Fluidization-suspending two-stage type compound combustion device

A combustion device, a two-stage technology, is applied in the direction of fluidized bed combustion equipment, fuel burning in a molten state, combustion chamber, etc., to achieve the effect of intensifying combustion, sufficient combustion, and reducing the generation of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

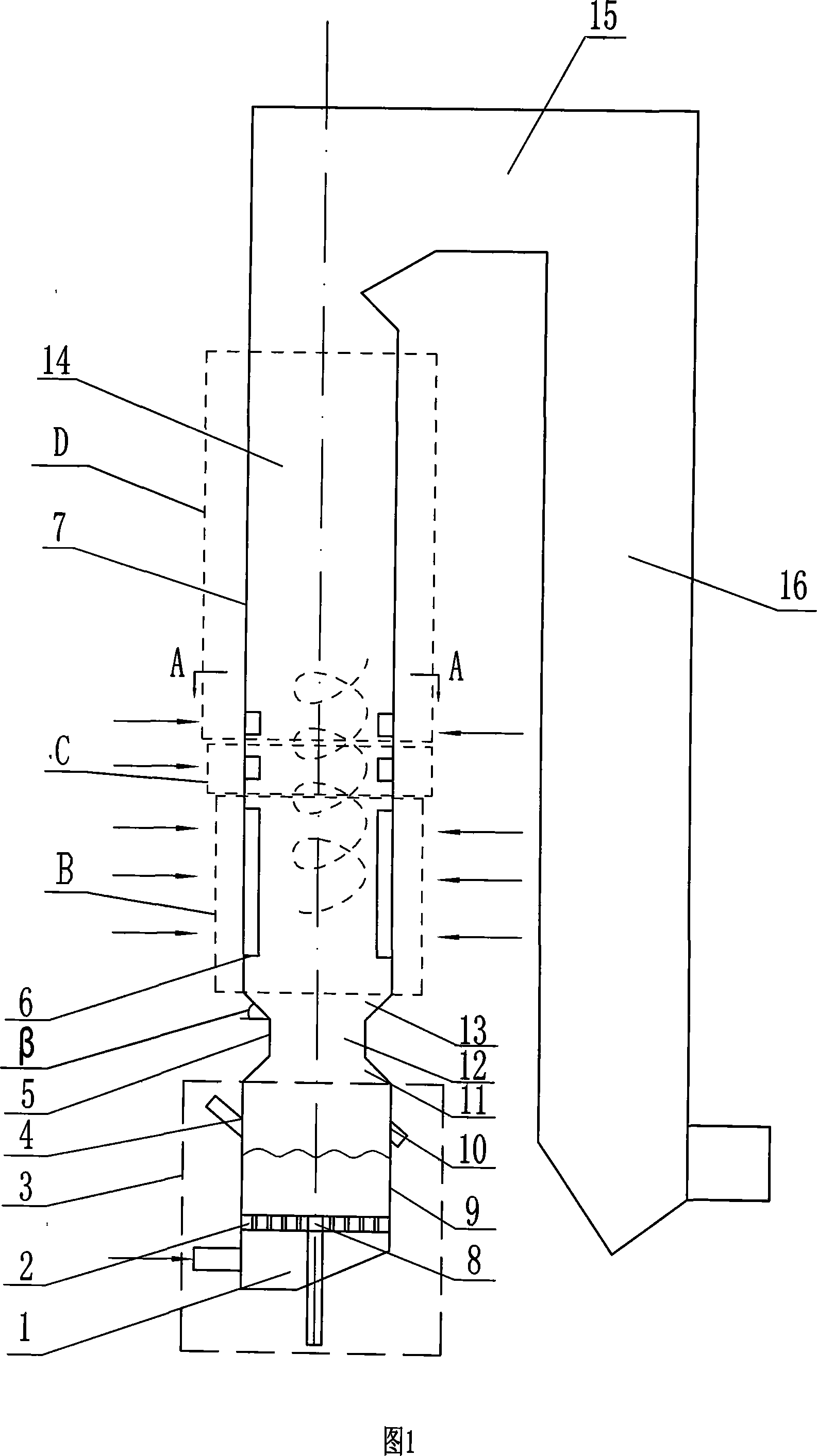

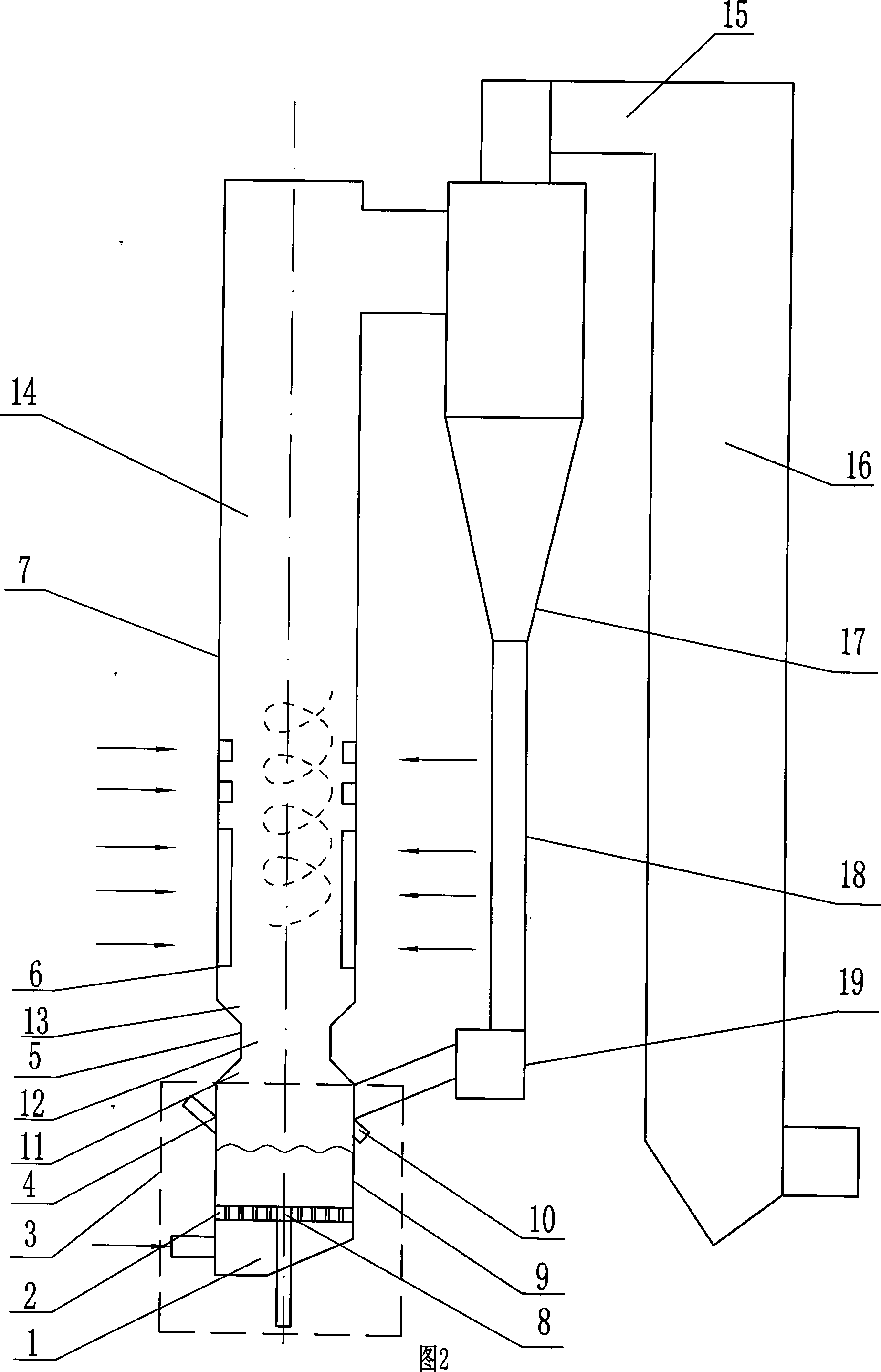

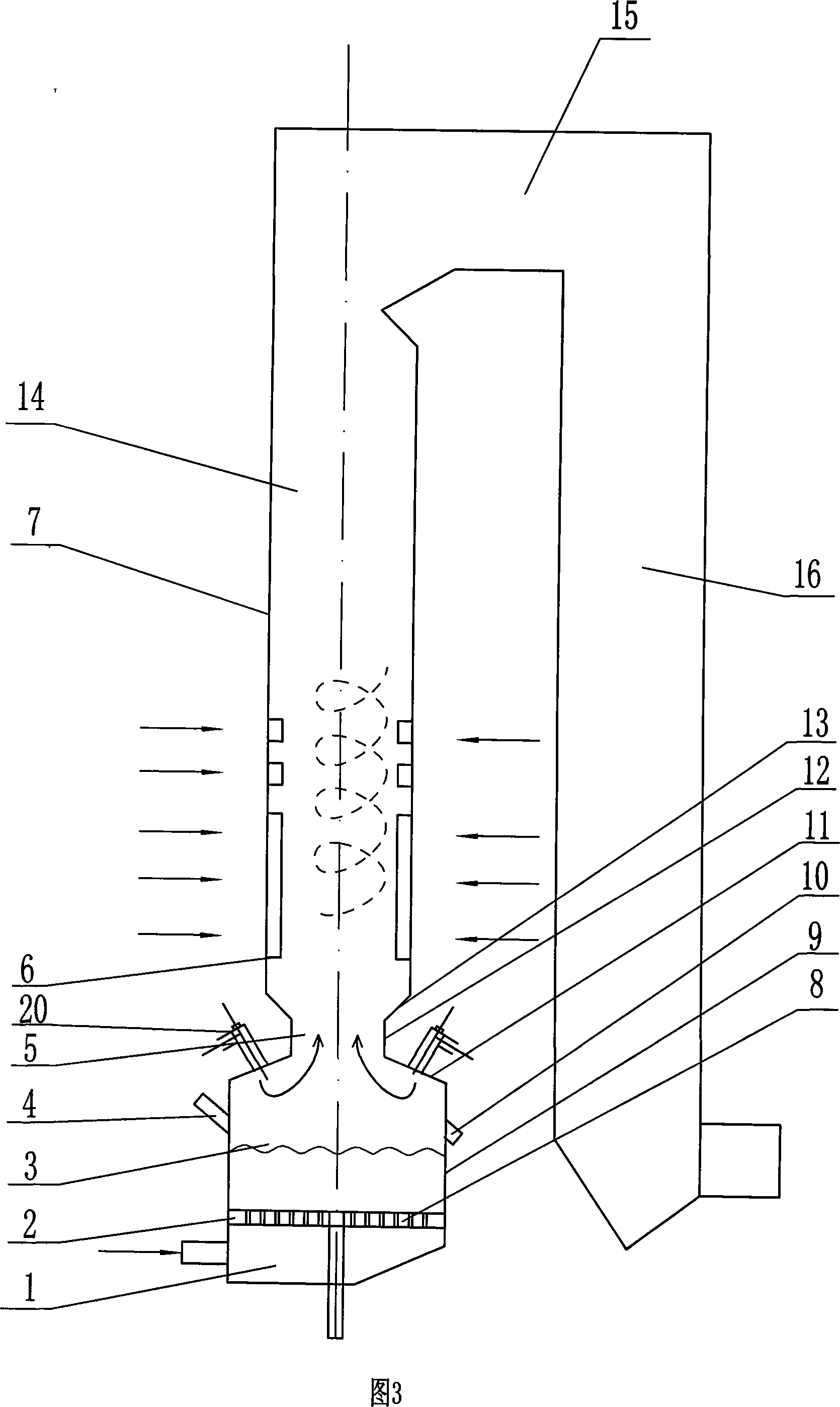

[0008] Embodiment 1: As shown in Figure 1, the fluidized-suspension two-stage composite combustion device of this embodiment consists of a bubbling fluidized bed low-temperature combustion chamber 3, a high-temperature vortex suspension combustion chamber 7, a variable-diameter section chamber body 5, Composed of horizontal flue 15 and tail flue 16, the high-temperature vortex suspension combustion chamber 7 is located above the bubbling fluidized bed low-temperature combustion chamber 3, and the lower end of the high-temperature vortex suspension combustion chamber 7 is connected to the bubbling fluidized-bed low-temperature combustion chamber 3 The upper end of the upper end communicates with the chamber body 5 through the variable diameter section, the lower end of the high-temperature vortex suspension combustion chamber 7 communicates with one end of the horizontal flue 15, and the other end of the horizontal flue 15 communicates with the upper end of the tail flue 16.

[...

specific Embodiment approach 2

[0010] Specific embodiment two: As shown in Figure 1, the variable diameter section chamber body 5 in this embodiment is composed of a tapered section chamber body 11, a constant diameter section chamber body 12, and a gradually expanding section chamber body 13. The upper end of the chamber body 11 is affixed to the lower end of the chamber body 13 of the expanding section through the chamber body 12 of the constant diameter section. The variable-diameter chamber body 5 is mainly used to separate the bubbling fluidized bed low-temperature combustion chamber 3 and the high-temperature vortex suspension combustion chamber 7 into two relatively independent combustion spaces, organize the flue gas flow after the bubbling fluidized bed combustion, and increase The residence time of the particles, and the formation of a drop channel for the large slag generated by suspended combustion. The cross section of the variable diameter section chamber body 5 can be rectangular, square, cir...

specific Embodiment approach 3

[0011] Embodiment 3: As shown in FIG. 1 , the angle β formed between the chamber body 13 of the expanding section and the horizontal plane in this embodiment is greater than or equal to the angle of repose of the flow of slag particles. By changing the angle and size of the chamber body 5 of the reducing section, it can meet the needs of burning different fuels in the upper and lower parts. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com