Solenoid valve with compact structure

A technology with a compact structure and a solenoid valve, applied in the field of solenoid valve, can solve the problems affecting the use effect of the solenoid valve, high installation environment requirements, troublesome operation, etc., and achieve the effect of reasonable waterway layout, compact overall structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

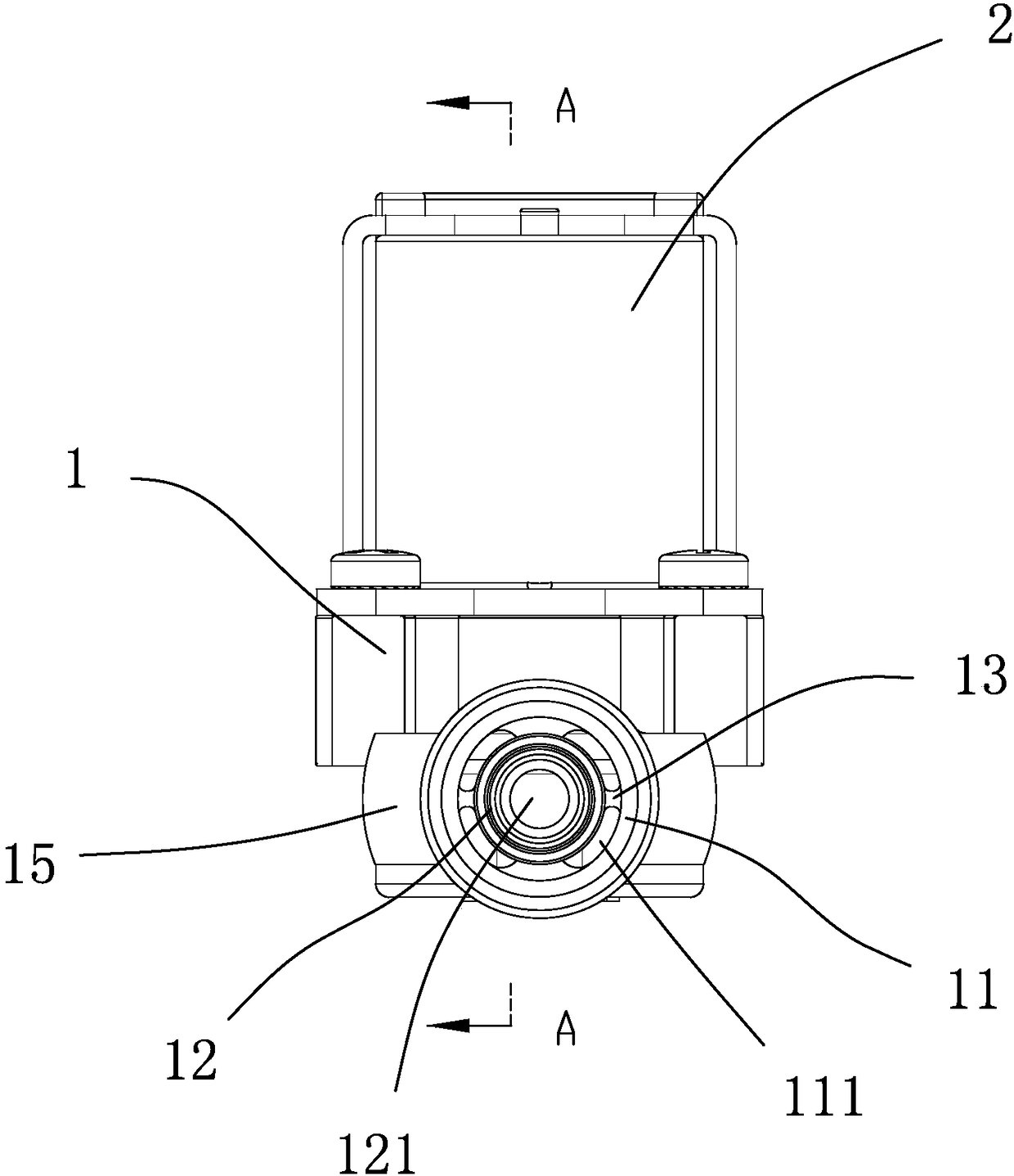

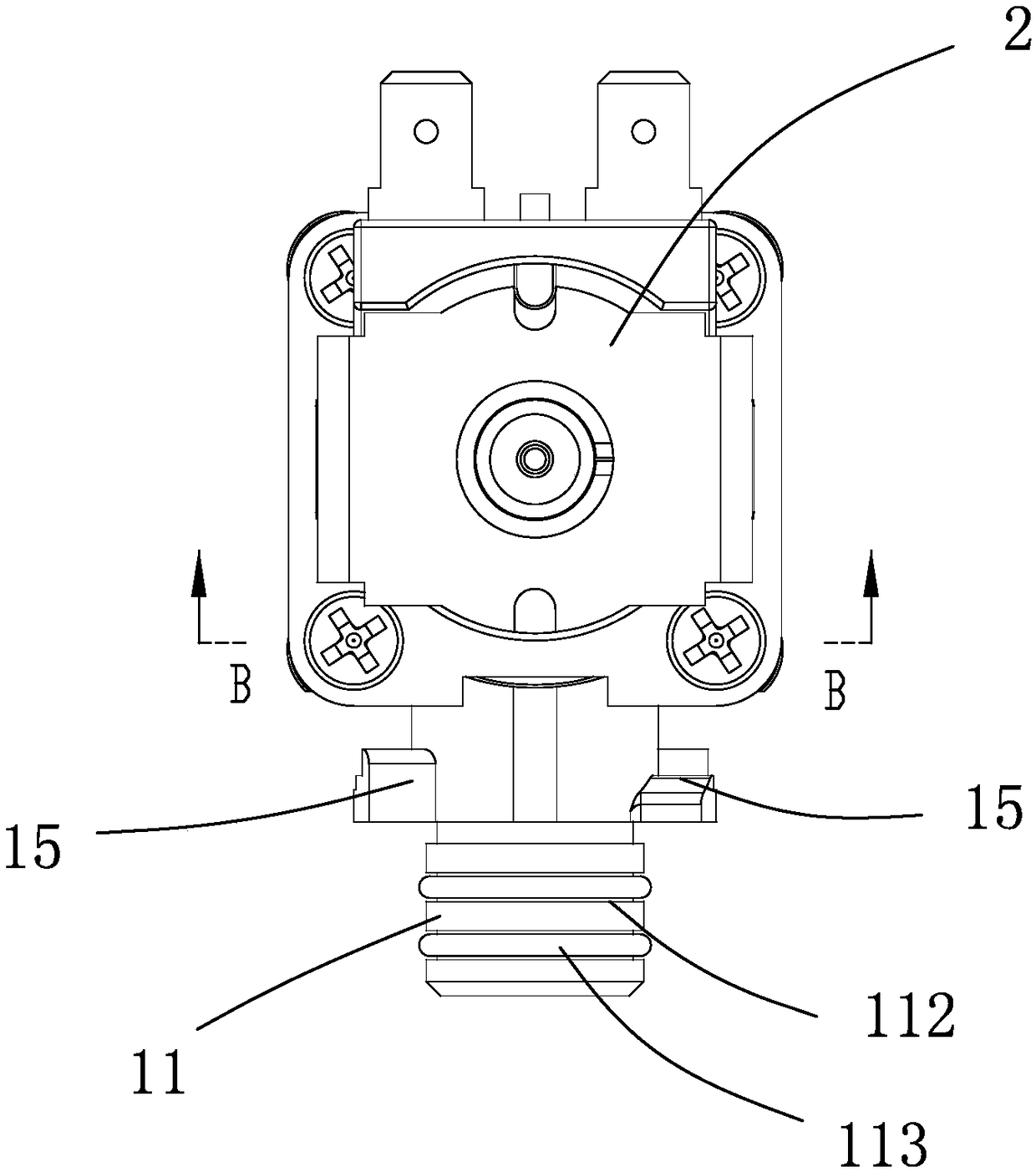

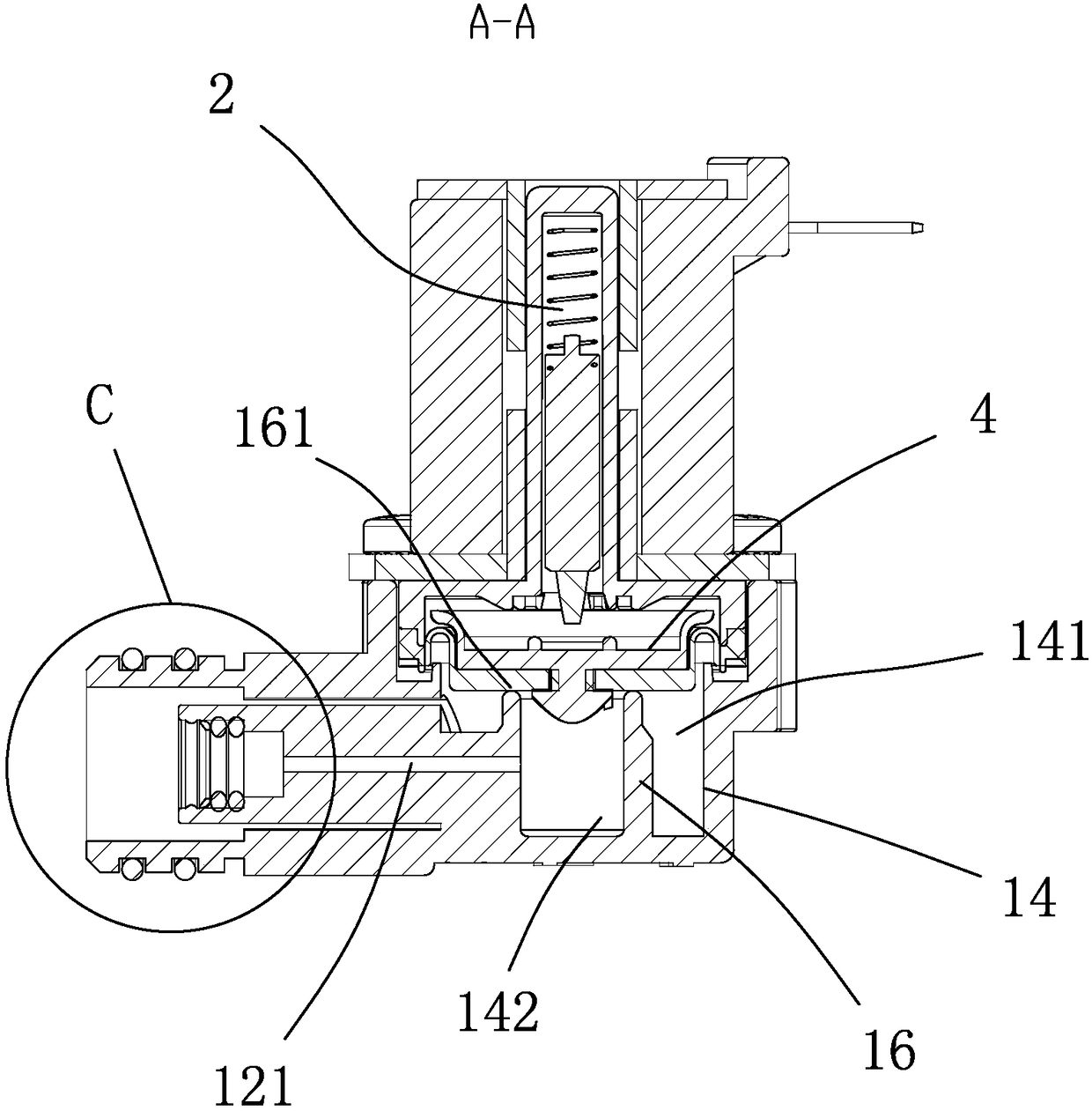

[0025] Embodiments of the compact solenoid valve of the present invention are Figures 1 to 7 Shown: It includes a valve body 1 and an electromagnetic drive mechanism 2 connected to the valve body 1. The electromagnetic drive mechanism 2 is a mechanism that uses the principle of electromagnetic drive to generate a driving force. The direction of its driving force can be linear or rotating Type. The valve body 1 includes an inner cavity 14, and an annular water barrier 16 is arranged in the valve inner cavity 14, and the inner cavity 14 is divided into a water inlet cavity 141 and a water outlet cavity 142 by the water barrier wall 16. One end is provided with a valve port 161, with the valve port 161 as the boundary, the water inlet chamber 141 is arranged on the inner side of the water barrier 16, the water outlet chamber 142 is arranged on the outside of the water barrier 16, and the inner cavity 14 of the valve body is also provided with a The electromagnetic drive mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com