COB packaging structure of light-emitting diode

A technology of light-emitting diodes and packaging structures, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as complex circuits, achieve high density, reduce precision requirements, and save the number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

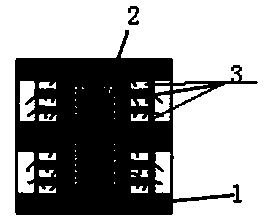

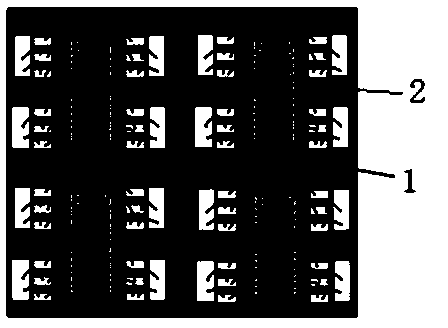

[0022] Such as Figure 1-3 As shown, a COB packaging structure of light-emitting diodes includes a substrate 1, n driver chips 2 and n light-emitting diode chip groups 3, each light-emitting diode chip group includes N light-emitting diode chips, where n and N are integers and n≥1, N≧1; n driver chips 2 and n LED chipsets 3 are packaged in a modular form on the front of the substrate 1 to form a COB display module, n driver chips 2 and n LED chipsets 3 A one-to-one connection is used to form a lamp drive coplanar device group. A fixed number of pads 11 are provided on the back of the substrate 1. Each driver chip 2 and each light-emitting diode chip group 3 are soldered to the back of the substrate 1 through wiring vias. Disk 11 communicates.

[0023] In the present invention, through the circuit design of the substrate 1, it is changed to N lamp driver coplanar devices (CIS) to form a new COB device, which saves a large number of pins, greatly reduces the difficulty of PCB d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com