Electromagnetic valve drive circuit for fuel gas system

A solenoid valve drive and circuit technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of complicated PCB board wiring, troublesome debugging, and non-expandability, etc., to simplify the circuit design of the whole machine, reduce the number of solder points, and quickly The effect of extended adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

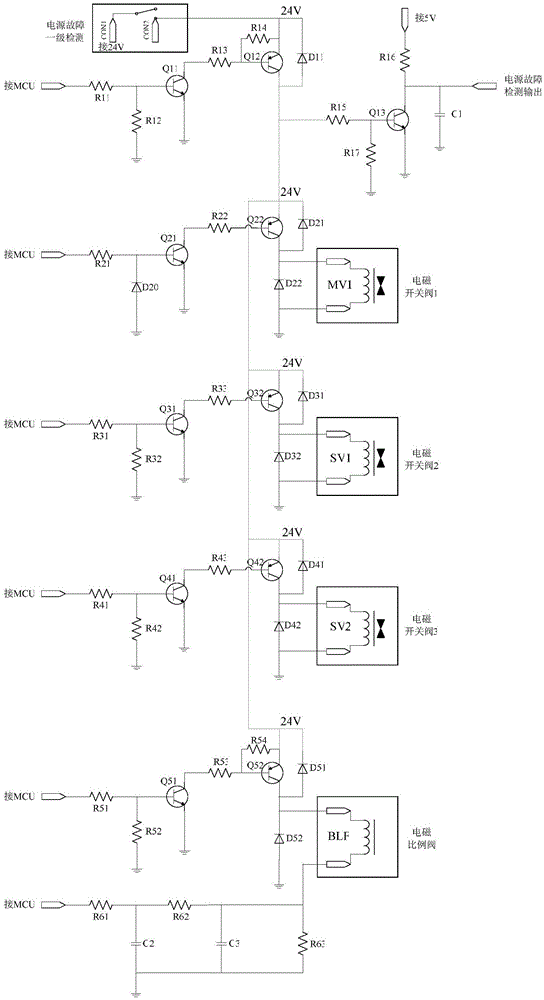

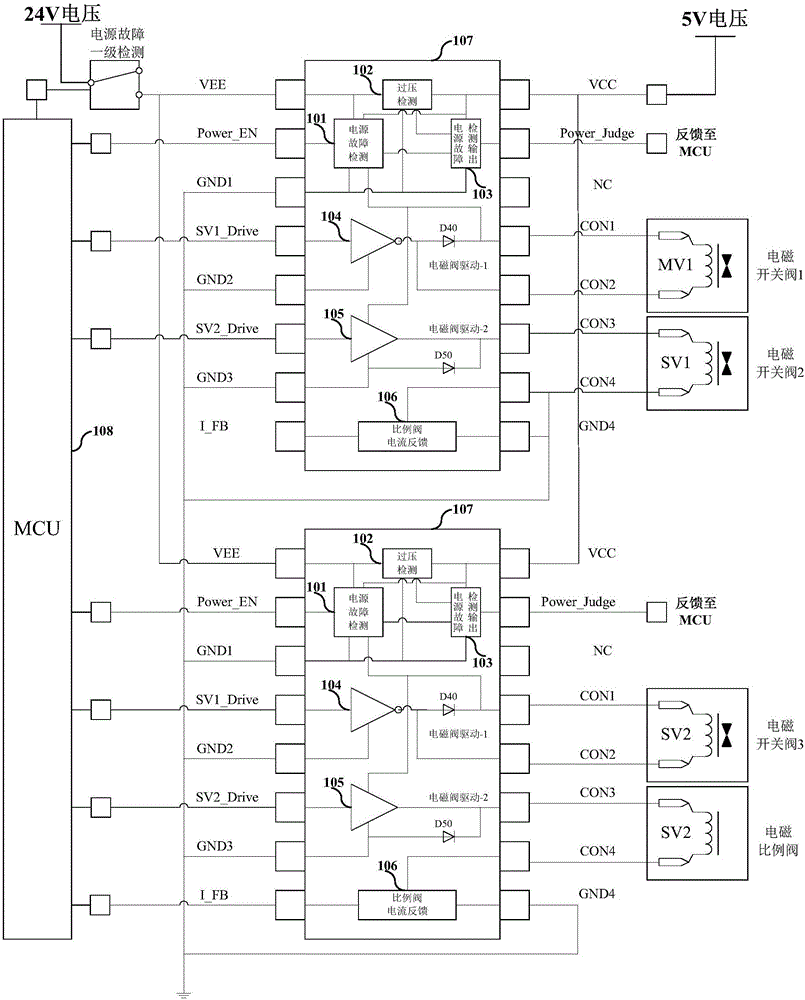

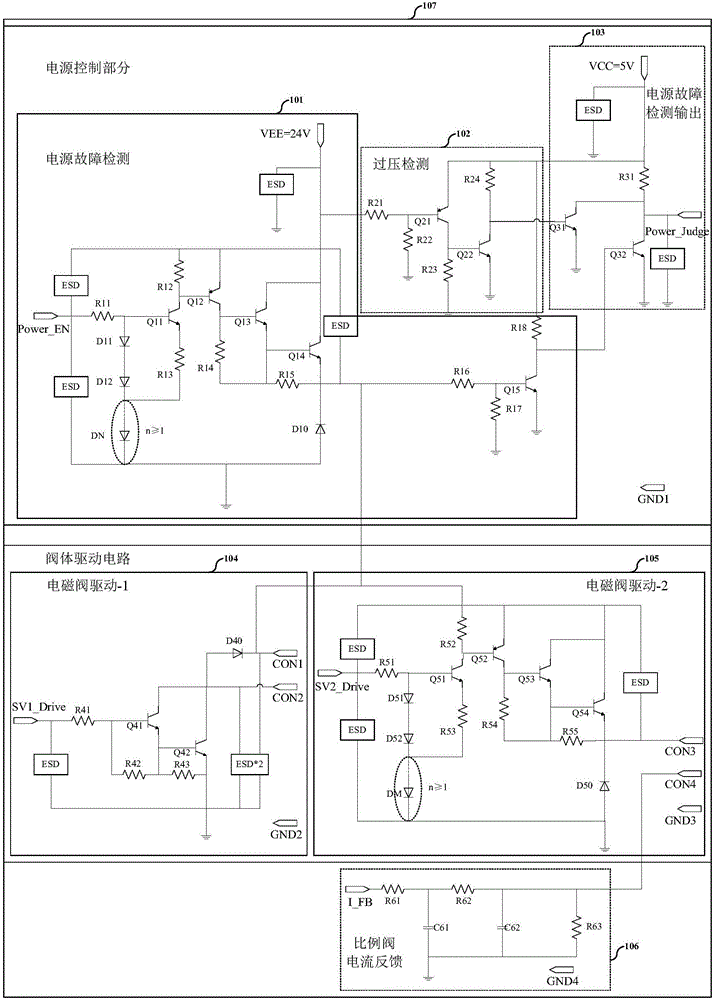

[0030] Example 1: see figure 2 , 3 As shown, a solenoid valve driving circuit for a gas system includes a control unit MCU and several driving chips. The driving chip integrates several solenoid valve driving circuits. The control unit receives the control signal and selects to send it. For the driving chip, the driving chip that has received the control signal controls the corresponding solenoid valve driving circuit to work, and outputs the driving signal to drive the corresponding solenoid switch valve.

[0031] In this embodiment, as figure 2 As shown, the control unit MCU (108) inputs a control signal to the integrated driver chip (107) to control the driver circuit in the driver chip (107) to open and close the electromagnetic switch valve or to control the open and close proportional state of the electromagnetic proportional valve.

[0032] like figure 2 The described driver chip (107) internally includes: a power failure detection circuit (101), an overvoltage de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com