Patents

Literature

122results about How to "Cooperate skillfully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

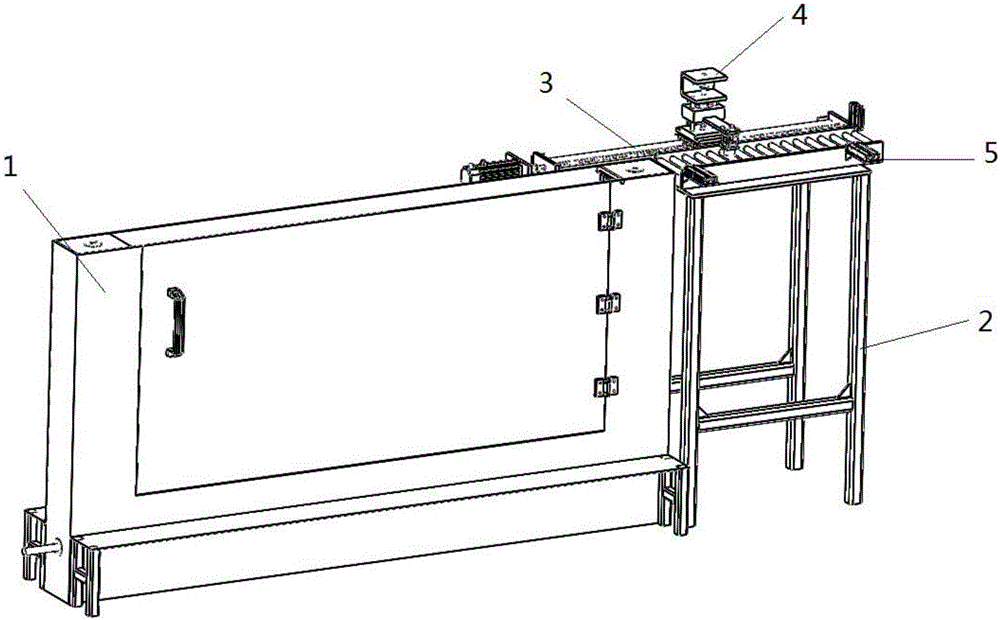

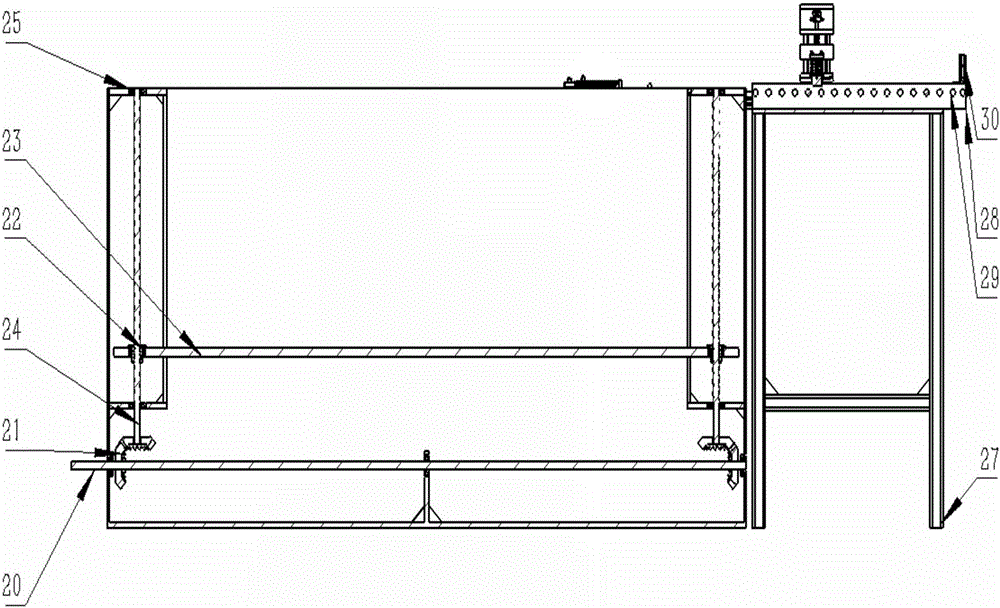

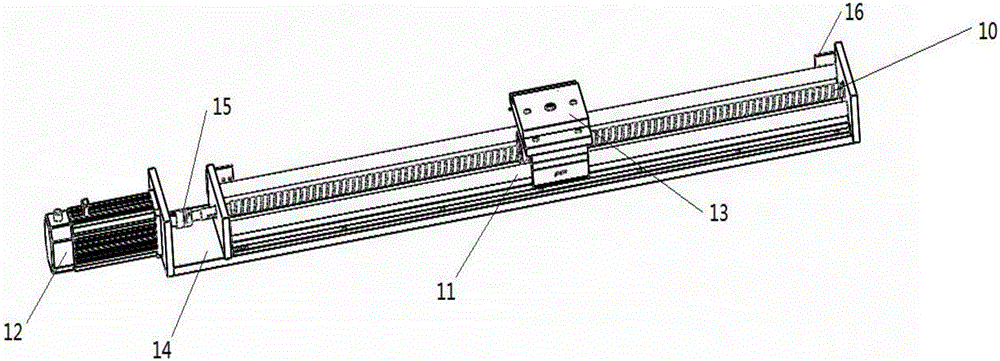

Large multifunctional environmental simulator for electrical test

ActiveCN101799515AUniform temperatureUniform air flowTesting dielectric strengthUltra high voltageHigh pressure

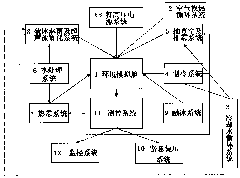

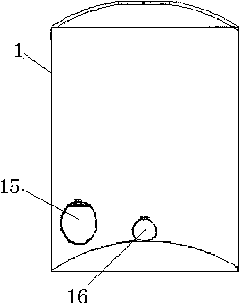

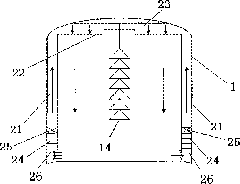

The invention relates to a large multifunctional environmental simulator for electrical tests, which comprises an environmental stimulation chamber and is characterized in that an air heat-exchange circulation system and an ice-melting system are arranged in the environmental stimulation chamber; and the environmental stimulation chamber further comprises an ice-coating, rain-exposing and ultrasonic-atomizing system, a water treatment system, a heat-fogging system, a cooling water circulation system, a refrigeration system, a vacuuming and defogging system, a measurement and control system and an ultra-high voltage power supply system for providing a high-voltage charging state for test-pieces. By achieving the skillful coordination among the systems and the uniform operation control by the measurement and control system, the large multifunctional environmental simulator integrates various testing functions of environmental simulations, such as high-altitude, ice-coating, contamination, rain-exposing and other simulations into a whole. Therefore, the invention is widely suitable for the testing process for large multi-parameter environmental simulations.

Owner:BEIHANG UNIV +1

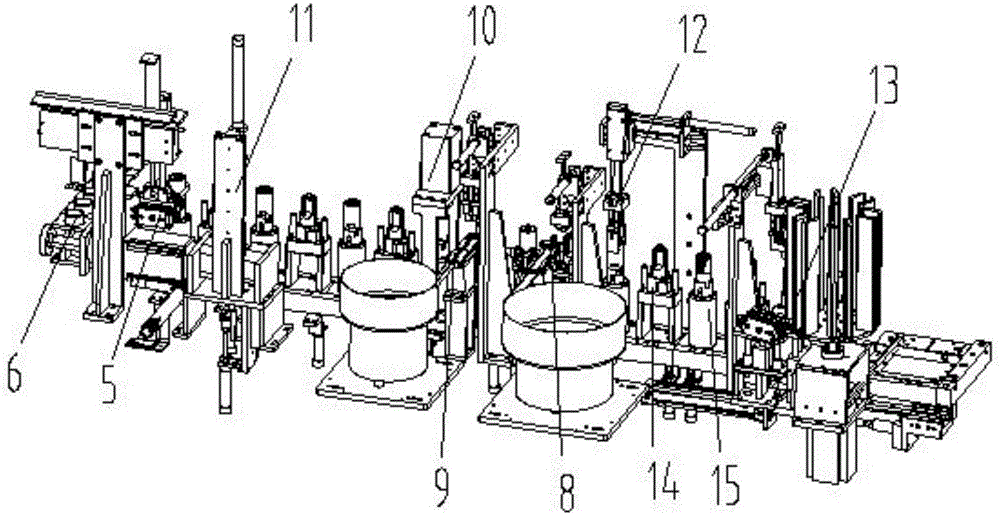

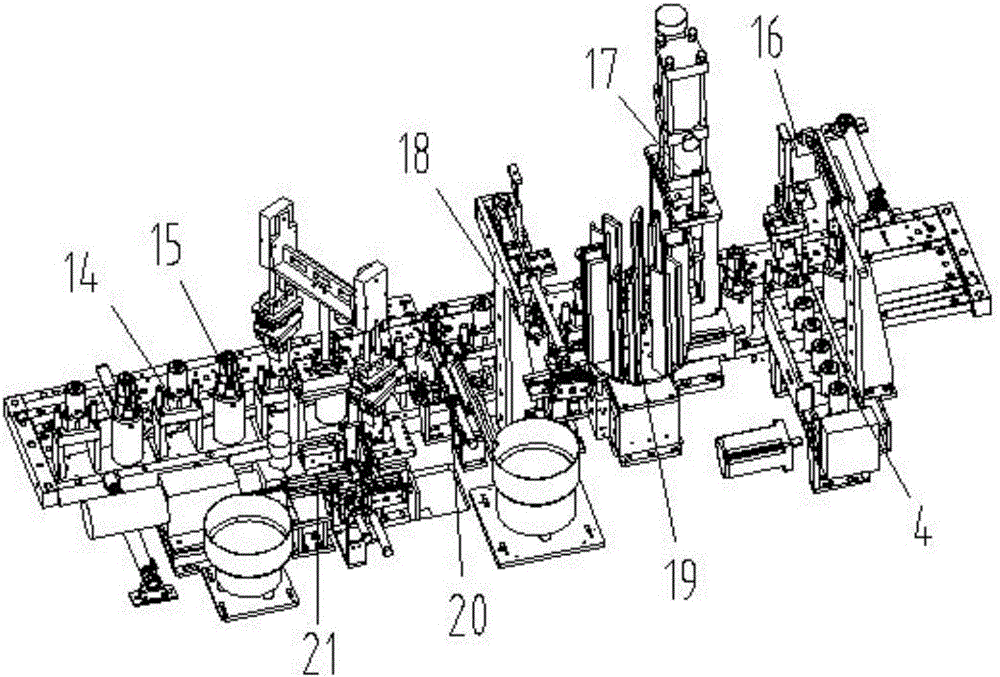

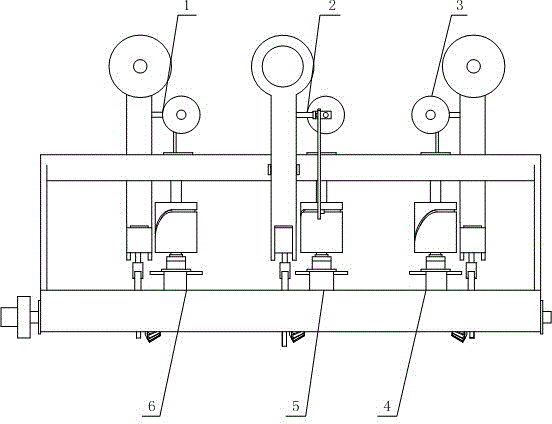

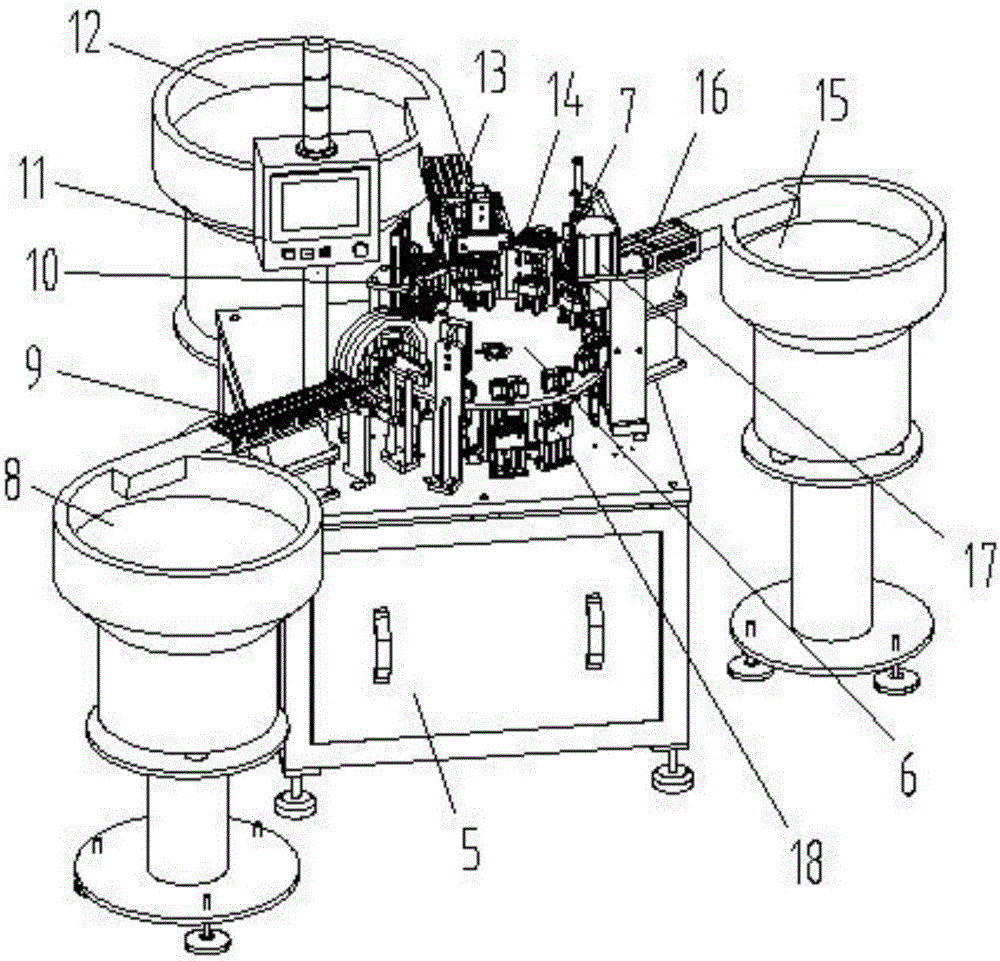

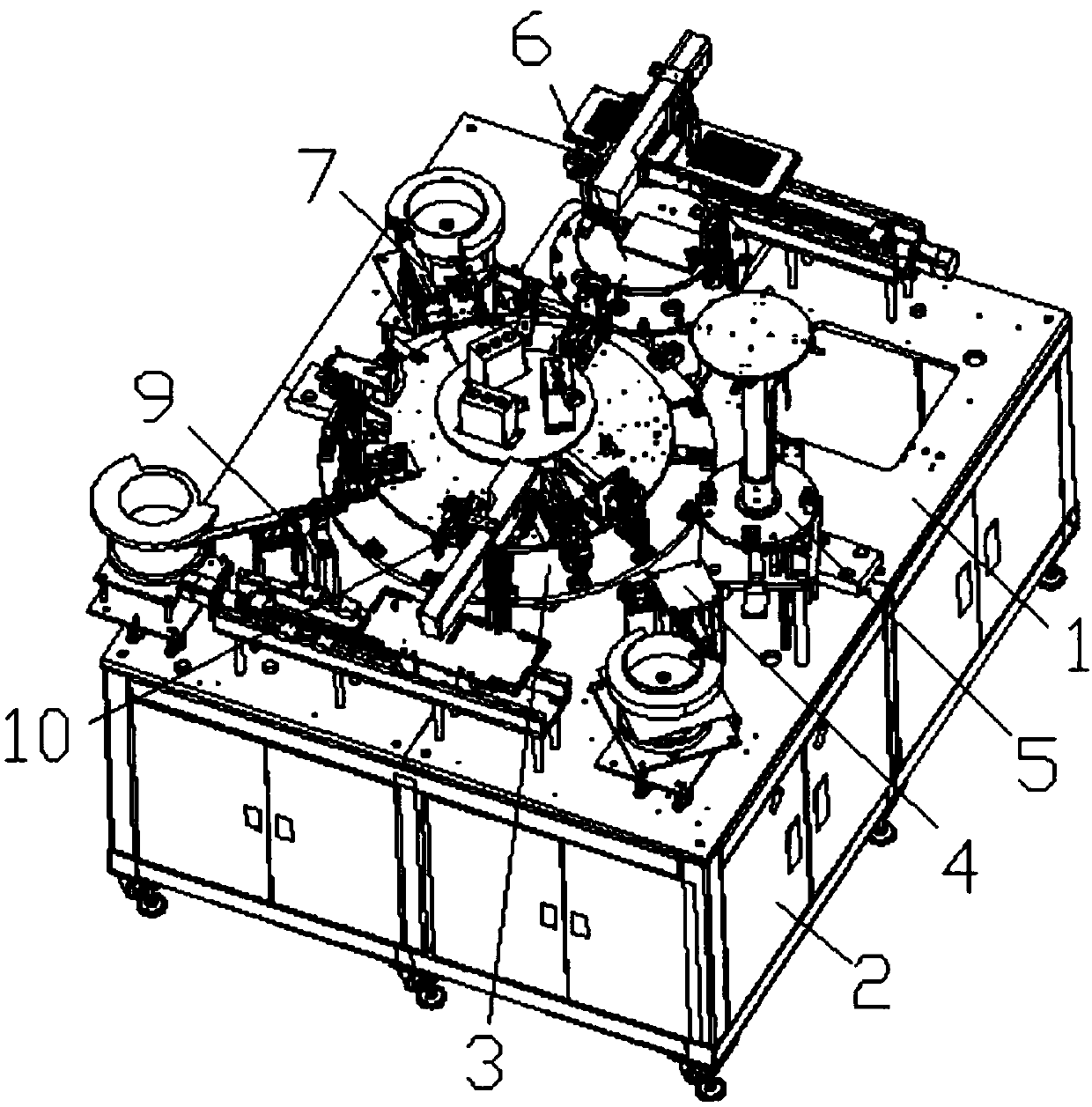

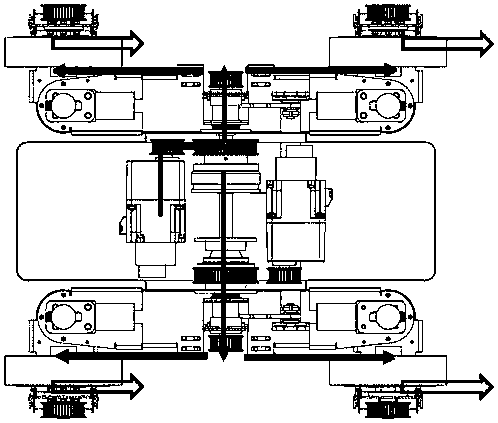

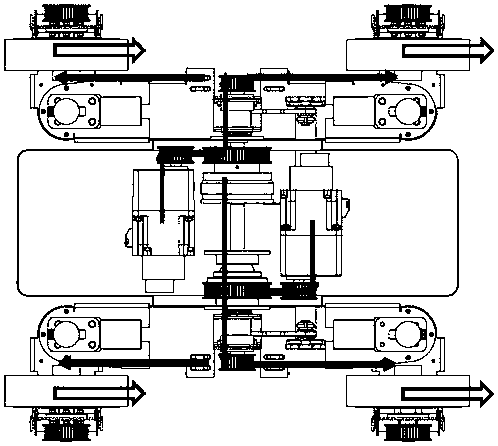

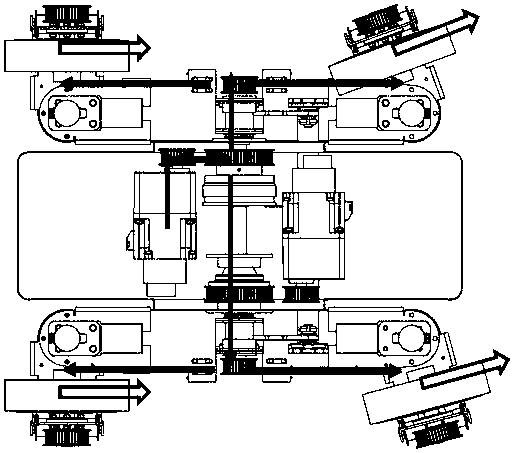

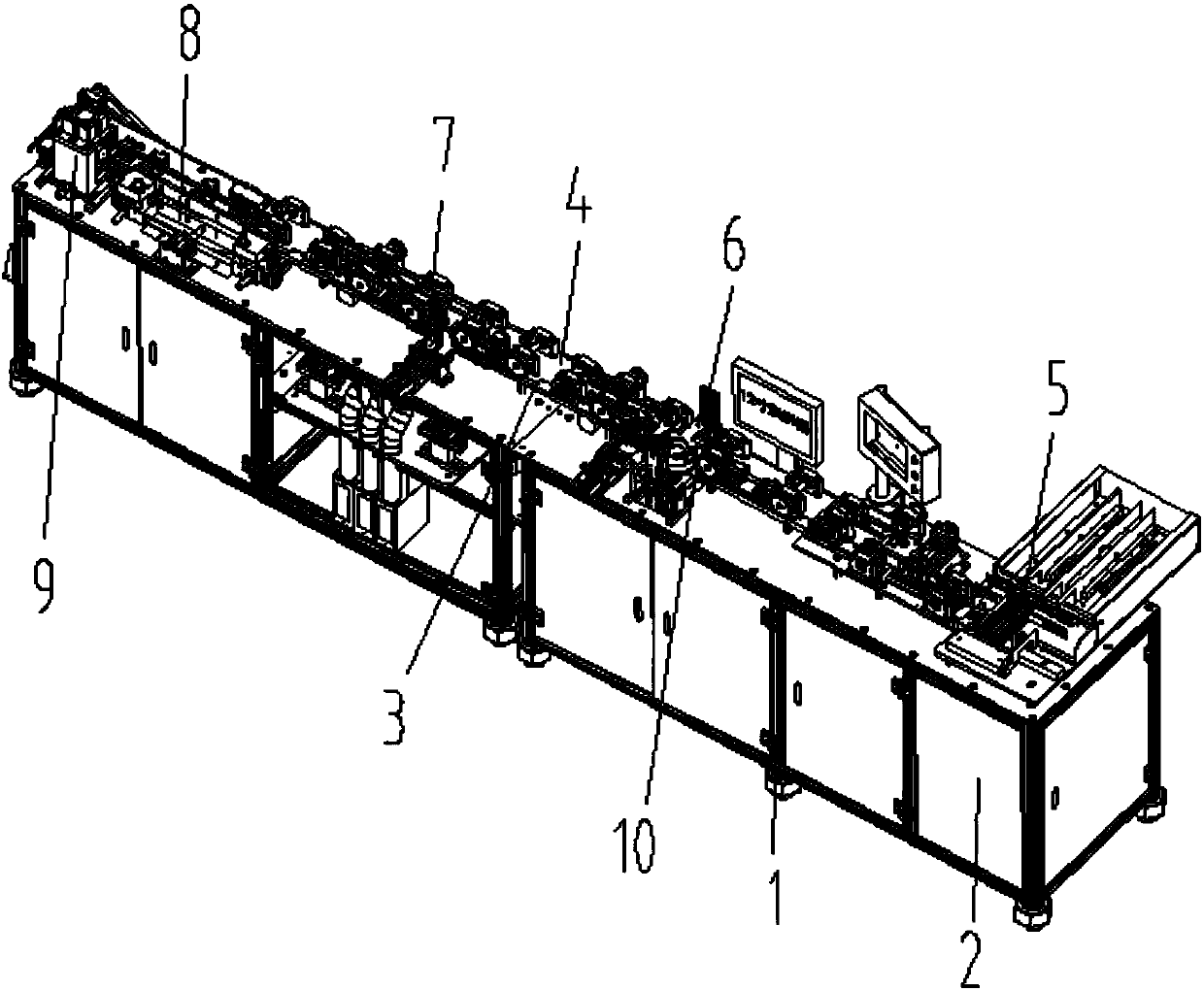

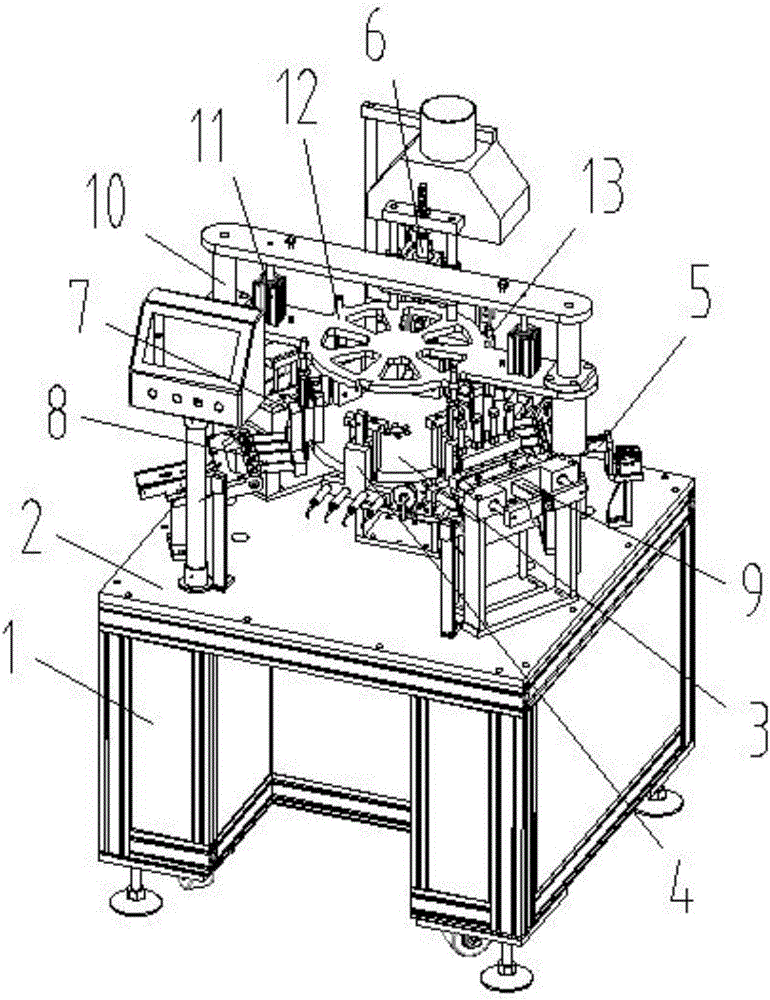

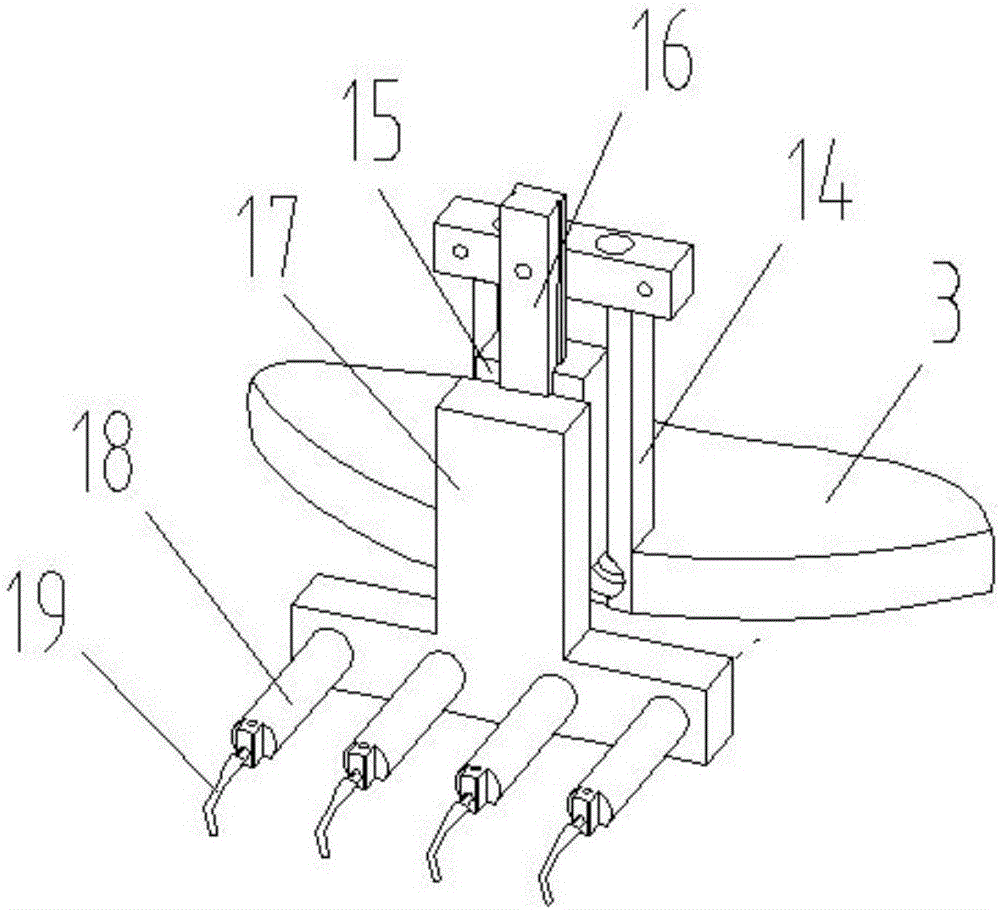

Full-automatic assembly production machine for motor stator

ActiveCN106787494AImprove efficiencySimple structureManufacturing stator/rotor bodiesManipulatorStator

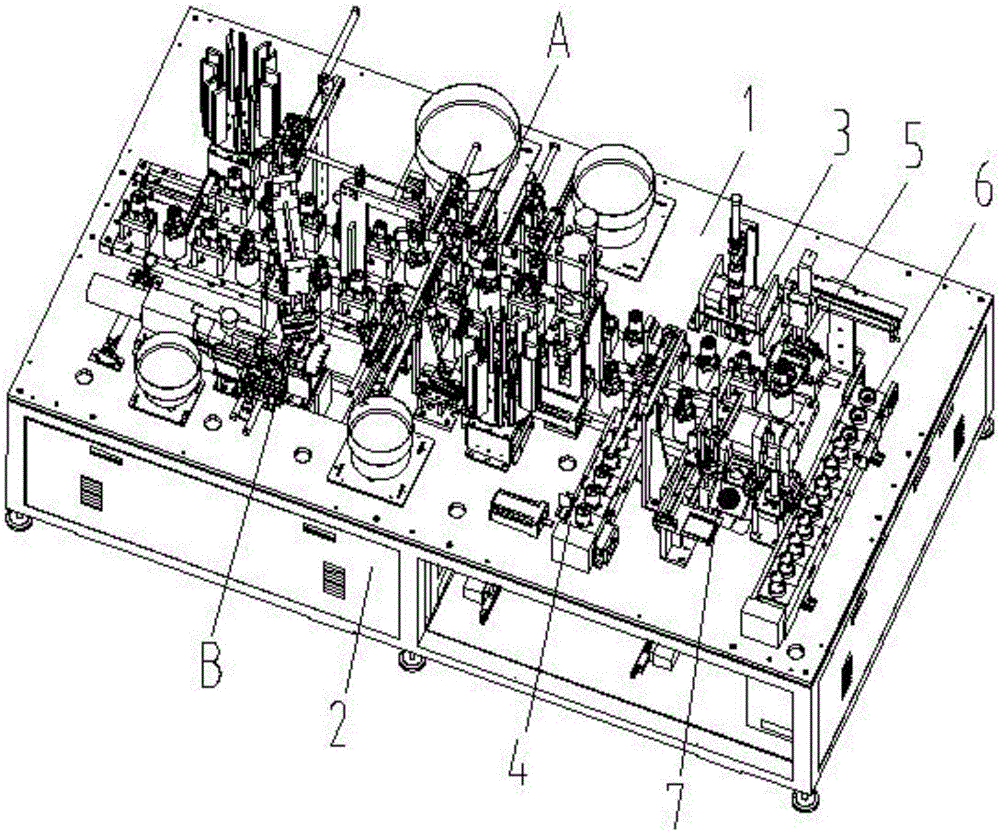

The invention relates to a full-automatic assembly production machine for a motor stator. The full-automatic assembly production machine comprises a frame and a distribution control box, a conveying device is arranged on the frame and comprises two feeding devices, feeding blocks are arranged on the feeding devices, transposition cylinders are arranged at ends of the two feeding devices, shell assembly carriers and magnetic tile assembly carriers are arranged on the feeding blocks, a clamp spring feeding device, an oil bearing feeding device, a shell feeding manipulator, a riveting device, a grounding terminal assembly device, a left magnetic tile feeding device, a magnetic tile spring piece feeding device, a right magnetic tile feeding device, a sleeving manipulator, a compression device, a magnetizer and a turnover discharging device are arranged on the frame, the shell feeding manipulator is matched with a shell conveying belt on the frame, and the turnover discharging device is matched with a discharging conveying belt on the frame. Integrated automatic assembly is realized, and assembly efficiency is greatly improved.

Owner:ANHUI DALAI MOTOR CO LTD

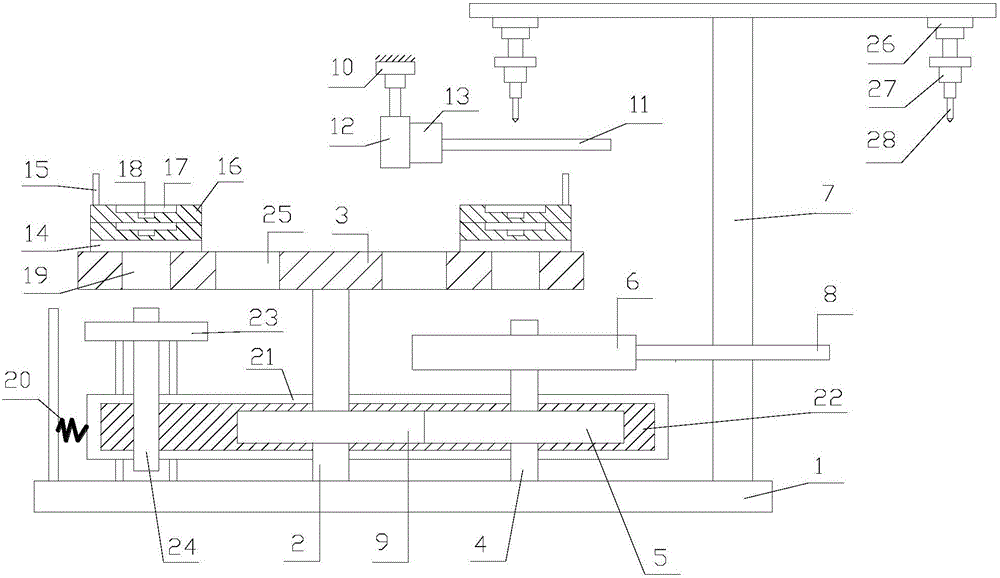

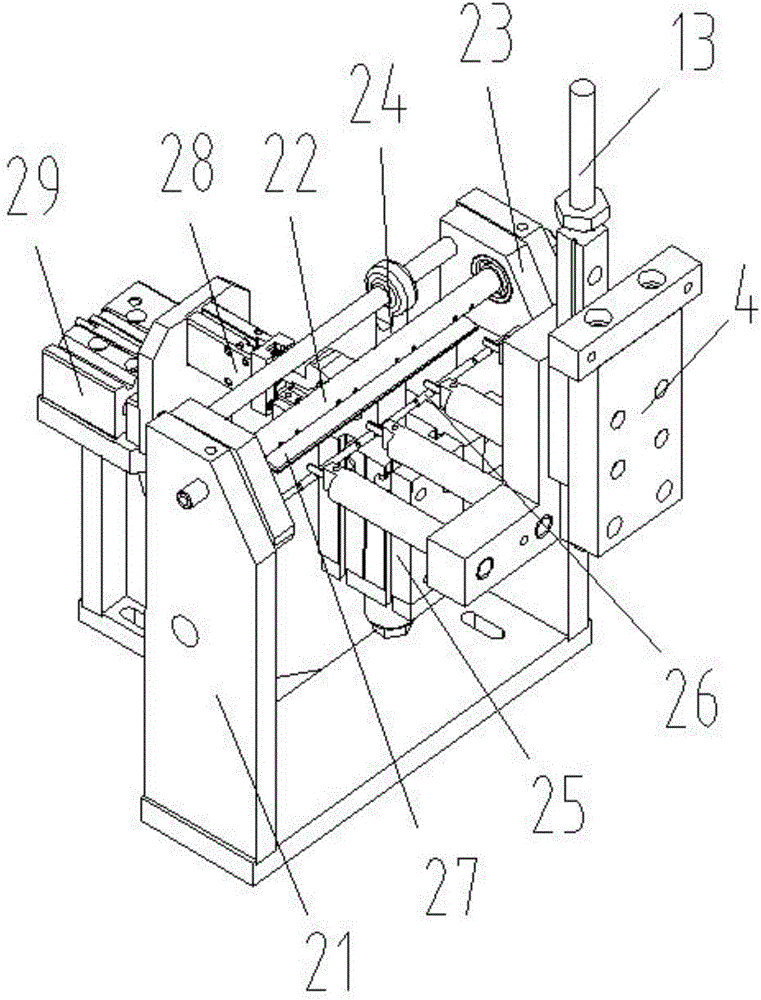

Machine tool for processing workpieces

InactiveCN105710730ACooperate skillfullyConvenient and flexible processingMetal working apparatusPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool for workpiece processing, which comprises a base, a rotating shaft, a wheel disc, a plurality of clamps, a rotating shaft, a first rotating wheel, a second rotating wheel, a supporting shaft, a driven gear, and M actuators . Drive mechanism, wherein, M is an integer greater than or equal to 2; the rotating shaft is installed on the base in rotation, the center line of the rotating shaft is vertically arranged, and the circumferential surface of the rotating shaft is provided with first gear teeth; the wheel disc is installed on on the rotating shaft; multiple fixtures are installed on the wheel, and the multiple fixtures are evenly distributed on the circumference centered on the center of rotation of the wheel; the rotating shaft is installed vertically on the base, and the rotating shaft is connected to the base in rotation on one side of the wheel. The invention has high processing precision and good processing effect.

Owner:芜湖中驰机床制造有限公司

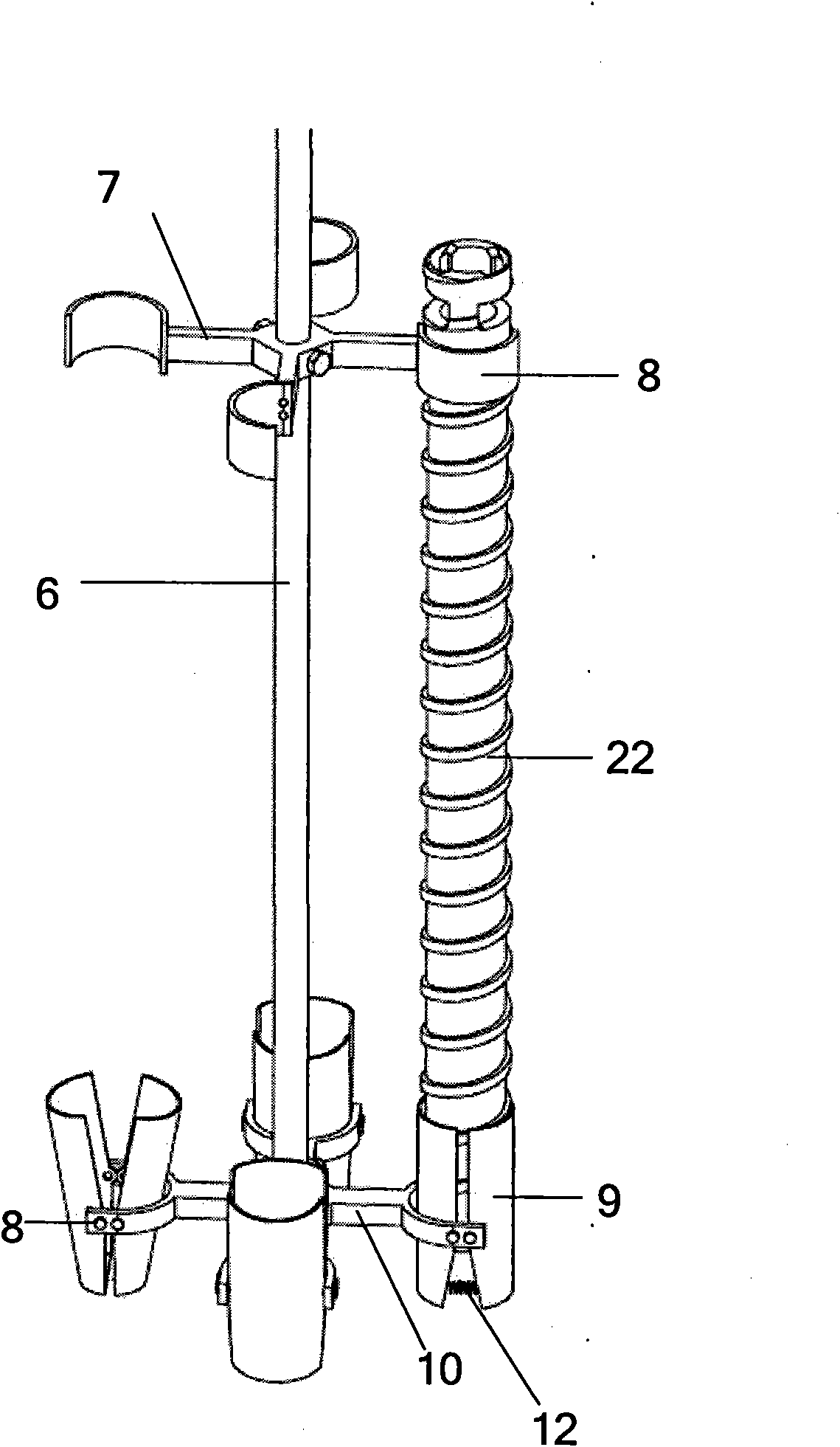

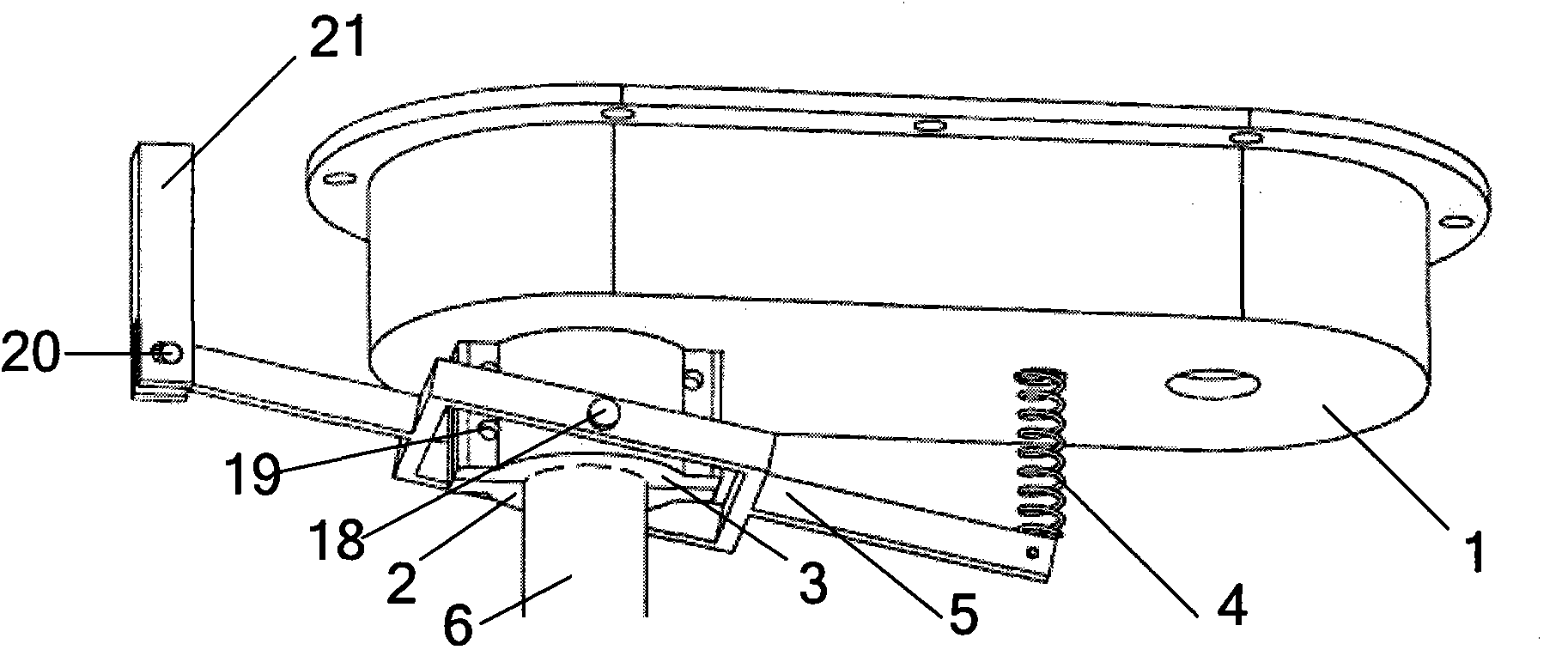

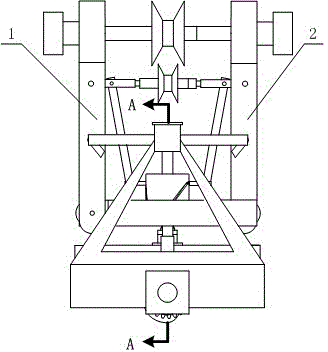

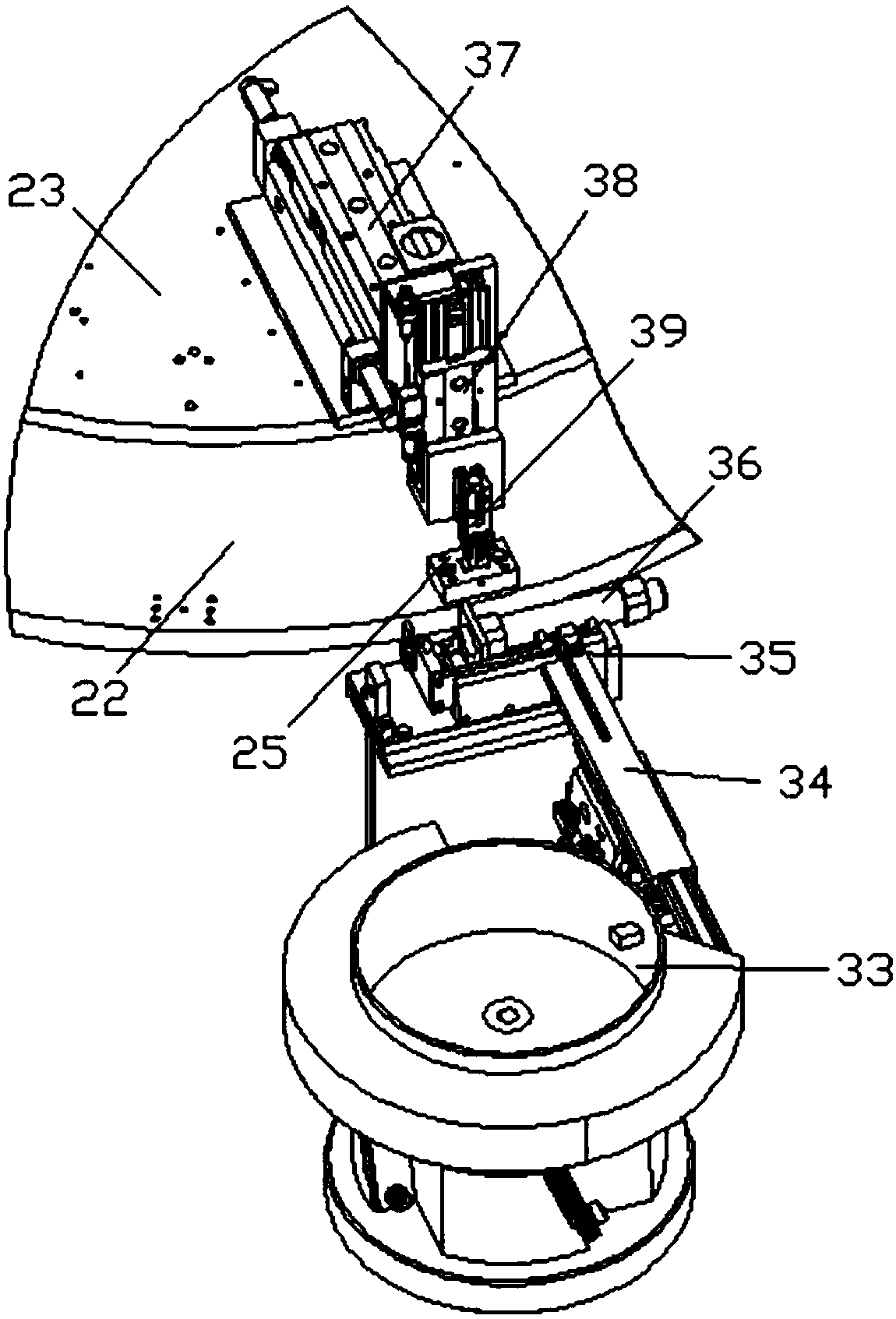

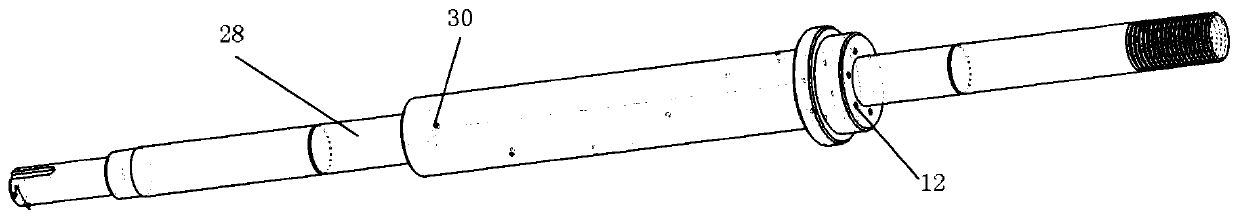

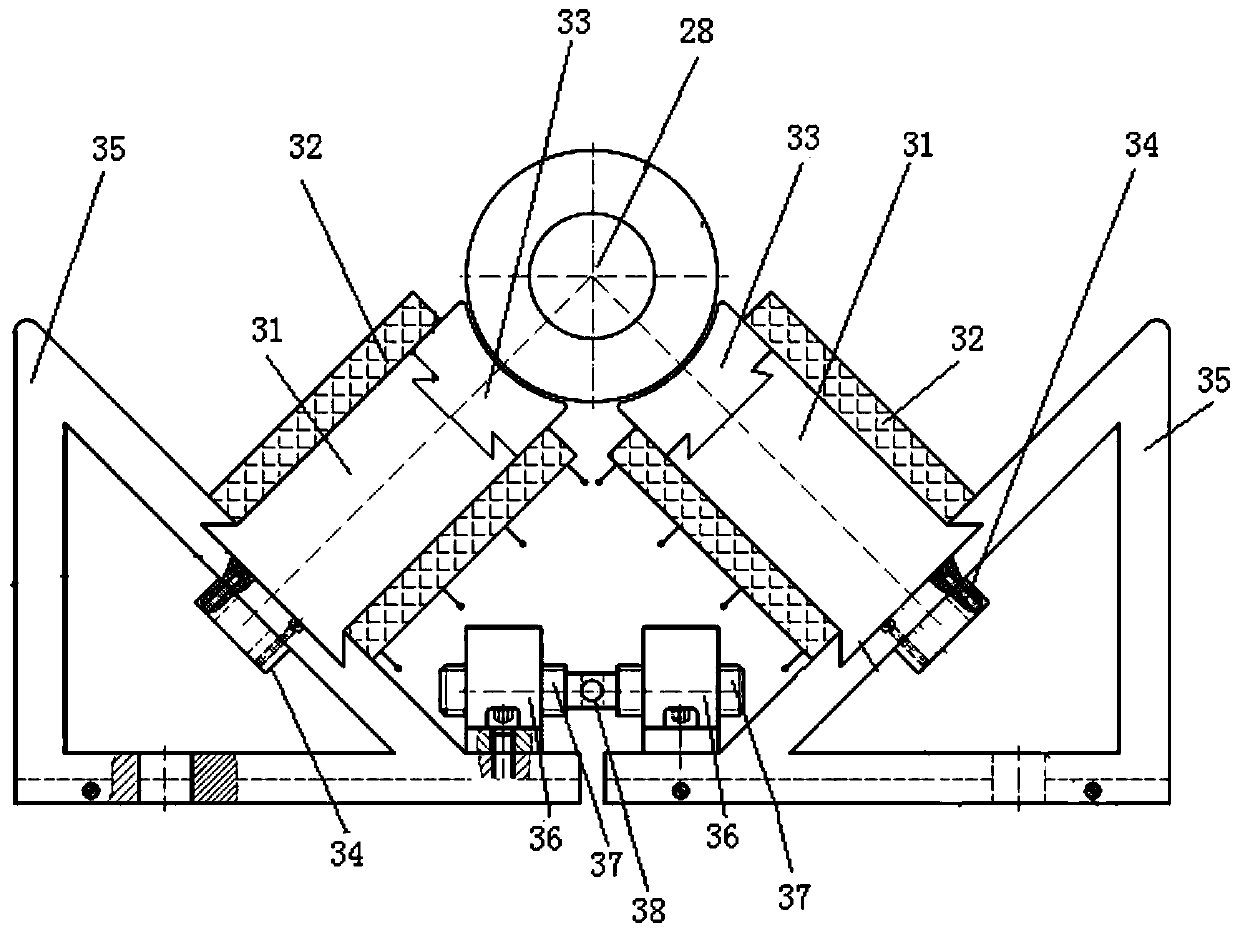

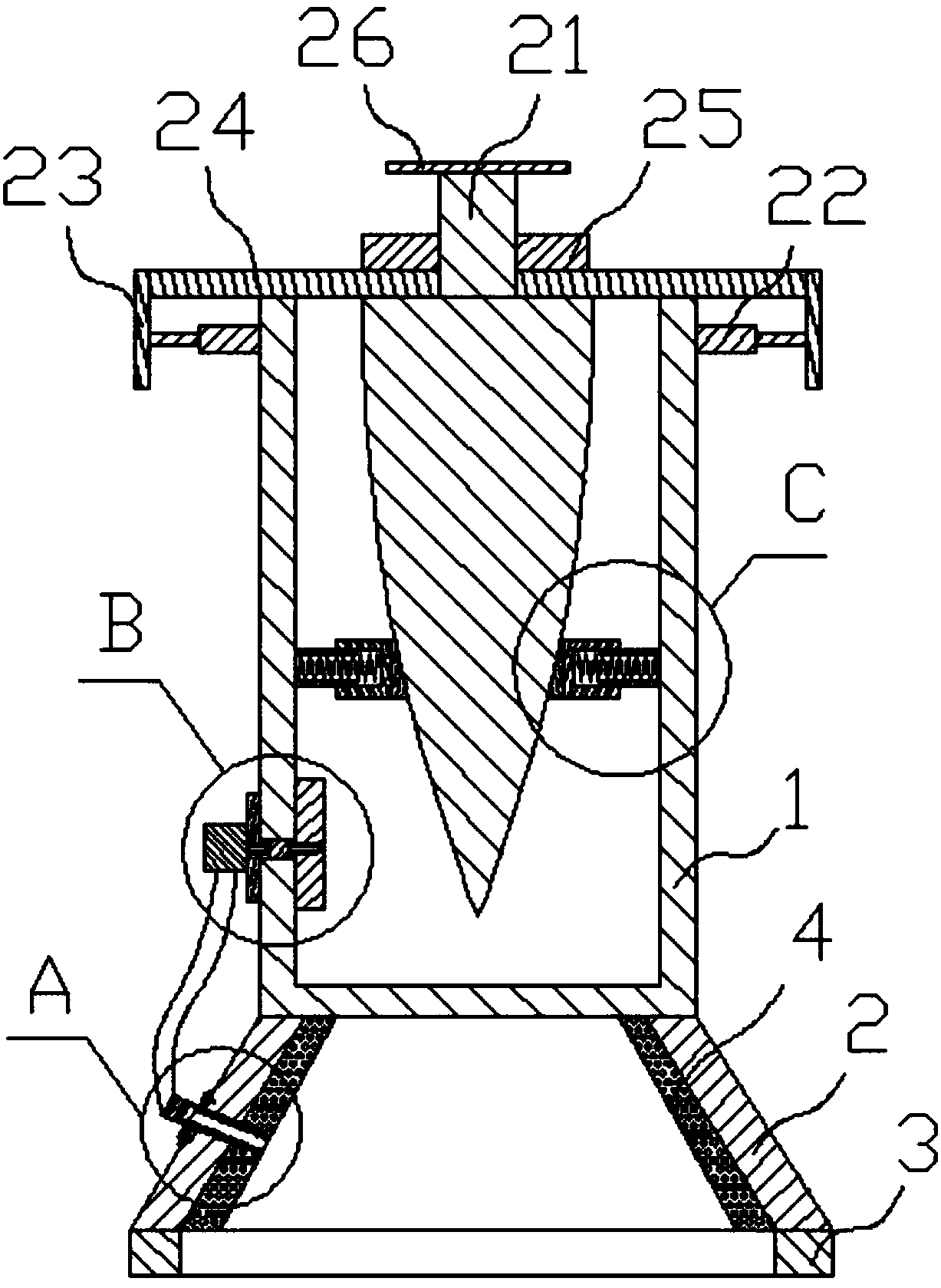

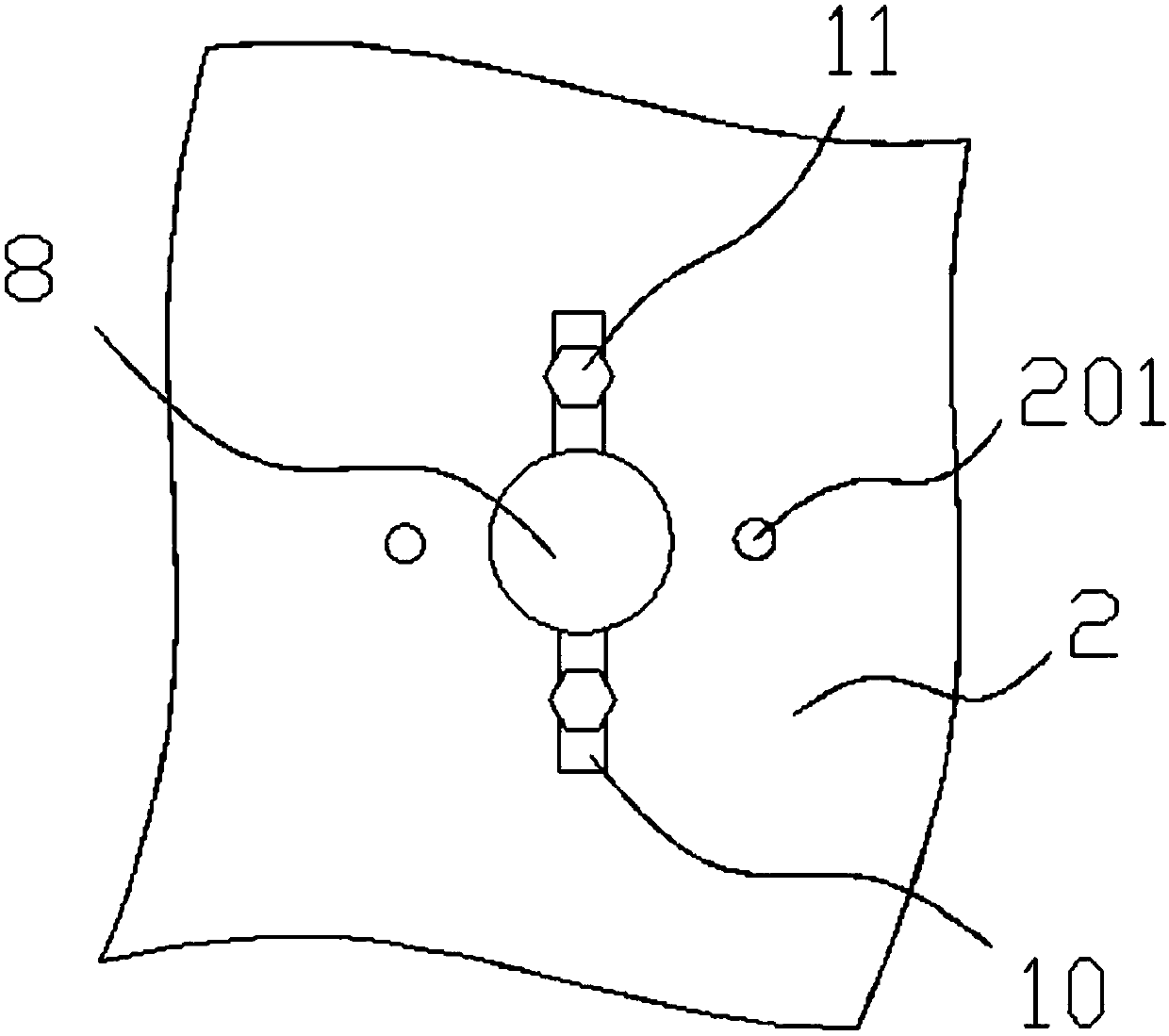

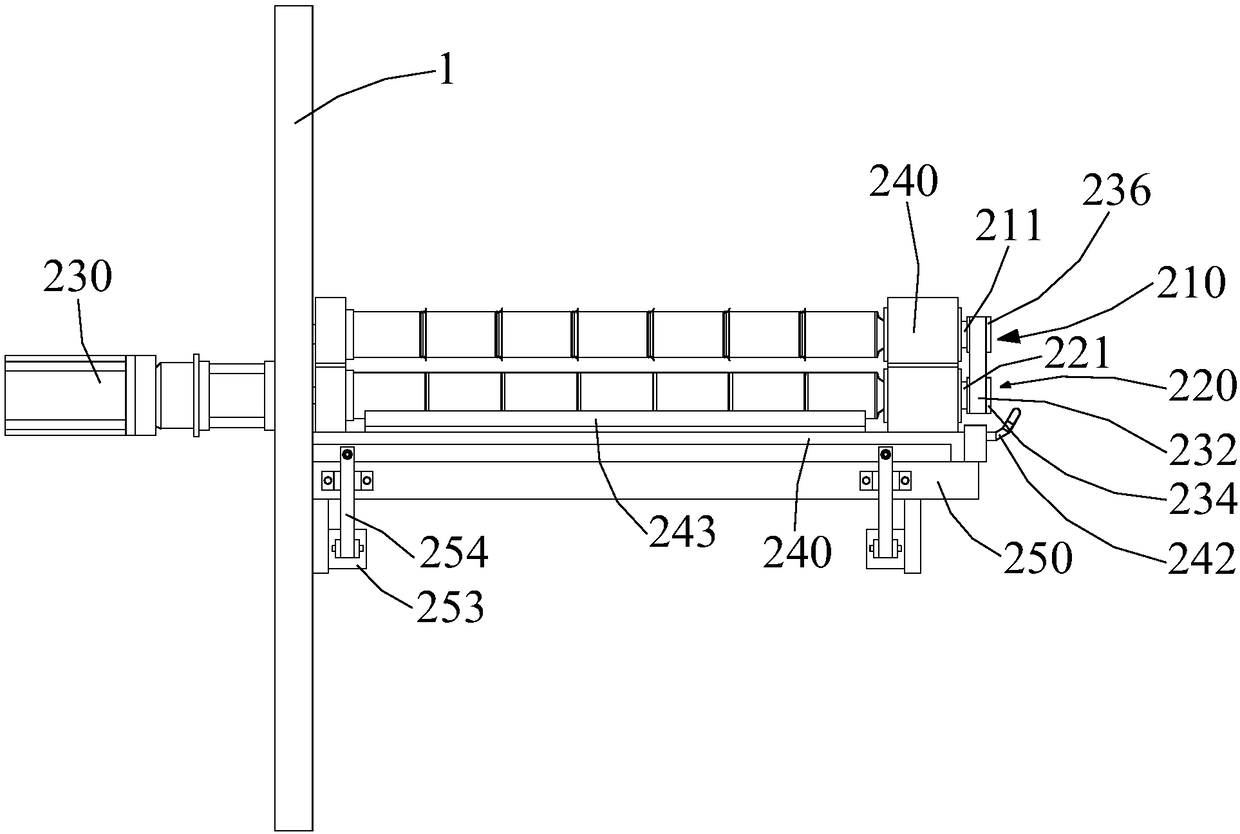

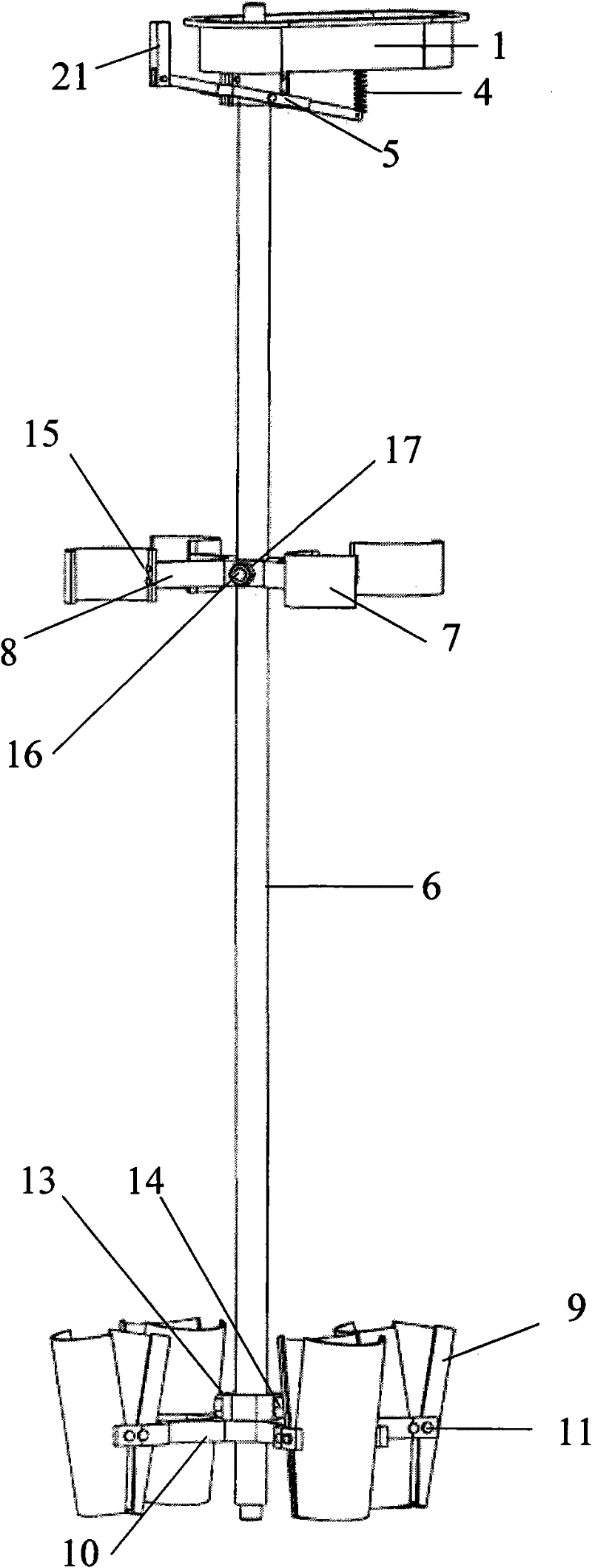

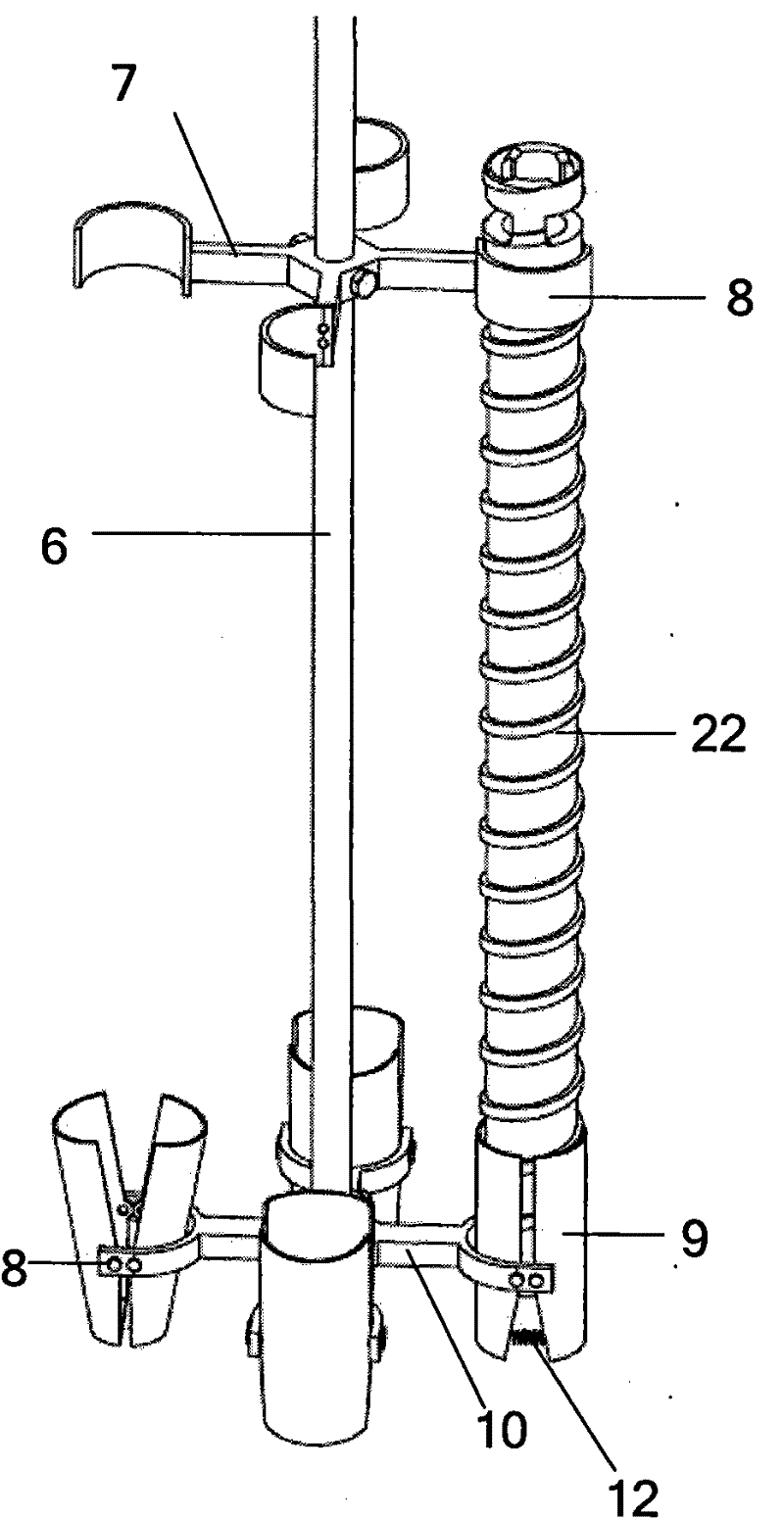

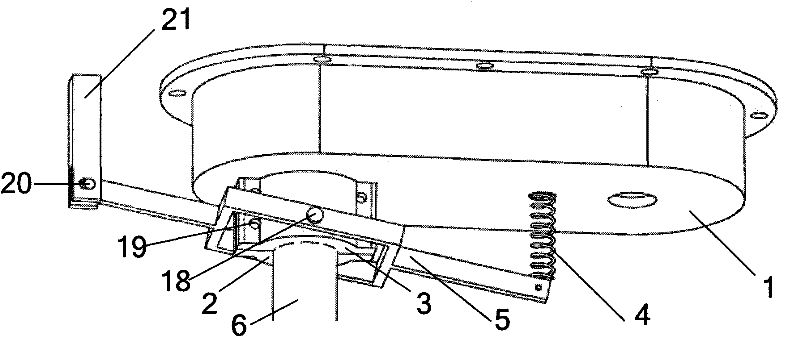

Pole-changing positioning mechanism and pole-changing positioning method for multi-pole deep lunar soil sampler

InactiveCN101936822AAchieve lockingAchieve unlockWithdrawing sample devicesLunar soilInterference problem

The invention provides a pole-changing positioning mechanism and a pole-changing positioning method for a multi-pole deep lunar soil sampler. The pole-changing positioning mechanism comprises a clamping mechanism and a pole-changing mechanism, wherein the clamping mechanism comprises a support mechanism at the lower end, a guide mechanism at the upper end and a central rotating shaft. The support mechanism at the lower end comprises a cylindrical clamp, a tension spring, a rotating shaft of the cylindrical clamp, a clamp rotating disc, a bolt A and a nut A; the guide mechanism at the upper end comprises a guide handle, a screw A, a guide rotating disc, a bolt B and a nut B; and the pole-changing mechanism comprises a positioning sliding block A, a positioning sliding block B, the rotating shaft of a lever frame, a pivot bracket, a return spring, the lever frame, a screw B, a pivot rotating shaft and a gear case. The pole-changing positioning mechanism has simple structure and low energy consumption, and can simplify the control process; simultaneously, the pole-changing positioning mechanism can solve the motion interference problem during pole-changing positioning, lead a drill rod to realize complete drilling down and achieve the desired sampling depth.

Owner:BEIHANG UNIV

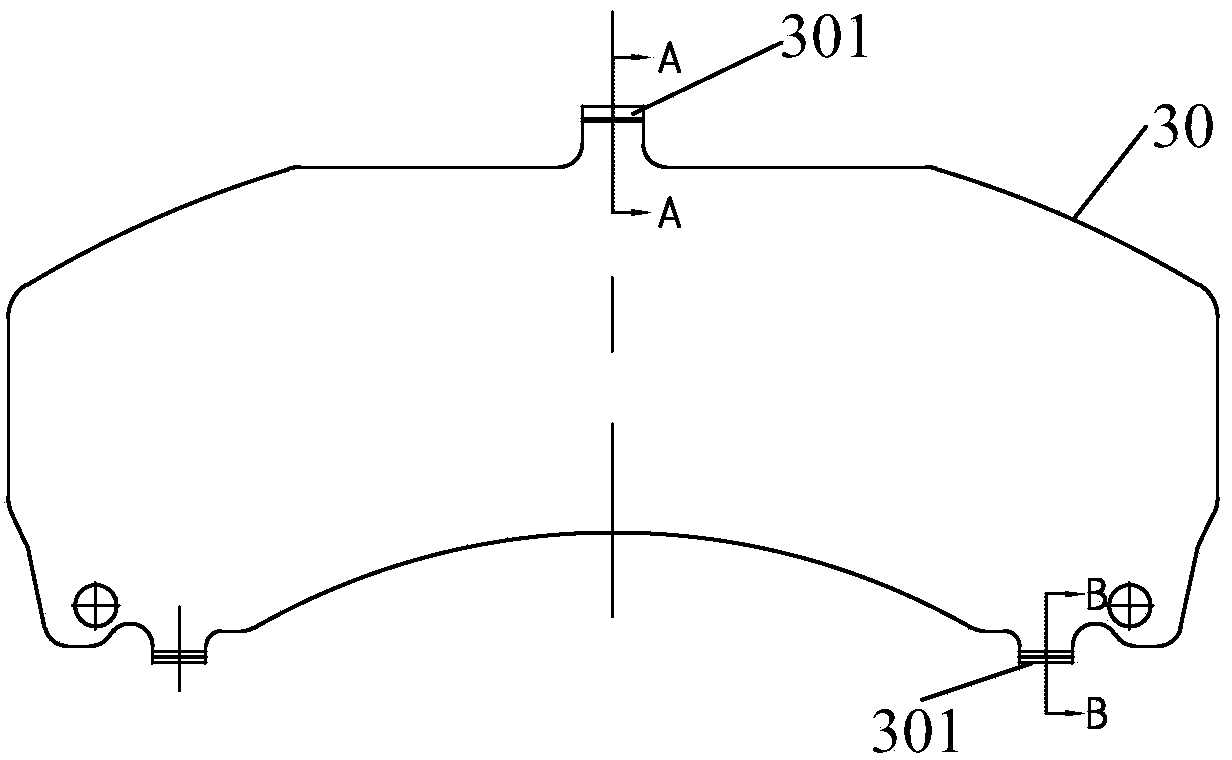

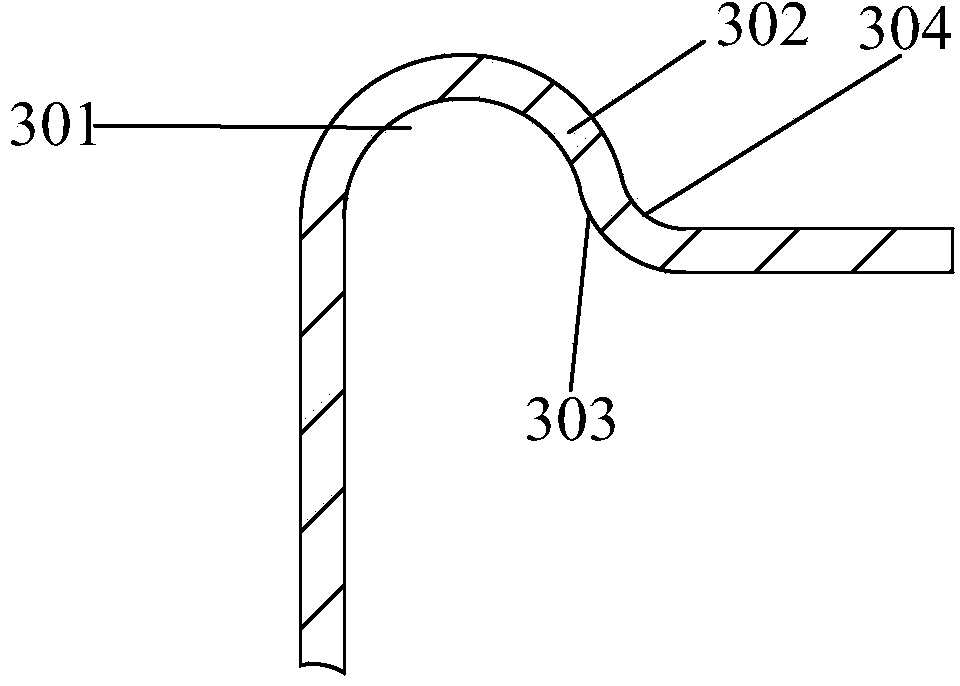

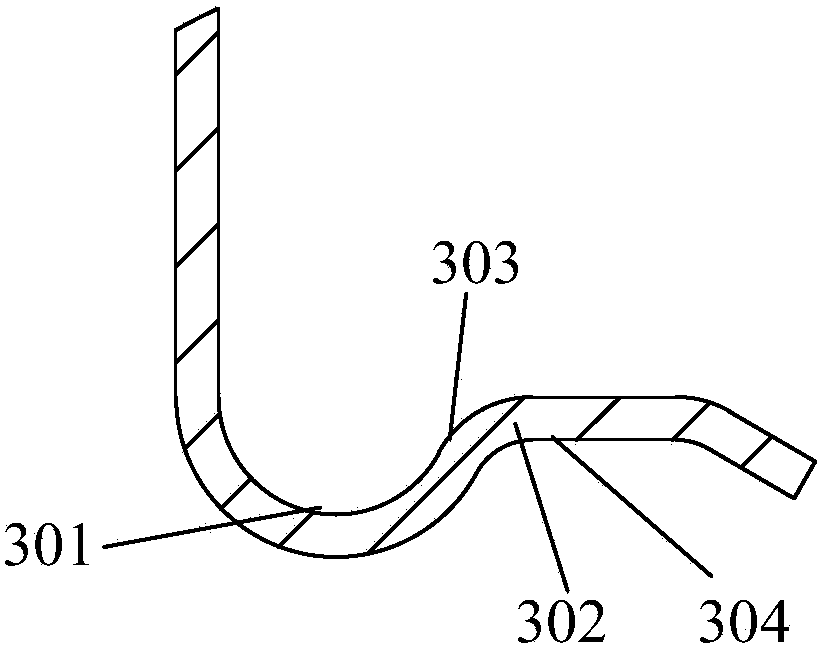

Progressive die of concave bayonet bloop and production method of concave bayonet bloop

ActiveCN103506492AImprove operational safetyStrong order response abilityShaping toolsPunchingEngineering

The invention discloses a progressive die of a concave bayonet bloop and a production method of the concave bayonet bloop. The progressive die of the concave bayonet bloop comprises an upper die and a lower die matched with the upper die, and a bloop material strap goes forward between the upper die and the lower die; in the advancing direction of the bloop material strap, the lower die is sequentially provided with a lower die punching insert core used for punching the bloop material strap, a lower die pre-bending insert core used for concave bayonet half forming, and a lower die blocking foot bending insert core used for blocking foot forming; the upper die is provided with a punching plunger chip matched with the lower die punching insert core, a pre-bending insert core matched with the lower die pre-bending insert core, and a blocking foot bending plunger chip matched with the lower die blocking foot bending insert core. The progressive die is high in production automation degree, productivity and quality of products are greatly promoted, manual operation safety is high, labor intensity is also greatly weakened, manpower and drilling crews are saved, production management is convenient and fast, and customer order response ability is high.

Owner:韶关德嘉汽车零部件有限公司

System used for automatically machining workpiece

InactiveCN105773313AEasy to collectContinuous operationMetal working apparatusEngineeringMechanical engineering

Owner:芜湖中驰机床制造有限公司

Robot-dedicated mechanical fixture

ActiveCN106272507AAddressing Structural ComplexitySolve installation difficultiesGripping headsInstabilityCam

The embodiment of the invention discloses a robot-dedicated mechanical fixture. An end rotary shaft of a robot is utilized as a power source, the power of the end shaft of the robot is transmitted to a first stepped shaft by connecting the first stepped shaft with an end moving shaft of the robot, moreover, the power is transmitted onto a cam via a half-tooth bevel gear, second stepped shafts and third stepped shafts, the cam then alternately rotates by 180 degrees to open and close grabbing plates, and thereby the requirement of the action of clamping a workpiece is met. The robot-dedicated mechanical fixture solves the technical problems of complex structure, difficulty in mounting and instability in use existing in industrial robot fixtures with an additional power source.

Owner:GUANGDONG UNIV OF TECH

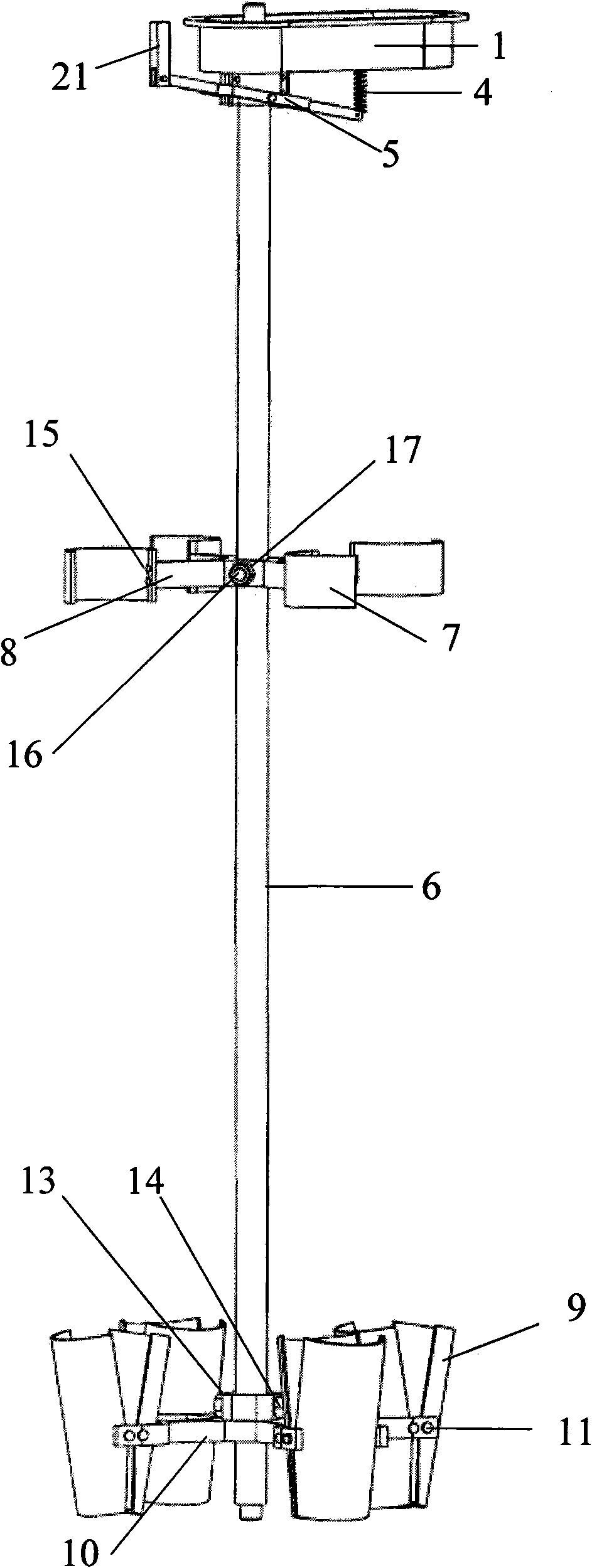

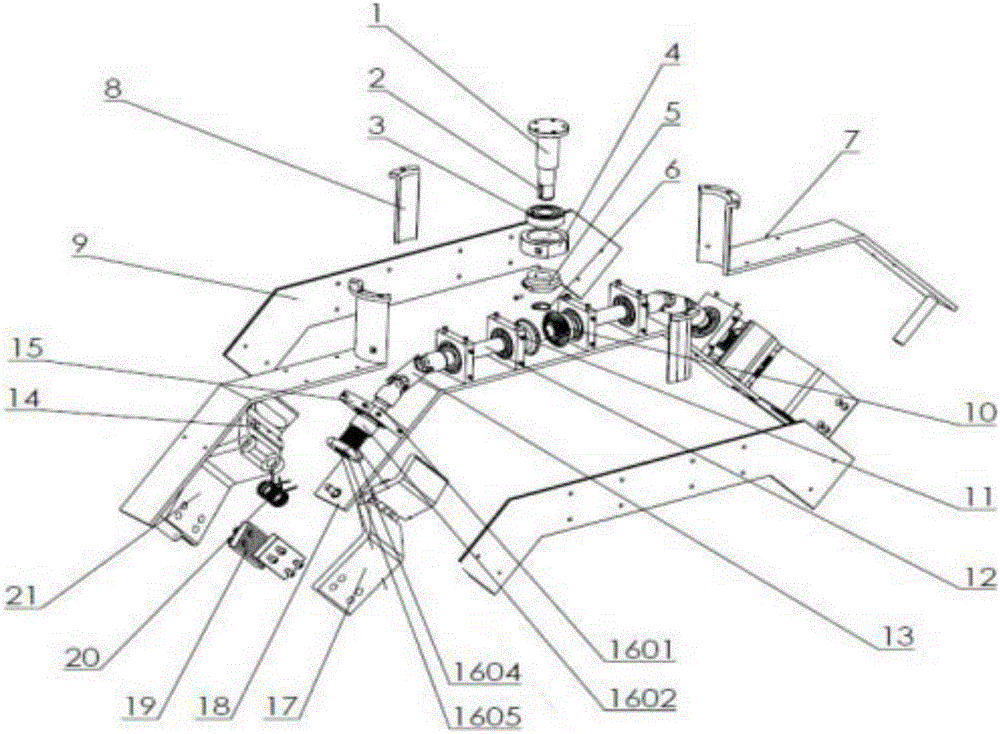

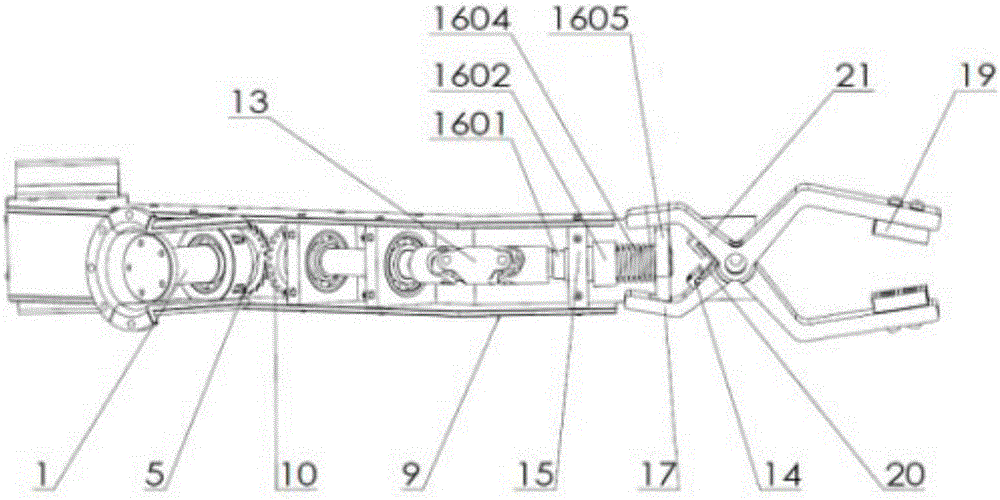

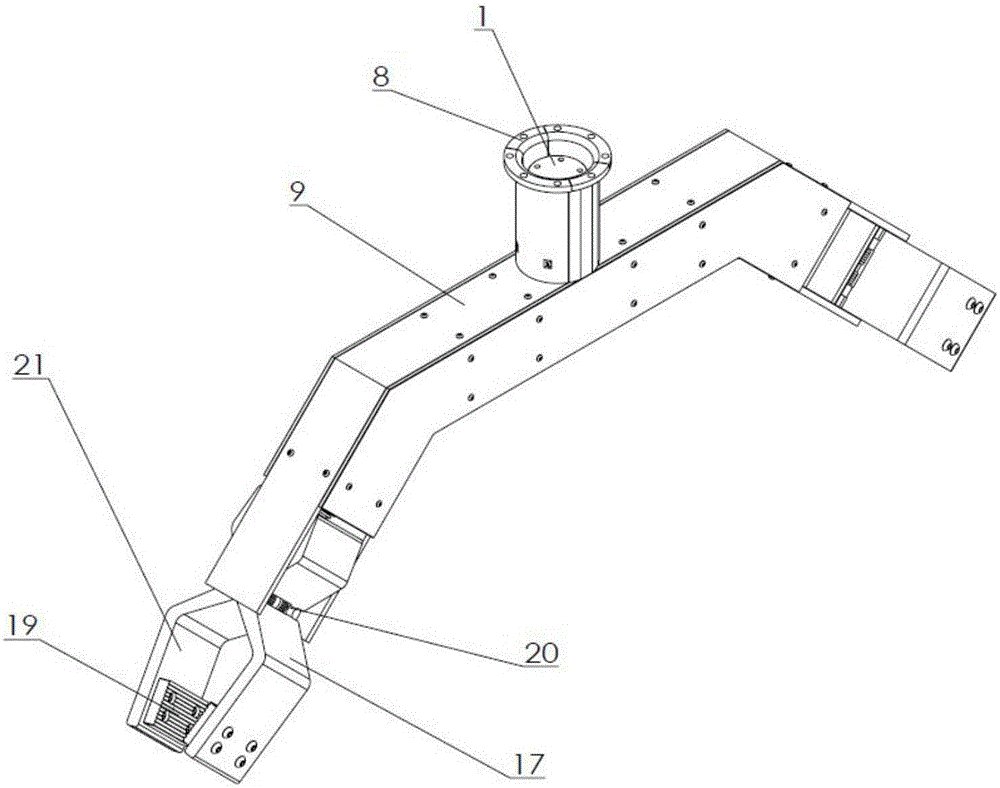

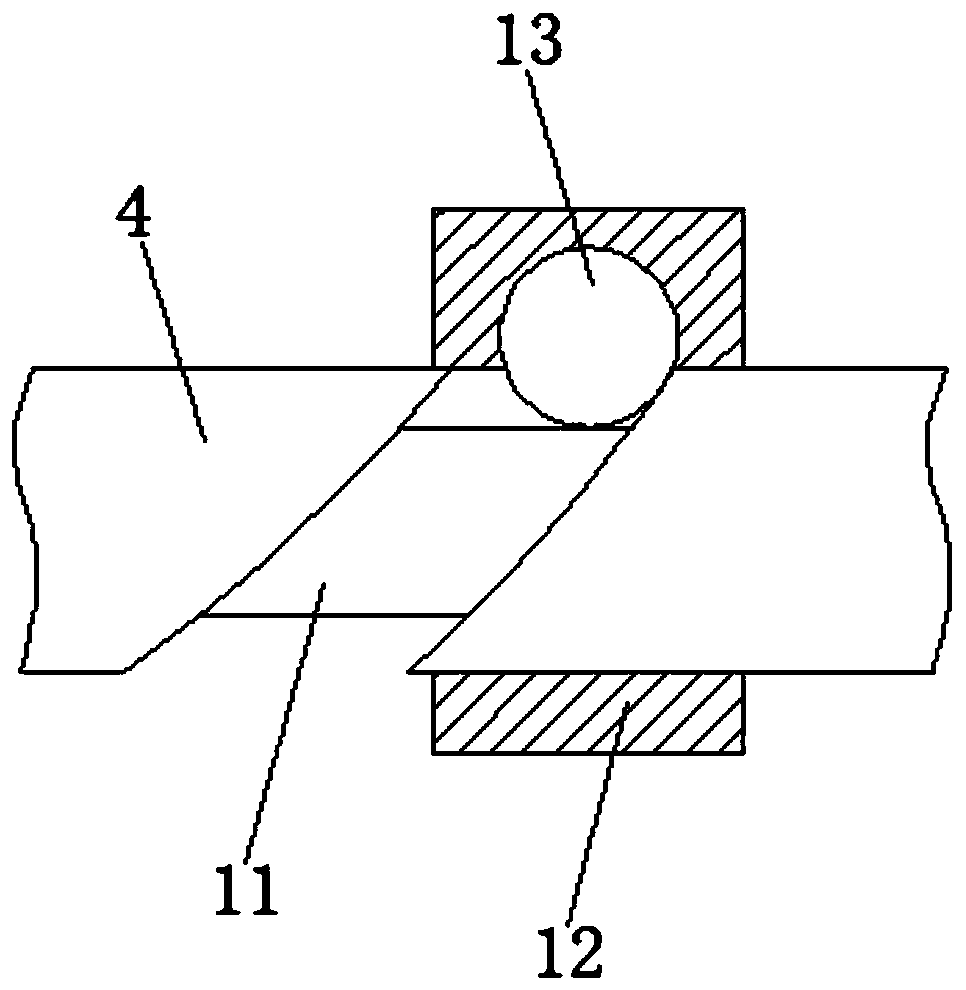

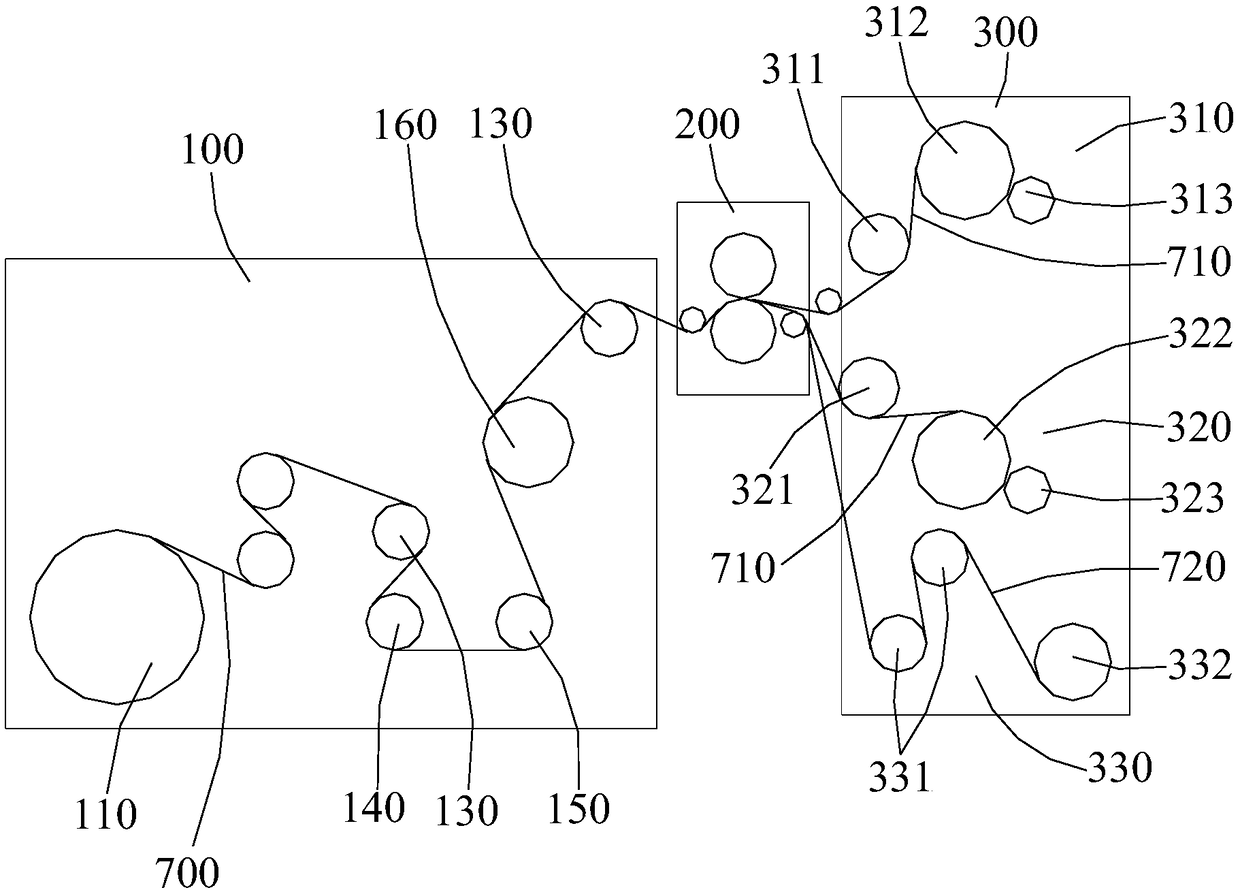

High voltage line patrol robot with single motor to control movement of three arms

ActiveCN104485607AIngenious structureSimple structureApparatus for overhead lines/cablesElectric machineEngineering

The invention relates to a high voltage line patrol robot with a single motor controlling movement of three arms. The high voltage line patrol robot comprises a first mechanical arm fixedly mounted on the left side of the bracket via a left support arm and a right support arm, wherein the first mechanical arm is located right behind a cross beam of the bracket. A second mechanical arm is fixedly mounted in the middle of the bracket via a left support arm and a right support arm and located right ahead the cross beam of the bracket, and a third mechanical arm is fixedly mounted on the right side of the bracket via a left support arm and a right support arm and located right behind the cross beam of the bracket. Disc cams and vertical bevel gears are mounted at the bottom ends of the three mechanical arms, a rotation shaft is fixedly mounted at the bottom of the bracket, a swing motor is mounted at the front end of the rotation shaft, and the disc cams and the vertical bevel gears are concentrically and fixedly mounted on the rotation shaft. The robot has the advantages that the cam move to control the movement of the mechanical arms, the robot can avoid a barrier when encountering the barrier and return to the original position for clamping, and the high voltage line patrol robot is driven by the cams, and has a small number of motors, and good climbing ability.

Owner:武汉科技大学资产经营有限公司

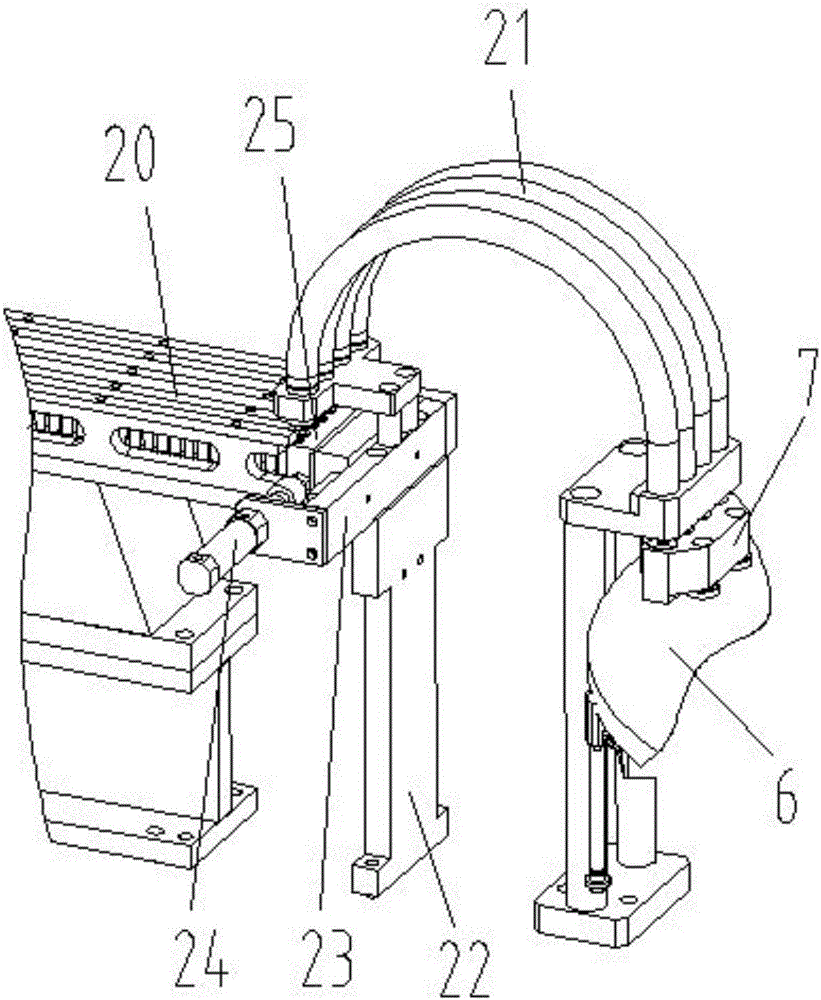

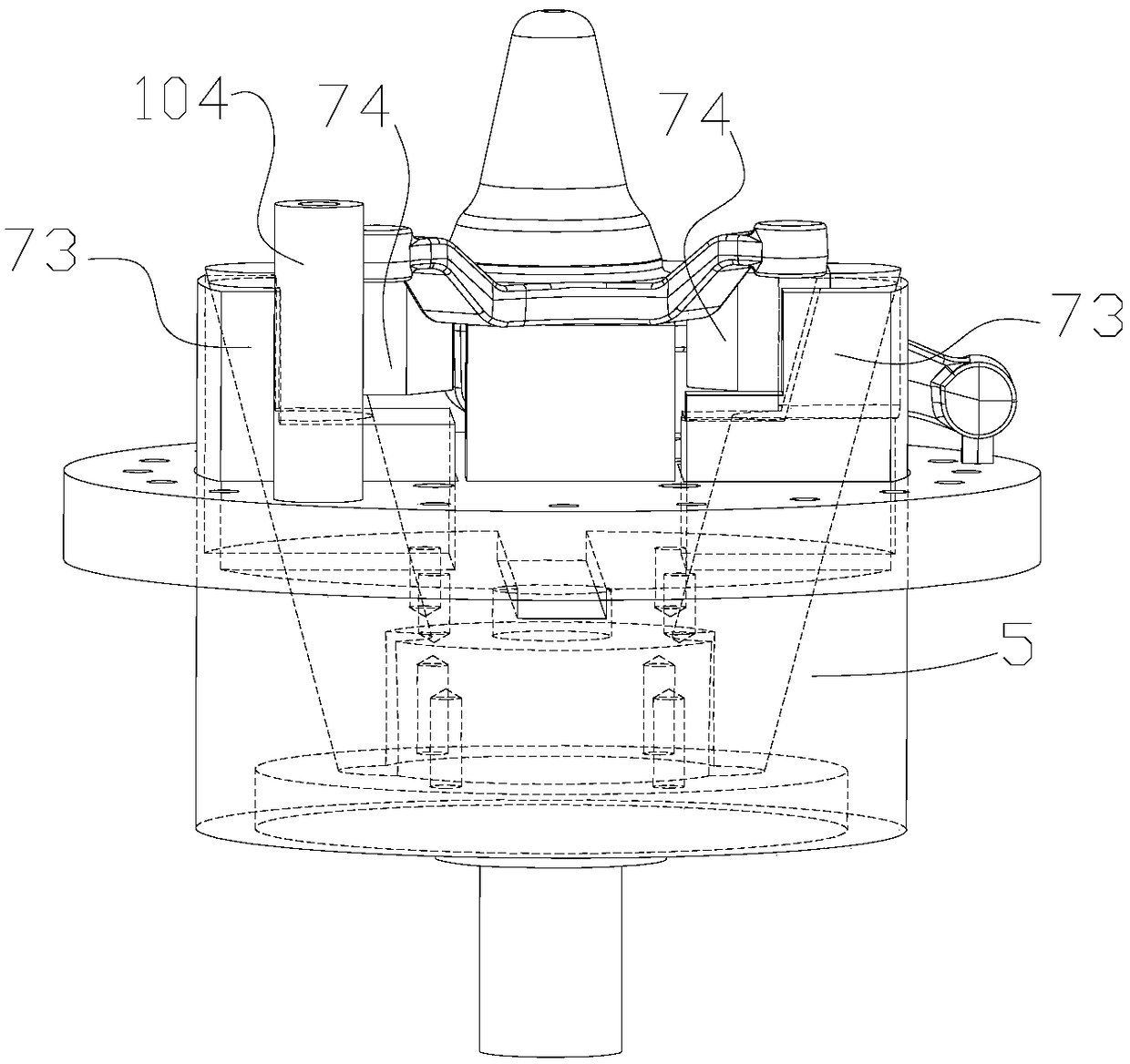

Integrated assembly machine of liquid shampoo gland

ActiveCN106826217ARealize integrated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusDistribution controlEngineering

The invention relates to an integrated assembly machine of a liquid shampoo gland. The integrated assembly machine comprises a power distribution control box, a rotary disc and an operation display screen, the rotary disc and the operation display screen are connected with the power distribution control box, carriers are evenly arranged on the rotary disc, each carrier comprises a carrier body arranged on the rotary disc, a matching hole matched with a spring base and a spring sleeve is arranged on each carrier body, and a guide rod penetrating out the rotary disc is fixedly connected to each carrier body; a spring base feeding device, a spring feeding device, a spring base feeding device, a thimble pipe feeding device and a pressing device which are matched with each carrier are sequentially arranged above the rotary disc in the anti-clockwise direction and are all connected to the power distribution control box; and each pressing device comprises a pressing base provided with a pressing air cylinder, a pressing block matched with the corresponding carrier is connected to the lower portion of each pressing air cylinder, and the pressing air cylinders are connected to the power distribution control box. By means of the integrated assembly machine, integrated assembling of the liquid shampoo gland can be automatically achieved, the assembling efficiency is greatly improved, the production hours are reduced, and the manpower consumption is reduced.

Owner:广州市柏亚化妆品有限公司

Steel rail grinding device and use method thereof

ActiveCN110241668AEfficient automatic grindingEasy to useGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention discloses a steel rail grinding device and a use method thereof. The steel rail grinding device comprises a motor, a bracket, a grinding mechanism, a driving device, a first transmission mechanism and a second transmission mechanism, wherein the grinding mechanism is used for grinding an iron rail; the driving device is used for driving the bracket to move relative to the iron rail; the first transmission mechanism is used for connecting an output shaft of the motor with the grinding mechanism; the second transmission mechanism is used for connecting the output shaft of the motor with the driving device; the driving device is rotationally mounted on the bracket and can be used for being connected to the two sides of the iron rail in a contacting manner; the motor is mounted on the bracket; and the grinding mechanism can rotate relative to the bracket and can be arranged to move in a reciprocating manner. The steel rail grinding device disclosed by the invention has the advantages that the structure is skillful, reasonable and compact, the operation is convenient, and the iron rail can be efficiently ground.

Owner:江苏领岳重工有限公司

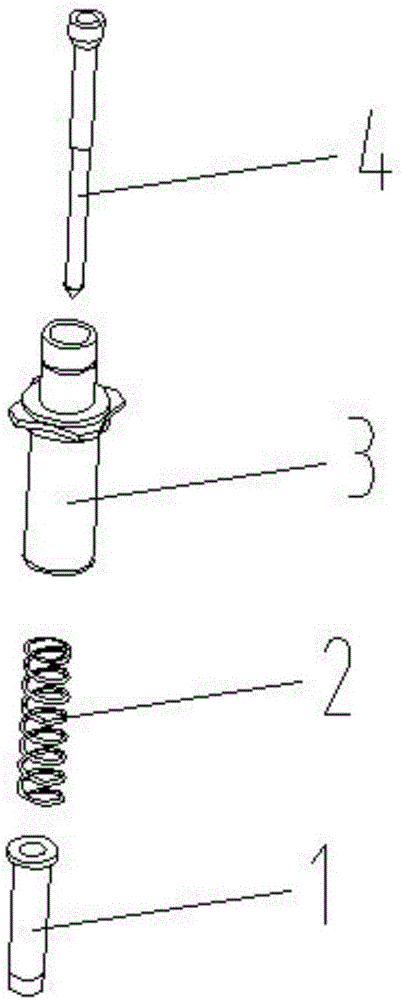

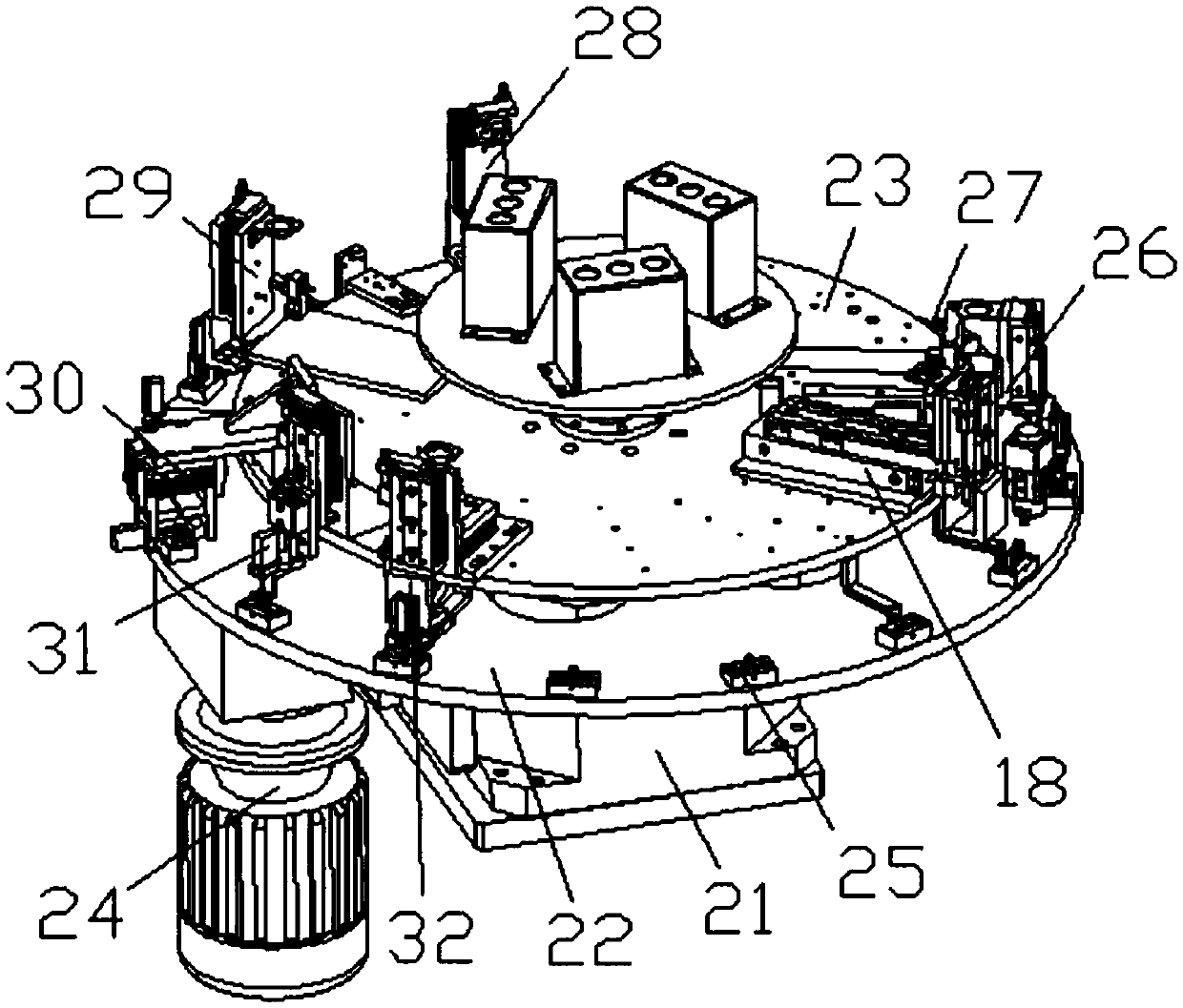

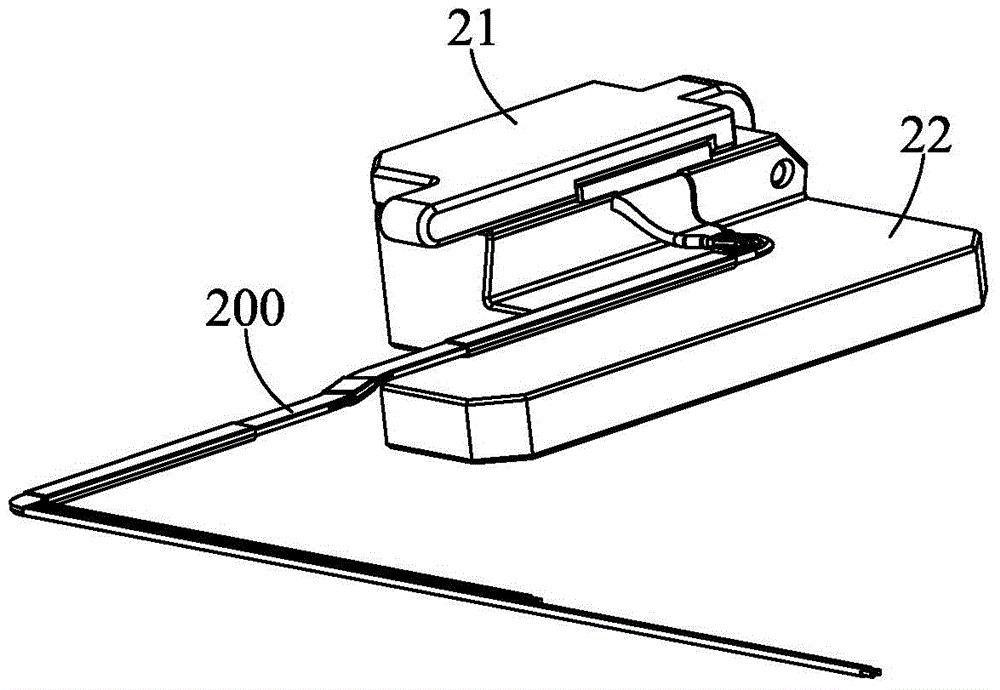

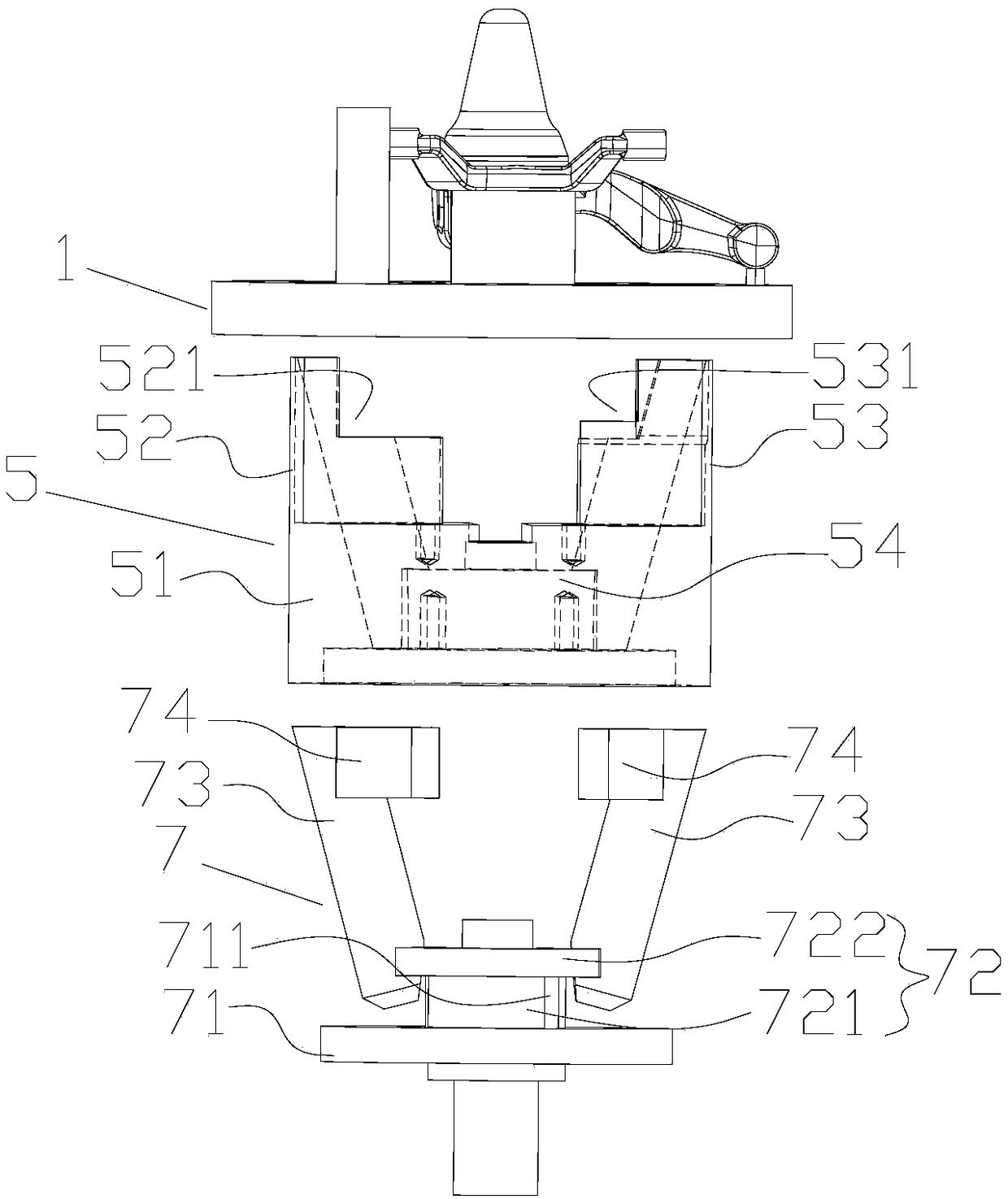

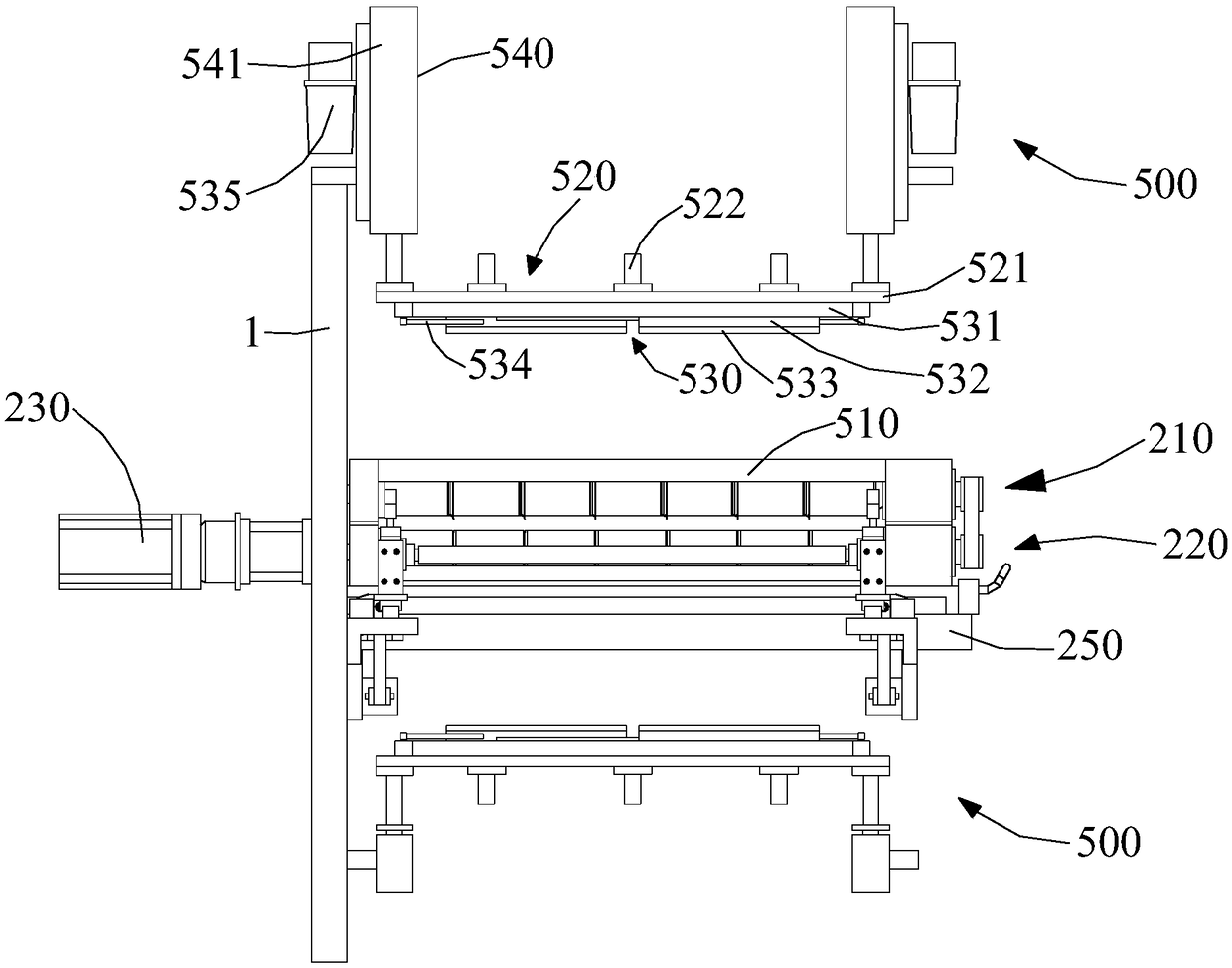

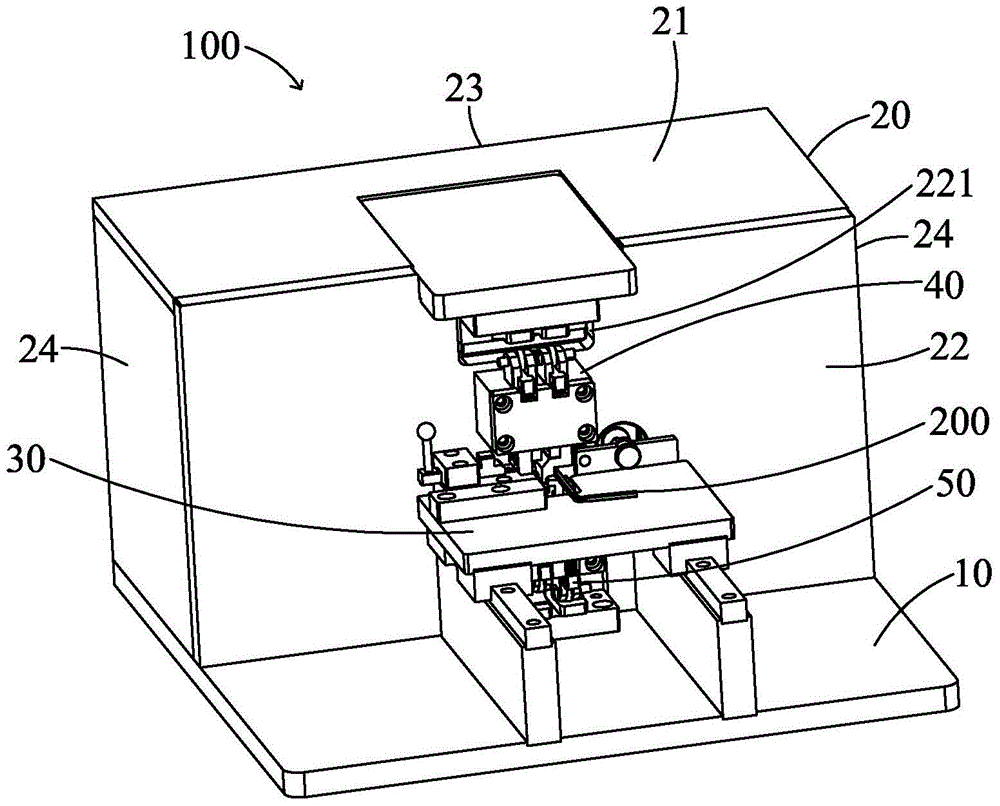

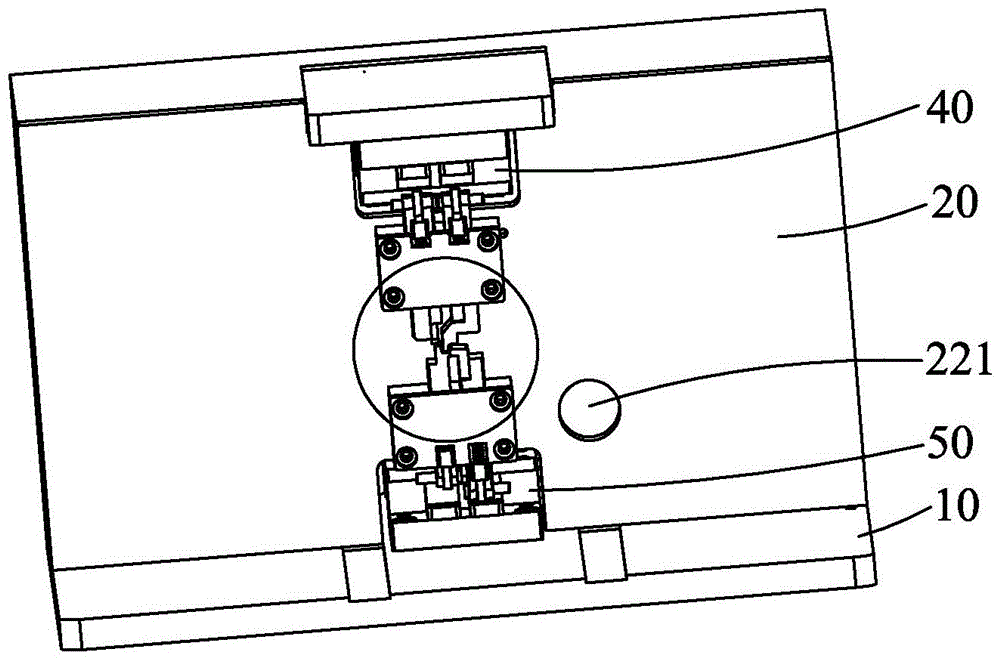

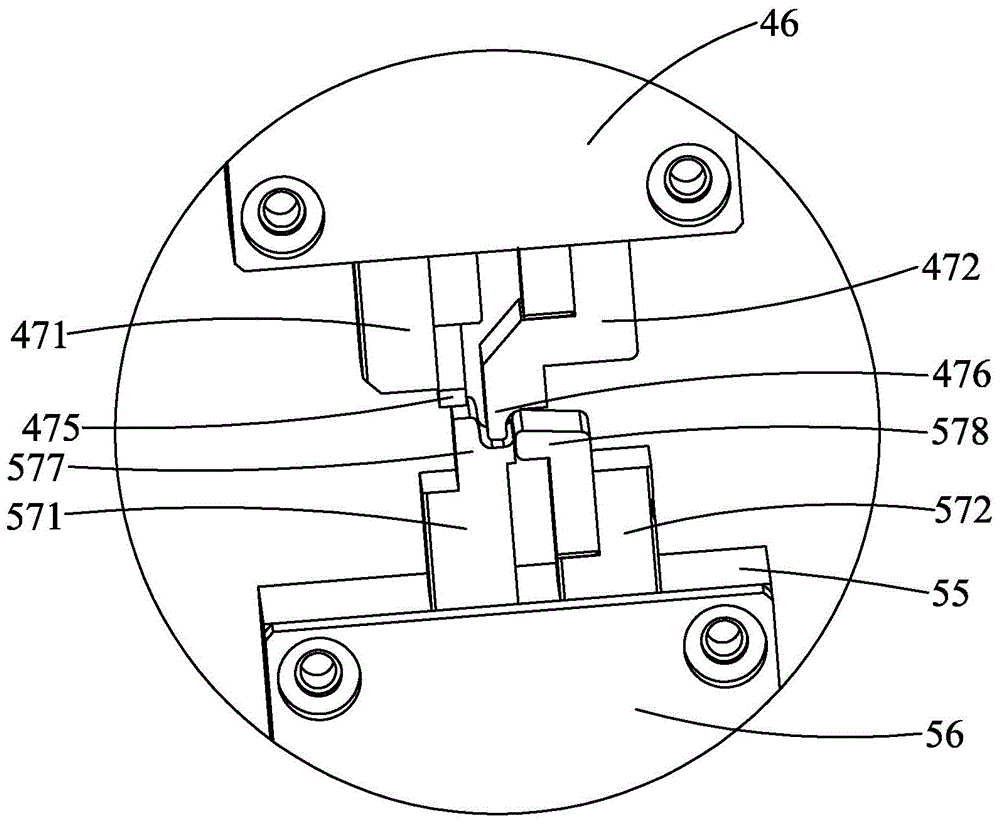

Full-automatic optical fiber head assembling machine capable of conducting insertion core assembling

ActiveCN107553130AImprove processing efficiencyTighten to achieveAssembly machinesDistribution controlButt joint

The invention relates to a full-automatic optical fiber head assembling machine capable of conducting insertion core assembling. The full-automatic optical fiber head assembling machine comprises a rack and a power distribution control box. The rack is provided with a rotary disc assembly, a base assembling mechanism, a spring assembling mechanism, a shell assembling mechanism, a cover sealing assembling mechanism and a discharging device, wherein the base assembling mechanism, the spring assembling mechanism, the shell assembling mechanism, the cover sealing assembling mechanism and the discharging device are matched with the rotary disc mechanism. A rotary disc rack comprises an assembling rotary disc installation base arranged on the rack, an assembling rotary disc and an assembling fixing disc which are concentric are installed on the assembling rotary disc installation base, the assembling rotary disc is matched with an assembling rotary disc motor, and assembling carriers are evenly arranged at the outer portion of the assembling rotary disc in an annular shape. An insertion core assembling mechanism is arranged between the spring assembling mechanism and the shell assemblingmechanism. By means of the full-automatic optical fiber head assembling machine capable of conducting insertion core assembling, an insertion core assembling rotary disc can be matched with an insertion core assembling part to synchronously machine the insertion core while all parts of the assembling rotary disc are used for assembling, meanwhile, unqualified products of insertion core sleeves can also be removed, in addition, the assembled insertion core and a rotary disc assembling part can be in seamless butt joint, and the overall machining efficiency of an optical fiber head is improved.

Owner:东莞鸿辉光联通讯技术有限公司

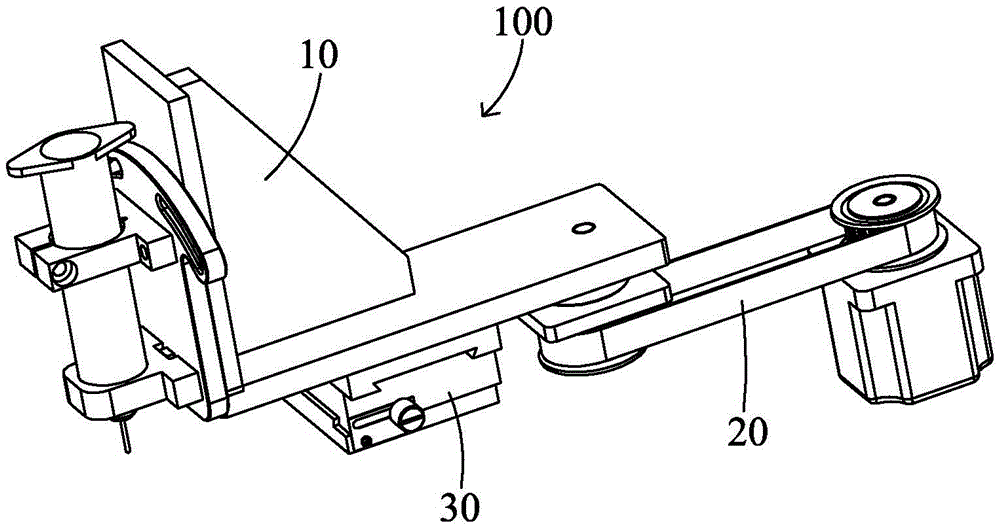

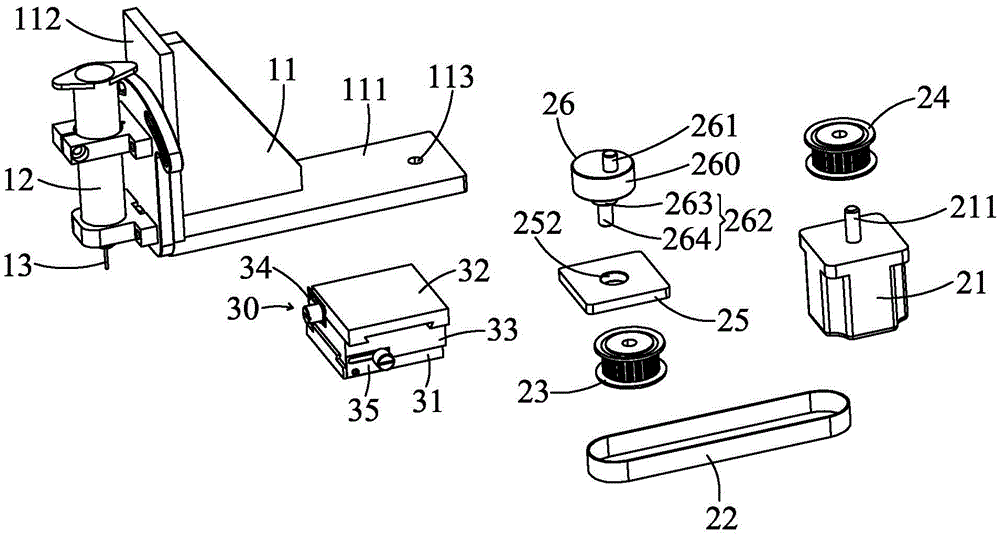

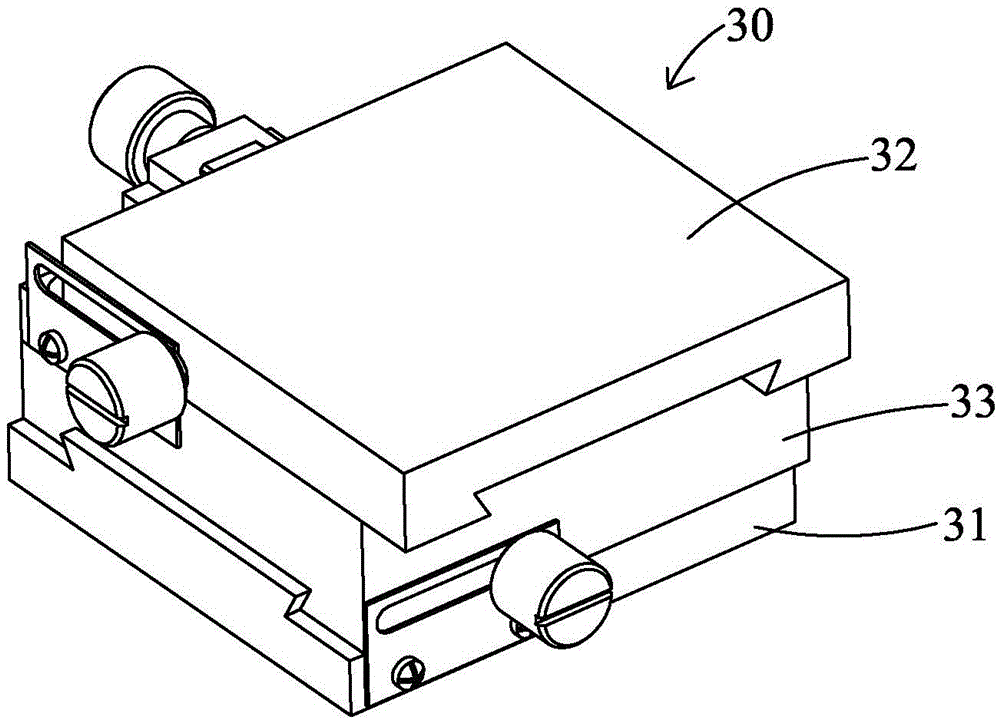

Automatic dispensing feeding device

ActiveCN105478302ASimple structureReduce manufacturing costLiquid surface applicatorsCoatingsCircular discAutomatic Dispensing

The invention relates to an automatic dispensing feeding device. The automatic dispensing feeding device comprises a dispensing mechanism, a power mechanism and a drive mechanism. The dispensing mechanism comprises a support, a pressure barrel fixed to the support, and a dispensing gun arranged at the bottom of the pressure barrel. A pivot hole is formed in the rear portion of the support. The automatic dispensing feeding device is characterized in that the power mechanism comprises a power motor, a belt, a front power wheel, a rear power wheel located behind the front power wheel, and an eccentric wheel; the drive mechanism comprises a disc, a first rotating shaft and a second rotating shaft; the center axis of the first rotating shaft and the center axis of the second rotating shaft are not collinear; the drive mechanism comprises a base, a lower sliding block arranged on the base in a sliding manner, and an upper sliding block arranged on the lower sliding block in a sliding manner, and the support and the upper sliding block are fixed together; and all the mechanisms are compact and ingenious in cooperation, the structure is simple, and the cost is reduced.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

Adjustable intelligent charging and discharging mechanism of punch press

ActiveCN106001305AHigh precisionQuick RetrievalMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention provides an adjustable intelligent charging and discharging mechanism of a punch press. The adjustable intelligent charging and discharging mechanism is mounted at a charging position of a machine tool, and comprises a charging mechanism, a feeding mechanism, an X-axis left-and-right movement liner die set, and a Z-axis up-and-down movement liner die set, wherein the charging mechanism is mounted on one side of the machine tool; the feeding mechanism is erected on the charging mechanism, and the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set are mounted on the feeding mechanism. The adjustable intelligent charging and discharging mechanism of the punch press comprises the charging mechanism, the feeding mechanism, the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set, and through the X-axis left-and-right two-dimensional movement liner die set, and the Z-axis up-and-down two-dimensional movement liner die set, rapid and intelligent material taking can be realized. The adjustable intelligent charging and discharging mechanism is simple in structure and high in operating stability, the precision of a manipulator is high, and the consistency of products is notably improved; besides, normal time for charging and discharging needs to be four hours or above, and the normal processing time of the adjustable intelligent charging and discharging mechanism disclosed by the invention is within 2 hours, so that the efficiency is doubled.

Owner:江苏迈步智能装备科技有限公司

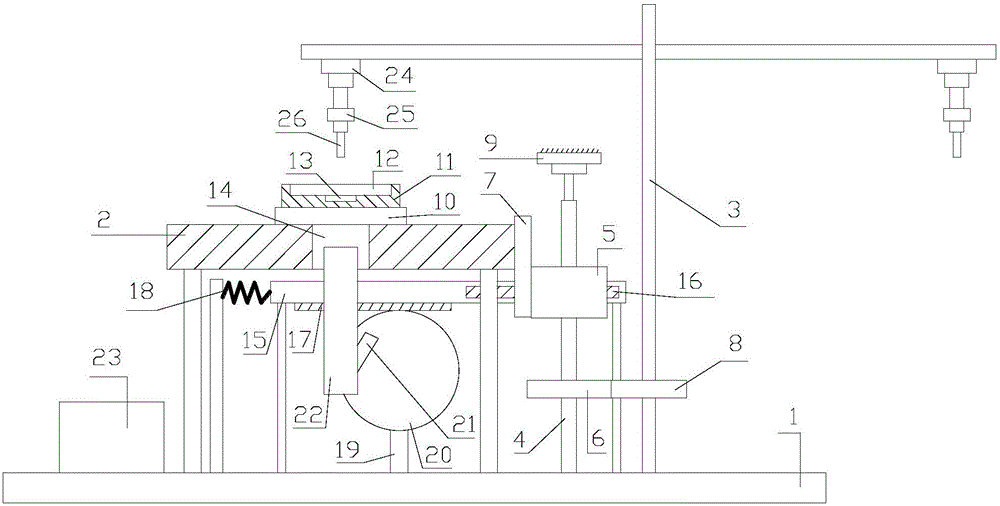

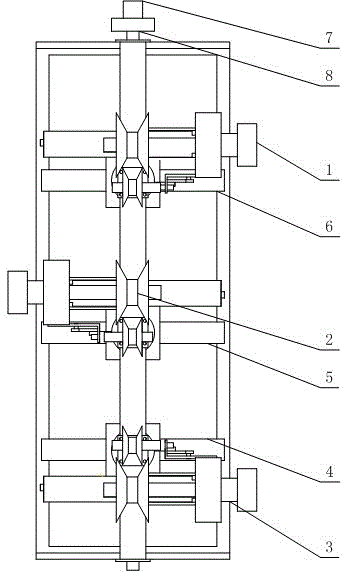

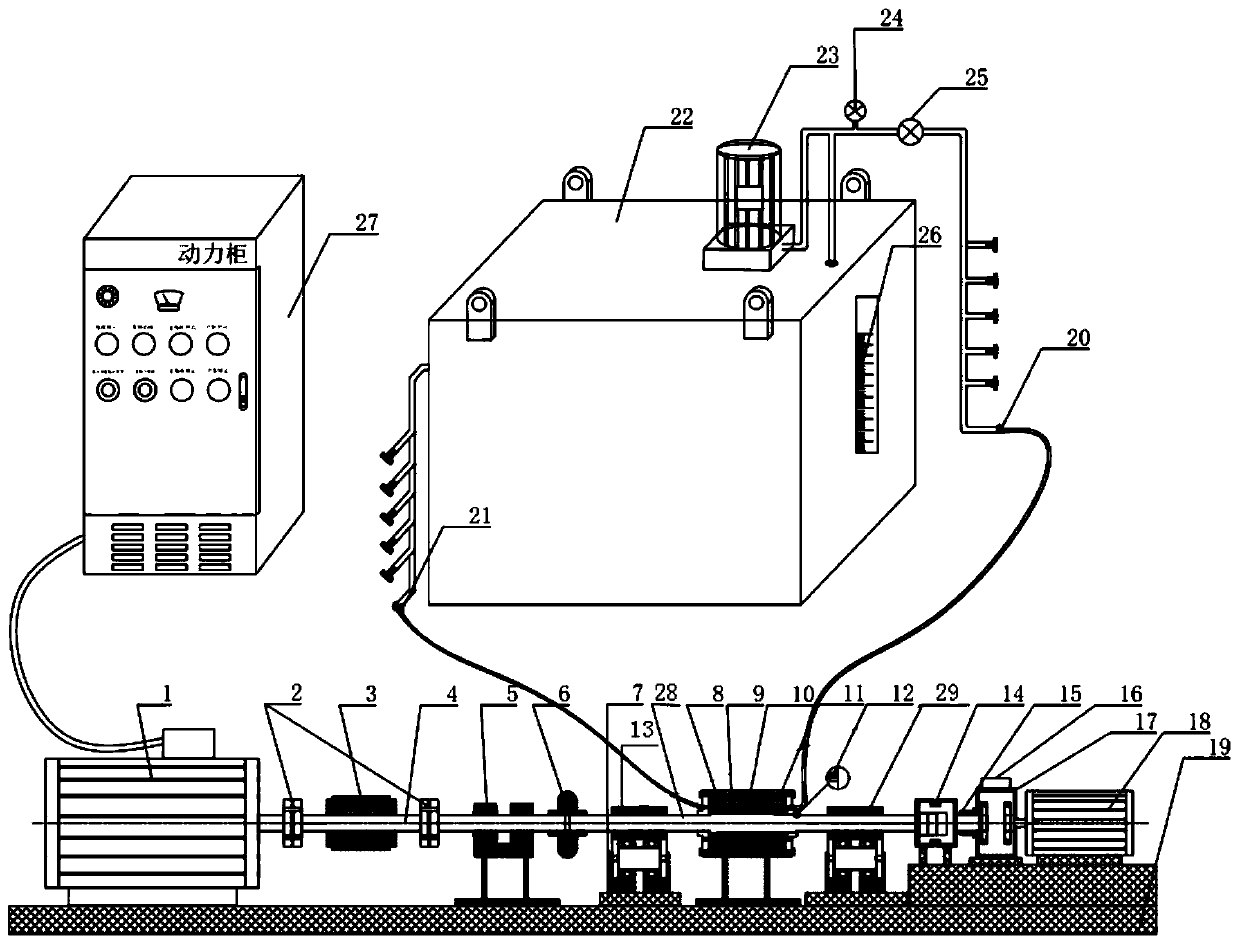

Water-lubricated bearing online monitoring test platform and bearing characteristic test analysis method

ActiveCN111272424AFeatures are easy to studyThe test content is richElectric signal transmission systemsMachine bearings testingRotational axisMotor speed

The invention discloses a water-lubricated bearing online monitoring test platform. The platform comprises a variable frequency motor, a torque tester, a rotating shaft, a main rotating shaft, a speedreducer, a permanent magnet generator and the like. The variable frequency motor is connected with an electric control cabinet, a rolling bearing support is arranged on the rotating shaft, and a bearing system support, a non-contact electromagnetic loading device a and a non-contact electromagnetic loading device b are arranged on the main rotating shaft. According to the present invention, different information fusion characteristics of multi-source parameters are considered, so that the characteristics of the water lubricated bearings can be researched more conveniently. The invention alsodiscloses a bearing characteristic test analysis method. The method comprises adjusting the water supply pressure, the variable frequency motor rotating speed and the shafting load; measuring variousparameters, analyzing the energy supply mechanism of an energy collection system of the rotating machinery wireless devices and the communication quality of the energy collection system of the rotating machinery wireless devices; and analyzing the bearing friction characteristics, the lubricating characteristics and the lubricating mechanism. According to the invention, various performance tests of the water-lubricated bearings are perfected, and test data and scientific basis are provided for the safe and stable operation of the bearings, the design and manufacture of the bearings and the like.

Owner:SHAANXI SCI TECH UNIV

Wire rod bending processing device

The present invention relates to a wire rod bending processing device for bending a certain position of a wire rod. The wire rod bending processing device comprises a pedestal, a putting mechanism, a support and a bending mechanism disposed on the support; the putting mechanism comprises upper and lower putting blocks which are pivoted with each other; the lower putting block comprises a thick portion and a thin portion protrudingly extending from the bottom of the thick portion to one side; the support is provided with a vertical plate supported on the pedestal and a support plate fixed on the vertical plate; the bending mechanism comprises a cylinder, a sliding plate, a connecting rod, a fixed block and an abutting block fixed on the fixed block; the sliding plate is arranged on the vertical plate in a manner of sliding in up and down directions; the abutting block is positioned over the putting mechanism; the abutting block is staggered with the thick portion up and down; and the abutting block is arranged to be opposite to the thin portion. According to the wire rod bending processing device, the mechanisms are cooperated ingeniously and tightly, automatic processing efficiency is high, shapes of bending portions of wire rods are effectively enabled to be structured and unified, and bending quality is stable.

Owner:LUXSHARE PRECISION INDUSTRY (CHUZHOU) CO LTD

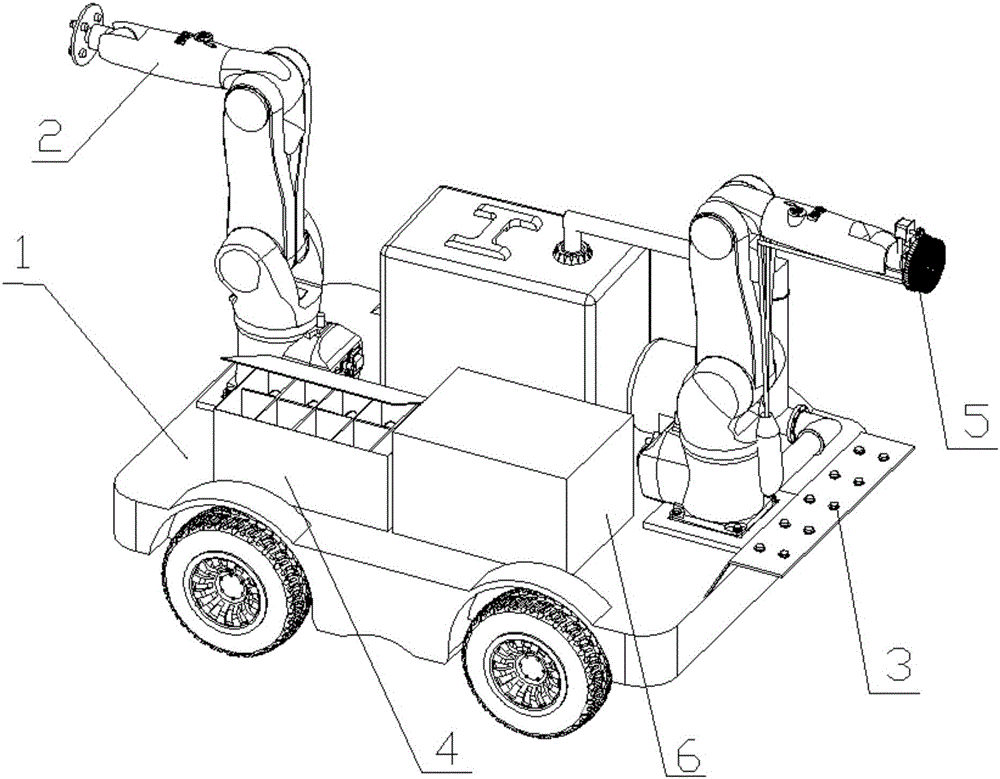

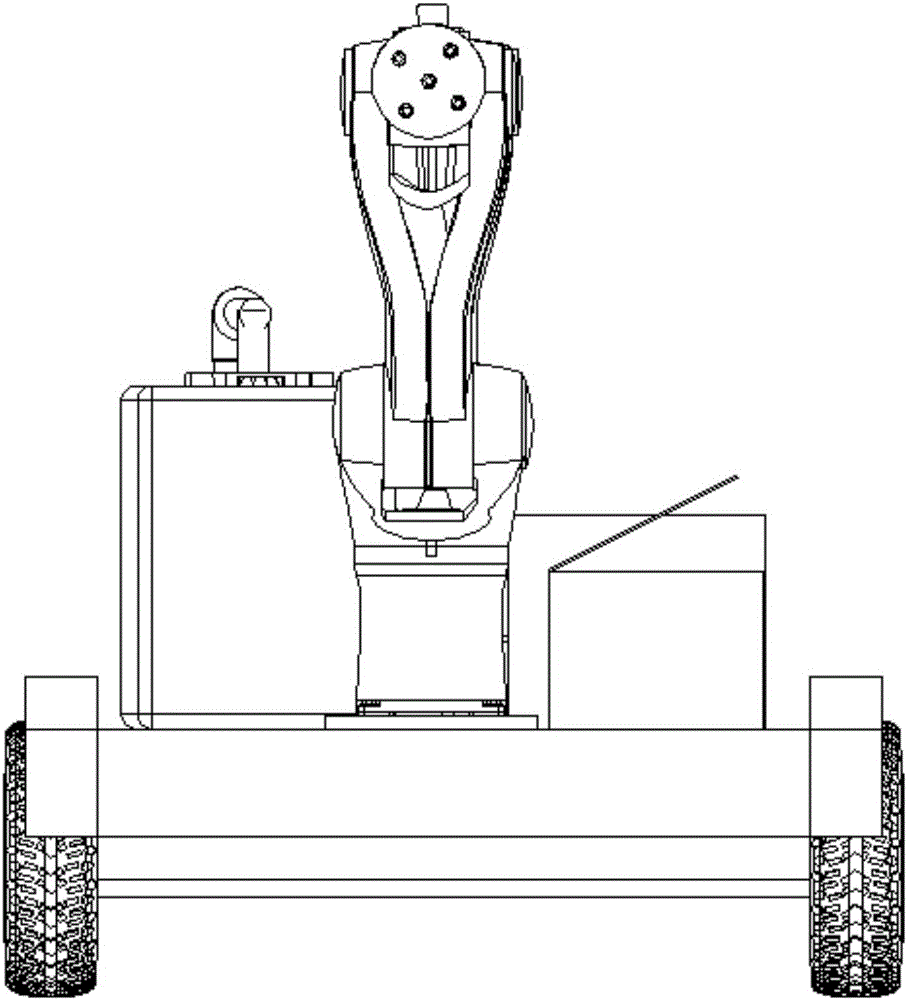

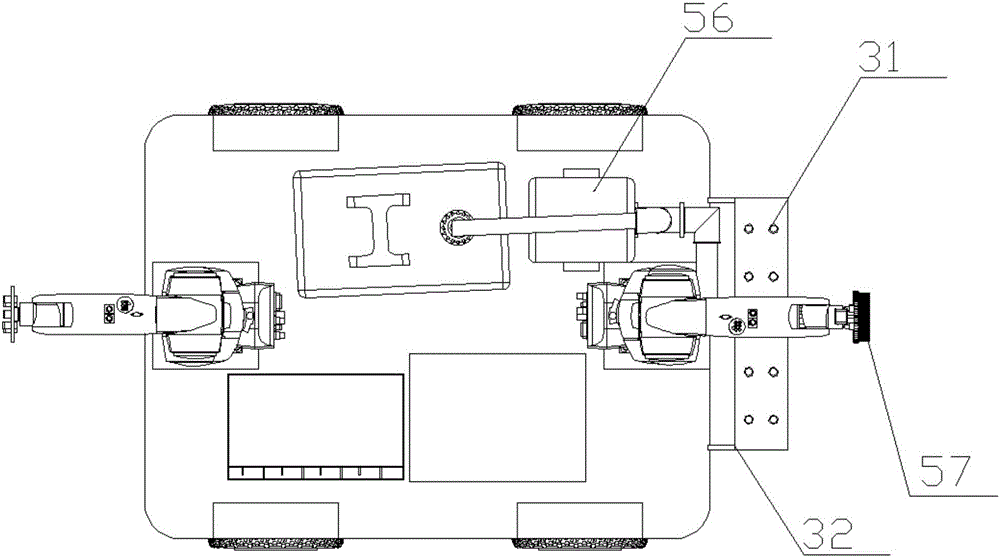

Full-automatic roof leakage finding and repairing robot and leakage finding and repairing method

ActiveCN105672692AImplement automatic lookupLow costDetection of fluid at leakage pointBuilding repairsMicrowaveEngineering

The invention relates to the technical field of automation and robots and particularly relates to a full-automatic roof leakage finding and repairing robot which comprises a chassis driving platform, a microwave directional transmission module, an infrared temperature directional detection mechanism, a control and electrical driving mechanism, a leakage repairing mechanism and a power lithium battery, wherein the microwave directional transmission module comprises a microwave directional transmission device, a microwave directional transmission turntable, a microwave directional transmission mechanical arm, a microwave directional transmission stand and a microwave directional transmission servo motor. The invention also discloses a leakage finding and repairing method using the robot. By utilizing the principle that the temperature of microwaves rises after the microwaves are absorbed by objects, directional detection of leakage points of a roof is realized; the robot is simple in principle, skillful in mechanical coordination and low in overall manufacturing cost; the robot can automatically finish the leakage repairing work, so that the finding cost and leakage repairing cost of the leakage points are lowered; and the current problems of family property loss and even life safety endangering caused by leakage repairing because of leakage of the roof can be solved.

Owner:SHANDONG GUOXING SMARTECH CO LTD

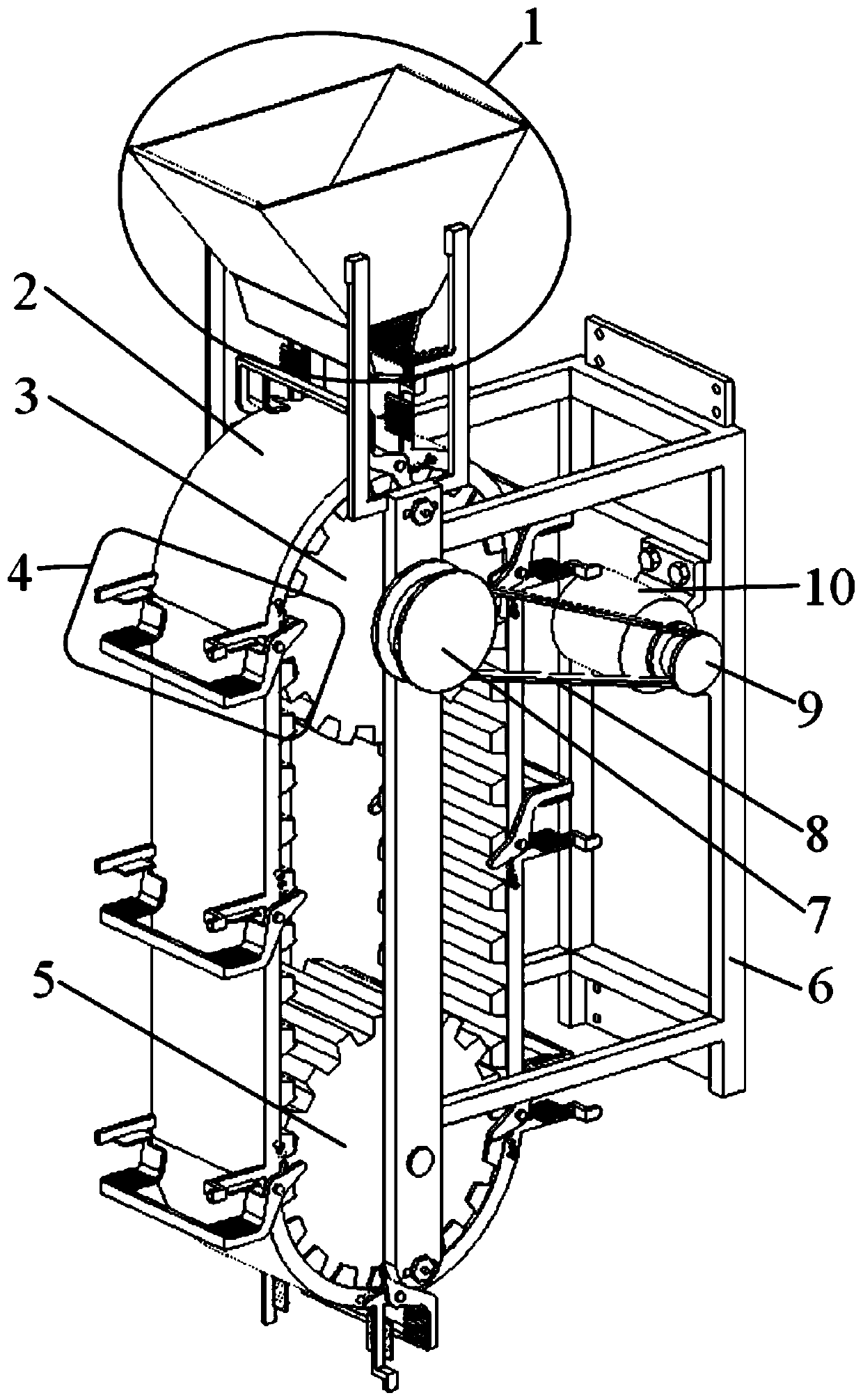

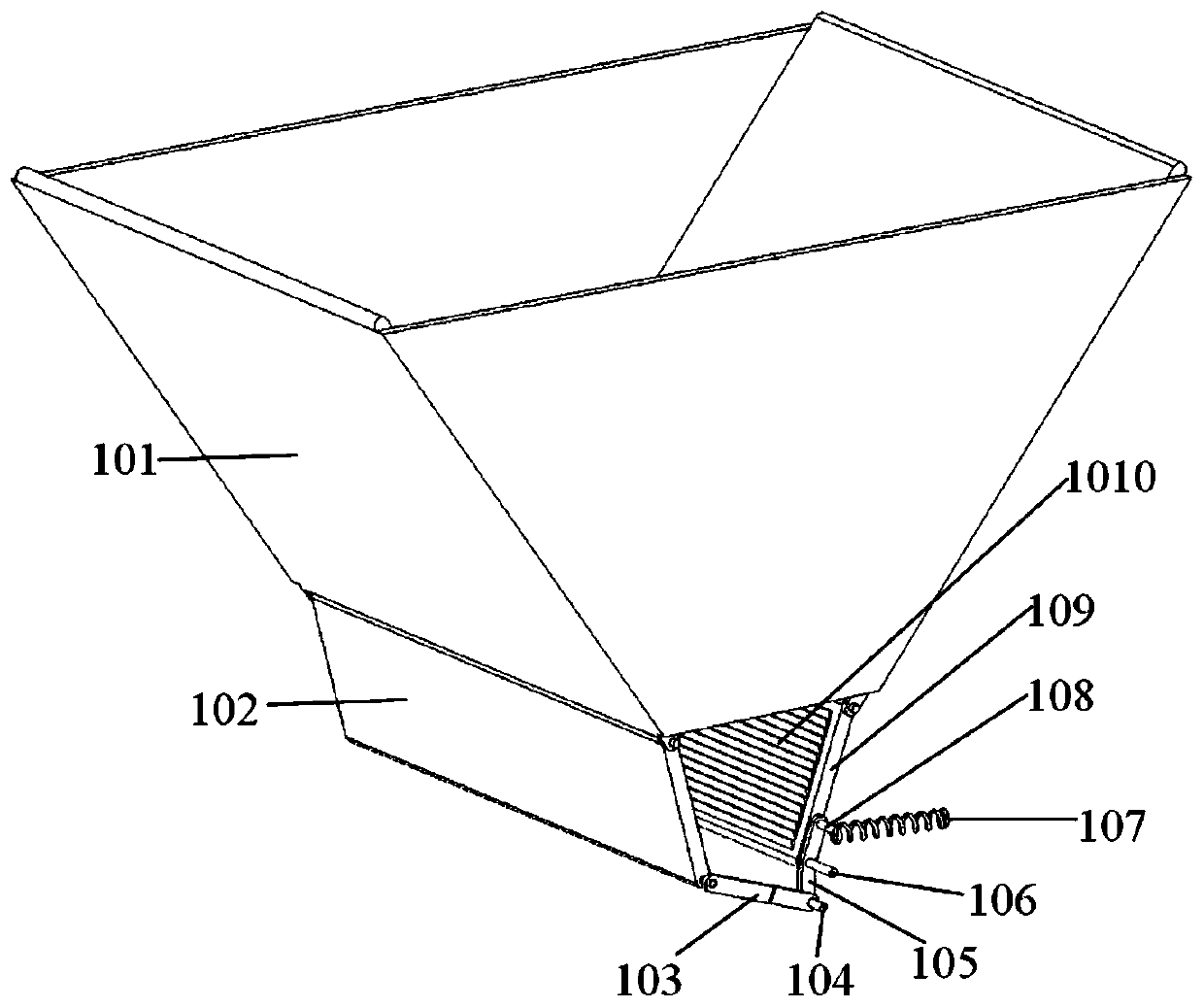

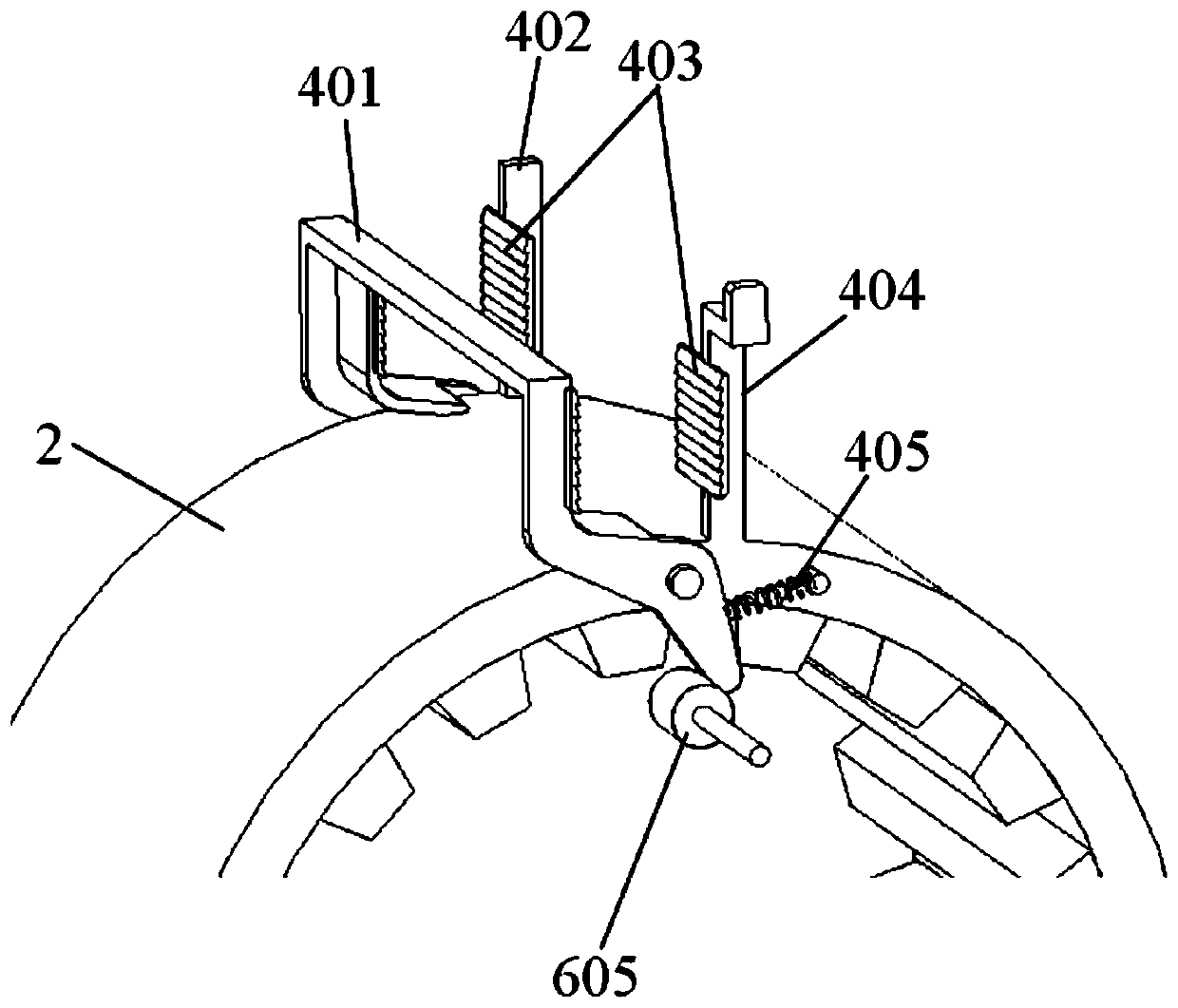

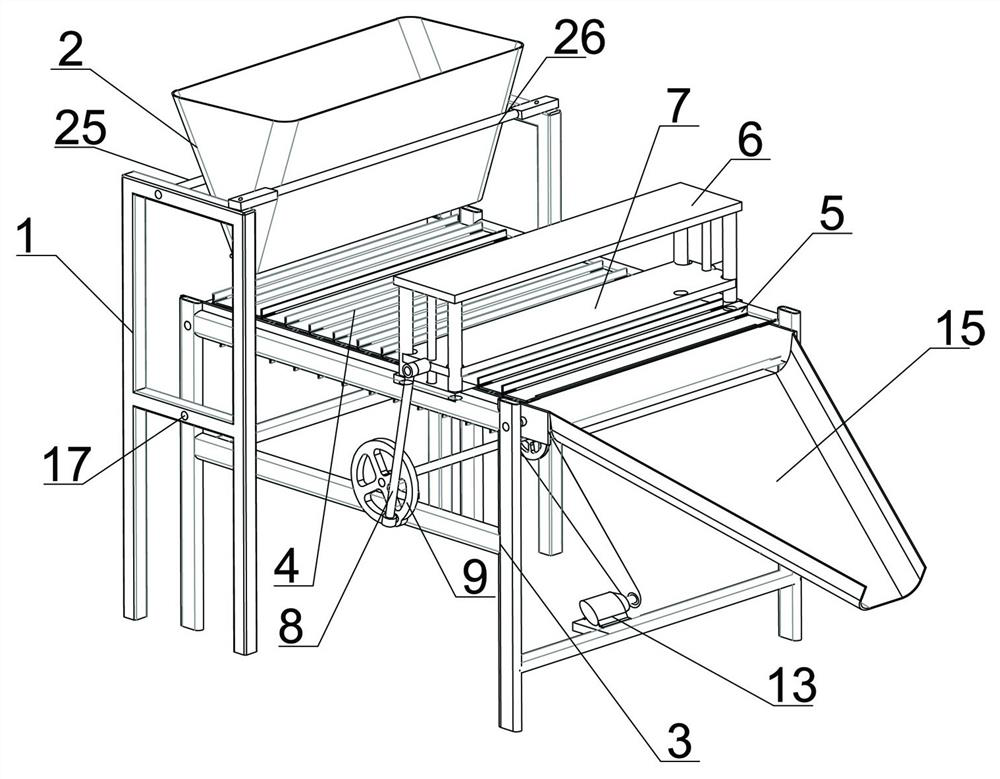

Multi-bud cane stem dropping apparatus

The invention provides a multi-bud cane stem dropping apparatus, comprising a support. A stem guide box assembly is mounted at the top end of the support; a transmission mechanism and a clamping component are mounted inside the support. Through the structure of the clamping component and stem guide box assembly and their ingenious cooperation, as well as simultaneous opening of stem guide plates and a moving claw, a dropping and clamping cooperation process of cane stems is achieved. If horizontal positions of a lower post and upper post are changed, opening time of the moving pawl may be adjusted; if extension length of a push bar is changed, the size of an opening of two stem guide plates and the opening time of the stem guide plates are changed; adjustment can be provided conveniently for the specific stem-dropping condition for different cane stems under different conditions. Each of the stem guide plates, the moving claw and a fixed claw is provided with a nonslip pad which is made of soft rubber or waterborne resin, providing good protection for buds during both cane stem clamping and conveying; uniform positions of buds are ensured before and after dropping and conveying ofcane stems, and it is ensured that the buds are in the horizontal positions during dropping.

Owner:NANNING UNIV

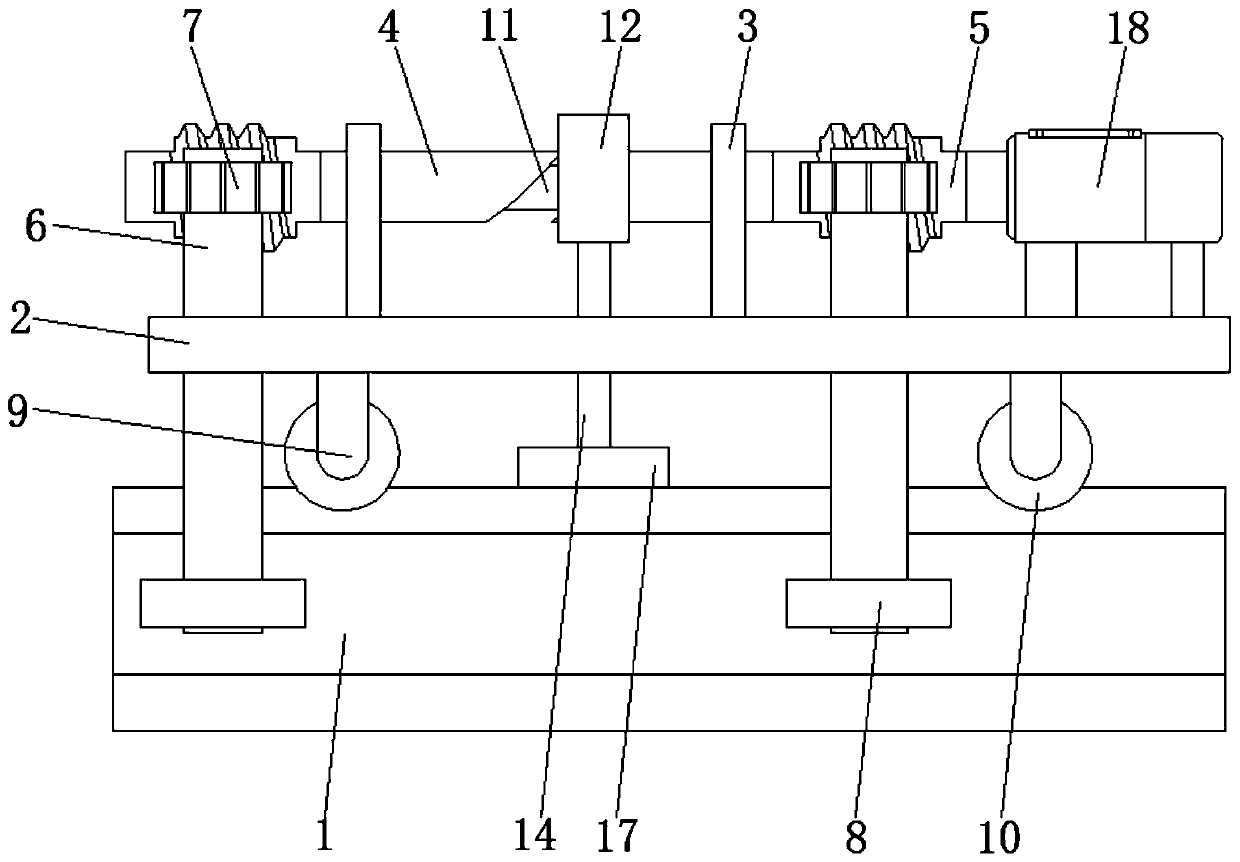

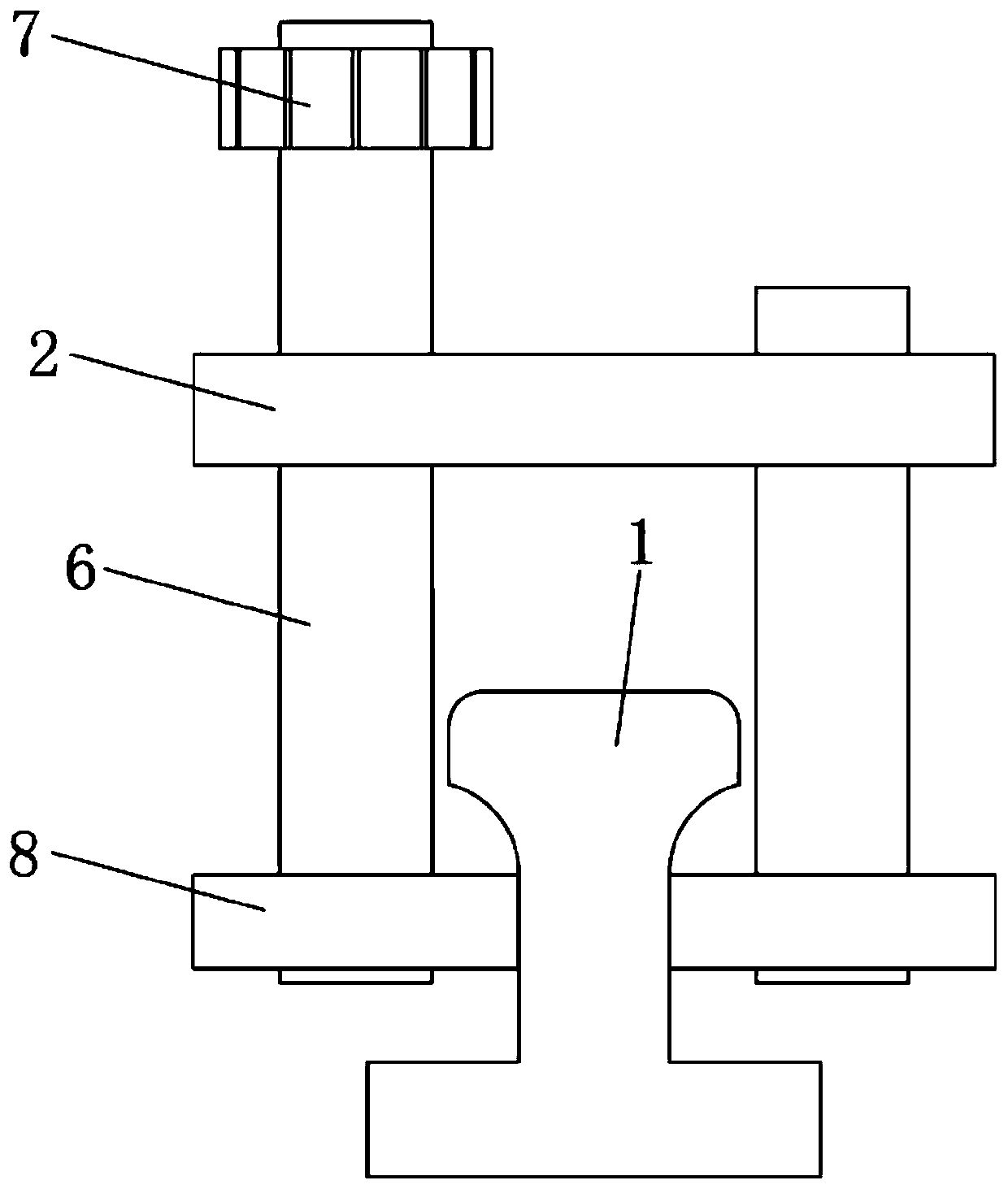

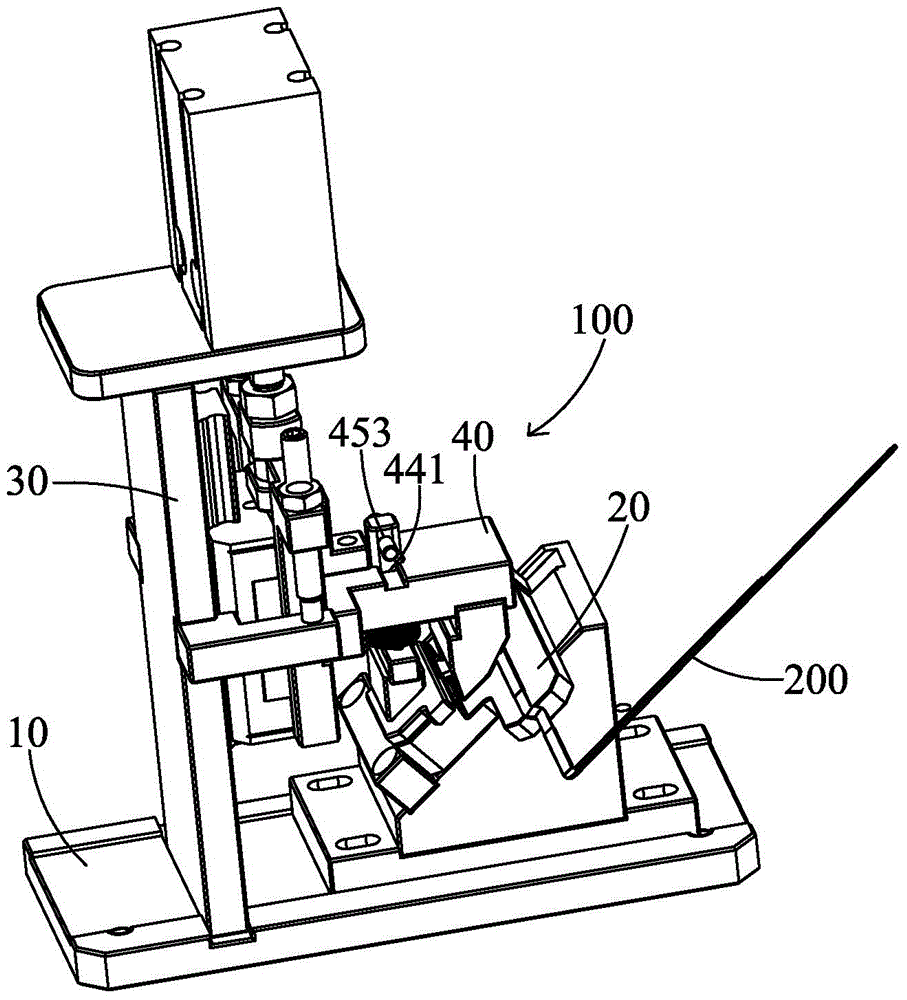

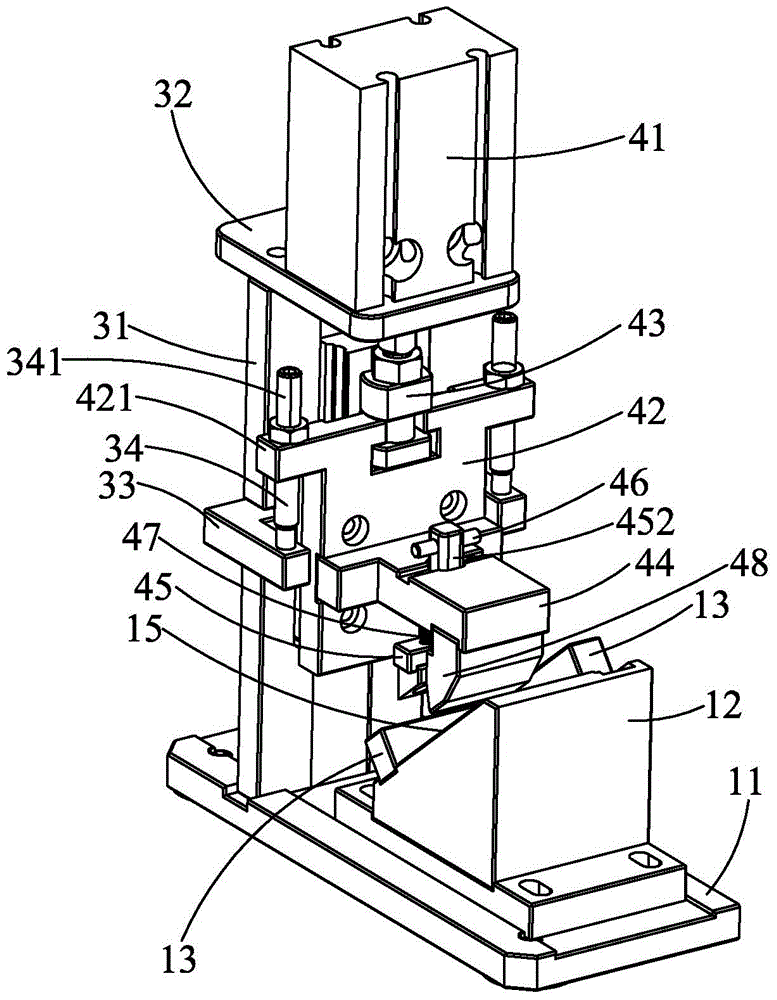

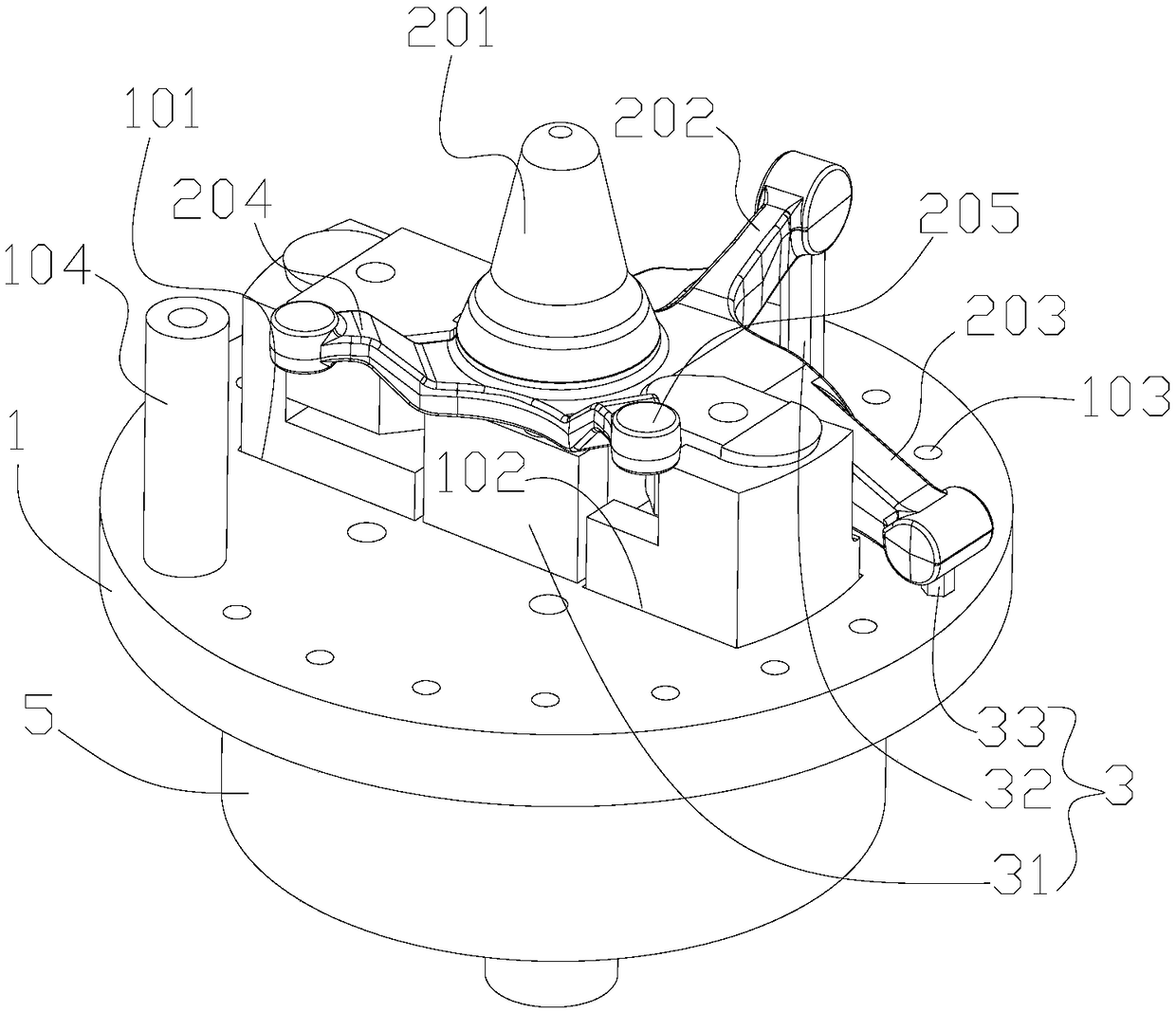

Rough and fine turning fixture for steering knuckle

ActiveCN108637718ACooperate skillfullyImplement steering knuckle placement functionPositioning apparatusMetal-working holdersEngineeringCalipers

The invention discloses a rough and fine turning fixture for a steering knuckle. The rough and fine turning fixture is used for clamping the steering knuckle. The steering knuckle is provided with a steering knuckle rod part, a steering cone arm, a damping arm, a first caliper mounting arm and a second caliper mounting arm, wherein the steering cone arm, the damping arm, the first caliper mountingarm and the second caliper mounting arm are arranged on the outer periphery of the steering knuckle rod part. The rough and fine turning fixture comprises a working plate used for allowing the steering knuckle to be placed on, an auxiliary positioning structure arranged on the working plate and used for positioning the steering knuckle in an assisting manner, an auxiliary clamping head and a clamping mechanism, wherein one end of the auxiliary clamping head is arranged on the working plate in a penetrating mode, and the other end of the auxiliary clamping head is connected with a rotating driving mechanism so as to drive the working plate to rotate; and the clamping mechanism is arranged on the auxiliary clamping head in a penetrating mode and can clamp and release the steering knuckle under the driving of a driving mechanism. According to the rough and fine turning fixture for the steering knuckle, compared with a traditional working procedure, each traditional working procedure needs a fixture, the production cost is wasted.

Owner:重庆齐信汽车零部件有限公司

Toothpaste extruding mechanism capable of facilitating decoration and mounting

InactiveCN107837021ARealize automatic extrusionEasy to useHolders and dispensersUnpacking by expelling contentsAir pumpToothpaste

The present invention relates to the field of daily life mechanical equipment, in particular to a toothpaste extruding mechanism that can be easily decorated and installed. The extrusion device, the lower part of the extrusion cylinder is connected with a square installation cone seat, the lower part of the installation cone seat is provided with an installation seal ring, and the installation cone seat is provided with a suction pipe passing through the wall of the cone seat, and the suction pipe passes through the installation ventilation hose The ventilation pump is connected, and the ventilation pump is installed on the extrusion cylinder through the ventilation pump installation block, and the extrusion device and the ventilation pump are connected to the controller; the present invention places the toothpaste in the extrusion cylinder, and cooperates with the extruding cylinder in the extrusion cylinder. The output device realizes the automatic extrusion of toothpaste. Through the installation part set at the lower part of the extrusion cylinder, the extrusion cylinder can be fixed on the washstand, which not only facilitates the use of toothpaste, but also can cooperate with the washstand to achieve a decorative and beautiful effect.

Owner:DONGGUAN UNIV OF TECH

Moving device

PendingCN110217103AReduce weightLight structureSteering linkagesElectric propulsion mountingEngineeringMechanical engineering

Owner:洛阳履坦智能科技有限公司

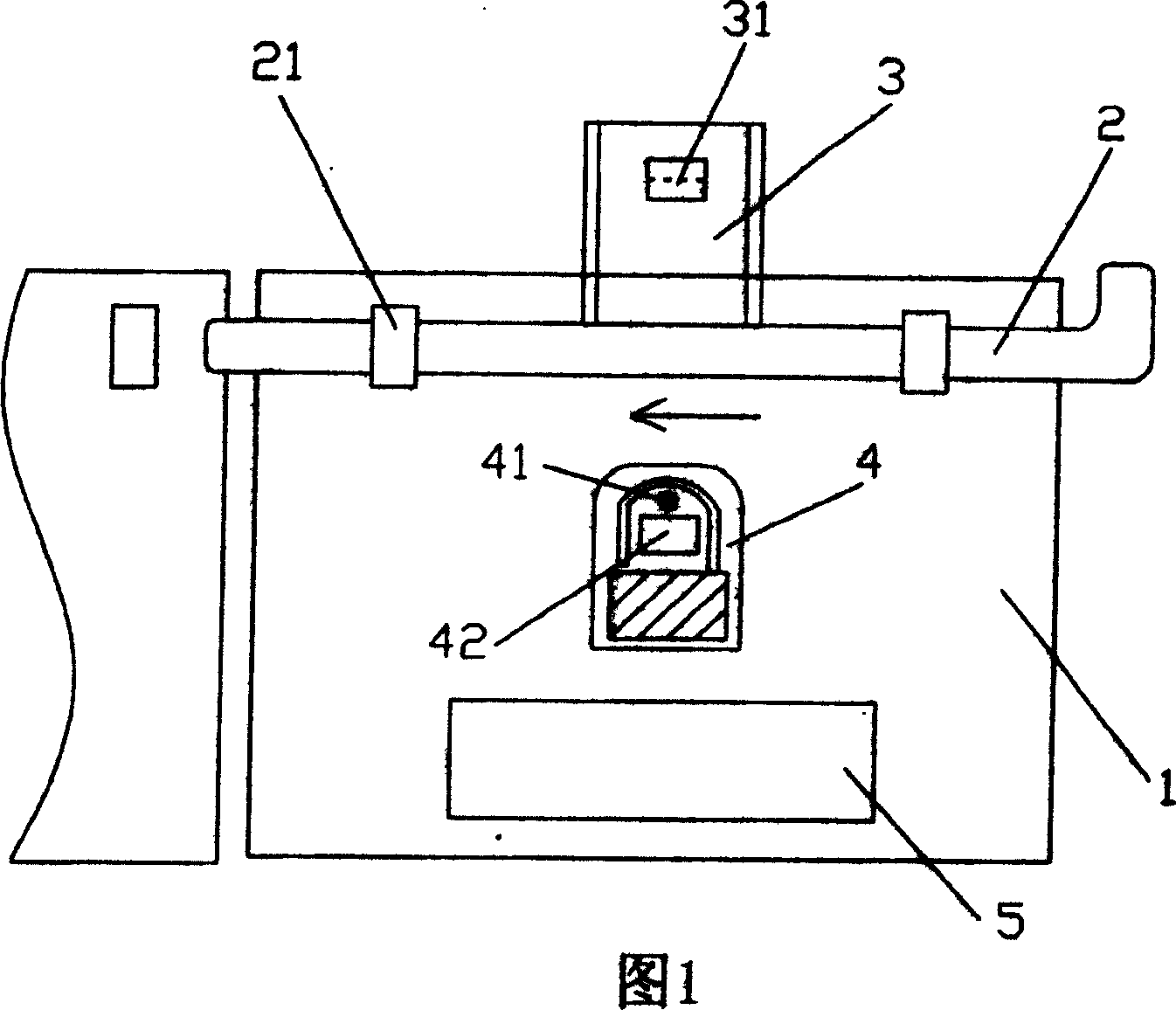

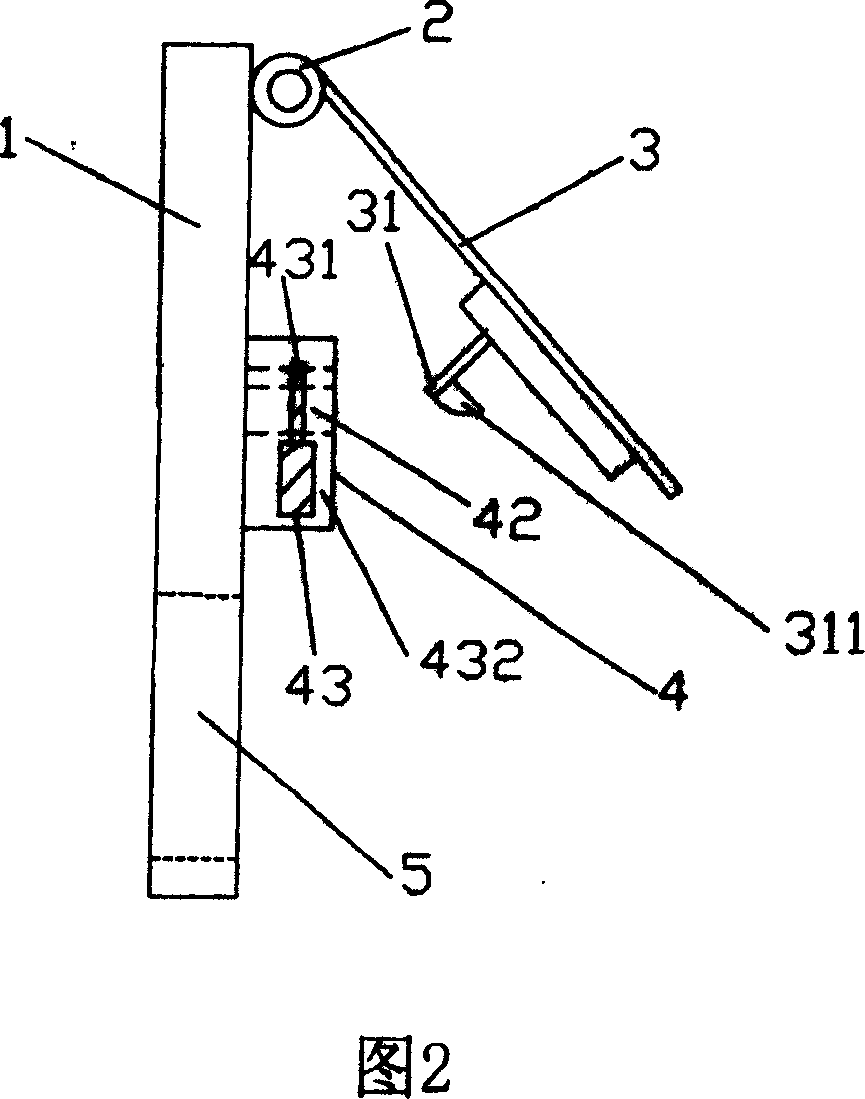

Safety sidelong latch

InactiveCN101063388ATo achieve the purpose of anti-theftNovel structureWing fastenersPadlocksBiochemical engineering

Owner:SHANGHAI NANHUI DISTRICT HANGTOU SCHOOL

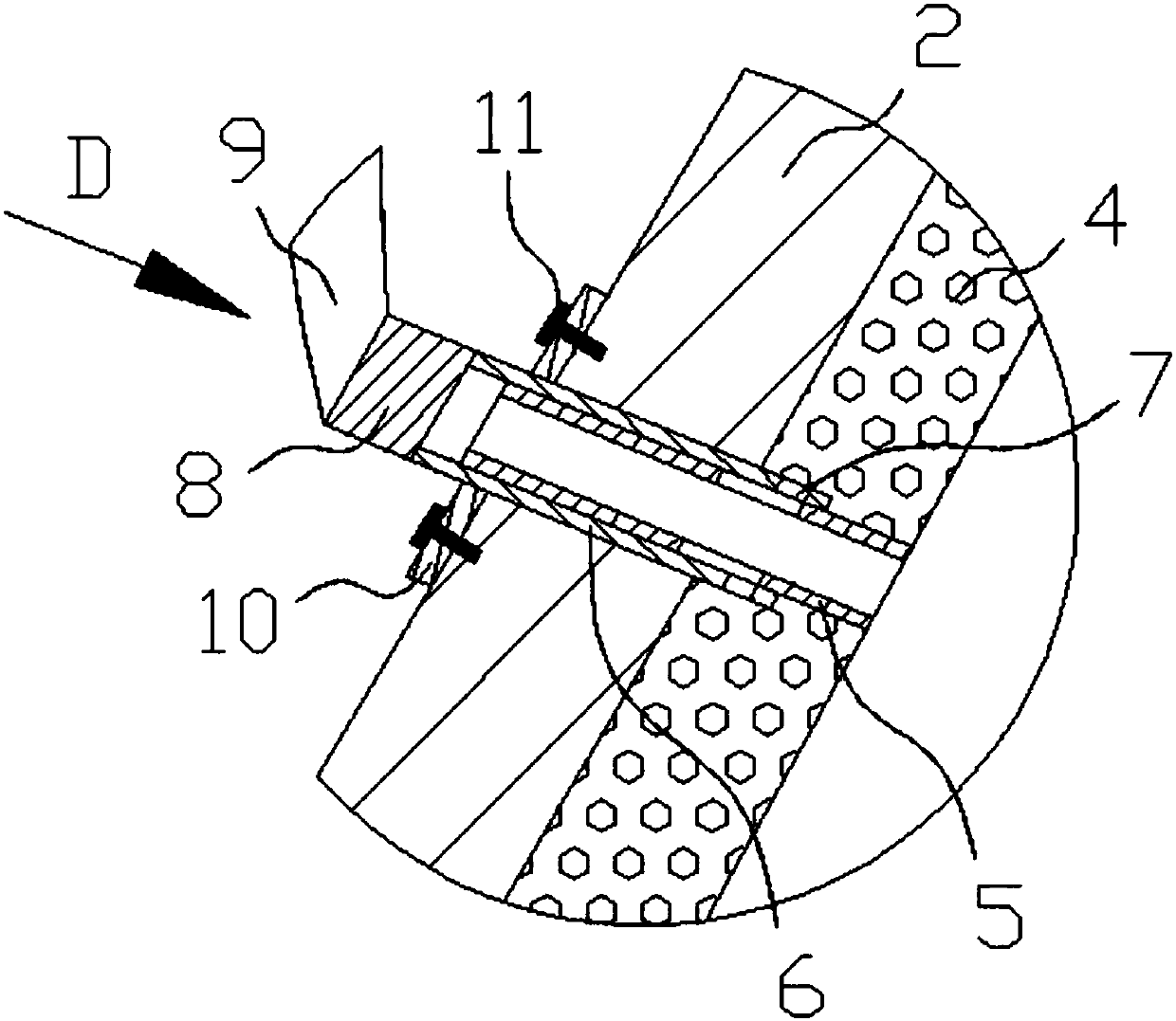

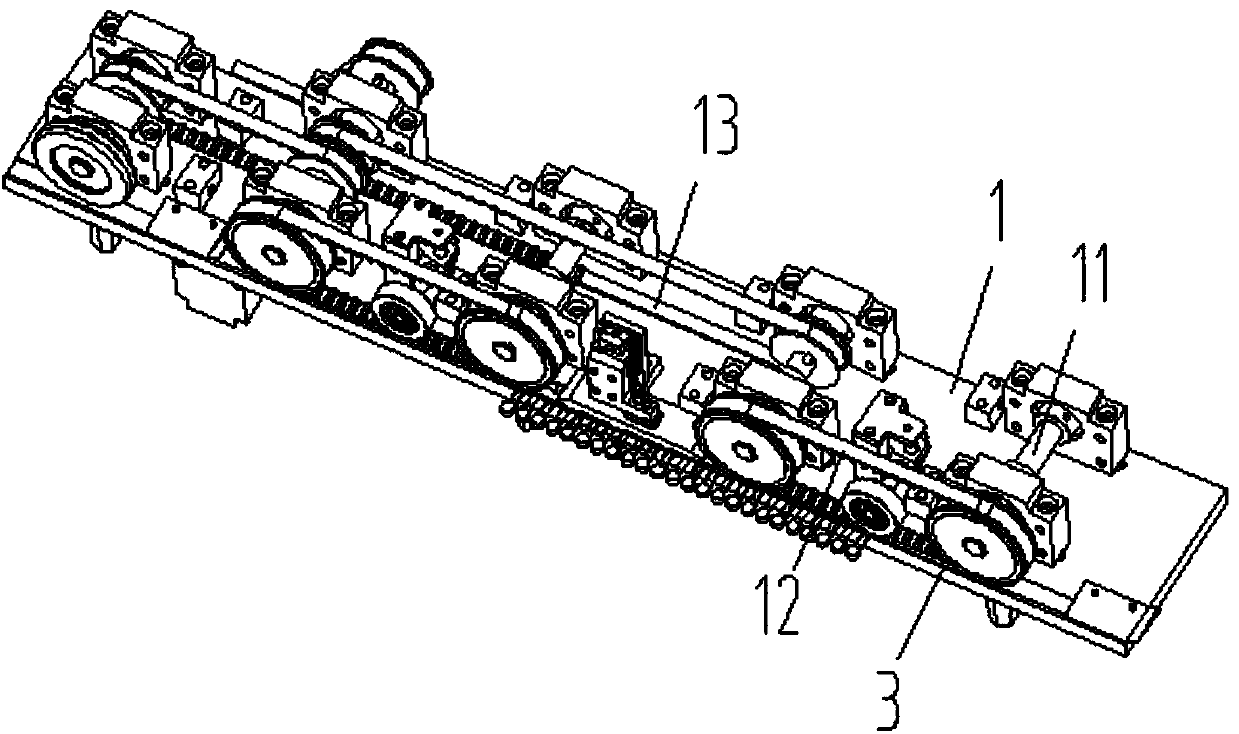

Diaphragm slitting machine

PendingCN109399316ACooperate skillfullyFit closelyCleaning using gasesArticle deliveryEngineeringMechanical engineering

The invention discloses a diaphragm slitting machine. The diaphragm slitting machine comprises a slitting mechanism, wherein the slitting mechanism comprises an upper cutter assembly, a lower cutter assembly, a cutter driving device used for driving the upper cutter assembly and the lower cutter assembly to rotate synchronously, a cutter rest and a cutter die bottom plate assembly, wherein the cutter rest and the upper cutter assembly as well as the lower cutter assembly are movably arranged on the cutter die bottom plate assembly. The design is achieved thus, so that switching of cutters is easy, simple and convenient.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Construction method with PC prefabricated slab replacing conventional brick tire mold

PendingCN111851558ASave moneyImprove securityConstruction materialFoundation engineeringStructural engineeringArchitectural engineering

The invention discloses a construction method with a PC prefabricated slab replacing a conventional brick tire mold. The construction method comprises the following steps of construction preparation,prefabricated slab mounting, prefabricated slab connecting and fixing, inner side supporting, backfilling construction and the like. The construction method can guarantee rigidity, strength and stability of a formwork effectively. Compared with a conventional construction method, a lot of funds can be saved.

Owner:中联世纪建设集团有限公司

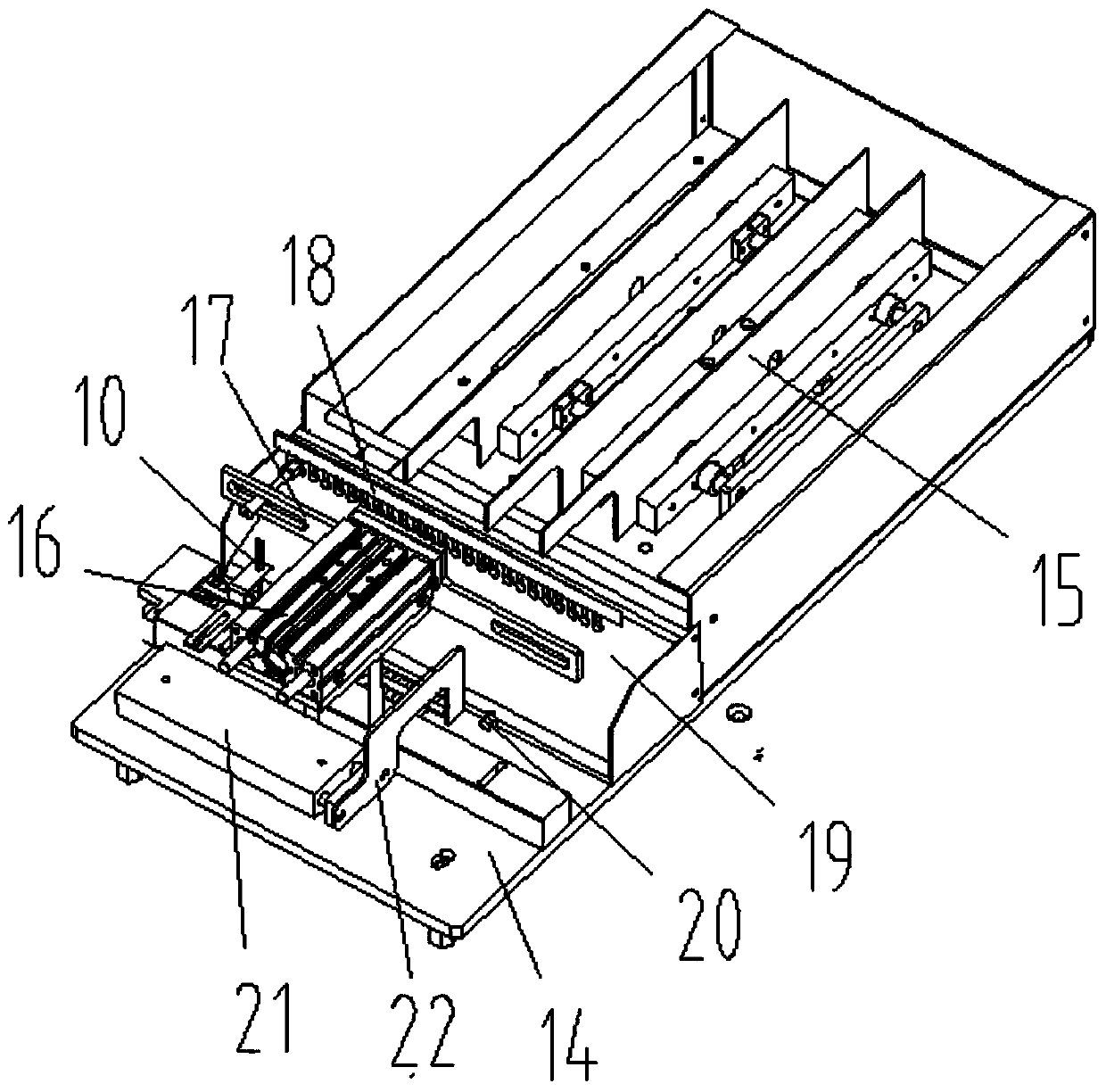

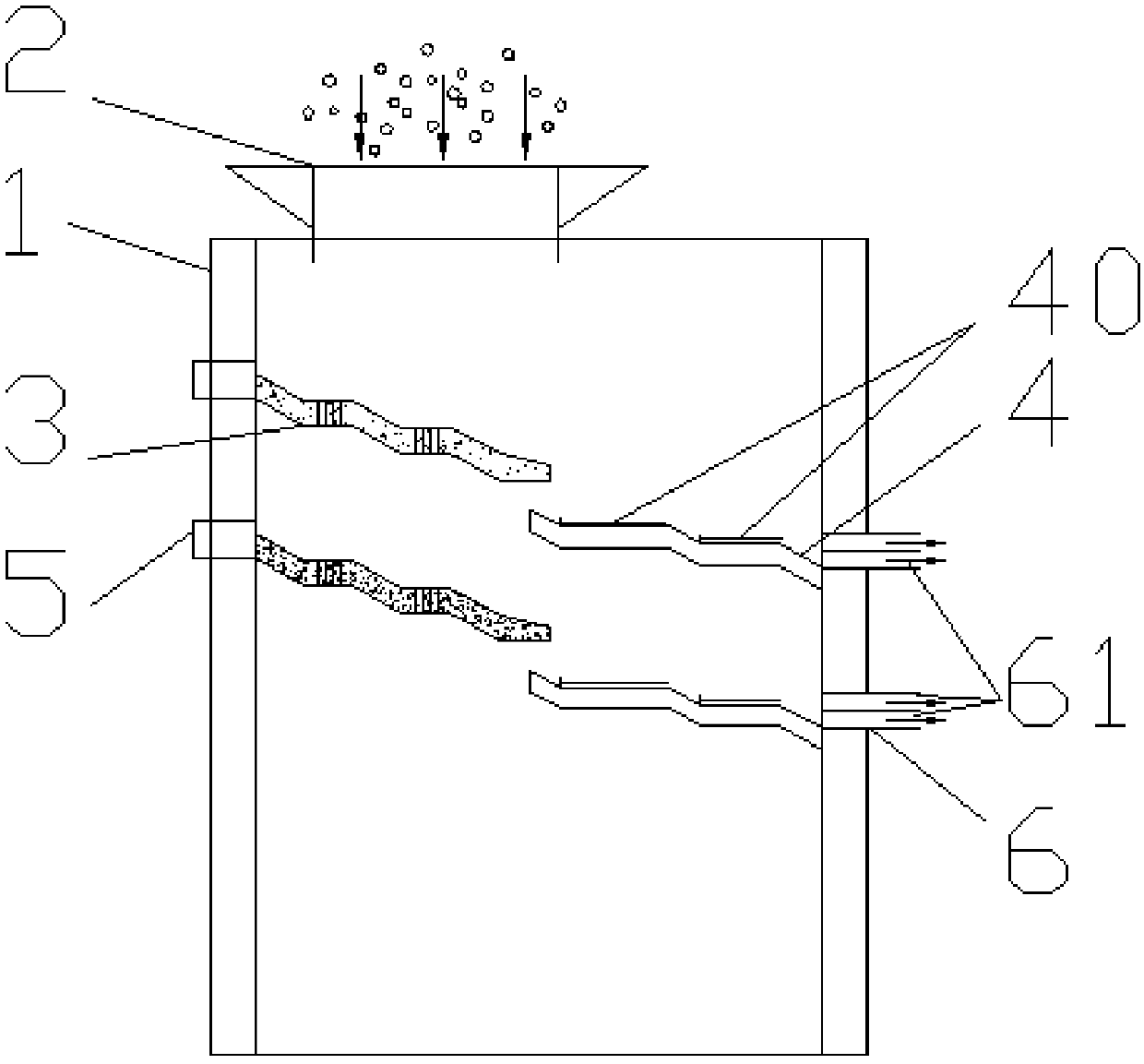

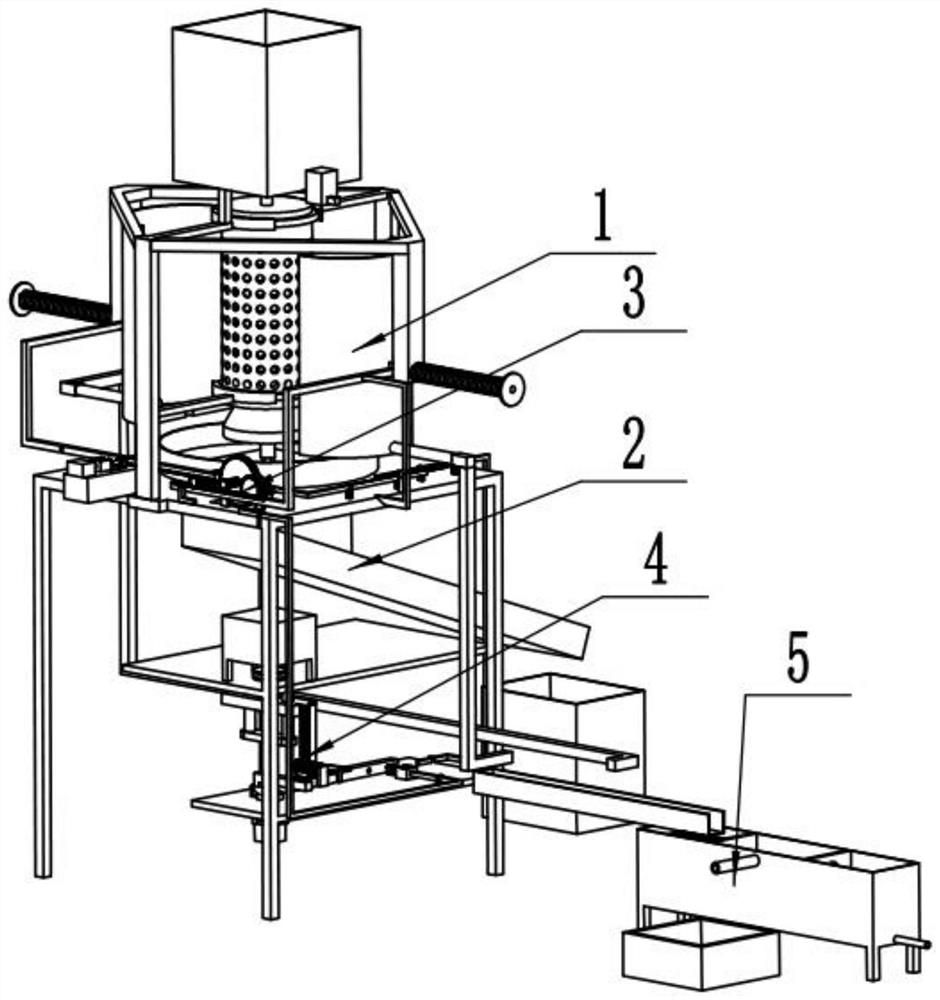

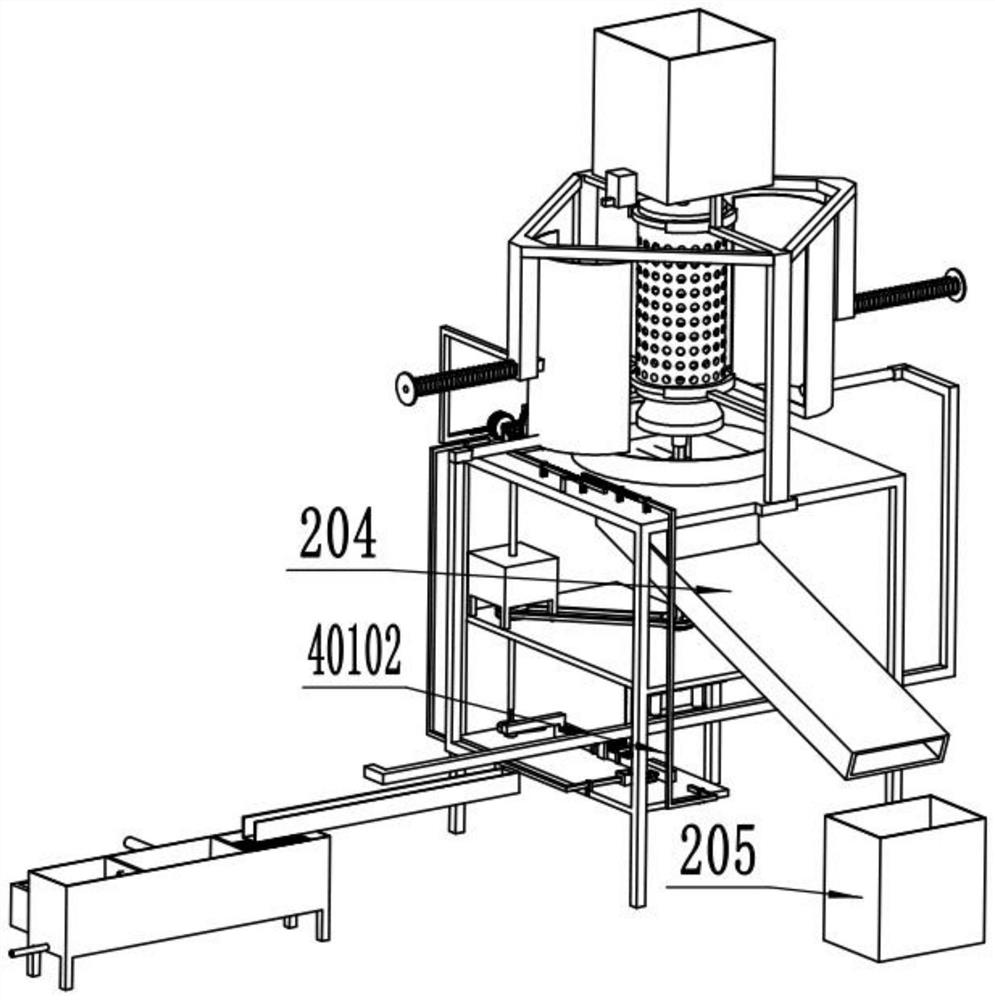

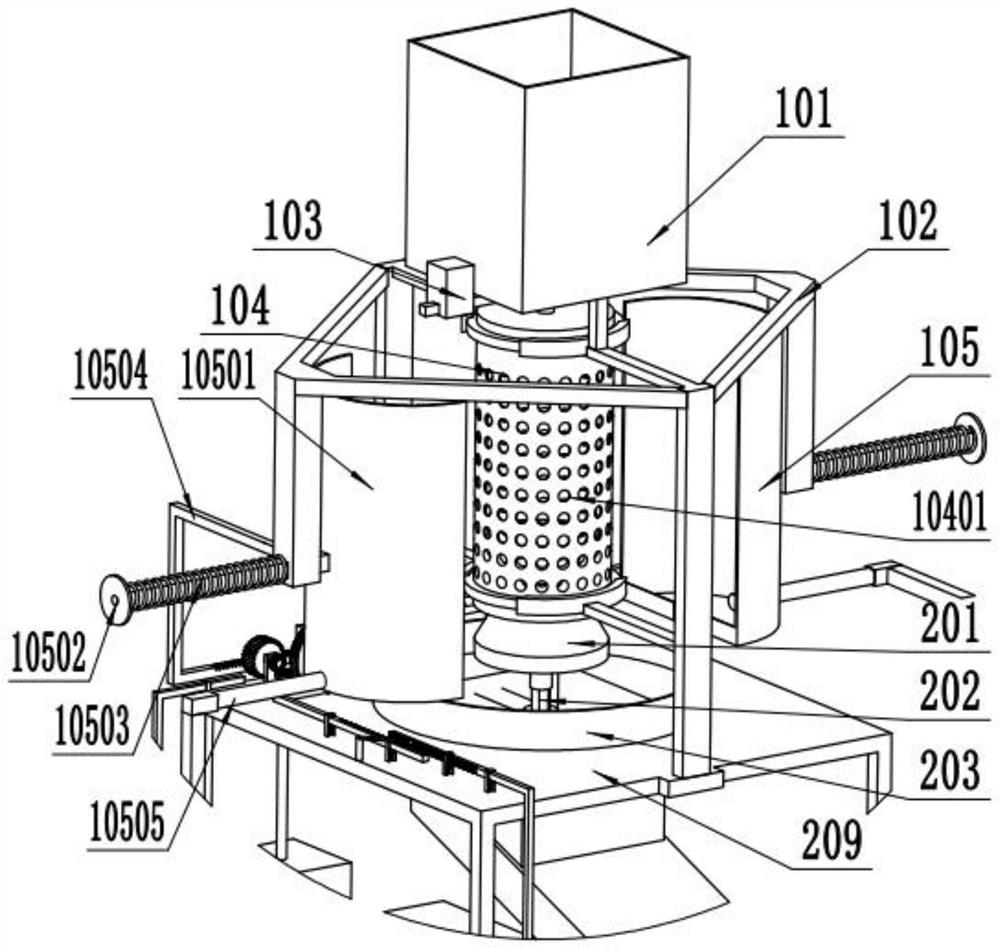

Automatic resistance sorting and detecting integrated machine

InactiveCN107824468AEasy to detectSuitable for mass productionNibbling shearing machinesSortingElectrical resistance and conductanceDistribution control

The invention relates to an automatic resistor sorting and testing integrated machine comprising a rack and a distribution control box. The rack is provided with a conveying chute, and conveyer devices matched with strip-type products are arranged on the conveying chute at intervals; the distance between every two adjacent conveyor devices is smaller than the length of the strip-type products, andappearance detecting and sorting devices and resistance sorting devices, which are matched with the strip-type products, are also arranged on the conveying chute, and located in gaps between every two adjacent conveyor devices; the right ends of the appearance detecting and sorting devices and resistance sorting devices are provided with optical sensors; each conveyor device comprises a conveyorshaft arranged on the rack, and the conveyor shaft is provided with a conveyor belt matched with the strip-type products through conveyor wheels; and the conveyor shaft is connected to a conveyor motor through a transmission part. According to the integrated machine provided by the invention, the strip-type products are conveyed according to the characteristics, so that integrated appearance detecting and sorting and the resistance sorting can be achieved, and the detecting effect is improved greatly; and the integrated machine is applied to mass production.

Owner:DONGGUAN UNIV OF TECH

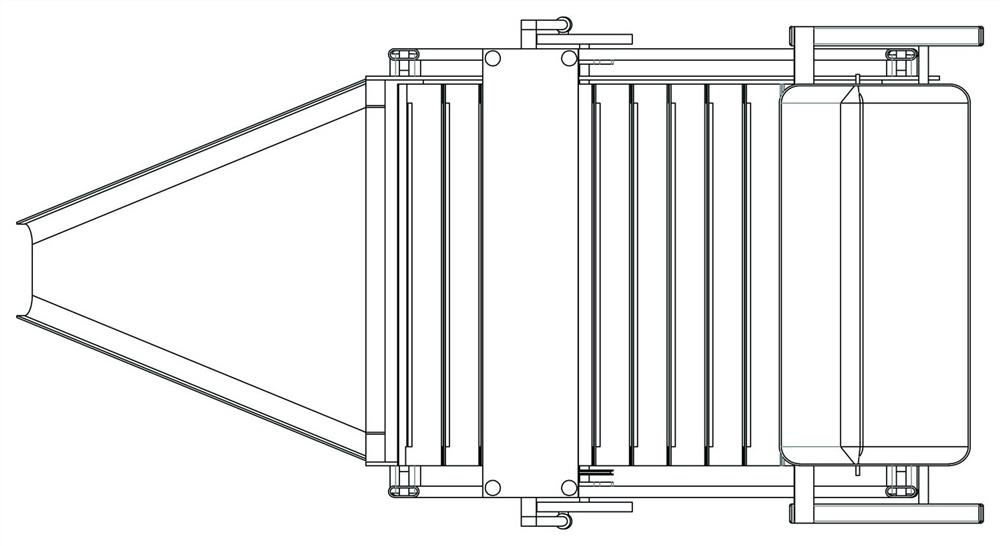

Nut crushing device

PendingCN111887437AEasy to assembleEasy to transportHuskingGrain treatmentsDrive wheelElectric machinery

The invention discloses a nut crushing device. The nut crushing device comprises a discharging mechanism, a conveying mechanism, a crushing mechanism and a discharging hopper, wherein the dischargingmechanism comprises a support, a discharging hopper and a material uniformizing device; the discharging hopper is arranged on the upper portion of the support, and the material uniformizing device isarranged at a discharging port of the discharging hopper; the conveying mechanism comprises a rack, a conveying belt, flexible baffles and conveying wheels; the flexible baffles are vertically installed on the conveying belt at intervals, and the crushing mechanism comprises a fixed mount, a lifting pressing plate, a driving wheel, an eccentric rod and a driving motor; sliding holes correspondingto limiting supporting rods are formed in the lifting pressing plate, the conveying belt is covered with the lifting pressing plate transversely, the lifting pressing plate is arranged on the limitingsupporting rods in a sleeving mode and can slide up and down along the limiting supporting rods; an accommodating area is provided for nuts in the crushing process, the positions of the nuts are limited, the accommodating area corresponds to an extrusion area, it is guaranteed that the nuts cannot be separated from the extrusion area during extrusion, the crushing effect is guaranteed, transmission cooperation of all components is ingenious, and cost input is saved.

Owner:ZHENGZHOU UNIV OF IND TECH

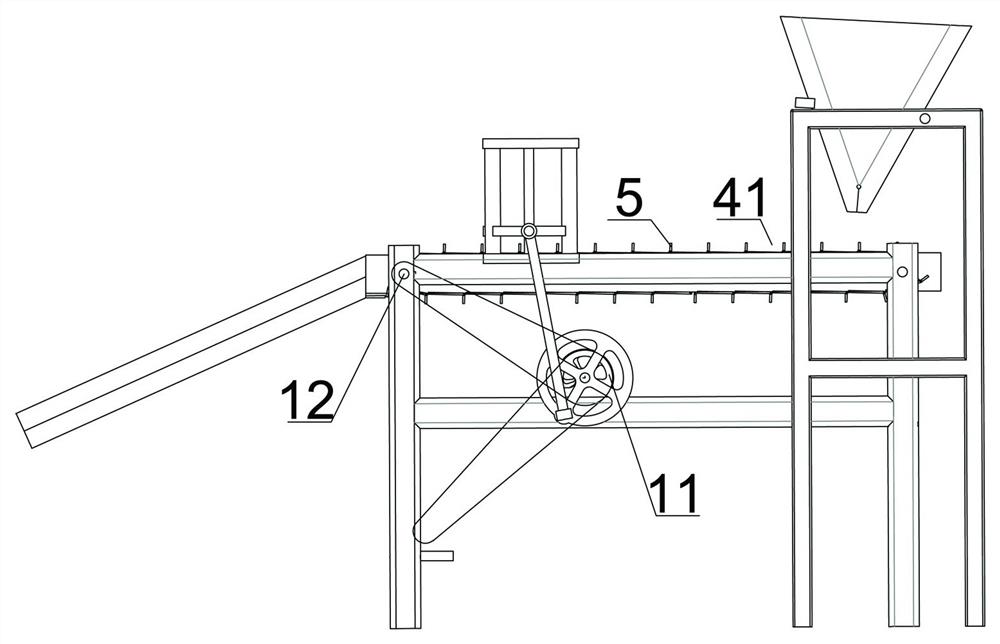

Recycling mechanism for shot blasting process for robot joints

PendingCN107891376ACooperate skillfullyClever oblique arrangementSolid separationAbrasive machine appurtenancesStructural engineeringMechanical engineering

The invention discloses a recycling mechanism for a shot blasting process for robot joints. The recycling mechanism for the shot blasting process for robot joints comprises a recycling box, a feedinghopper and screens, wherein the feeding hopper is mounted on the top of the recycling box; shots are fed into the feeding hopper; the screens are mounted on one side of the inside of the recycling box; a trough plate is arranged at the lower end of each screen; a trough is formed in the upper surface of each trough plate; one end of each trough plate is mounted on one side of the inside of the recycling box; the screens and the trough plates are obliquely downwards arranged relative to a placement plane of the recycling box; and a discharging opening is formed in the end, which is connected with the recycling box, of each trough plate. The targeted recycling mechanism is produced for fine shot blasting operation on the robot joints, the shots which have been used can be screened by the recycling mechanism in real time in a layered manner, the recycling mechanism is convenient and speedy, and improvement of production efficiency and reduction of the cost are facilitated.

Owner:苏州晖恩源医疗器械配件有限公司

Wire bending processing equipment

The invention relates to wire bending and processing equipment. The wire bending and processing equipment is used for bending some part of a wire into a U-shaped bending part through twice bending. The wire bending and processing equipment comprise a placement mechanism, an upper bending mechanism and a lower bending mechanism; the upper bending mechanism comprises a first cylinder, a second cylinder, a first horizontal lever, a second horizontal lever, an upper fixing block, an upper locating block, a first pressing block, a second pressing block, two rotating wheels and springs, wherein the first cylinder and the second cylinder are separated left and right, the first horizontal lever and the second horizontal lever are separated left and right, the first pressing block and the second pressing block are separated left and right, and the springs are pressed upwards on the first pressing block and the second pressing block; the lower bending mechanism comprises a third cylinder, a fourth cylinder, a third horizontal lever, a fourth horizontal lever, a lower fixing block, a lower locating block, a third pressing block, a fourth pressing block, rotating wheels and springs, wherein the third cylinder and the fourth cylinder are separated left and right, the third horizontal lever and the fourth horizontal lever are separated left and right, the third pressing block and the fourth pressing block are separated left and right, and the springs are pressed upwards on the third pressing block and the fourth pressing block. All mechanisms can be smartly and compactly matched, the processing efficiency of the automation is high, the shapes of the bending parts of all wires can be effectively ensured to be regular and unified, and the bending quality is stable.

Owner:SHANXI LUXSHARE PRECISION IND LTD

Soldering and electroplating integrated machine for tube terminals

ActiveCN106848803AImprove processing efficiencyReduce production capacityContact member manufacturingDistribution controlEngineering

The invention relates to a soldering and electroplating integrated machine for tube terminals. The integrated machine comprises a machine frame and a power distribution control box, and a rotary plate matched with a rotary plate motor is arranged on the machine frame and evenly provided with carriers. Each carrier comprises a carrying base arranged on the rotary plate, wherein the carrying base is provided with a fixed carrying slider, the carrying slider is provided with a movable carrying sliding rail in a matched mode, the carrying sliding rail is connected with a carrying lifting block, the upper portion of the carrying sliding rail is connected with a carrying lifting device, the carrying lifting block is provided with carrying columns matched with a product in a sleeving mode, and the outer side of the rotary plate is sequentially provided with a bending device, a soldering device, an electroplating device and a discharging device which are matched with products on the carrying columns. The rotary plate is arranged and provided with the specific product carriers, and the outer side of the rotary plate is sequentially provided with the bending device, the soldering device, the electroplating device and the discharging device, so that integrated machining is achieved, the machining efficiency is greatly improved, and production working hours and manpower consumption are reduced.

Owner:佛山市三水毅品电器配件有限公司

Centrifugal oil purifier capable of automatically collecting oil and use method thereof

InactiveCN113600349AIngenious coordination of institutionsEasy to operateRotary centrifugesElectric machineryEngineering

The invention relates to the technical field of oil purification, in particular to a centrifugal oil purifier capable of automatically collecting oil and a use method thereof. The centrifugal oil purifier capable of automatically collecting oil comprises an impurity removal mechanism, a treatment mechanism, a transmission mechanism, a power mechanism and a separation mechanism; the impurity removal mechanism is fixedly installed above the treatment mechanism; an impurity removal barrel is rotatably installed on a feeding support; the treatment mechanism and the transmission mechanism are connected through a belt; the impurity removal mechanism conducts preliminary impurity removal; a mechanical mechanism is ingeniously used for closing a sealing barrel; the impurity removal mechanism and the treatment mechanism are powered by the power mechanism, and the mechanisms are skillfully matched; the transmission mechanism is connected to the power mechanism, all the mechanisms interact, limit and drive through a linkage set, and operation is convenient; the separation mechanism further filters impurities, and water and oil are separated by utilizing the water-oil characteristics, so that oil purification is more thorough; mechanical transmission is utilized, all the mechanisms are tightly matched, one motor drives all the mechanisms to work, and practicability is high.

Owner:淄博威世能净油设备有限公司

Pole-changing positioning mechanism and pole-changing positioning method for multi-pole deep lunar soil sampler

InactiveCN101936822BAchieve lockingAchieve unlockWithdrawing sample devicesLunar soilInterference problem

The invention provides a pole-changing positioning mechanism and a pole-changing positioning method for a multi-pole deep lunar soil sampler. The pole-changing positioning mechanism comprises a clamping mechanism and a pole-changing mechanism, wherein the clamping mechanism comprises a support mechanism at the lower end, a guide mechanism at the upper end and a central rotating shaft. The supportmechanism at the lower end comprises a cylindrical clamp, a tension spring, a rotating shaft of the cylindrical clamp, a clamp rotating disc, a bolt A and a nut A; the guide mechanism at the upper end comprises a guide handle, a screw A, a guide rotating disc, a bolt B and a nut B; and the pole-changing mechanism comprises a positioning sliding block A, a positioning sliding block B, the rotatingshaft of a lever frame, a pivot bracket, a return spring, the lever frame, a screw B, a pivot rotating shaft and a gear case. The pole-changing positioning mechanism has simple structure and low energy consumption, and can simplify the control process; simultaneously, the pole-changing positioning mechanism can solve the motion interference problem during pole-changing positioning, lead a drill rod to realize complete drilling down and achieve the desired sampling depth.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com