High-efficiency open network pipe channel reverse osmosis membrane module

一种反渗透膜组件、开放式的技术,应用在逆渗透、半透膜分离、膜技术等方向,能够解决中心拉杆累赘、耐污堵能力差、投资成本高等问题,达到节省占地面积、减少压力损失、减少投资成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

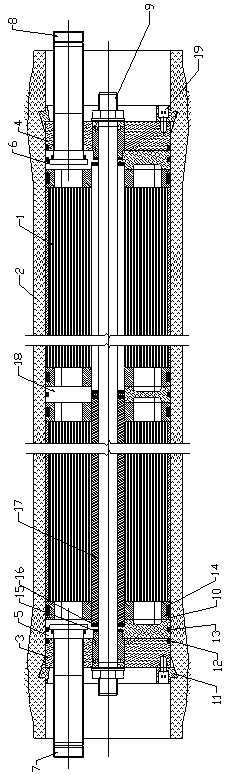

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

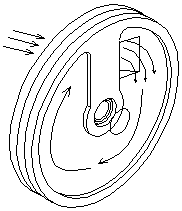

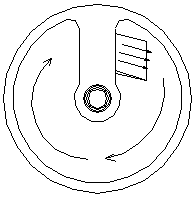

[0033] Such as Figures 1 to 4 As shown, the reverse osmosis membrane module in this embodiment includes a pressure membrane casing 2, a central water production pipe 17 arranged in the membrane casing 2, and several open network pipe flow channel membrane elements arranged radially around the central water production pipe 17 1. The membrane element sealing ring 14 is set between the membrane element 1 and the membrane housing 2. One end of the membrane shell 2 is provided with a raw water joint 7, the other end is provided with a concentrated water joint 8, one end of the water inlet of the membrane shell is provided with a water inlet flange end cover 3, and the inner side of the water inlet flange end cover 3 is further provided with Inlet swirl flow guide plate 5, sealing rings 12 and 13 are arranged on the contact surface between the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com