Automatic dispensing feeding device

An automatic dispensing and power technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of complex controller and high cost of the controller, and achieve easy realization, simple structure and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

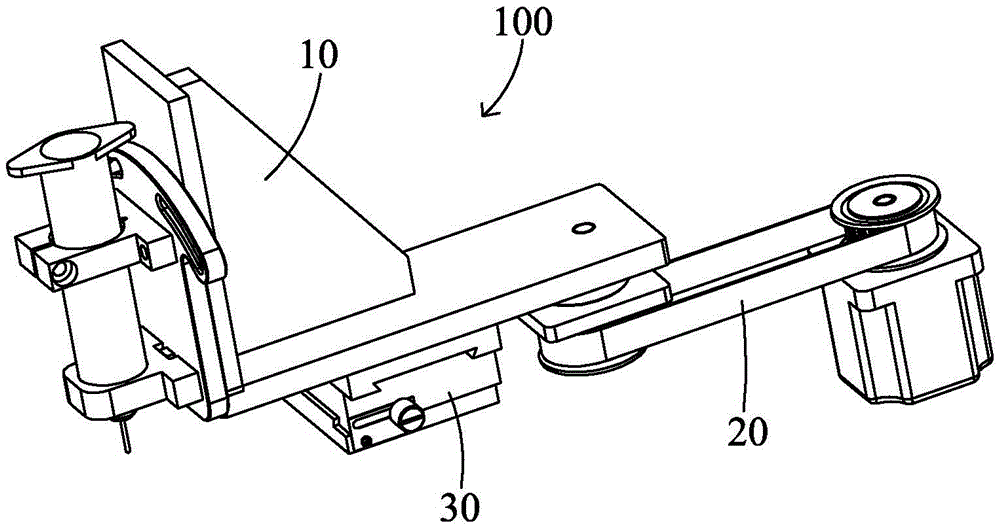

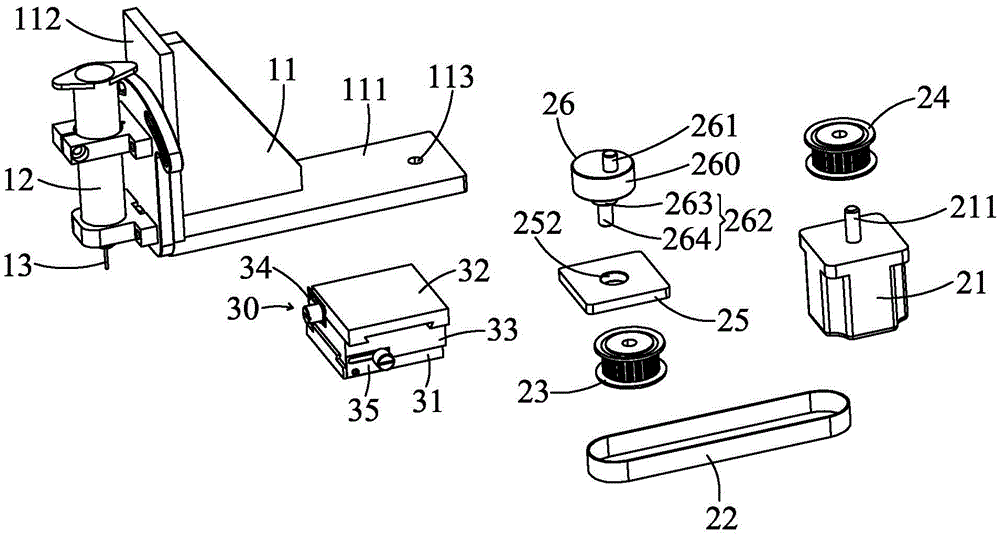

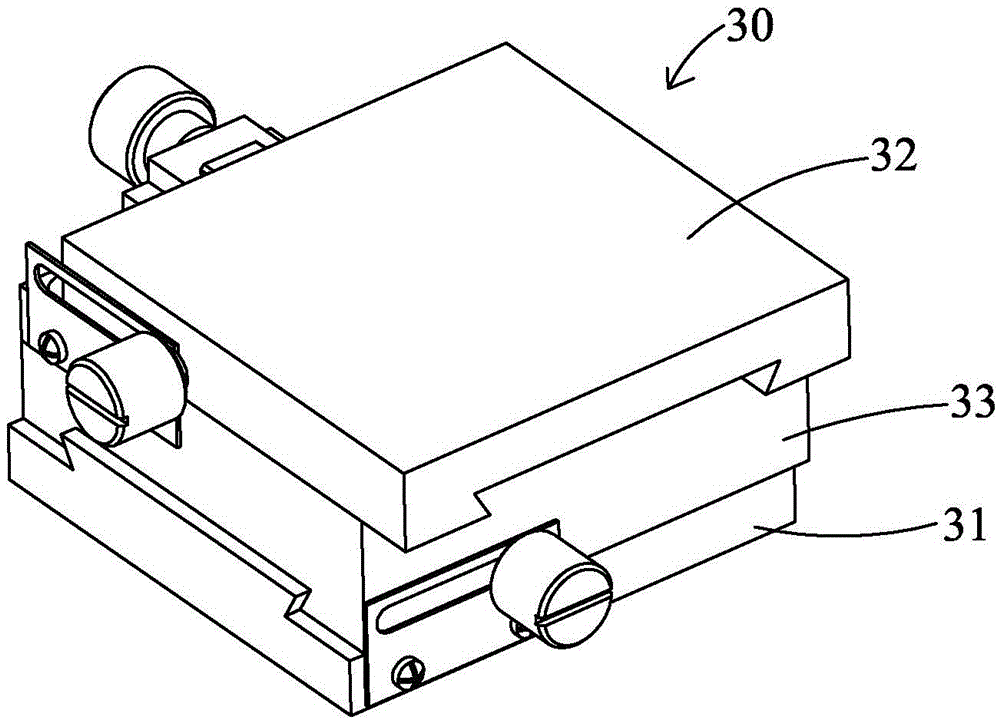

[0011] see Figure 1 to Figure 4 As shown, the automatic dispensing and feeding device 100 of the present invention includes a dispensing mechanism 10 , a power mechanism 20 and a driving mechanism 30 .

[0012] The dispensing mechanism 10 comprises a support 11, a pressure barrel 12 and a dispensing gun 13 located at the bottom of the pressure barrel 12, the support 11 comprises a base plate 111 and a vertical plate 112 fixed on the front portion of the base plate 111, and the pressure barrel 12 is fixed on Upright board 112 front surface. A pivot hole 113 is defined at the rear of the bottom plate 111 .

[0013] The power mechanism 20 comprises a power motor 21, a belt 22, a front power wheel 23, a rear power wheel 24, a horizontal positioning plate 25 and an eccentric wheel 26, the power motor 21 has an upwardly protruding rotating rod 211, and the rear power The wheel 24 is fixed on the rotating rod 211 and rotates together with the rotating rod 211 . The positioning pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com