Heat exchanger and heat exchange method

A heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of excessive load, large-scale installation cost, etc. Effect of decrease in exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

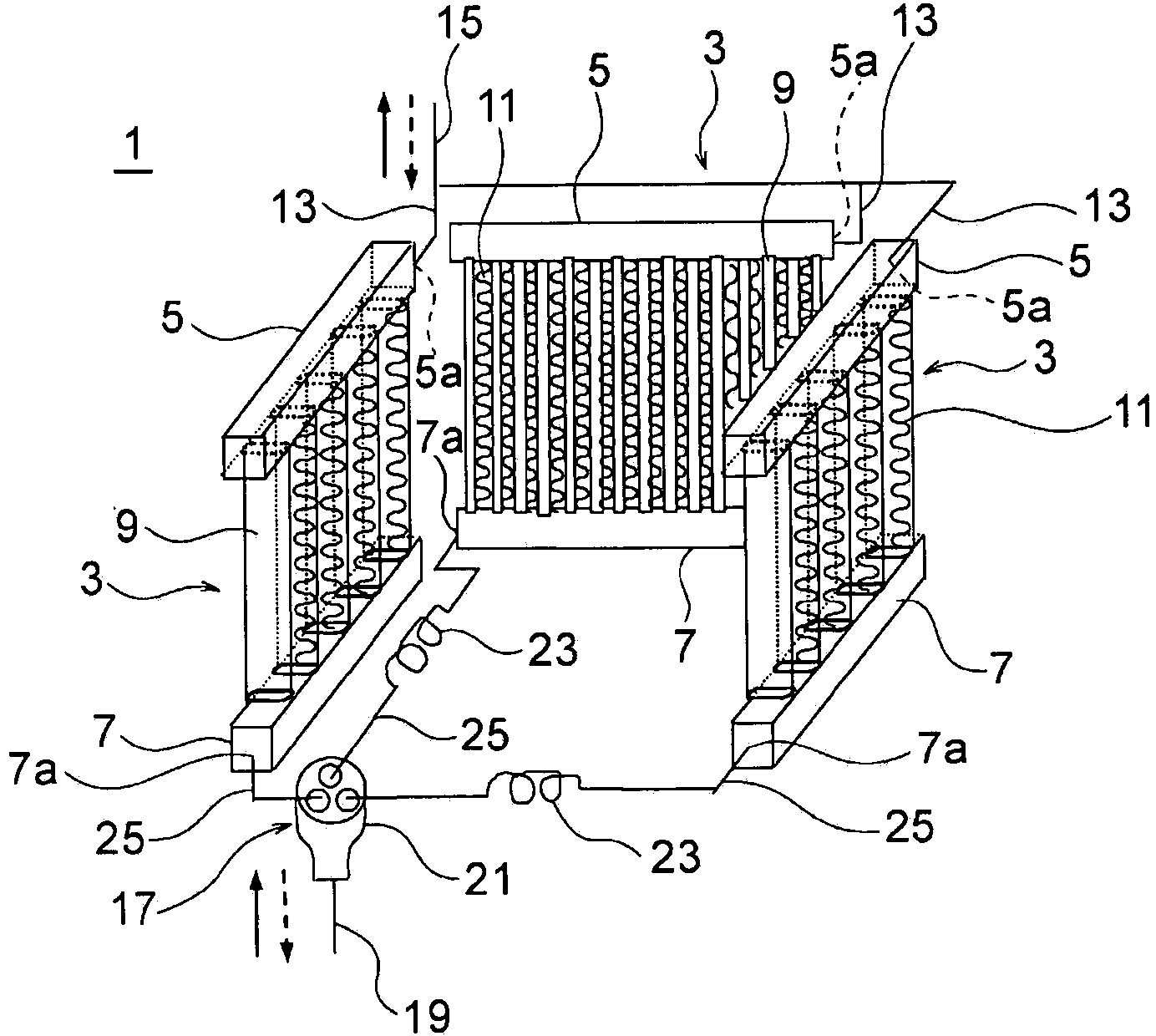

[0027] figure 1 It is a figure which shows the structure of the heat exchanger of this Embodiment 1. The heat exchanger of this embodiment functions as an outdoor unit of an air conditioner that is installed in a target space and performs cooling and heating. Therefore, it is a parallel flow heat exchanger in which the refrigerant such as figure 1 As indicated by the dotted arrow in , the refrigerant flows from top to bottom. When heating, the refrigerant acts as an evaporator, such as figure 1 Flow from bottom to top as indicated by the solid arrows in .

[0028] The heat exchanger 1 has a plurality of heat exchange functional surfaces 3 . also, figure 1 An example of the case where there are three heat exchange functional surfaces 3 is shown. In addition, in figure 1 In the example of , adjacent heat exchange functional surfaces 3 are configured to point in orthogonal directions.

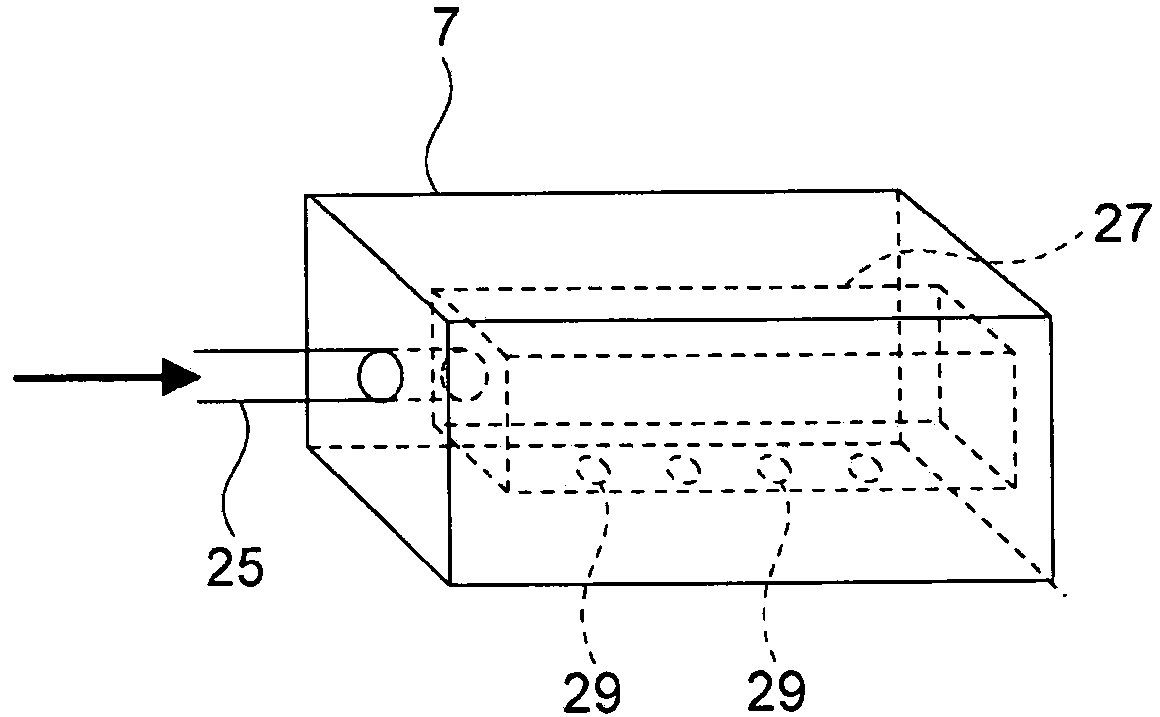

[0029] On each heat exchange functional surface 3, an upper header 5, a lower header 7,...

Embodiment approach 2

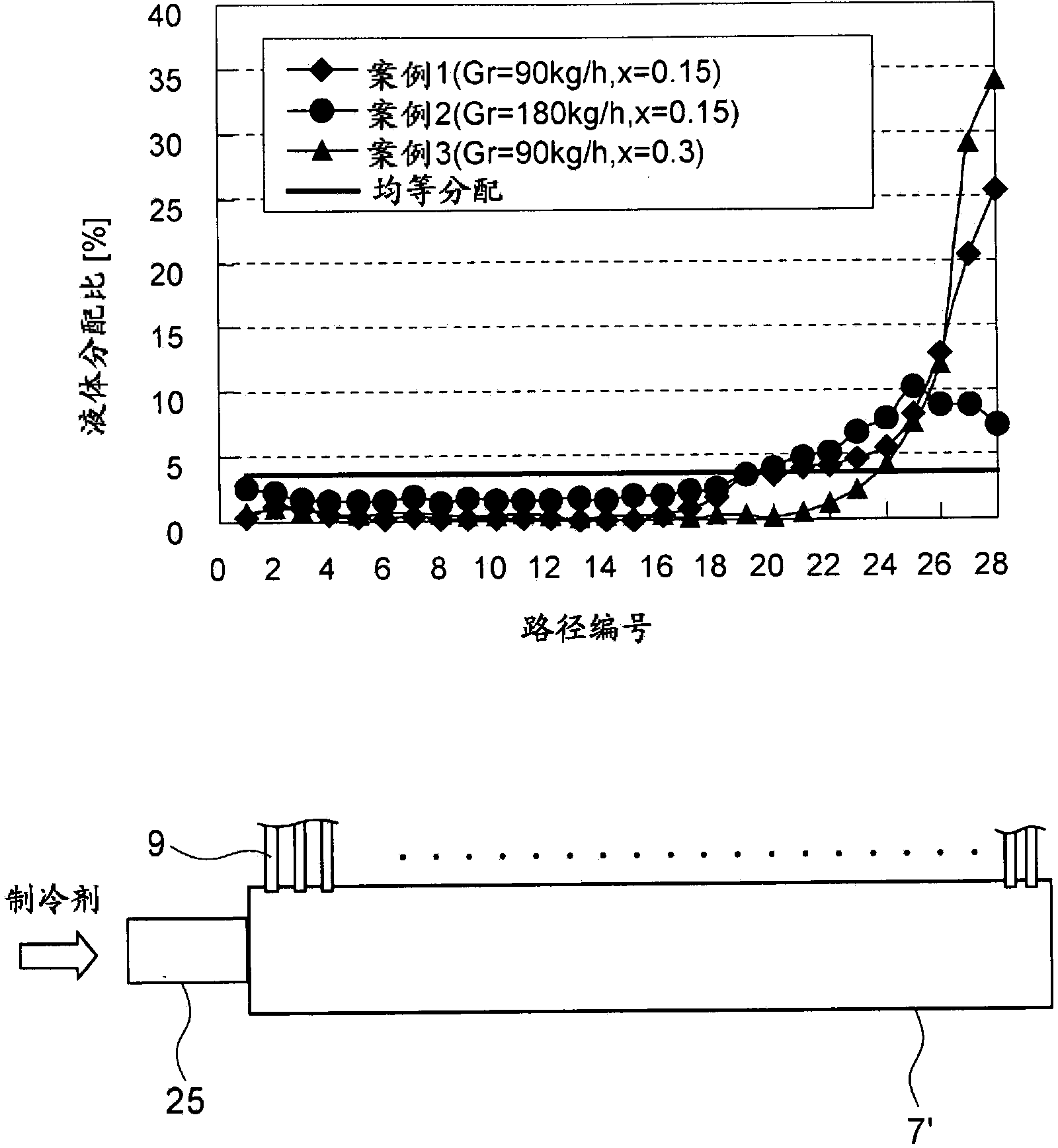

[0048] based on Figure 6 Embodiment 2 of the present invention will be described. In Embodiment 1 above, it was exemplified that the dryness of the refrigerant is adjusted uniformly on a plurality of heat exchange functional surfaces, and that the degree of dryness of the refrigerant is adjusted accordingly to the different heat loads on each heat exchange functional surface (mainly depends on the passing wind speed of the heat exchange unit). The manner of changing the refrigerant flow rate, but the present invention is not limited thereto. That is, the present invention also includes ways to adjust the dryness of the refrigerant and / or the flow rate of the refrigerant to be different on multiple heat exchange functional surfaces. As a specific example of application, an example of application to an outdoor unit of a box-type air conditioner can be mentioned. Figure 6 It is a diagram showing the appearance and plan of the outdoor unit of the box-type air conditioner.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com