Substrate with embedded element and manufacturing method thereof

A manufacturing method and embedded technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, printed circuit manufacturing, etc., can solve the problem of affecting the combination of the substrate and embedded components during lamination, affecting the alignment of embedded components and contacts, and the failure of components Issues such as embedding the substrate to achieve the effect of increasing space utilization, strengthening bonding, and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

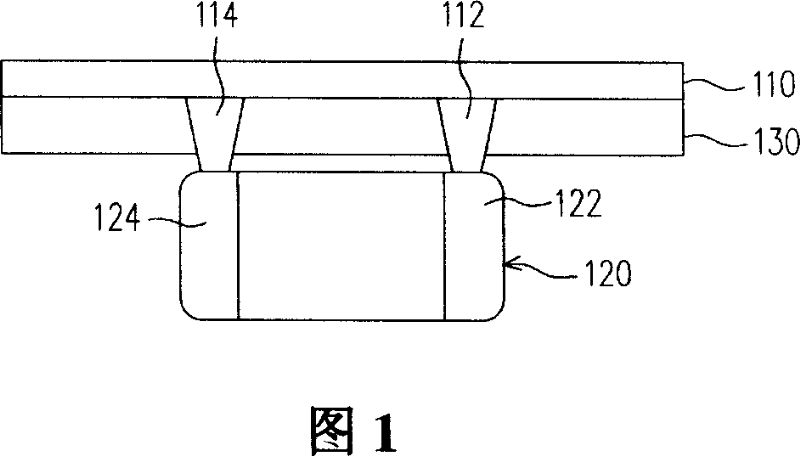

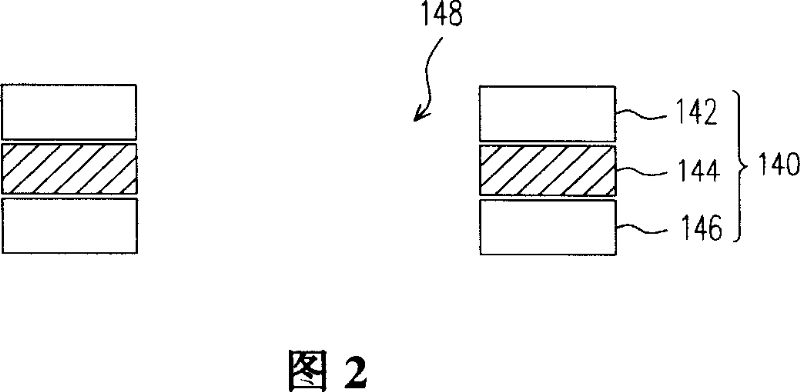

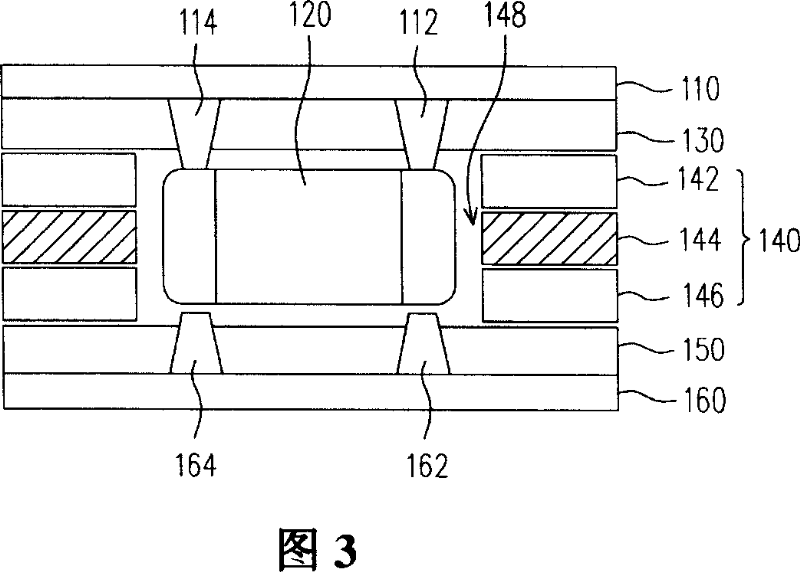

[0030] 1 to 5 are schematic diagrams of a method for manufacturing a substrate with embedded components according to a first embodiment of the present invention. First, referring to FIG. 1 , a first metal layer 110 and an embedding element 120 are provided. The embedding element 120 can be welded to two bumps 112 and 114 preformed on the first metal layer 110 by hot pressing (Hot pressing) technology. superior. Wherein, the material of the first metal layer 110 may be copper, and the two bumps 112 and 114 may be copper bumps produced by electroplating. When the two electrodes 122, 124 of the embedded component 120 are correspondingly placed on the two bumps 112, 114 of the first metal layer 110, the welding material (not shown) at the electrode end can be bonded by high temperature thermocompression, so that the first The two bumps 112 , 114 of the metal layer 110 are firmly bonded to the two electrodes 122 , 124 of the embedded element 120 . In addition, the fourth insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com