Structure of high-power brushless cooling fan power module

A power module and cooling fan technology, applied in the field of cooling fan controller assembly, can solve the problems of low cooling fan performance and potential safety hazards, and achieve the effects of improving current resistance, saving space, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

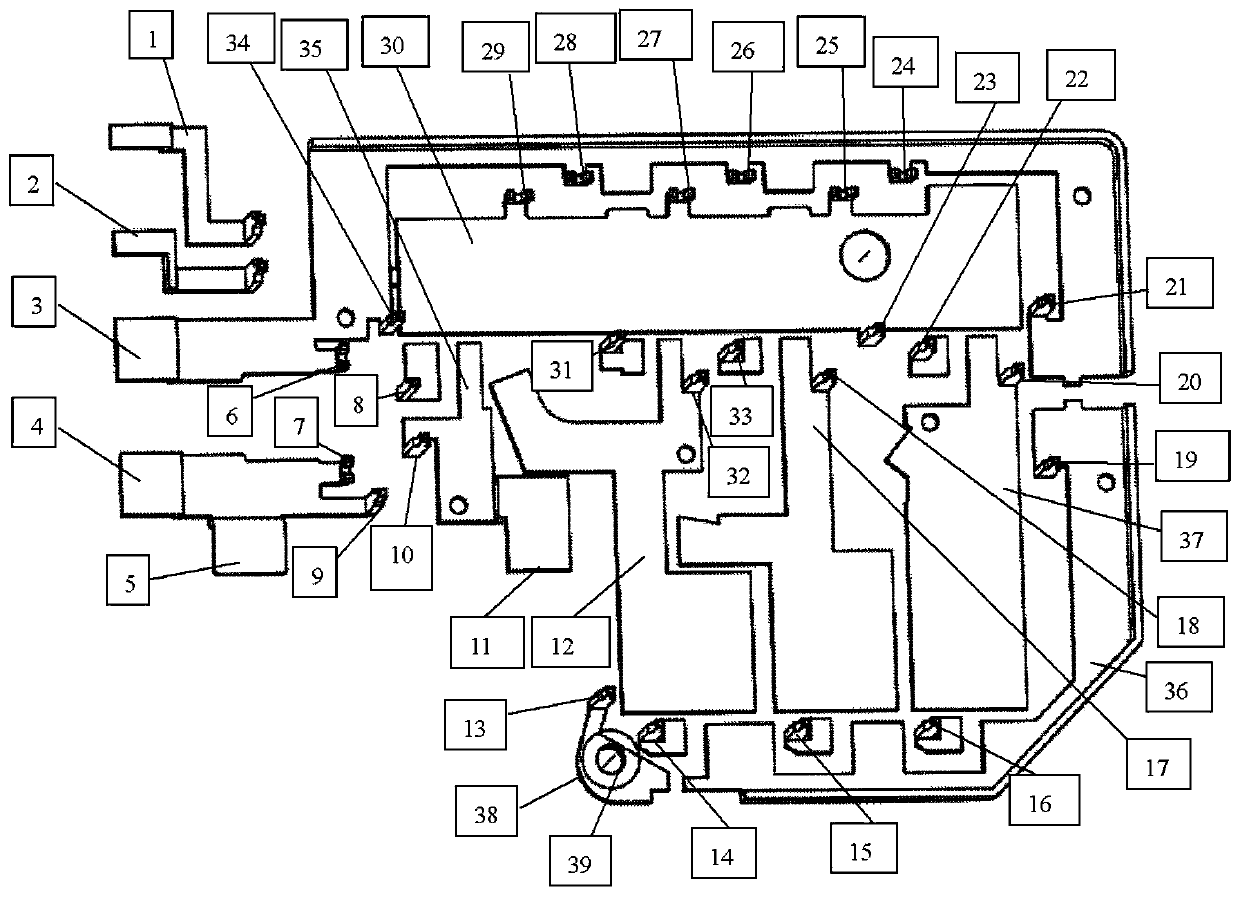

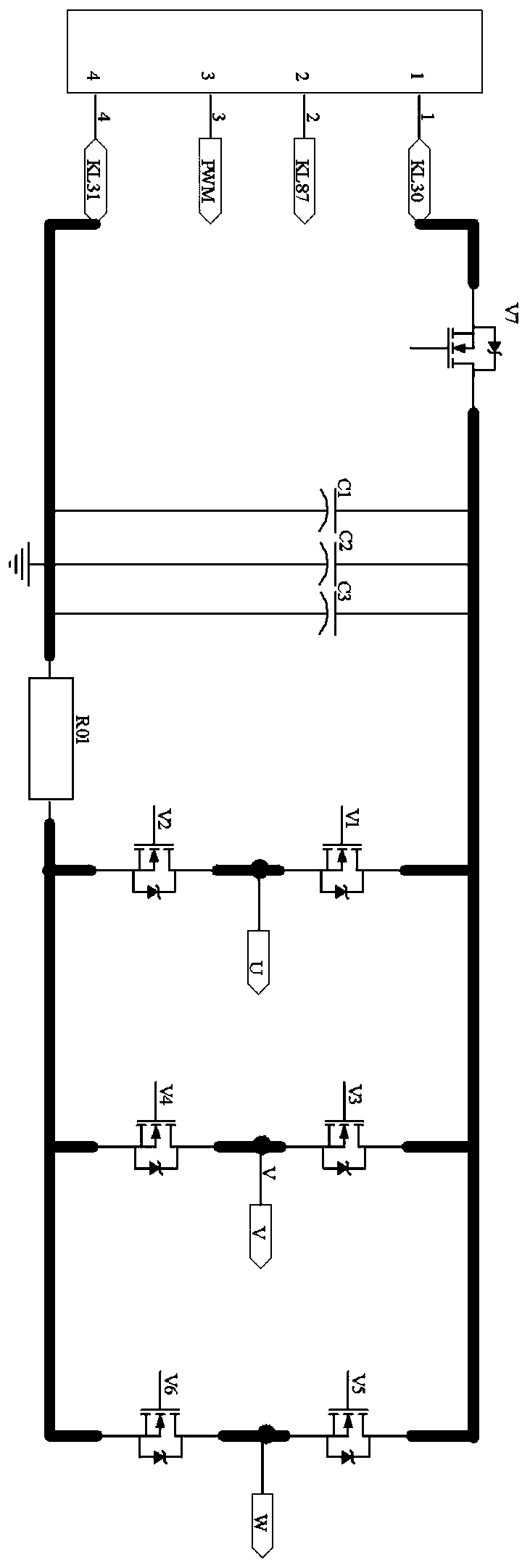

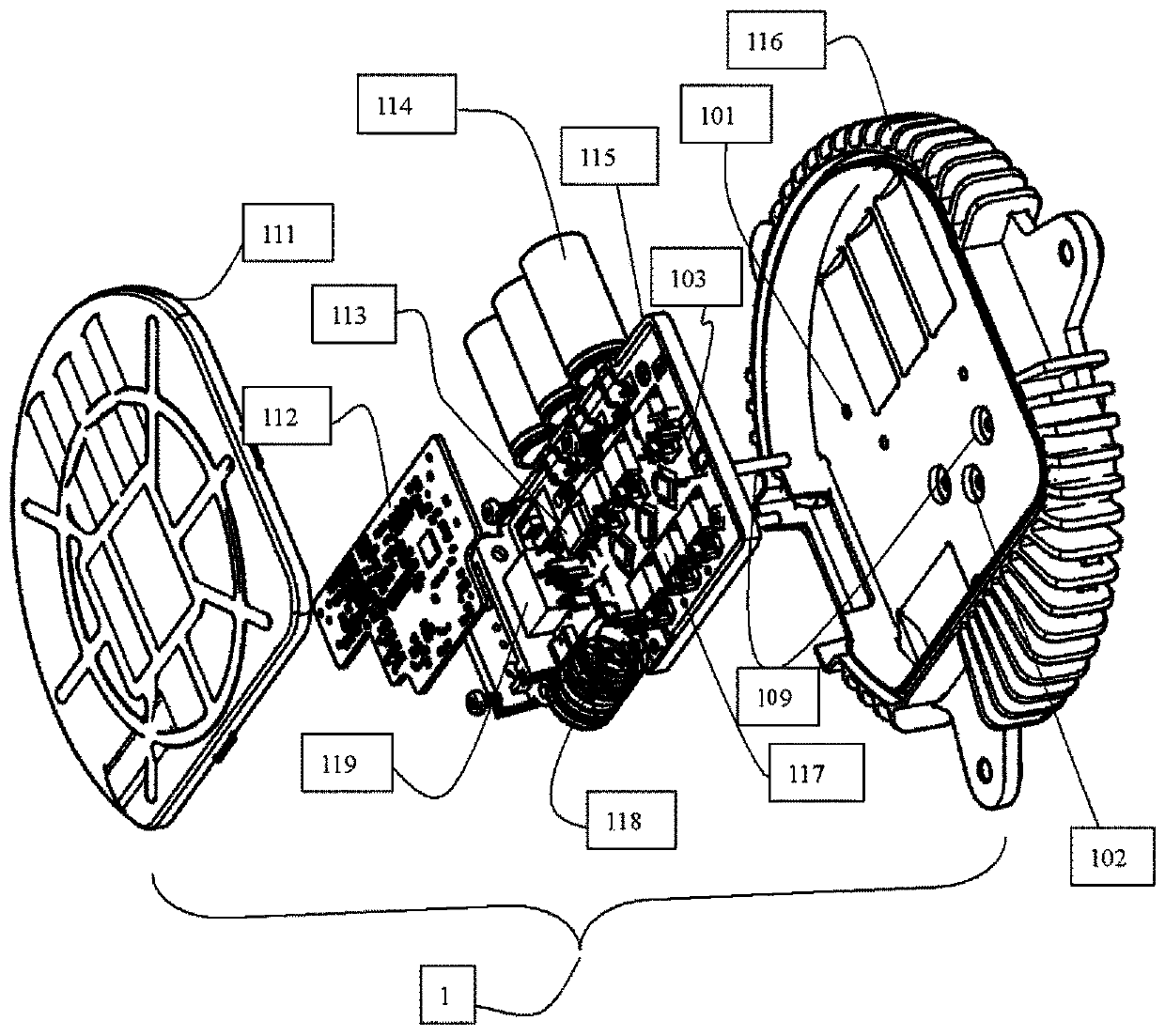

[0027] A structure of a high-power brushless cooling fan power module, characterized in that: comprising,

[0028] Conductive sheet group,

[0029] The conductive sheet group includes a first conductive sheet 3, a second conductive sheet 4, a third conductive sheet 5, a fourth conductive sheet 11, a fifth conductive sheet 30, a sixth conductive sheet 35 and a seventh conductive sheet 36,

[0030] pin group,

[0031] The set of pins includes a first pin 6, a second pin 24, a third pin 26, a fourth pin 28, a fifth pin 21 and a sixth pin 34 arranged on the first conductive sheet 3, wherein , the first pin 6 is used to weld the negative pole of the film capacitor provided, the second pin 24, the third pin 26 and the fourth pin 28 are used to weld the negative pole pin of the electrolytic capacitor provided, the fifth lead The pin 21 is used to collect the current of the provided sampling resistor end, the sixth pin 34 is used for welding with the ground terminal of the printed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com