Flue gas self-circulation low-nitrogen heat storage burner control method and device

A control method and self-circulation technology, applied in combustion methods, gas fuel burners, burners, etc., can solve problems such as high core temperature and air pollution, increase stability, maintain consistent injection state, and avoid local low temperature of the flame Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

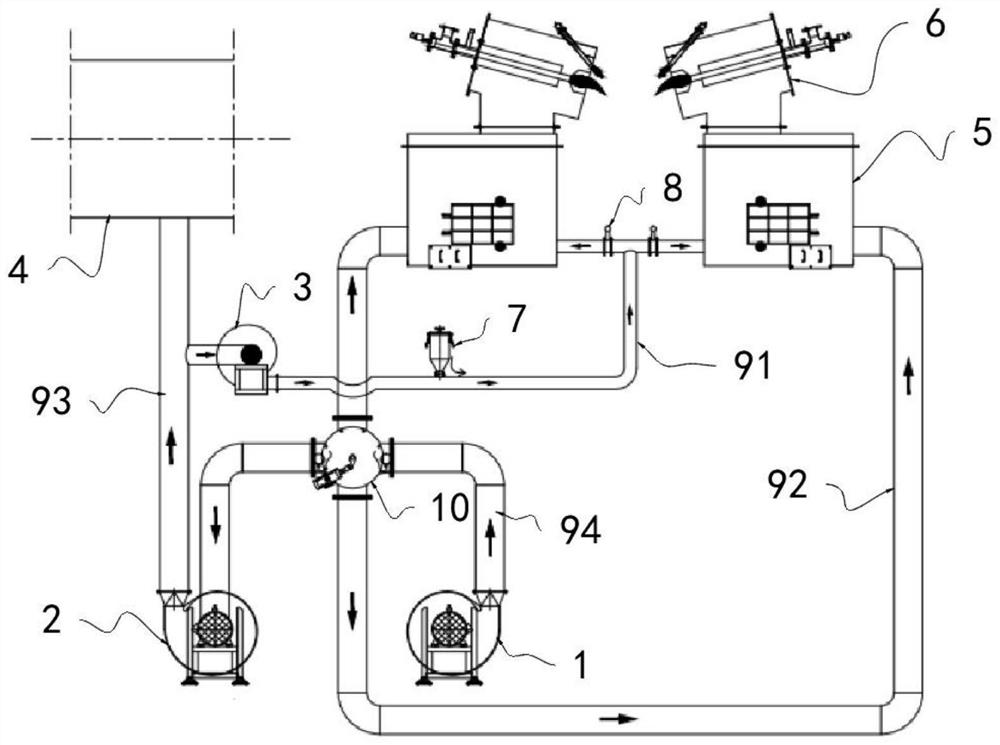

[0028] see figure 1 , a low-nitrogen regenerative burner device with flue gas self-circulation, including a regenerator box 5, a regenerator is formed inside the regenerative box 5, and the regenerator and the burner 6 are communicated through an insulated smoke pipe, At least one heat storage box 5 surrounds the two sides of the furnace; the burner 6 is installed on the heat storage box 5, and the flame injection port of the burner 6 is located in the furnace; the blower 1, the four-way valve 10 and the induced draft fan 2 The four-way valve 10 is connected to the furnace; each regenerator is connected to the same four-way valve 10 through the air pipe 92, and the air pipe 92 is used to suck the combustion-supporting air and exhaust gas into and Exhaust; the induced draft fan 2 and the smoke exhaust pipe 4 are connected through the exhaust pipe 93, the mixing pipe 91 is connected to the side end of the exhaust pipe 93, and the end of the mixing pipe 91 away from the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com