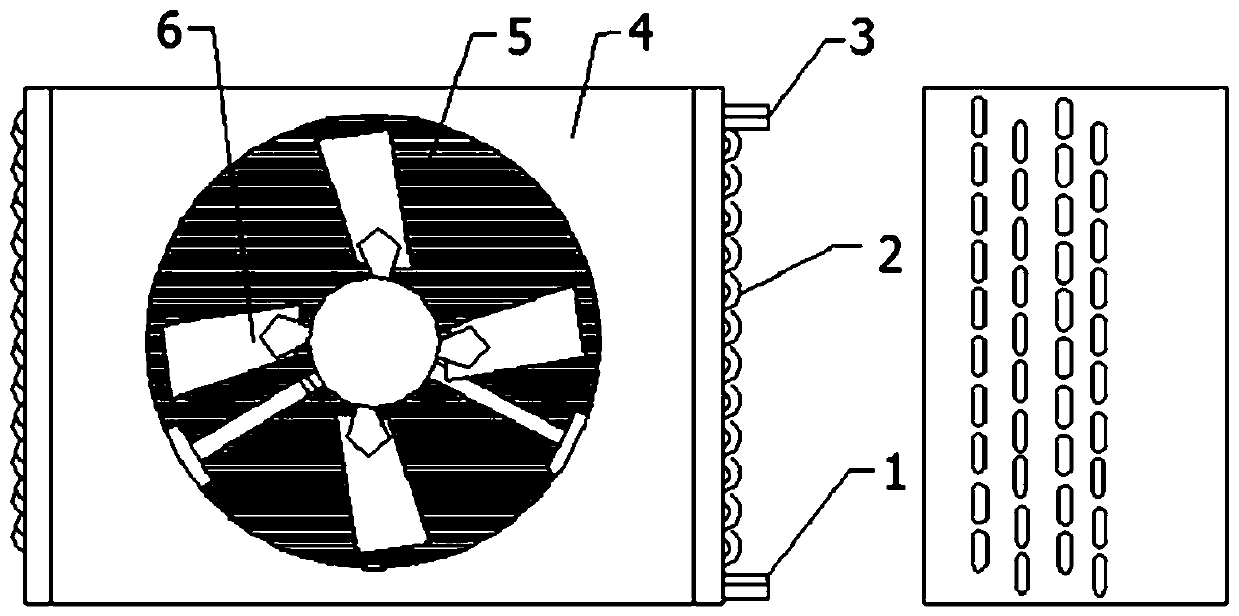

Finned pipe type heat exchanger

A heat exchanger, fin-and-tube technology, applied in the field of heat exchangers, can solve the problems of increased pressure drop of sawtooth fins, less heat transfer material and area, etc., to achieve the effect of suppressing the decline of heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the present invention, the finned tube heat exchanger is composed of a finned tube bundle, a shell and water inlet and outlet pipes; the finned tube bundle in the finned tube heat exchanger is a plurality of fins arranged side by side, passing A plurality of branch paths of fins; the plurality of branch paths include: a plurality of capillaries formed with a plurality of helical grooves on the inner peripheral surface; the main flow path includes: passing through the plurality of fins, A plurality of capillaries with a plurality of helical grooves are formed on the inner peripheral surface; the capillaries of the plurality of branch paths are composed of at least 3; the return elbow in the main flow path has a smooth inner Smooth bends around the perimeter.

[0019] The working mode of the finned tube heat exchanger is as follows: the finned tube bundle composed of many finned tubes according to a certain arrangement forms the heat exchange surface, and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com