Serpentine heat exchanger for an air conditioner

A technology for air conditioners and heat exchangers, which can be used in heat exchange equipment, heat sinks, heat transfer modification, etc., and can solve problems such as difficult air conditioner heat exchangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

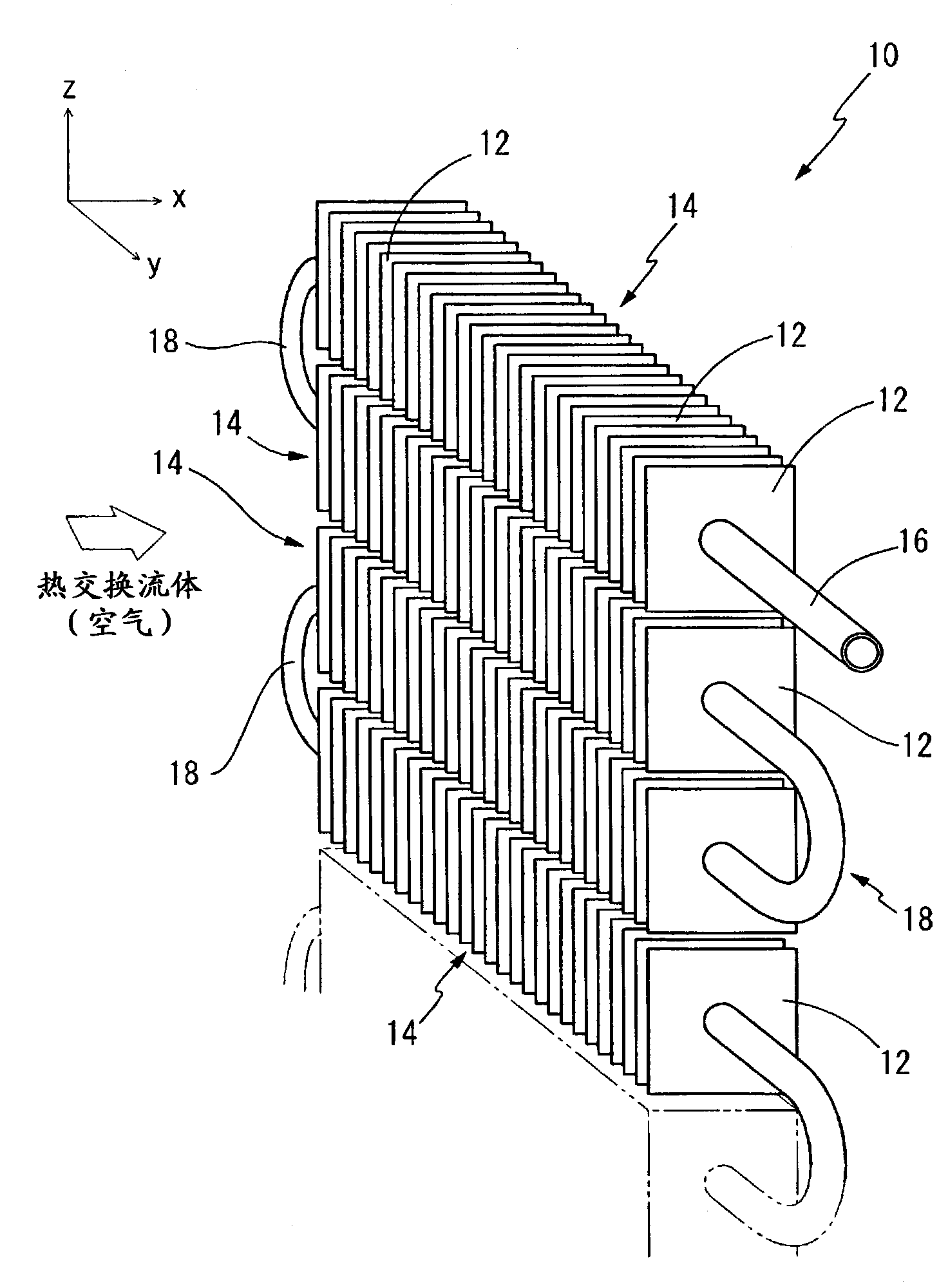

[0096] First, as the heat transfer tube for constituting the spiral heat exchanger for the air conditioner of the present invention, prepared is a material made of phosphorus-deoxidized copper, in which a plurality of inner surface grooves are formed as spiral grooves extending with a predetermined lead angle with respect to the tube axis. (JIS H3300 C1220) heat transfer pipe with grooves on the inner surface. The dimensions of the heat pipe with grooves on the inner surface are outer diameter: 6.35 mm, bottom wall thickness: 0.23 mm, groove depth: 0.15 mm, number of grooves: 58, and lead angle: 30°.

[0097] On the other hand, as a fin material, a plate material of pure aluminum (JIS A1050) with a plate thickness of 0.13 mm was prepared, and the surface of the fin material was subjected to the following steps: Figure 4 The surface treatment shown consists of 3 layers. That is, first, the chemical conversion coating 32 made of phosphochromate is formed on the surface of the ...

experiment example 2

[0109] Various spiral heat exchangers are produced as follows, that is, as the fin material, a plate of pure aluminum (JIS A1050) with a plate thickness of 0.12 mm is used, and a film thickness of 0.1 μm formed on the surface of the plate is made of phosphorus On the chemical conversion film (substrate treatment layer) made of chromate, a hydrophobic coating layer made of fluororesin, a hydrophilic coating layer made of polyurethane resin or The hydrophobic coating layer made of silicone resin, on the other hand, as the heat transfer tube, except that the inner surface grooved heat transfer tube made of phosphorus deoxidized copper (JIS H3300 C1220) with an outer diameter of 7.00 mm is used, which is different from the previous one. In the same manner as in Experimental Example 1, 16 fin groups with a fin pitch of 3.0 mm were arranged (the number of fins per one fin group was 100 sheets).

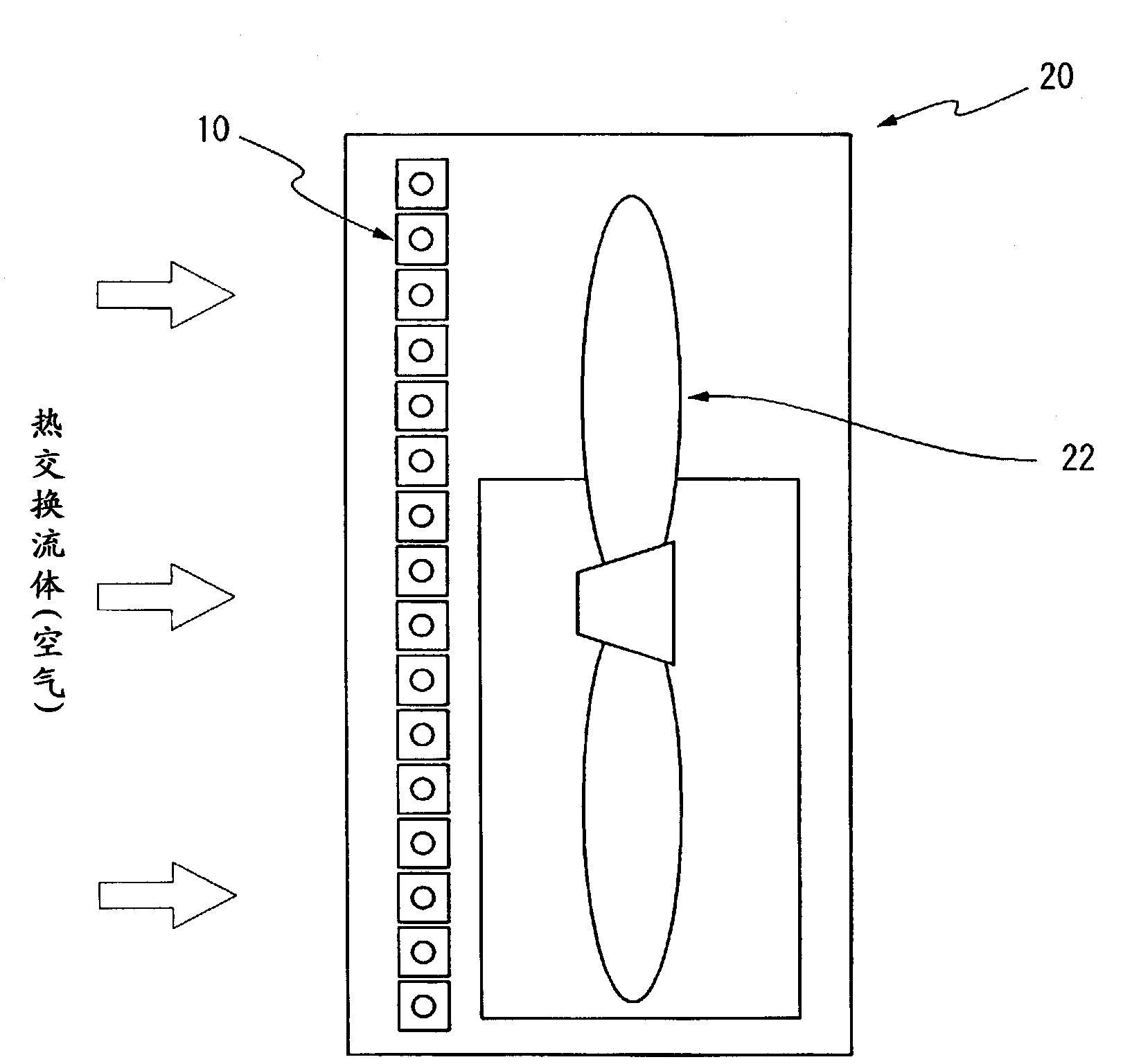

[0110] Next, the obtained various heat exchangers such as figure 2 It was fixed to a ...

experiment example 3

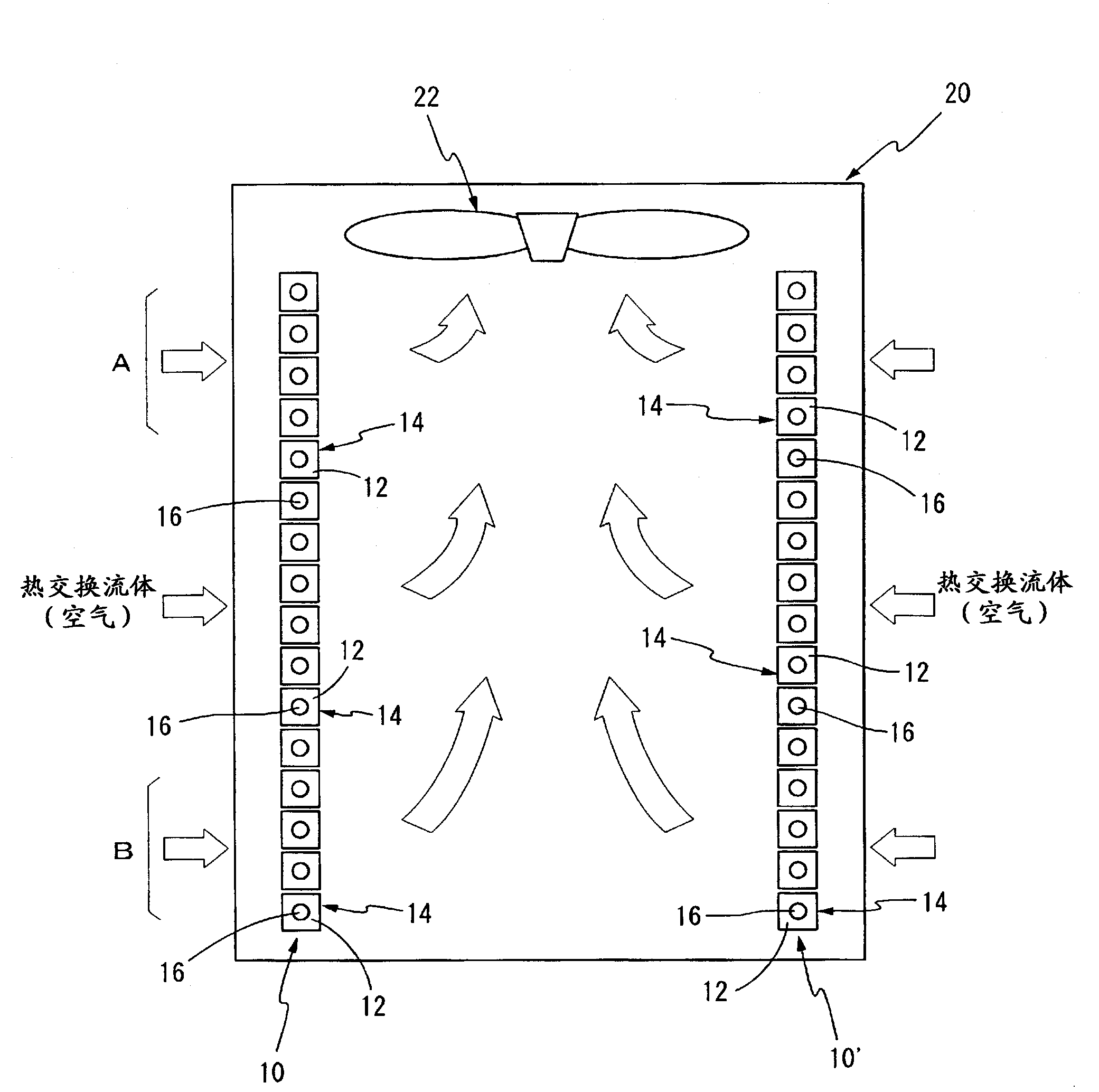

[0112] Made it as follows Figure 5 For the spiral heat exchanger of the shape shown, the fin material with the hydrophilic resin coating film formed on the surface and the heat transfer tube with grooves on the inner surface are prepared as in the above-mentioned Example 2, and the fin size is 12 mm. ×50mm (fin projection area is 600mm 2 ), with respect to one sheet of the fins running through two heat pipes. In addition, the pitch of fins, the number of fins, the number of layers of fin groups, and the like are the same as those of the heat exchanger of Example 2. Such a heat exchanger was fixed to a predetermined outdoor unit in the same manner as the heat exchanger of Example 2, and the presence or absence of splashing water and the heat exchange performance were checked. As a result, it was confirmed that good results were obtained in all of them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com