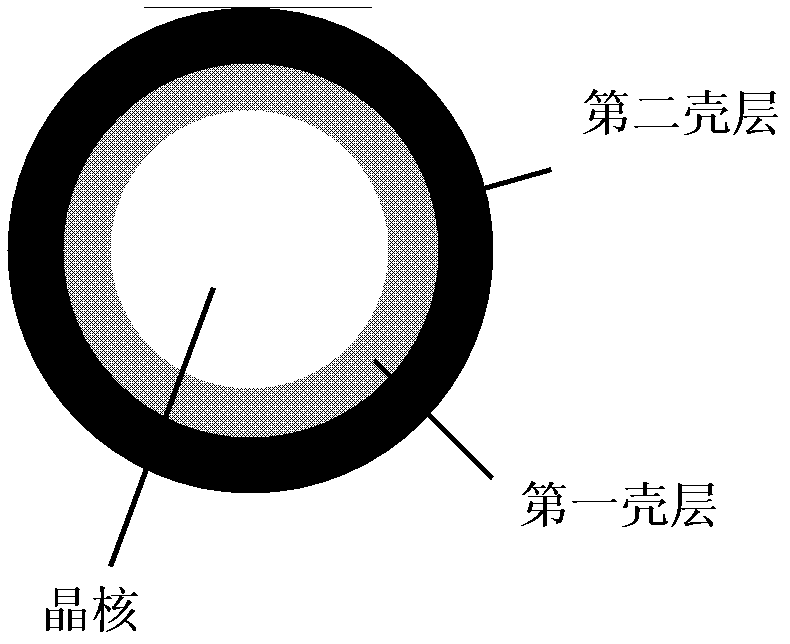

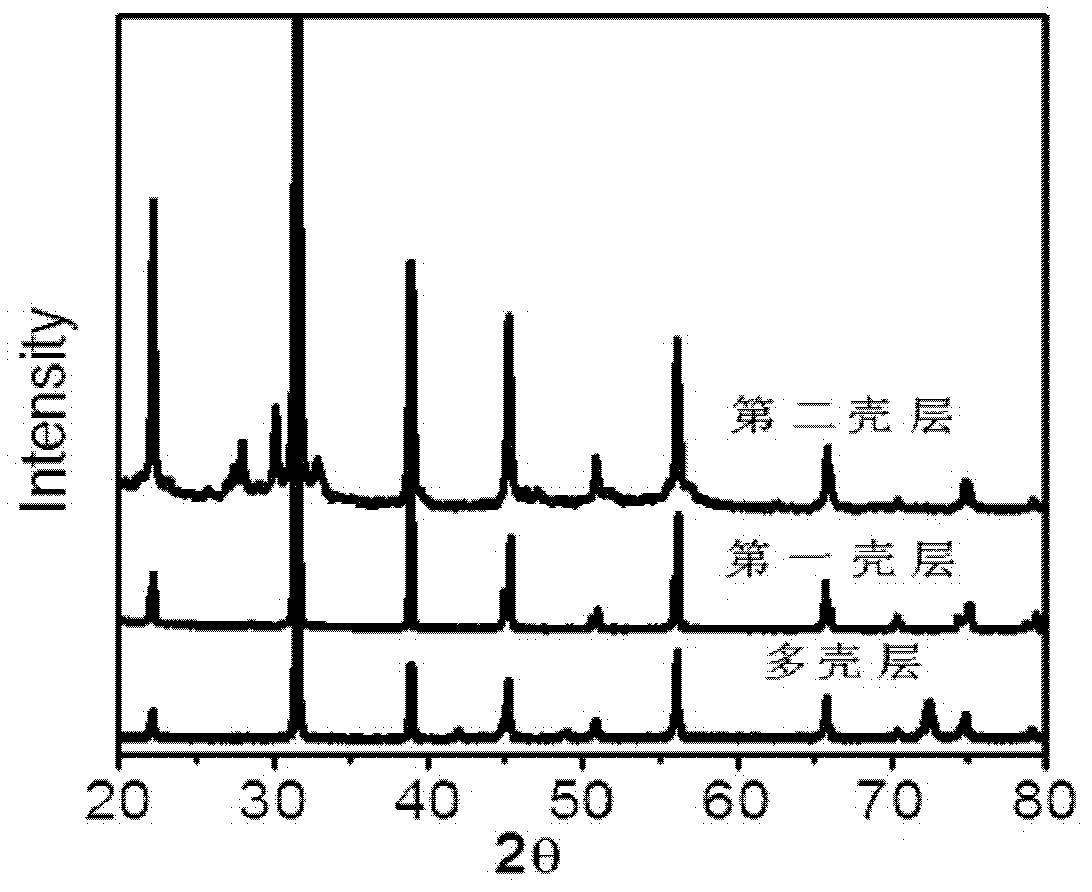

Multi-case-layer structure X8R capacitor dielectric ceramic and preparation method thereof

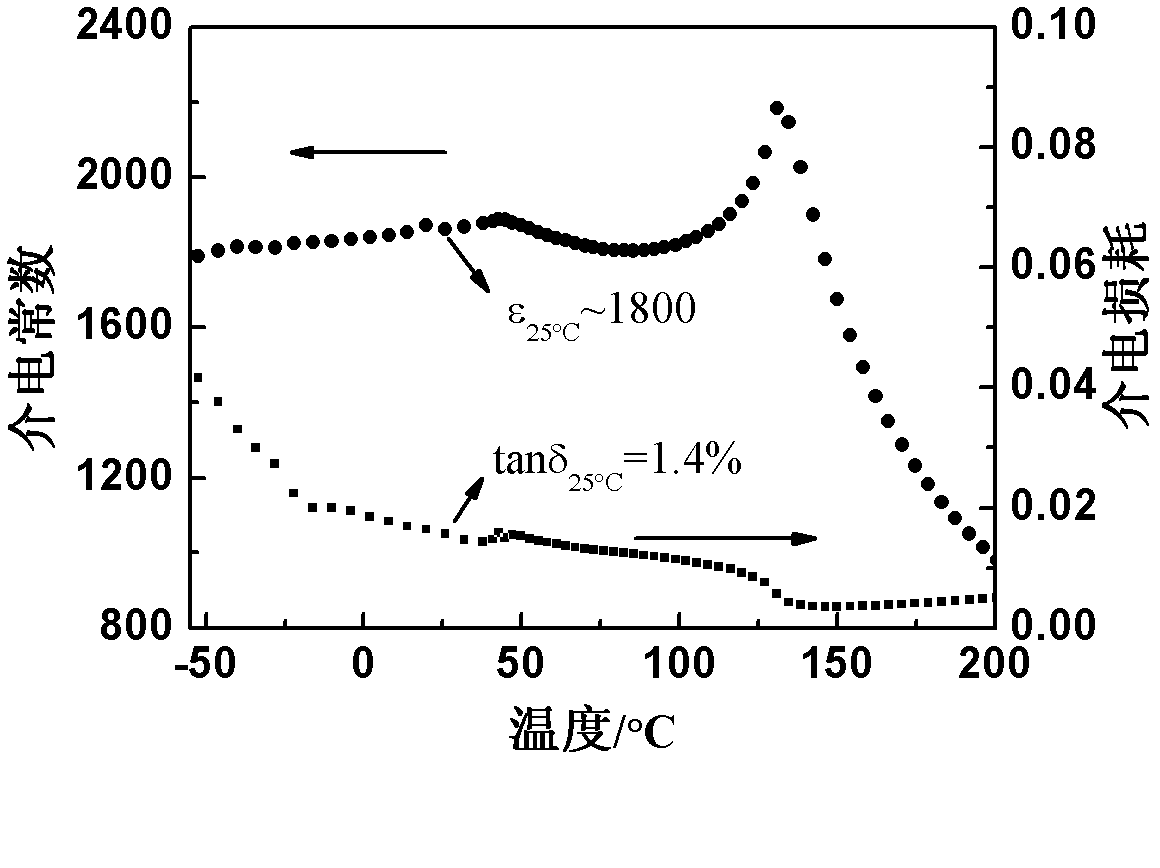

A technology of shell structure and dielectric ceramics, which is applied in the field of multi-shell structure X8R capacitor dielectric ceramics and its preparation, can solve the problems of "shell-core" structure collapse and promote the diffusion rate of Nb and other dopants, and achieve Good high temperature stability and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of multi-shell structure X8R capacitor dielectric ceramics, it comprises the steps:

[0031] 1) preparation sol: the Nb of 50g 2 o 5 Dissolve in 250mL of HF at 90°C, add 100mL of stabilizer ammonium oxalate aqueous solution (concentration of the ammonium oxalate aqueous solution is 0.1g / mL) after 10 hours of sufficient reaction, stir fully and drop in ammonia water to adjust the pH value to 10[ Generate Nb(OH) 5 white precipitate], then aged at 80°C for 12 hours, filtered with suction, and the precipitate was washed with water [to remove NH 4 + 、C 2 o 4 2- , F - ], to get Nb(OH) 5 White precipitate; Nb(OH) 5 Dissolve in 100mL citric acid aqueous solution (the concentration of described citric acid aqueous solution is 1g / mL) after the white precipitate is dried, make Nb(OH) 5 The white precipitate is completely dissolved to obtain a stable Nb salt sol; use ICP to measure Nb in the Nb salt sol 5+ Concentration, spare;

[0032] Nb in Nb s...

Embodiment 2

[0041] The preparation method of multi-shell structure X8R capacitor dielectric ceramics, it comprises the steps:

[0042] 1) preparation sol: the Nb of 50g 2 o 5 Dissolve in 250mL of HF at 90°C, add 120mL of ammonium oxalate aqueous solution (concentration of the ammonium oxalate aqueous solution is 0.1g / mL) after 10 hours of full reaction, stir well and add ammonia water dropwise to adjust the pH value to 10 [Nb (OH) 5 white precipitate], then aged at 80°C for 12 hours, filtered with suction, and the precipitate was washed with water [to remove NH 4 + 、C 2 o 4 2- , F - ], to get Nb(OH) 5 White precipitate; Nb(OH) 5 Dissolve in 100mL citric acid aqueous solution (the concentration of described citric acid aqueous solution is 1g / mL) after the white precipitate is dried, make Nb(OH) 5 The white precipitate is completely dissolved to obtain a stable Nb salt sol; use ICP to measure Nb in the Nb salt sol 5+ Concentration, spare;

[0043] Nb in Nb salt sol 5+ , Co(NO ...

Embodiment 3

[0052] The preparation method of multi-shell structure X8R capacitor dielectric ceramics, it comprises the steps:

[0053] 1) preparation sol: the Nb of 50g 2 o 5 Dissolve in 250mL of HF at 90°C, add 150mL of ammonium oxalate aqueous solution (concentration of the ammonium oxalate aqueous solution is 0.1g / mL) after 10 hours of full reaction, stir well and add ammonia water dropwise to adjust the pH value to 10 [Nb (OH) 5 white precipitate], then aged at 80°C for 12 hours, filtered with suction, and the precipitate was washed with water [to remove NH 4 + 、C 2 o 4 2- , F - ], to get Nb(OH) 5 White precipitate; Nb(OH) 5 Dissolve in 100mL citric acid aqueous solution (the concentration of described citric acid aqueous solution is 1g / mL) after the white precipitate is dried, make Nb(OH) 5 The white precipitate is completely dissolved to obtain a stable Nb salt sol; use ICP to measure Nb in the Nb salt sol 5+ Concentration, spare;

[0054] Nb in Nb salt sol 5+ , Co(NO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com