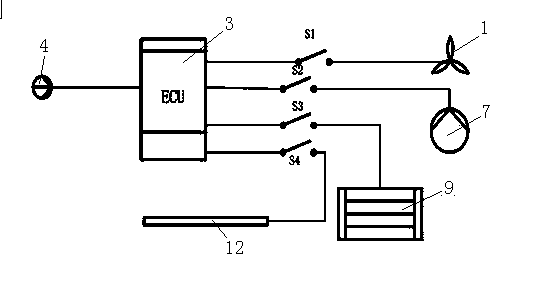

[0018] Such as figure 1 As shown, the present invention includes a water tank 8 and a liquid circulation pump 7. There is circulating liquid in the water tank 8, and the output end of the water tank 8 is connected to the liquid circulation pump 7 in series through a pipeline. Refrigerator 9 is fixedly installed above in water tank 8. Refrigerator 9 adopts magnetic refrigeration technology, and this refrigerator is a commercially available product. A vehicle battery is composed of a plurality of single cells 5, and a flat aluminum tube 6 is wound between the single cells 5, one end of the flat aluminum tube 6 is connected to a liquid circulation pump 7 through a pipe, and the other end of the flat aluminum tube 6 is connected to a water tank through a pipe 8 inputs. A temperature sensor 4 is installed on the vehicle battery, and the temperature sensor 4 and the liquid circulation pump 7 are respectively connected to the battery control unit (ECU) 3 through respective control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com