Method for improving environment of furnace top area of coke oven

A furnace top and coke oven technology, which is applied to the heating of coke ovens, coke ovens, coke oven parts and other directions, can solve problems such as difficulty in ensuring safe and stable coke oven production and operation, solve the problems of safety and environmental protection risks, and improve the working environment. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

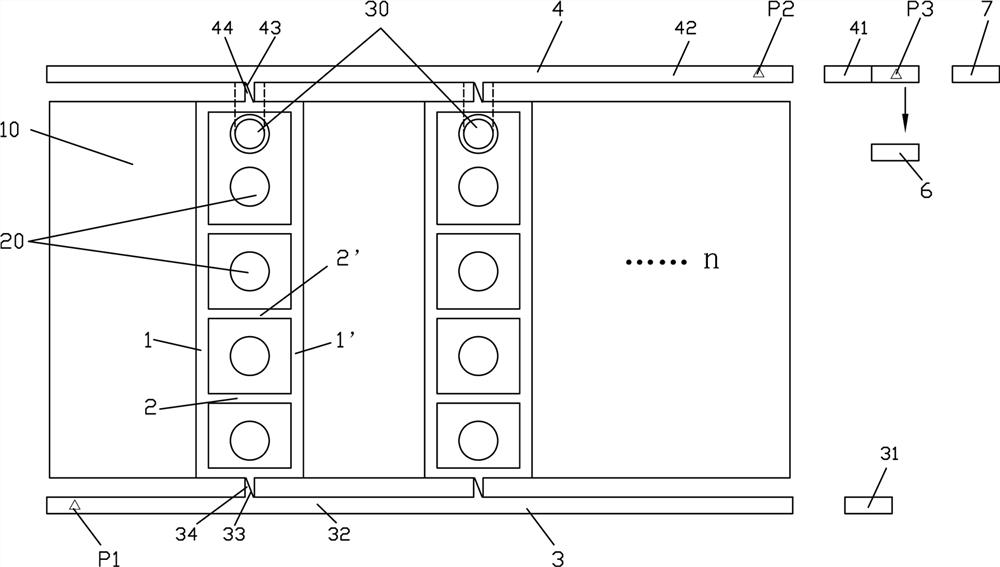

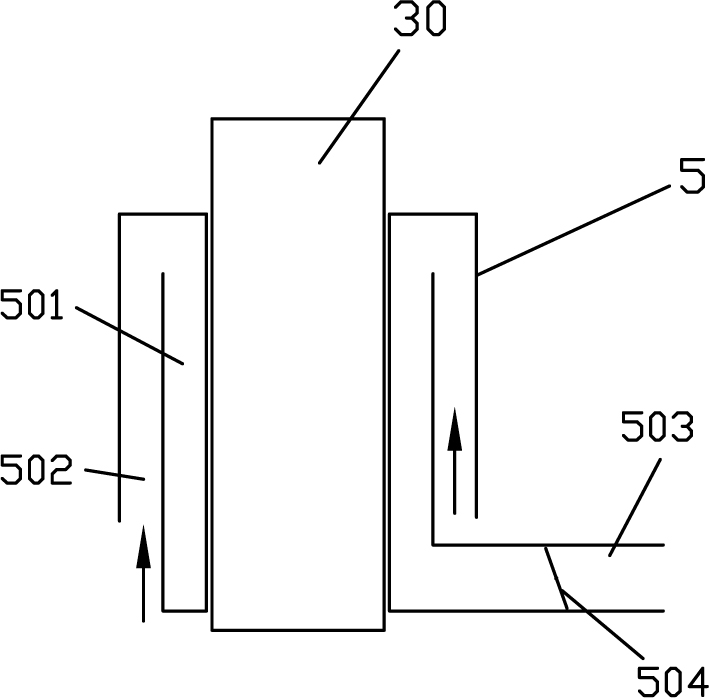

[0034] see figure 1 , figure 2 , the method for improving the environment of the coke oven roof region of the present invention, the coke oven roof 10 faces along the tie ditch on both sides of the coal inlet 20 to set the tie ditch air duct 1, 1 ', and the two tie ditch air A number of connecting air passages 2 and 2' are arranged between the passages 1 and 1' to connect; the coke side of the coke oven roof 1 and the machine side are respectively provided with an air supply system 3 and a hot air collection system 4; wherein,

[0035]The air supply system 3 includes a blower 31, a cold air duct 32, a flow orifice on the coke side or an opening adjustment valve 33; 1. One end is connected to the cold air duct 32 through the coke-side connecting duct 34, and the air is supplied by the blower 31 to ensure that the air maintains positive pressure circulation in the air channel 1 and the connecting air channel 2 of the furnace top surface; the coke-side flow orifice plate Or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com