Low bed pressure recombination fluidized bed burning fuel with ultralow heat value and using method thereof

A fluidized bed and calorific value technology, which is applied in combustion methods, fluidized bed combustion equipment, and fuels burned in a molten state, can solve problems such as inability to adapt to the full combustion of low-burning value fuels, and reduce environmental protection operating costs and costs. The effect of NOX emission and tail wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

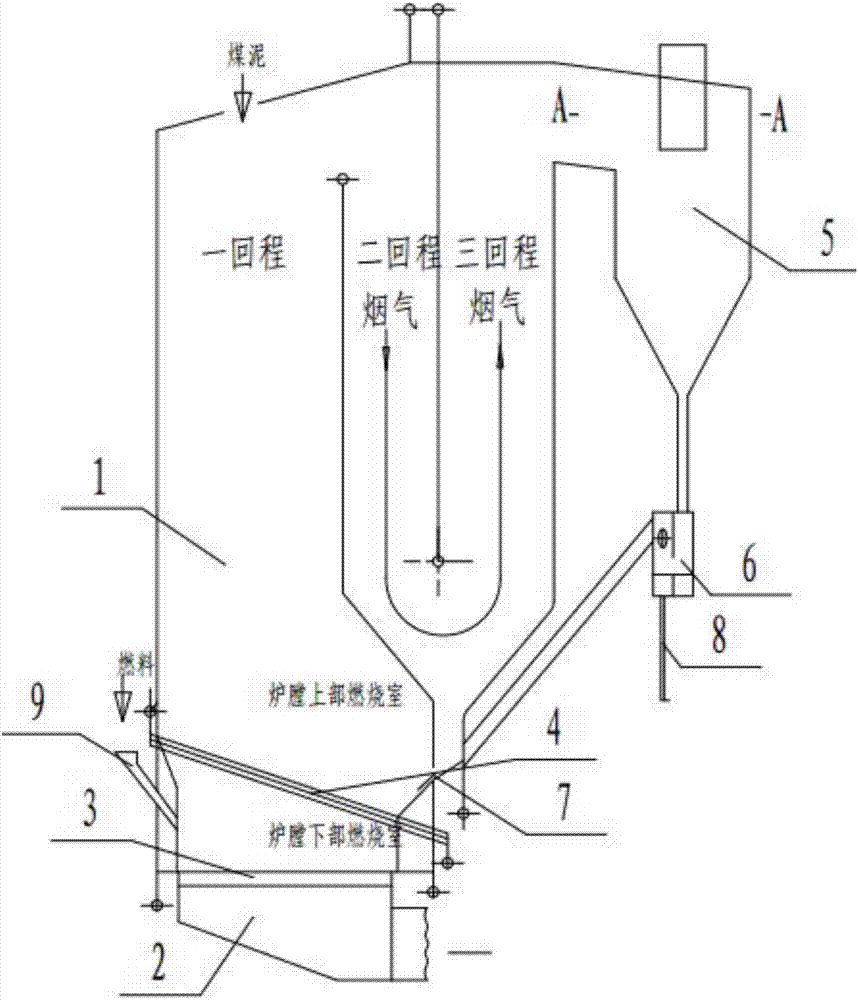

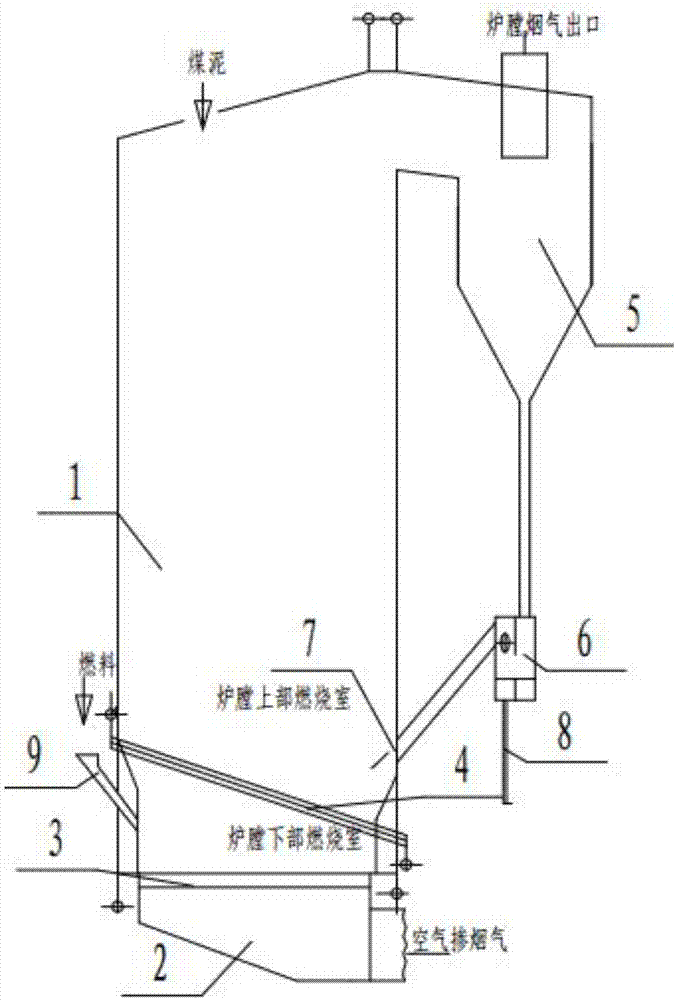

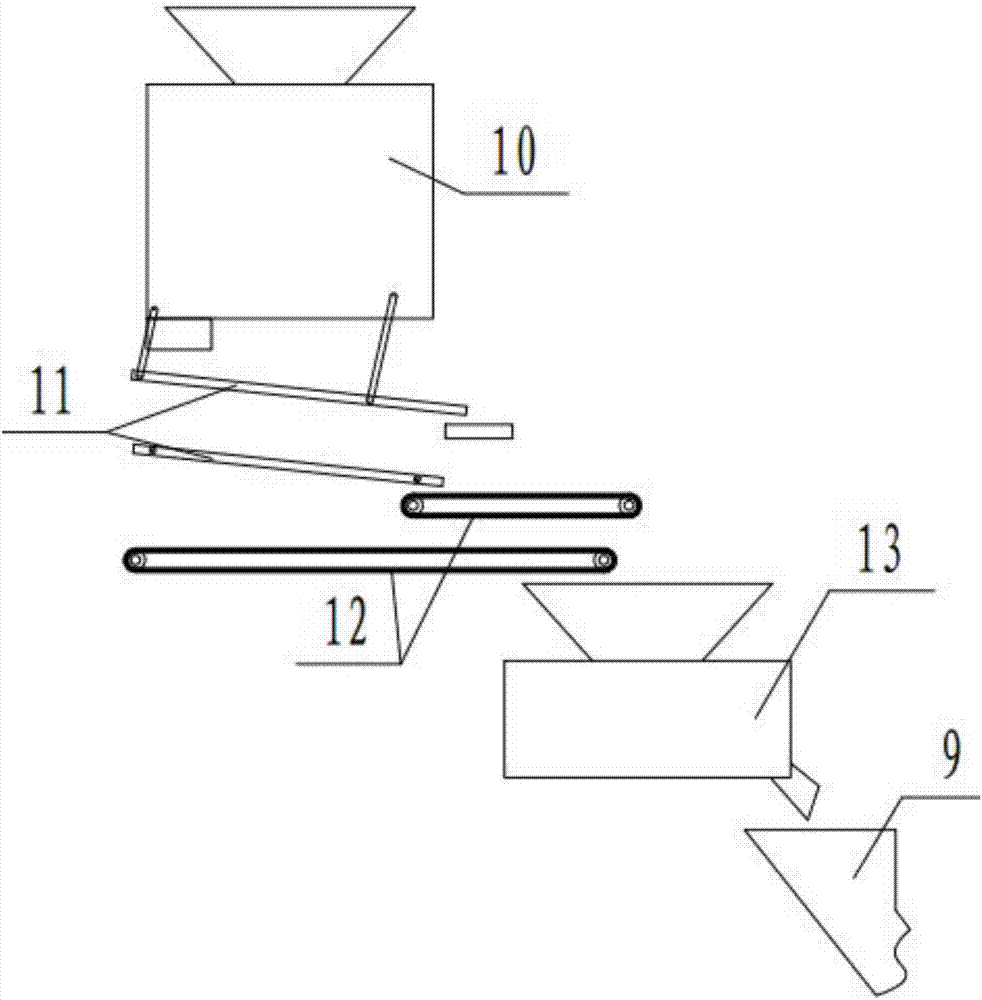

[0032] Embodiment 1: as Figure 1-Figure 4As shown, a low bed pressure reorganization fluidized bed for burning ultra-low calorific value fuel includes a furnace 1, an isobaric air chamber 2 is arranged below the furnace 1, and is communicated with the isobaric air chamber 2 through a small air cap air distribution plate 3 , a high-level buried pipe 4 is arranged above it, and a volute separator 5 is arranged at the flue gas outlet. The volute separator 5 is connected to the furnace return material port 7 through a selective U-shaped return material A discharge pipe 8 is also provided on one side of the feeder 6, a crushing device 10 is provided at the feeding port 9 of the furnace 1, and the outlet of the crushing device 10 is provided with an upper and lower double-layer screening plate 11. 6mm and 4mm respectively, the outlet of the lower screening plate 11 and the lower part are respectively connected to the agitator 13 through two weighing belt feeders 12, and the outlet ...

Embodiment 2

[0042] Embodiment 2: A method for using a low-bed pressure reorganized fluidized bed fueled with ultra-low calorific value fuel, including the above-mentioned low-bed pressure reorganized fluidized bed fueled with ultra-low calorific value fuel, the method includes: The chamber is set as an isobaric air chamber. The inlet medium of the air chamber is blended with natural air and tail flue gas with a specific gravity of less than 30%. Coal slime or sludge is added from the top of the furnace. The feed port is added to the air distribution plate of the small air cap at the lower part of the fluidized bed. The particle diameter of the extremely low calorific value fuel passes through the crushing device with a double-layer screening plate. After crushing and screening, the particle diameter is 0-6mm, of which the particle diameter is less than 4mm The ratio is greater than 80%, the particle diameter is 4-6mm, and the proportion is less than 20%, totaling 100%, because reducing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com