Power and heat co-supply system based on Stirling engine and power and heat co-supply method of system

A technology of cogeneration and heat storage, which is applied in the direction of combustion methods, heat storage heaters, mechanical equipment, etc., can solve the problems of large fluctuations in power output, unstable residence time, and unstable fuel volume, etc., and achieve power output quality Stability, reduced fly ash carrying amount, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

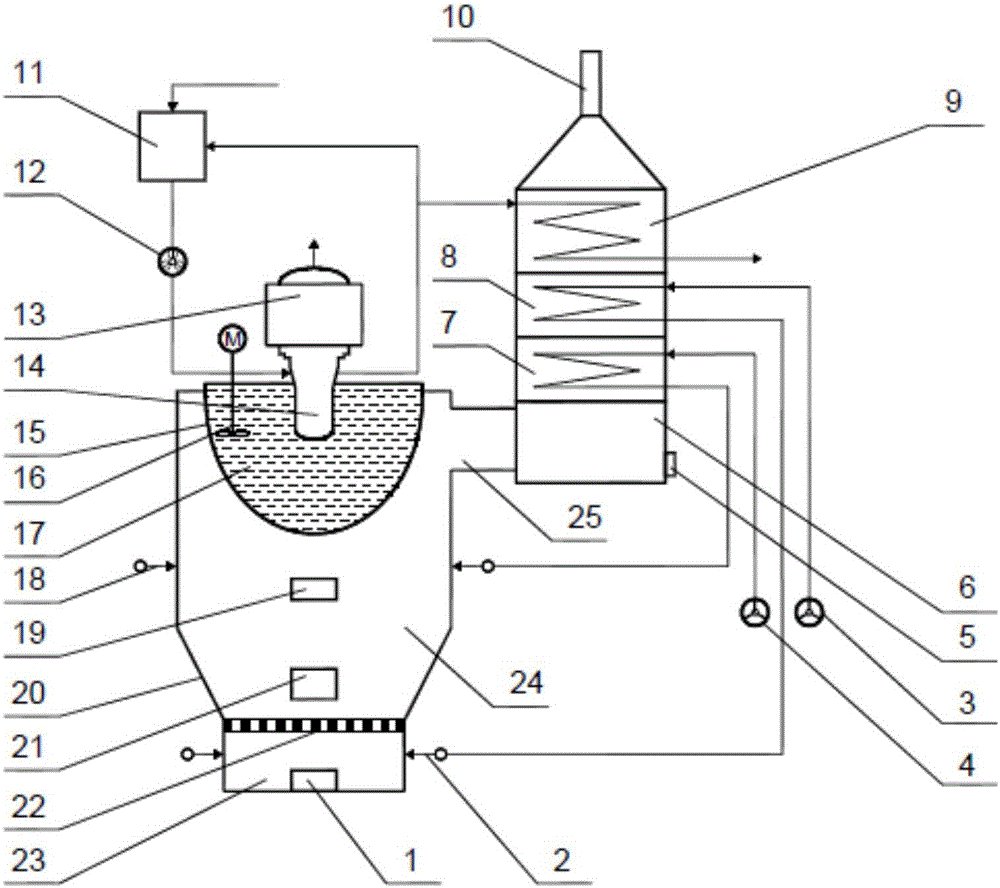

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1As shown, a cogeneration system based on a Stirling machine includes a primary fan 3, a secondary fan 4, an ash collection chamber 6, a secondary air air preheater 7, a primary air air preheater 8, and a coal-saving Device 9, exhaust pipe 10, water tank 11, circulating water pump 12, Stirling machine 13, heat storage pot 15, stirring device 16, combustion furnace 20 and flue 25; combustion furnace 20 includes primary tuyere 2, secondary tuyere 18 , Hearth 24, fire grate 22 and slag collecting chamber 23. The heat storage pot 15 is set on the top of the furnace 24; the fire grate 22 is set on the bottom of the furnace 24; the slag collection chamber 23 is set on the bottom of the fire grate 22; 21 and observation window 19. The top of the side wall of the furnace 24 communicates with the side wall of the ash collection chamber 6 through the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com