Oscillating mechanical fire grate used for lamellated decoupling burning furnace

A reciprocating swing, mechanical grate technology, applied in the direction of shaking grate, combustion method, combustion equipment, etc., can solve the problems of insufficient environmental protection stability, difficult operation, large footprint, etc., to improve boiler efficiency and environmental protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

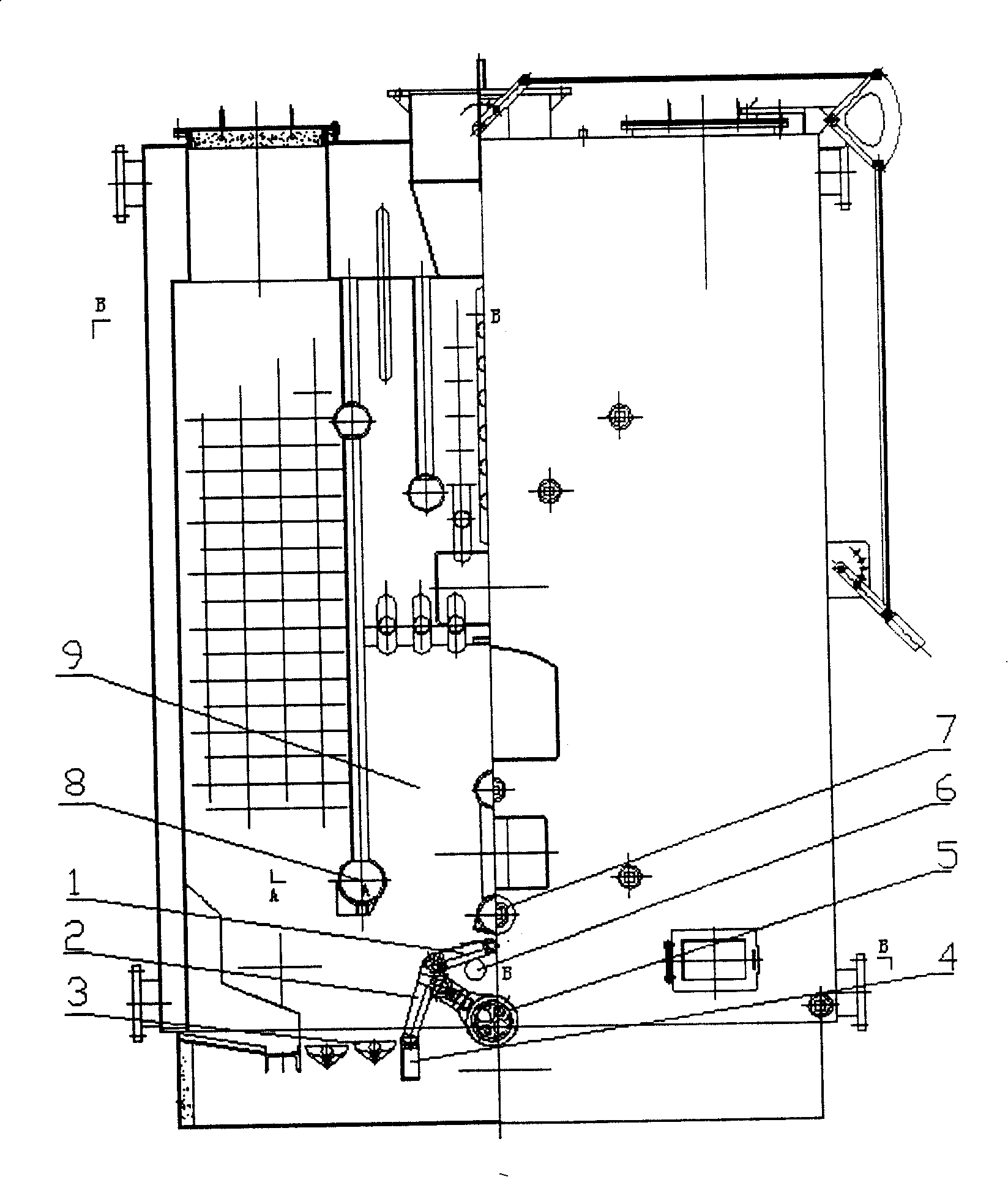

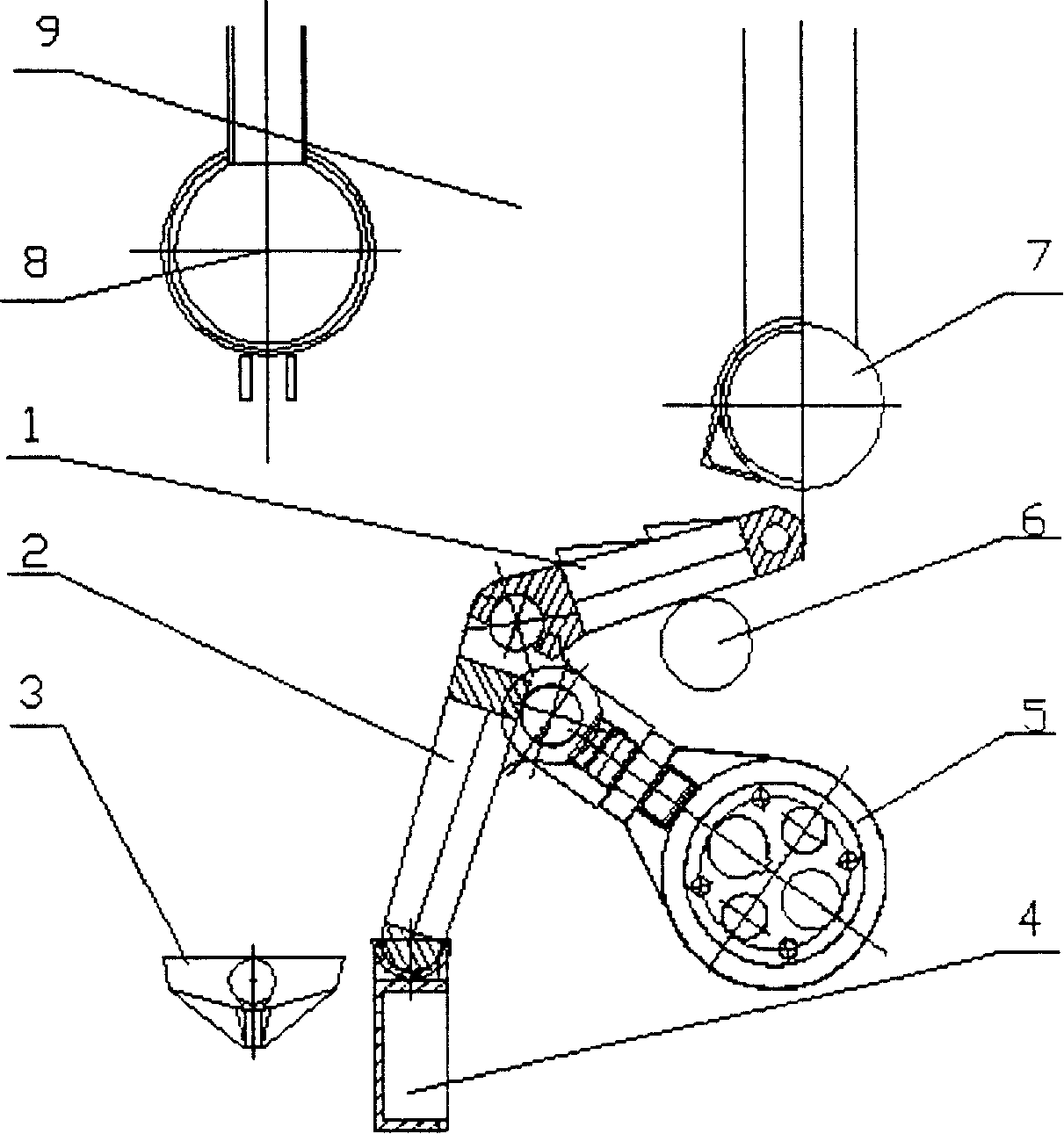

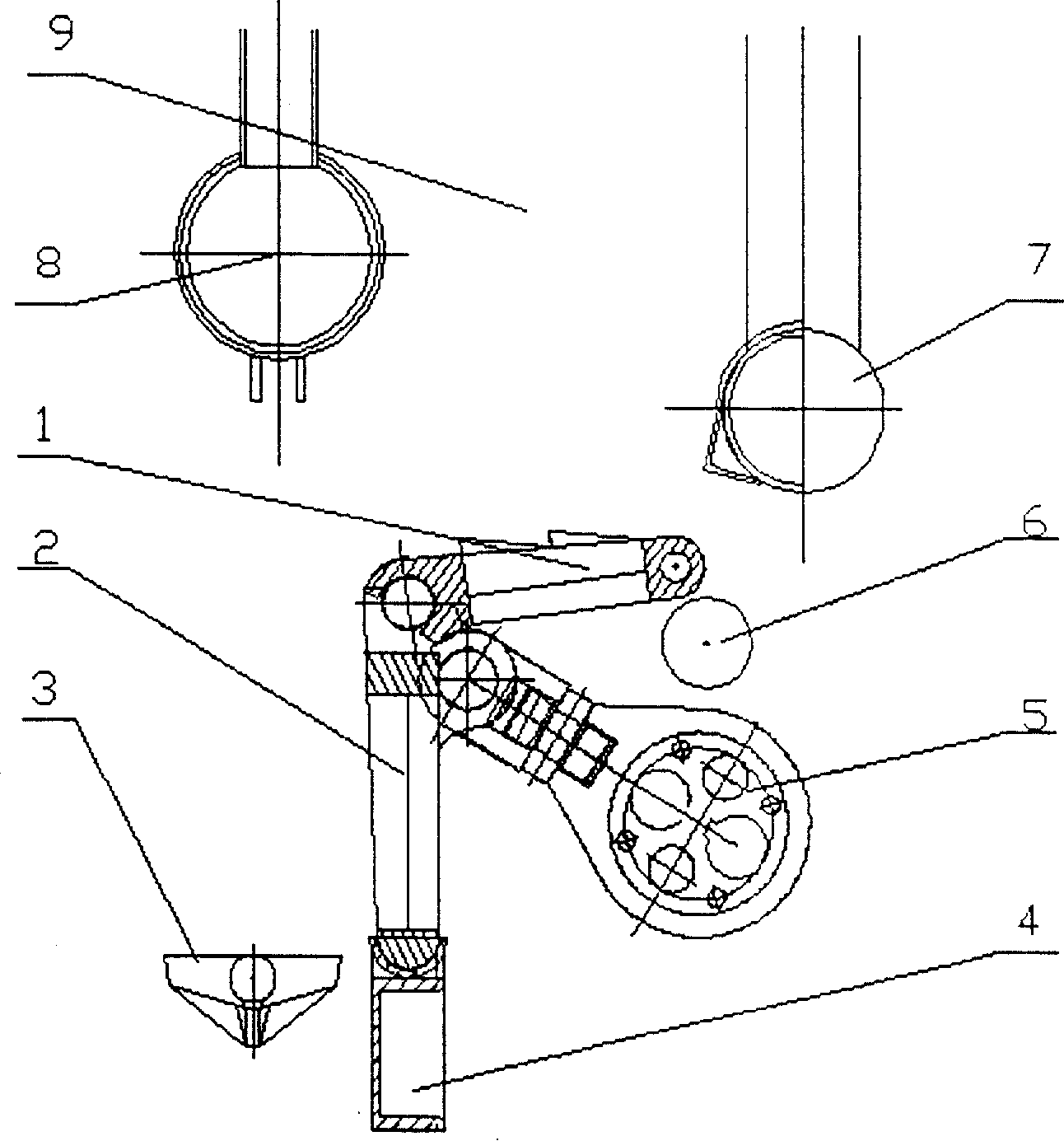

[0028] Depend on figure 2 and image 3 It can be seen that the reciprocating swing mechanical grate for layered decoupling combustion furnaces provided by the present invention includes: a reciprocating upper grate 1, a swinging lower grate 2 and a lower grate 3;

[0029] Both the reciprocating upper grate 1 and the swinging lower grate 2 are plate-shaped grates with a grating structure, and the left end of the reciprocating upper grate 1 is lapped on the upper end of the swinging lower grate 2; the reciprocating upper grate The right end of grate 1 is supported and connected by support rod 6;

[0030] The lower end of the swing-type lower grate 2 is supported and connected by the support beam 4, the lower end surface of the swing-type lower grate 2 is connected with the transmission mechanism 5, and driven by the transmission mechanism 5, the upper part of the support beam 4 is used as the center. Alternate reciprocating swing clockwise and counterclockwise; the included s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com