Scroll compressor having a press-fitted motor and a vertically central suction inlet

A scroll compressor and suction port technology, applied in the field of scroll compressors, can solve the problems of increasing the manufacturing cost of the scroll compressor, complicating the assembly of the scroll compressor, etc., and achieve the effect of improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

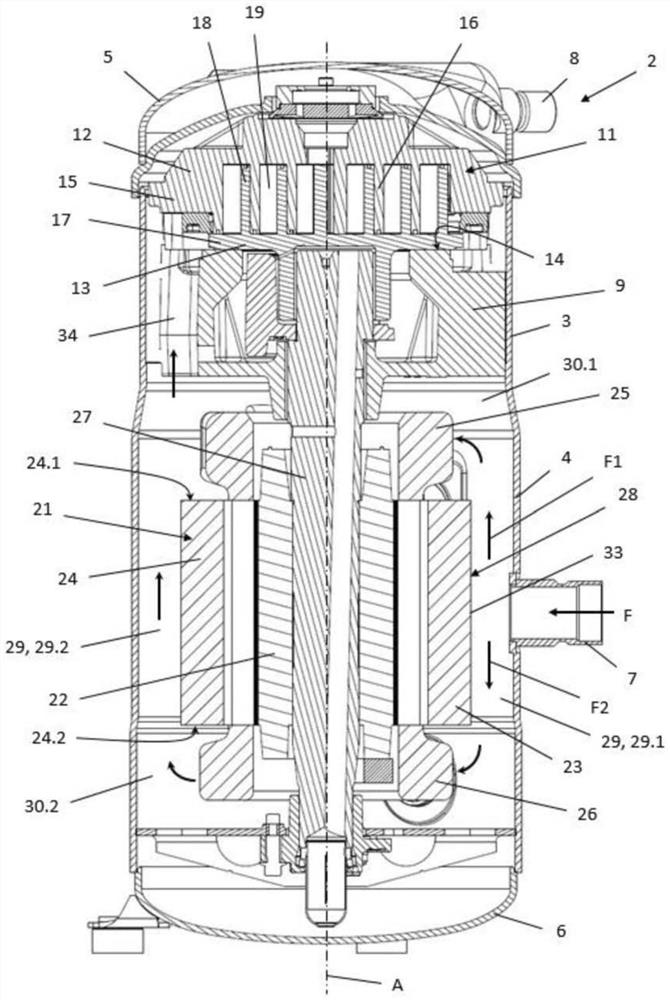

[0055] figure 1 The scroll compressor 2 is shown in a vertical position. However, the scroll compressor 2 according to the present invention can be in an inclined position or a horizontal position without significant modification of its structure.

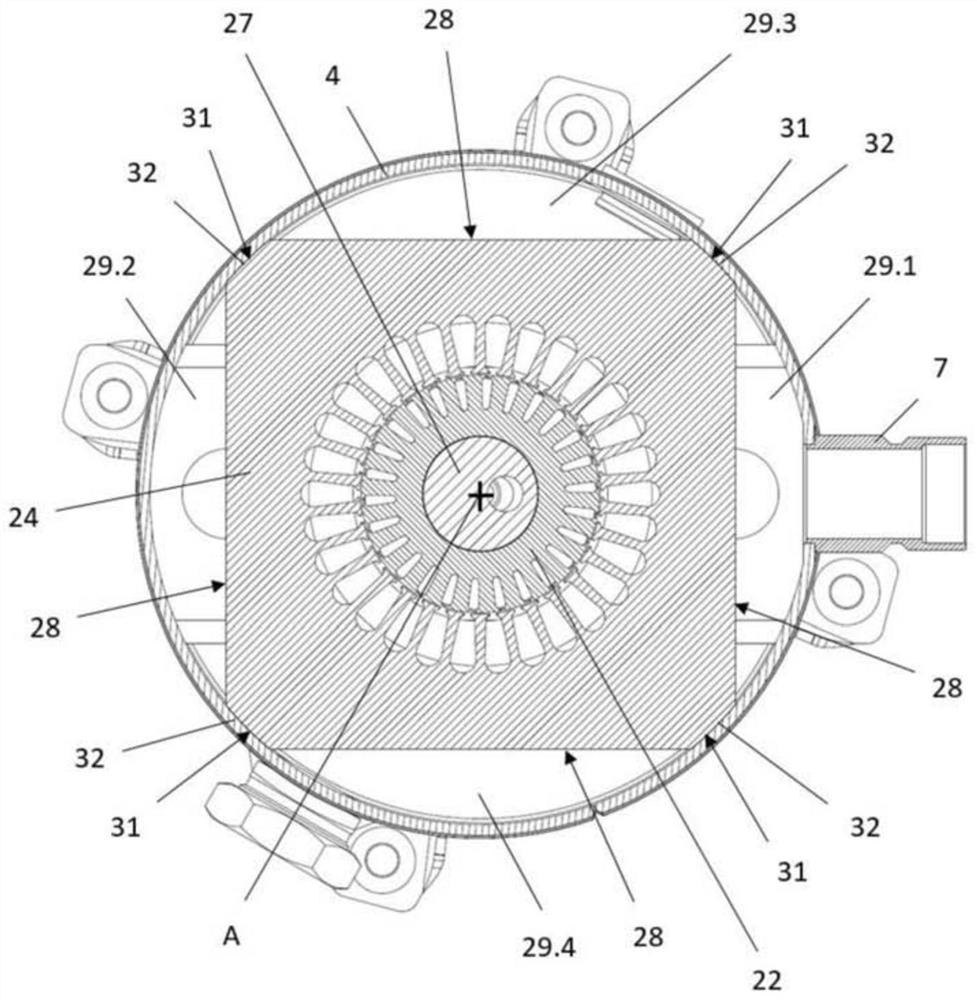

[0056] The scroll compressor 2 includes a hermetic casing 3 including a middle casing 4 , an upper cover 5 and a lower cover 6 . The intermediate housing 4 is substantially cylindrical and may have a constant outer diameter over the entire length of the intermediate housing 4 or a variable outer diameter along the length of the intermediate housing 4 .

[0057] The scroll compressor 2 also includes a suction port 7 configured to supply the scroll compressor 2 with refrigerant to be compressed, and a discharge port 8 configured to discharge the compressed refrigerant. Advantageously, the suction port 7 is provided on the middle housing 4 , while the discharge port 8 is provided on the upper cover 5 .

[0058] The scroll compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com