4D multidimensional low-nitrogen combustor

A low-nitrogen burner, multi-dimensional technology, applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

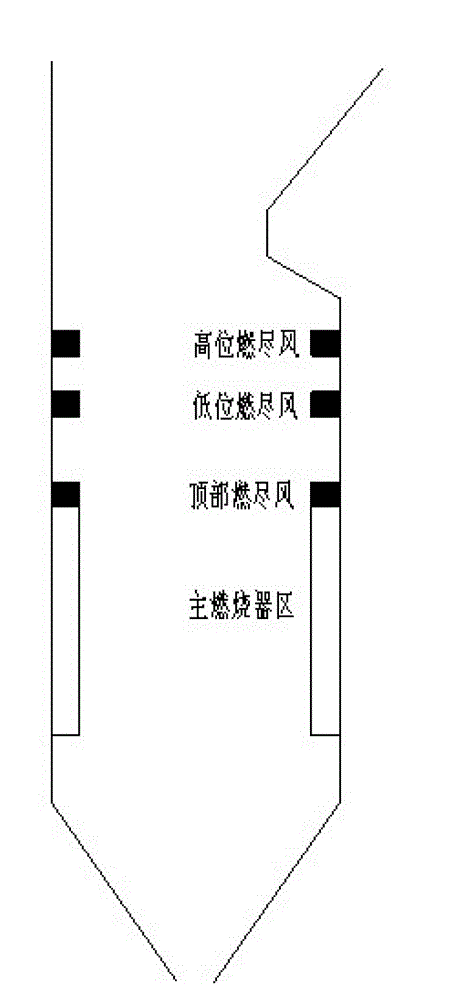

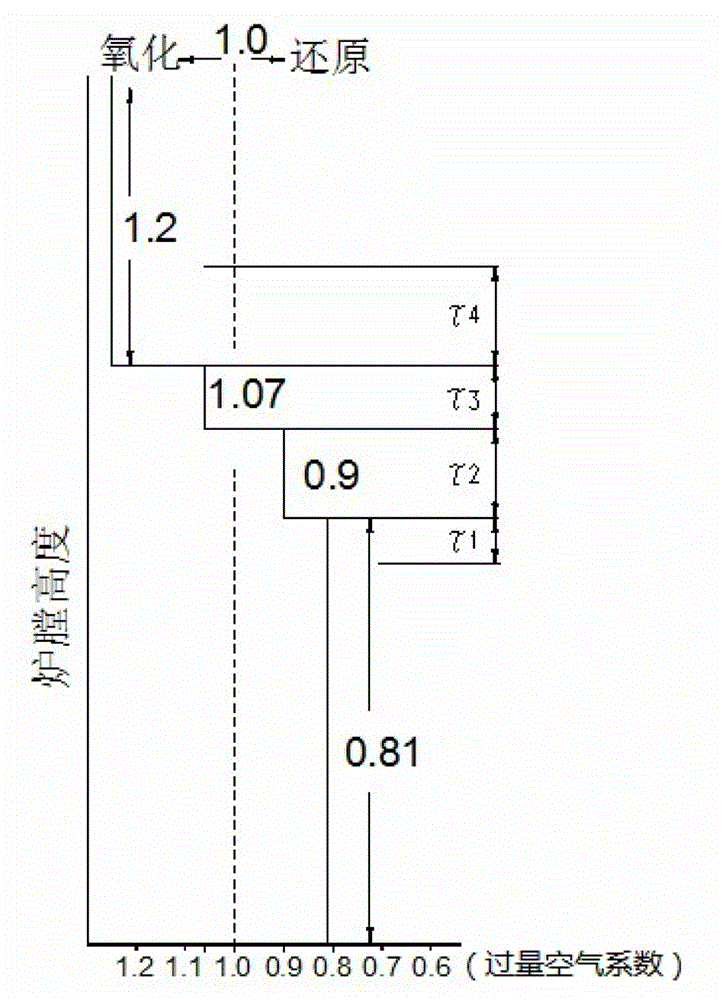

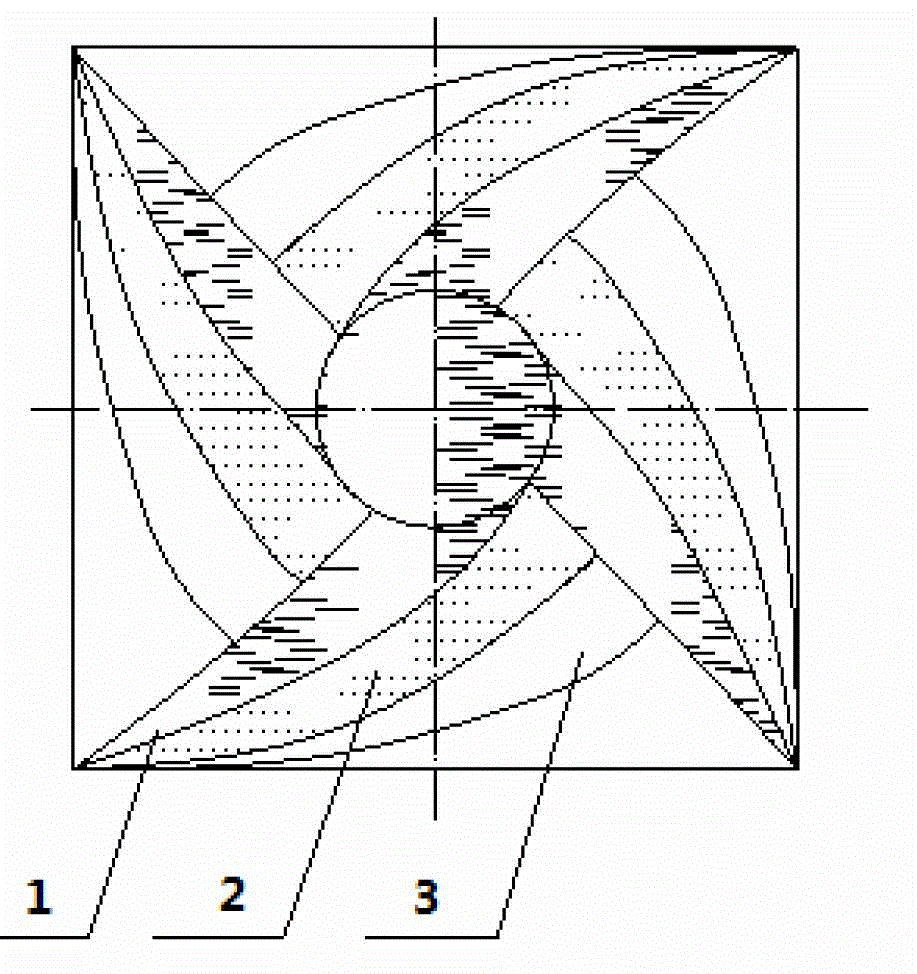

[0146] A 4D multi-dimensional low-nitrogen burner, including the boiler furnace, divides the air required for combustion into four stages along the vertical height of the boiler furnace, the first stage is the main burner area, and the second stage is the exhaust air close to the top of the main burner , the third stage is the low-level overburning air located at a certain height above the main burner, and the fourth stage is the high-level overburning air located at a certain height above the low-level overburning air. Three air staged combustions are carried out in the vertical height direction; while along the furnace horizontal The section direction divides the airflow from the inside to the outside into thick coal powder airflow, light coal powder airflow and wall-adhering airflow, and implements secondary air staged combustion in the horizontal direction; at the same time, the reduction and burnout time of the flue gas in the combustion area of the furnace is controlled ...

Embodiment 2

[0148] A 4D multi-dimensional low-nitrogen burner, the same as Embodiment 1, the difference is that in the four-stage structure of the furnace along the vertical direction, the first stage is the main burner area, and the second stage is located above the main burner. The OFA burn-off air area, the third level is the low-level OFA separation burn-off wind area, and the third level is the high-level SOFA separation burn-off wind area above the low level OFA.

Embodiment 3

[0150] A 4D multi-dimensional low-nitrogen burner, the same as Embodiment 2, the difference is that in the three-stage airflow from the inside to the outside of the furnace along the horizontal direction, the first stage is the dense coal powder airflow area, and the second stage is the light Pulverized coal air flow area, the third-level wall-attached secondary air area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com