Tank body of water treatment device

A technology for water processors and tanks, which is applied in the field of water treatment equipment, and can solve problems such as affecting filtration and ion exchange efficiency, rapid central water flow, and slow peripheral flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

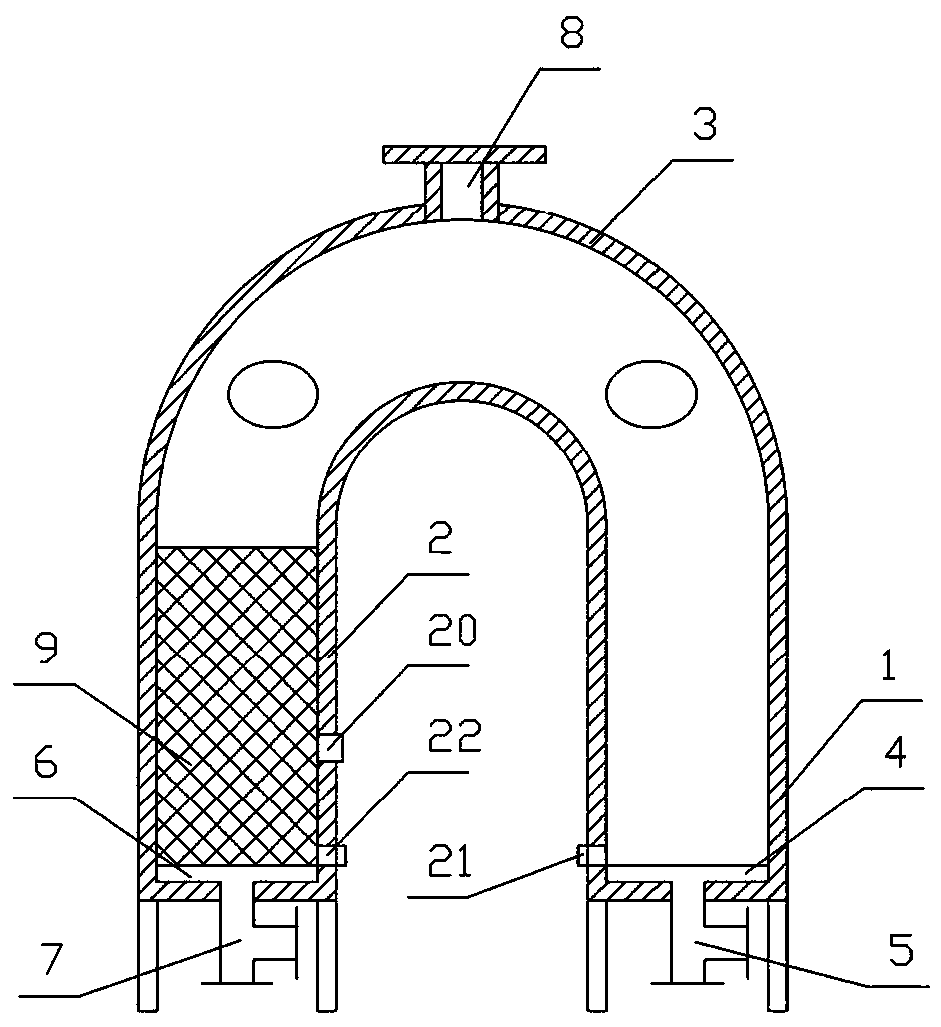

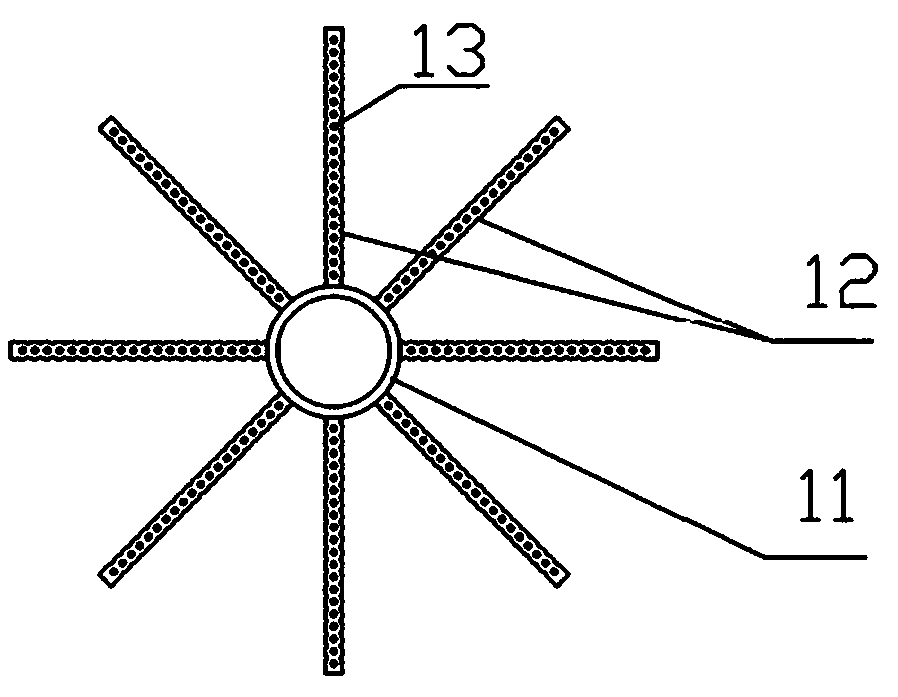

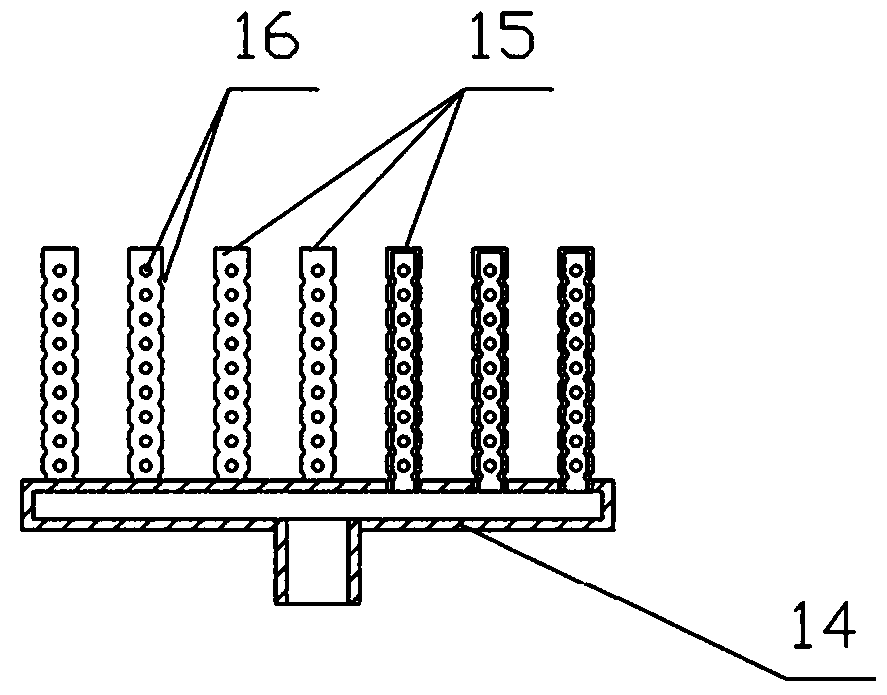

[0015] Such as figure 1 As shown, the water processor tank body of the present invention includes a first compartment 1, a second compartment 2 and a communication compartment 3 connected between the first compartment 1 and the second compartment 2, three The inner cavities of the storage chambers communicate with each other. The first storage chamber 1 and the second storage chamber 2 are arranged parallel to each other and arranged side by side. A first water distributor 4 is installed in the inner chamber of the first storage chamber 1. The first cloth The water tank 4 is connected to the first tee 5 installed at the lower end of the first compartment 1. The two taps of the first tee 5 are respectively connected to the water inlet pipe and the sewage pipe through flanges and valves. Open the water inlet pipe when working The water inlet valve of, close the sewage valve on the sewage pipe, and inject raw water into the first warehouse 1 through the first three-way 5 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com