Through-flow type narrow-clearance integral condensation hot-water boiler

A hot water boiler, narrow gap technology, applied in fluid heaters, air heaters, lighting and heating equipment, etc., can solve the problems of complex structure, increased maintenance and repair difficulty, etc., to improve the condensation rate, simple structure, reduce The effect of pollution in the small environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

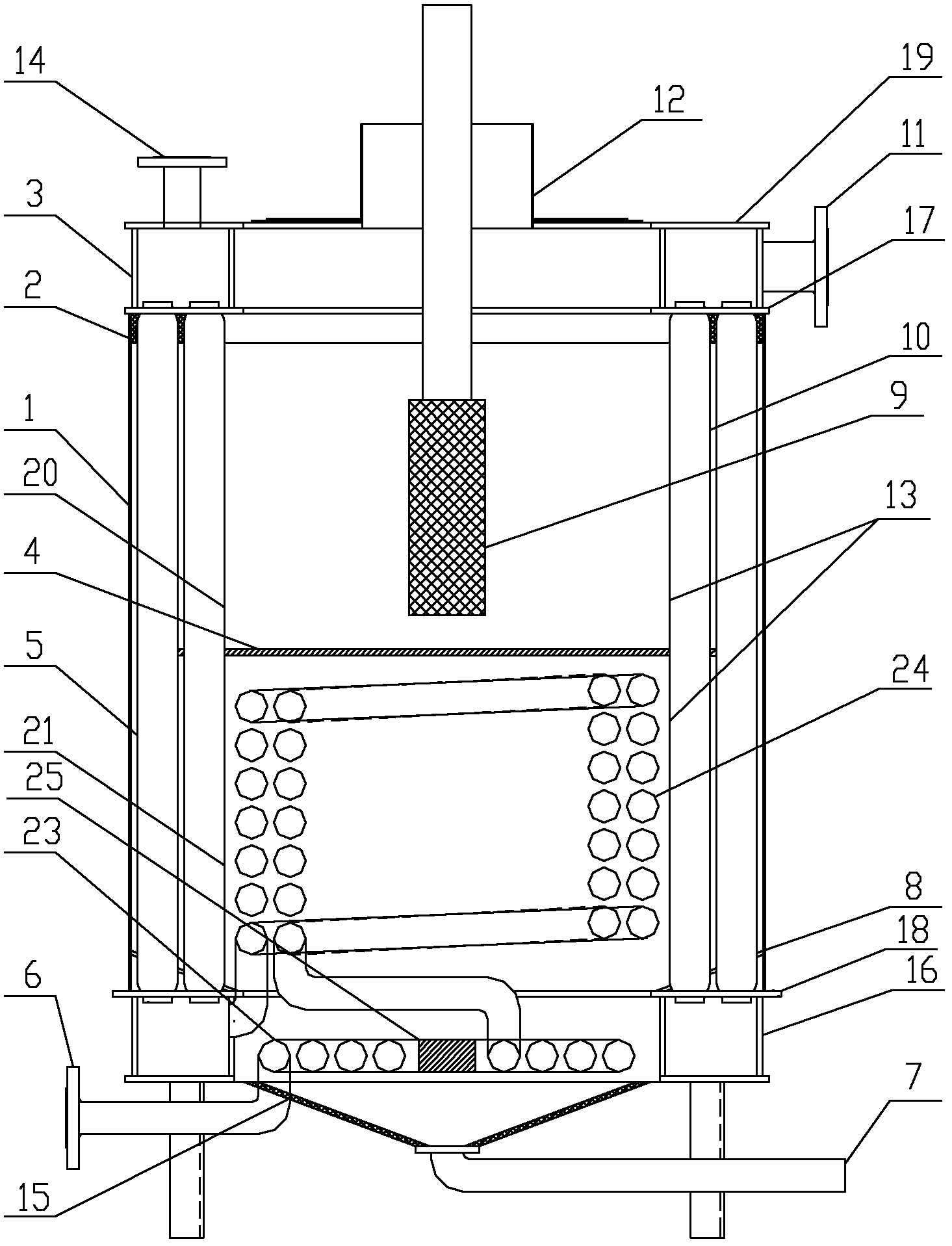

[0026] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

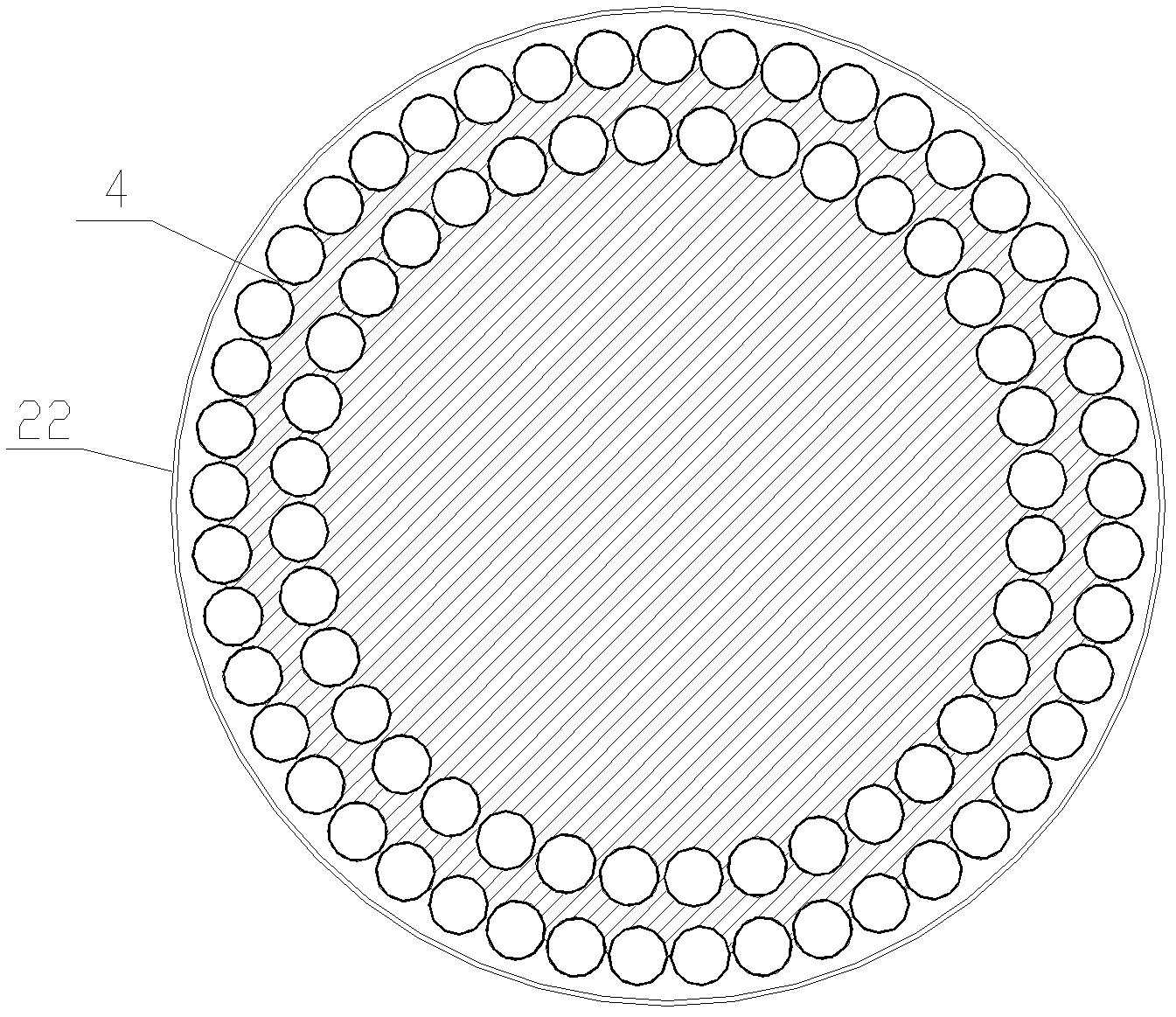

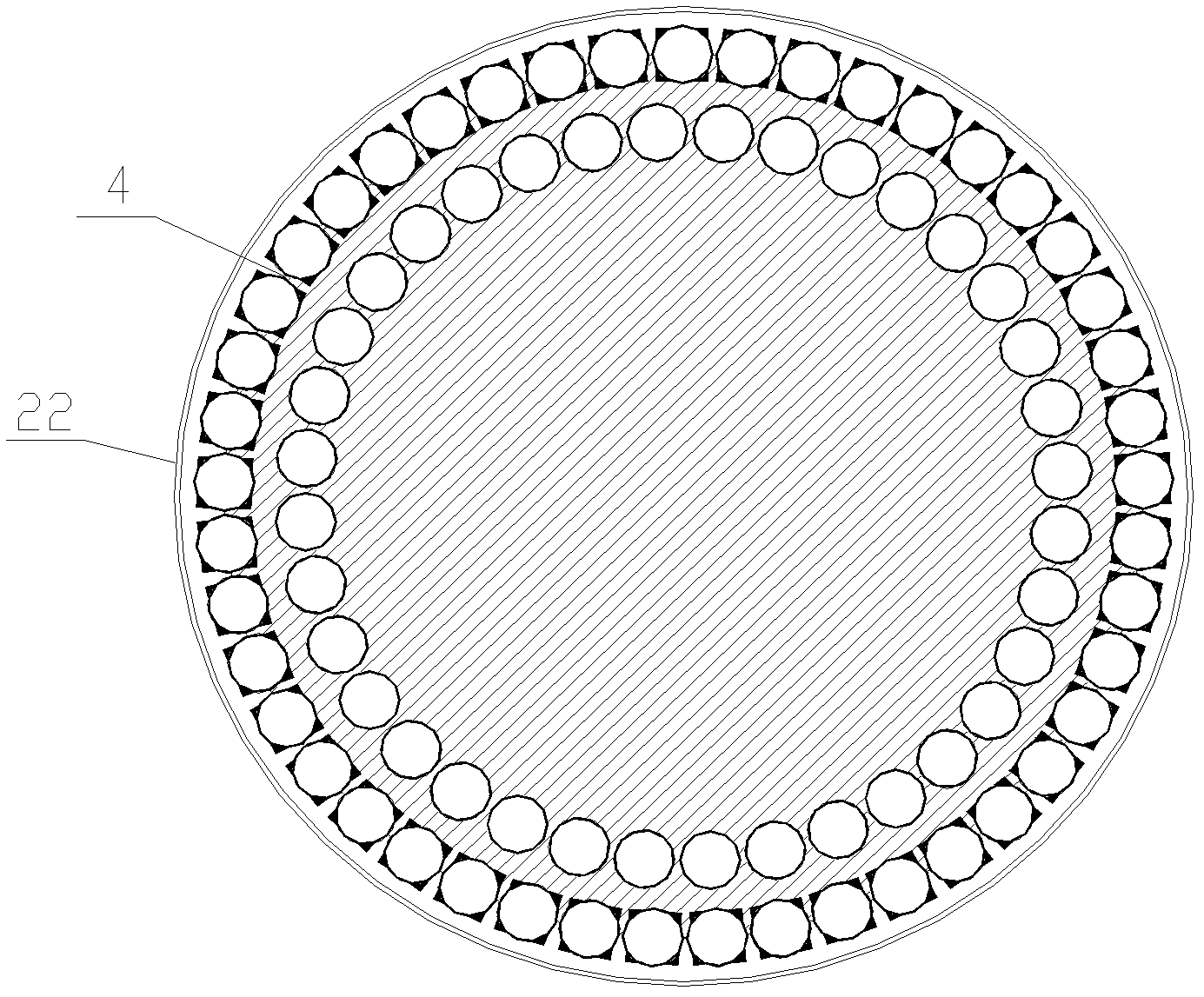

[0027] like figure 1, as shown in Fig. 2, the through-flow type narrow-gap integral condensing hot water boiler of the present invention comprises a shell 1, and inside the shell 1, a plurality of outer ring vertical water pipes are sequentially arranged to form an outer ring annular water cooling wall 5, and the outer ring vertical A plurality of vertical water pipes in the inner circle arranged at intervals of the straight water pipes form the inner ring water-cooled wall 10 in sequence, and the inner ring water-cooled wall 10 surrounds and forms the furnace space 13, and the furnace space 13 is divided into the furnace radiation exchange by the partition plate 4. The heat space 20 and the smoke exhaust chamber 21, the lower end of the outer annular water cooling wall 5 and the inner annular water cooling wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com