Smoke recirculator for boiler

A flue gas recirculation and recirculation technology, applied in the transportation of non-flammable liquid/gas, combustion method, indirect carbon dioxide emission reduction, etc. To achieve the effect of optimizing the structure of the flue system, improving the overall efficiency, improving the stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

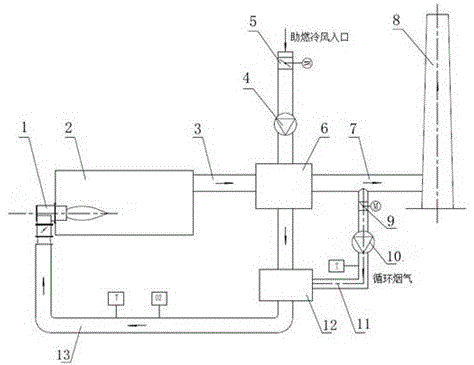

[0014] refer to figure 1 , a flue gas recirculation device for boilers, including burner 1, fuel gas boiler 2, boiler rear flue 3, blower 4, air control valve 5, air preheater 6, air preheater rear flue Road 7, chimney 8, flue gas circulation control valve 9, recirculation fan 10, recirculation flue gas pipe 11, flue gas air mixing chamber 12 and air duct 13. The burner 1 is installed on the fuel gas boiler 2, the fuel gas boiler 2 is connected to the air preheater 6 through the boiler rear flue 3, one end of the air preheater rear flue 7 is connected to the air preheater 6, and the other end is connected to the chimney 8 connections, the air control valve 5 is set at the combustion-supporting cold air inlet of the flue gas recirculation air channel, which can control the volume of recirculated flue gas and the volume of mixed air, and the blower 4 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com