Heat exchanger

A technology of heat exchange device and exchange body, which is applied in heat exchange equipment, lighting and heating equipment, instruments, etc., can solve the problems of electronic emission element performance change, element performance change, unclear mechanism, etc., and achieve excellent heat exchange performance, The effect of suppressing the decrease in heat exchange performance and improving heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0062] Below, based on figure 1 or Figure 9 Embodiment 1 of the present invention will be described.

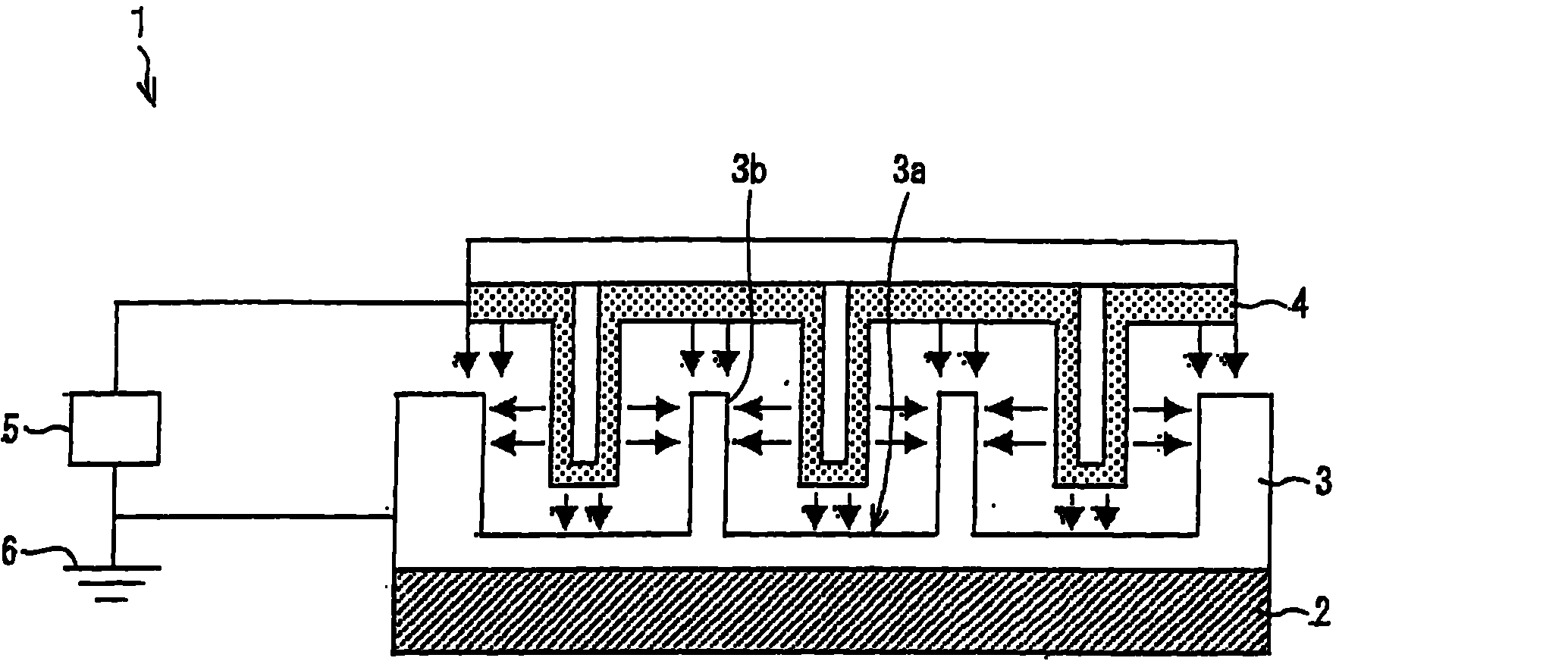

[0063] It should be noted that the structure described below is only a specific example of the present invention, and the present invention is not limited thereto. figure 1 It is a cross-sectional view of a preferable example of the heat generating body radiator (cooling device) 1 of this embodiment.

[0064] The heating element cooling device 1 is a device that radiates the heat emitted by the heating element 2 to the outside, and includes: a heat sink (heated exchange body) 3; an electron emission element 4; a power supply (second voltage applying unit) 5. The heat sink 3 is made of a conductive material and is in contact with the heating element 2 . Furthermore, the surface 3a of the fin 3 on the side opposite to the heating element 2 is in contact with air, and a plurality of protrusions 3b are formed in at least a part of the area. In addition, the electron emitting...

Embodiment 1

[0091] As an example, in the heating element cooling device of this embodiment, use Figure 4 as well as Figure 5 To illustrate the verification experiment of exothermic effect. In addition, this experiment is an example of implementation, and does not limit the content of this invention.

[0092] In this example, use Figure 4 Experiments were carried out on the heating element cooling device shown. exist Figure 4 A fan 14 is provided in the shown heat exchange device to deliver an air flow to the cooling fins 3 . The heating element 2 as a heat source has a structure to switch heat generation according to the on and off of the switch, and when the switch is turned off, the heating element does not generate heat. In this embodiment, the heating element 2 is turned off (opened) at the same time as the temperature measurement terminal 15 starts measuring the temperature. The temperature measurement terminal 15 measures the surface temperature of the heat sink 3 without ...

Embodiment approach 2

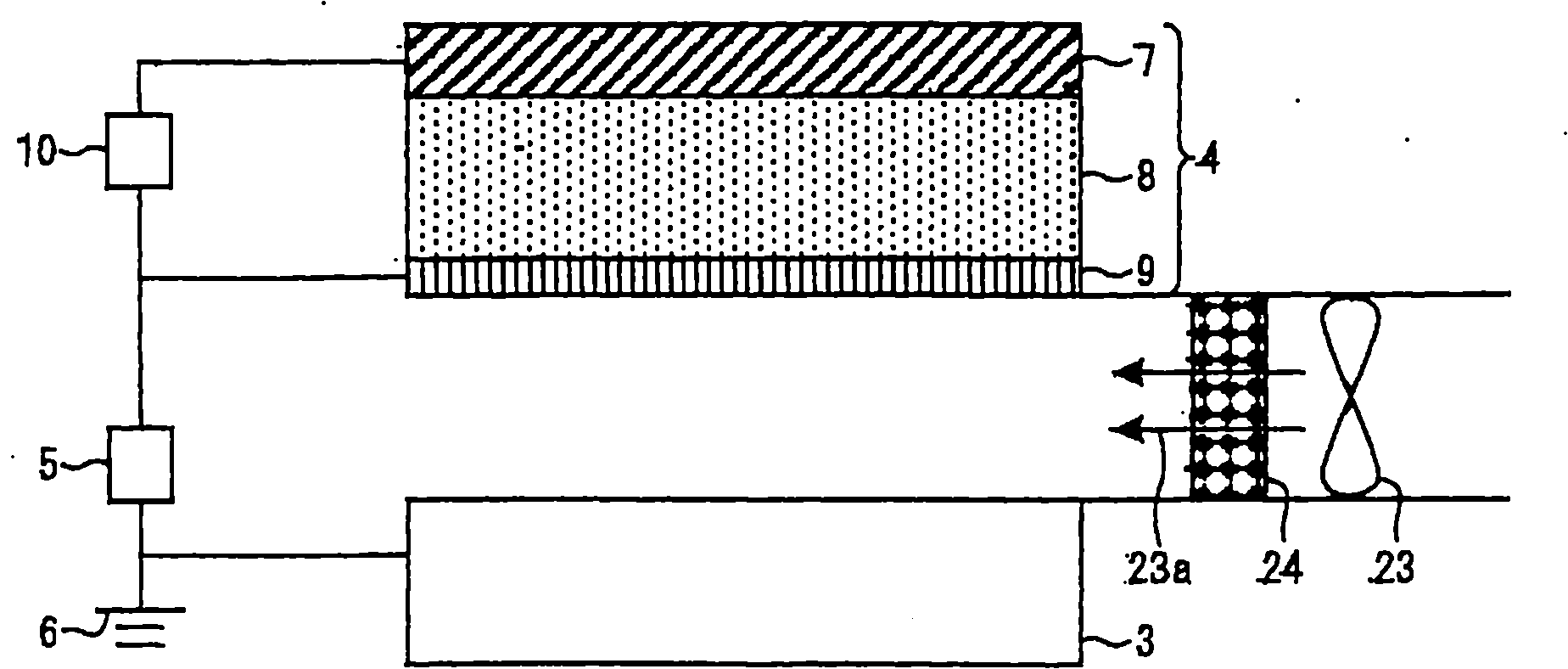

[0098] Regarding other embodiments of the present invention, according to Figure 6 Instructions are given below.

[0099] The basic driving concept of the heating element cooling device of this embodiment is the same as that of the above-mentioned first embodiment, and thus description thereof will be omitted. In the heating element heat dissipation device of this embodiment, the difference from the first embodiment lies in the structure of the electron emitting element. Figure 6 It is a figure which shows the structure of the periphery of an electron emission element in the heat sink heat sink of this embodiment.

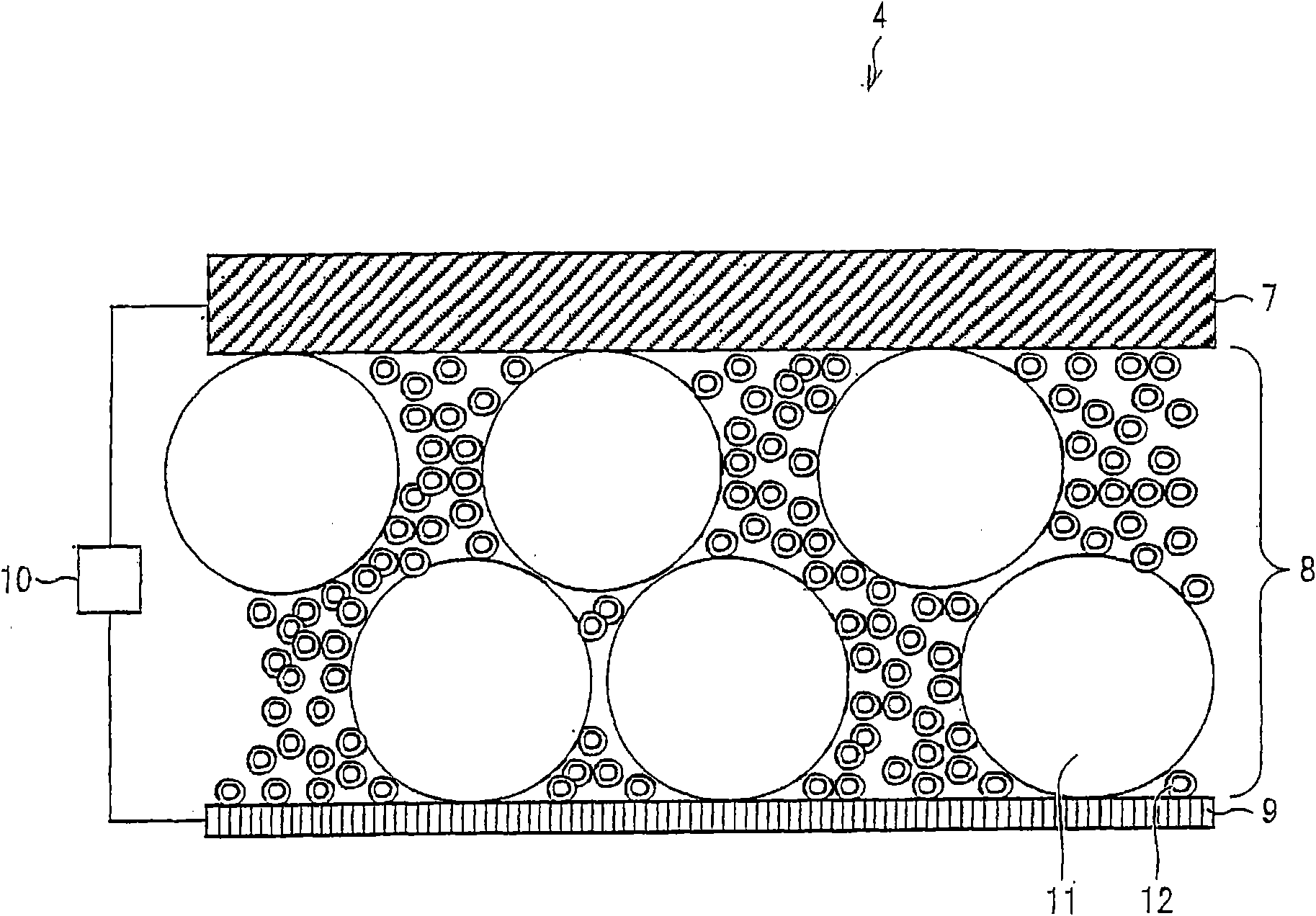

[0100] Such as Figure 6 As shown, the electron emitting element 16 is characterized by being flexible. The electron emission element 16 includes: a flexible base material 17 ; a substrate thin-film electrode 18 ; an electron acceleration layer 8 ; and a thin-film electrode 9 . The substrate film electrode 18 and the film electrode 9 are connected to a power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com