Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

A composite nanofiber and nanofiber technology, which is applied in hollow filament manufacturing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of poor adhesion between zinc oxide and carbon fibers, uneven dispersion of nanoparticles, and low loading of titanium dioxide. , to achieve the effect of favorable infiltration, large specific surface area and rapid de-embedding

Active Publication Date: 2022-05-31

DONGHUA UNIV

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Titanium dioxide coatings prepared by this method have poor adhesion to carbon fiber substrates, resulting in reduced long-term performance

Chinese patent CN104452268A discloses a method for preparing a fiber composite material loaded with titanium dioxide nanoparticles, but the loading of titanium dioxide in this method is less (4.5%)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

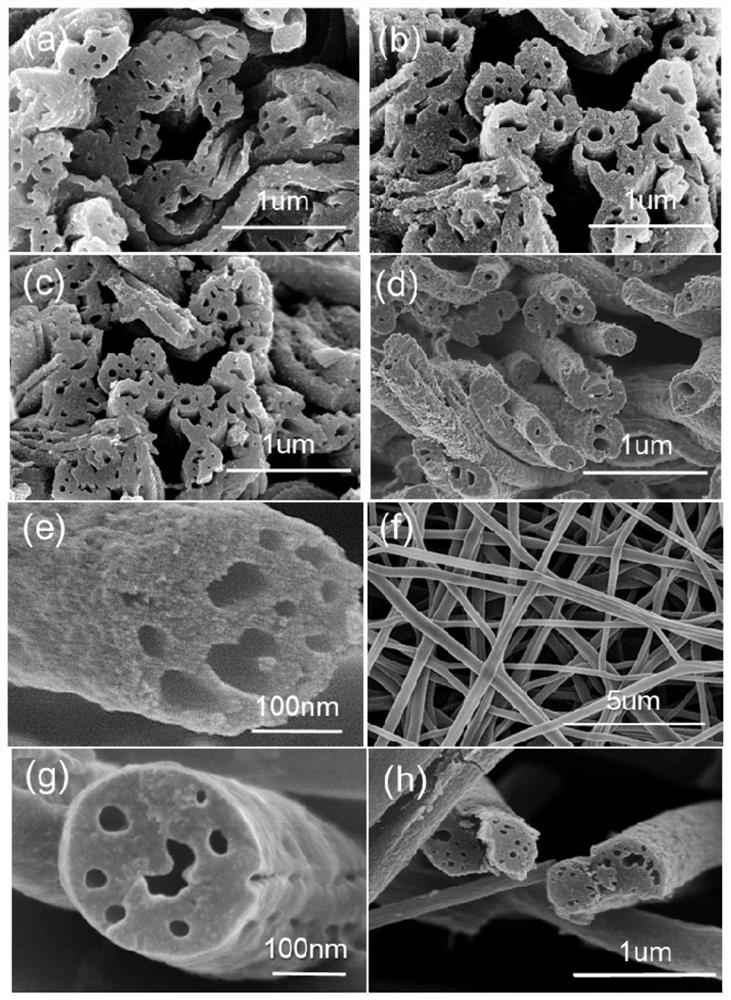

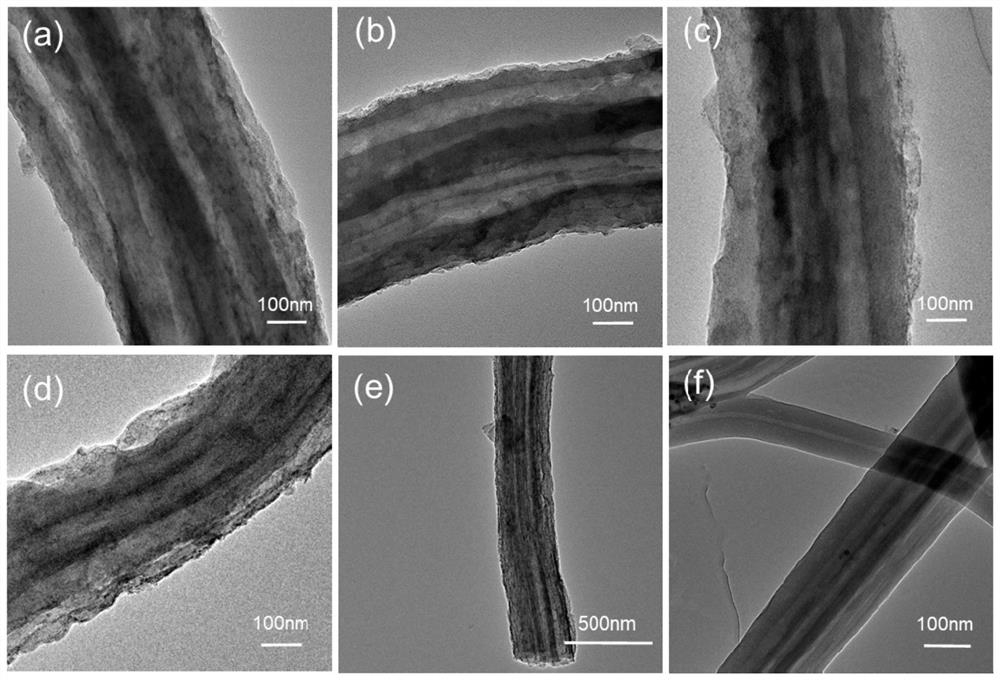

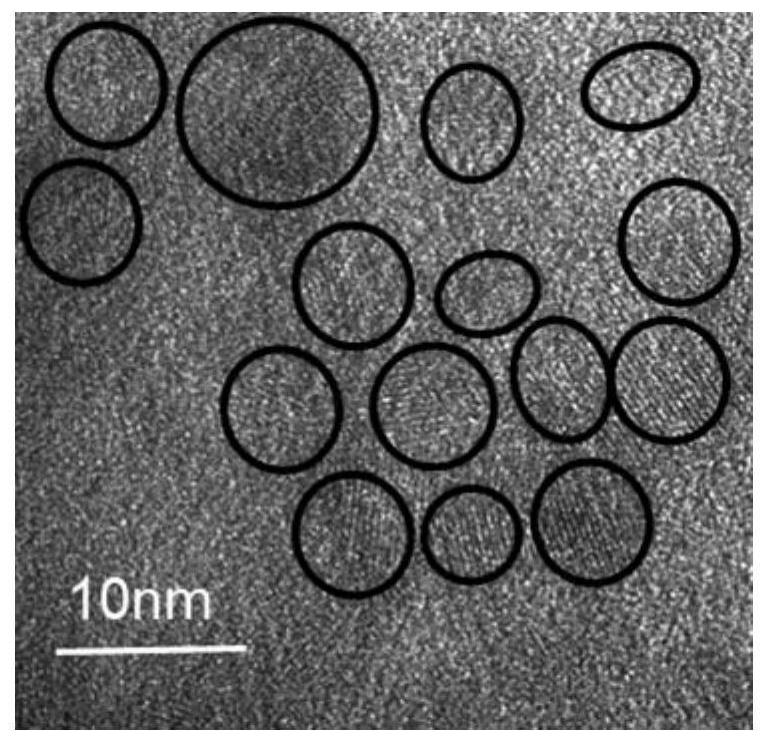

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. The method is to prepare a porous multi-hollow flexible composite nanofiber membrane through coaxial electrospinning; the outer layer solution of coaxial electrospinning is prepared by sacrificial Composed of high molecular polymer, retained high molecular polymer and solvent A; the inner layer solution of coaxial electrospinning is composed of sacrificial high molecular polymer, which can generate both semiconducting properties and low surface energy substances during the spinning process. material and solvent B; then remove the sacrificial polymer in the porous multi-hollow flexible composite nanofiber membrane to obtain a membrane material composed of porous multi-hollow nanofiber stacks, the porous multi-hollow nanofiber has multiple hollow The three-dimensional through-hole micro-nano structure from the pipe and the surface to the hollow; the membrane material of the present invention has good flexibility and mechanical strength, and solves the problems of brittleness and low mechanical strength of porous composite fiber materials and single hollow fiber materials.

Description

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof technical field The invention belongs to the technical field of nanofiber membrane materials, and relates to a porous multi-hollow flexible composite nanofiber membrane material materials and methods for their preparation. Background technique In recent years, nanofiber membrane materials have been widely used due to their large specific surface area, high porosity and three-dimensional network structure. It is widely used in new energy, sensing, filtration, desalination, aerospace and other fields. Chinese patent CN101445963A published A method for preparing ultrafine polymer fibers by wet electrospinning technology, the fiber diameter can be controlled from nanometers to micrometers class. Designing synthetic porous fibers can increase the specific surface area of the fibers. Chinese patent CN103225135A combines pore-forming agent calcium carbonate, high The spi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D04H1/728D04H1/4391D01F1/08D01F1/10D01F9/22D01F9/24D01F9/16

CPCD04H1/728D04H1/4391D01F1/08D01F1/10D01F9/22D01F9/24D01F9/16Y02E60/10

Inventor 张晶晶李光苏正康彭威金俊弘杨胜林

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com