Louvered fins for heat exchanger

A heat exchanger and fin technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as insufficient heat exchange performance level and difficulty in adapting to belt thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

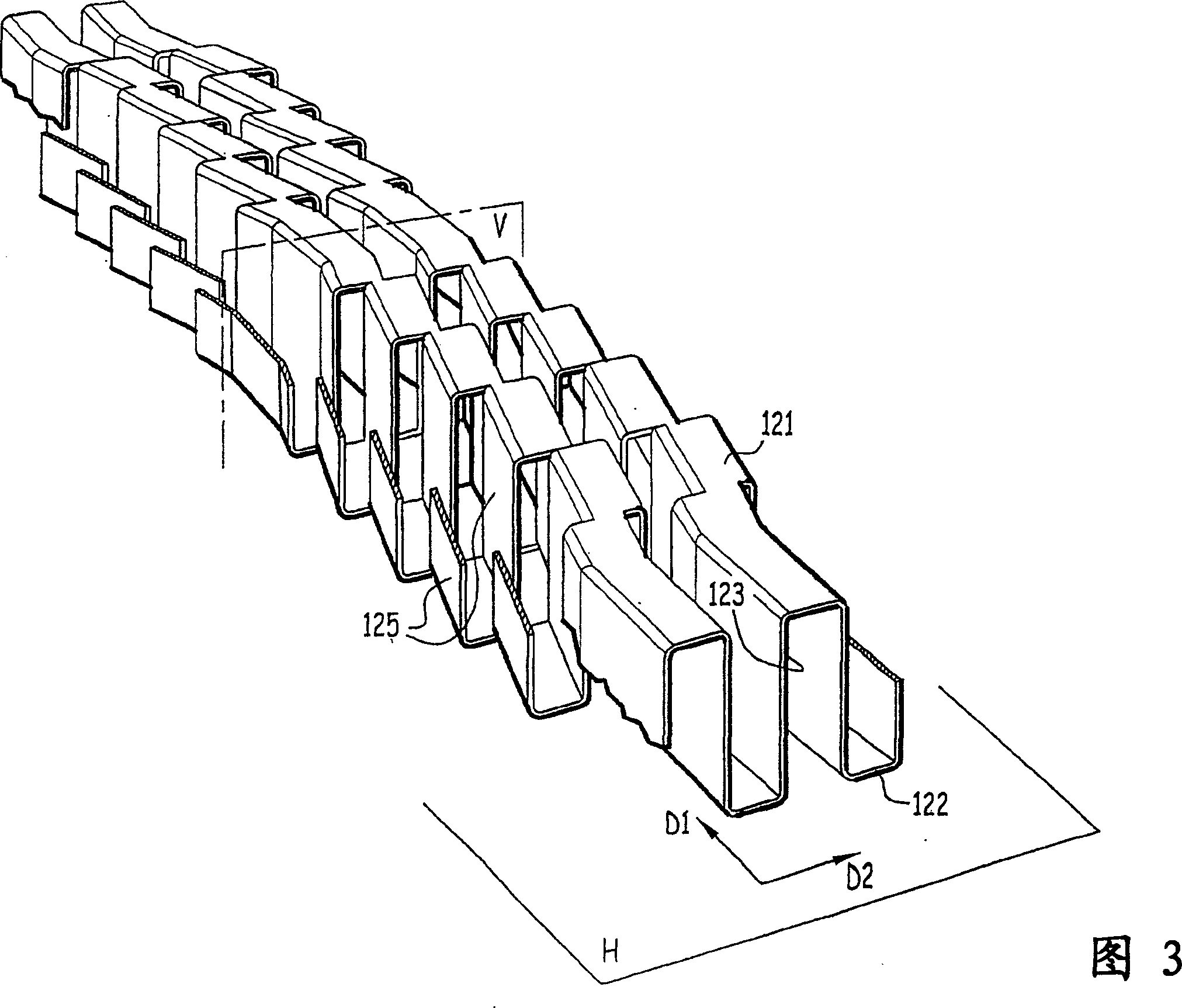

[0068] Figure 3 depicts a louvered corrugation according to the invention having a general main direction D1 of the corrugation and a cross-section in the form of a square wave ( Figure 4 ), the square wave thus defined extends along a direction D2 perpendicular to the direction D1. Here, for convenience of description, these two directions are also assumed to be horizontal directions.

[0069] The term "square wave" here means a succession, alternation of horizontal and vertical segments, the horizontal segments being aligned with each other.

[0070] The ribs have corrugated tops 121 defined by square wave crests, which are flat and horizontal. The ribs also have corrugated recesses 122 defined by square wave troughs, which are also flat and horizontal. Tops 121 and recesses 122 alternately connect corrugated flanks 123, which are vertical and flat, the mean planes of which extend perpendicular to direction D2.

[0071] Cut from the corrugated flanks 123 are a series of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com