Efficient open type net pipe flowing channel reverse osmosis membrane element

A reverse osmosis membrane and open technology, which is applied in the field of reverse osmosis membrane modules with open network pipe flow channels, can solve the problems of cumbersome center tie rods, cumbersome maintenance, and high investment costs, so as to reduce pressure loss, save floor space, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

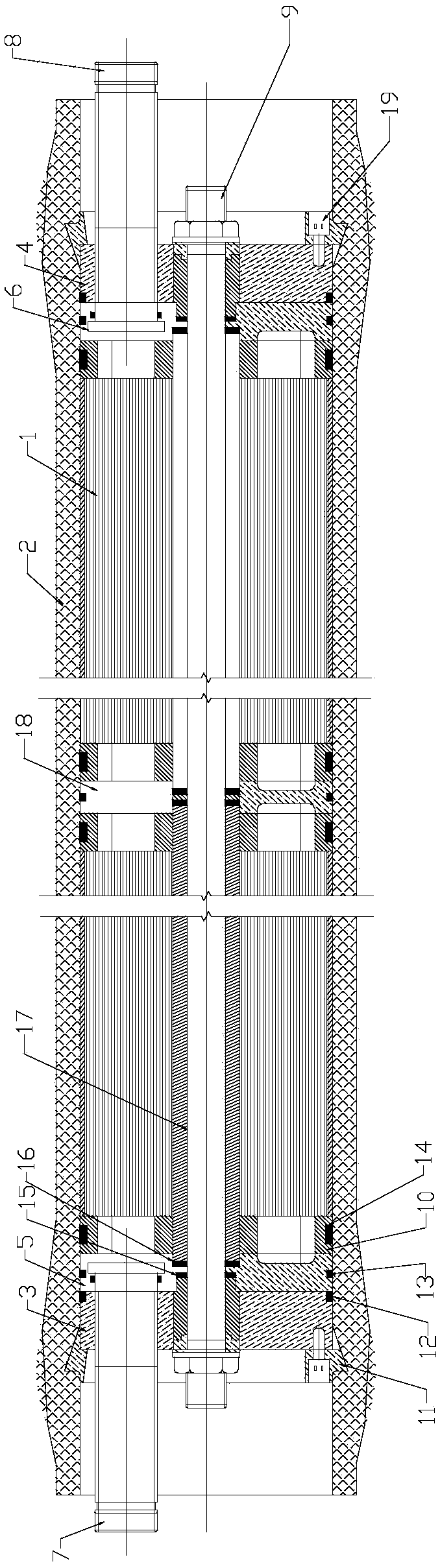

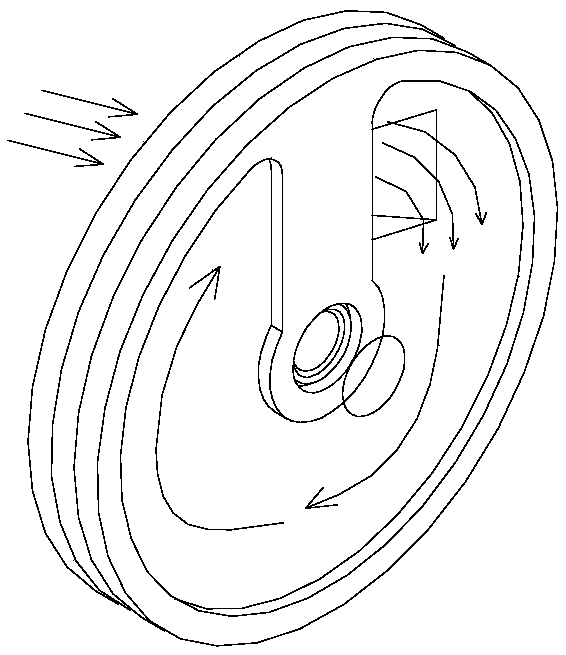

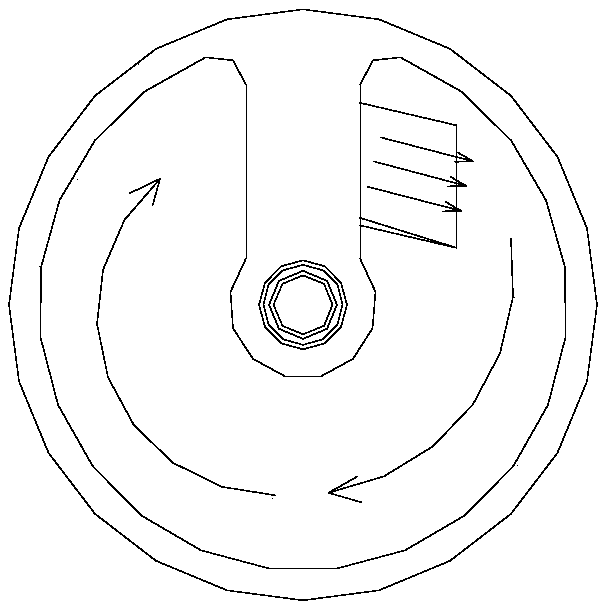

[0033] like Figures 1 to 4 As shown, the reverse osmosis membrane module in this embodiment includes a pressure membrane shell 2, a central water production pipe 17 arranged in the membrane shell 2, and a number of open mesh pipe flow channel membrane elements arranged radially around the central water production pipe 17. 1. A membrane element sealing ring 14 is arranged between the membrane element 1 and the membrane casing 2 . One end of the membrane shell 2 is provided with a raw water joint 7, the other end is provided with a concentrated water joint 8, one end of the water inlet of the membrane shell is provided with a water inlet flange end cover 3, and the inner side of the water inlet flange end cover 3 is further provided with a Water inlet cyclone diversion plate 5, sealing rings 12 and 13 are provided on the contact surface betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com