High voltage line patrol robot with single motor to control movement of three arms

A line inspection robot and single-motor technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of clamping mechanism, heavy motor loading, heavy body weight, poor climbing and climbing ability of the motor, etc., and it is easy to guarantee the processing accuracy , The structure of the parts is simple, and the effect of ensuring simultaneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

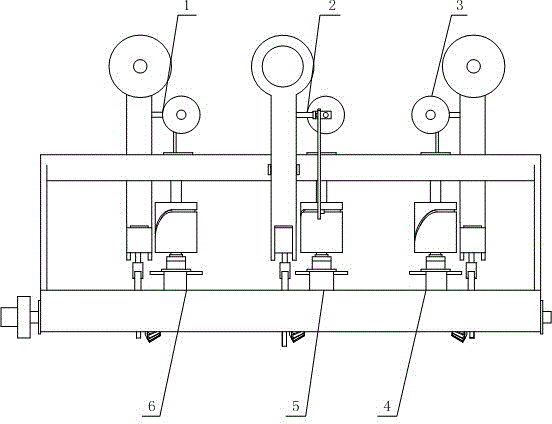

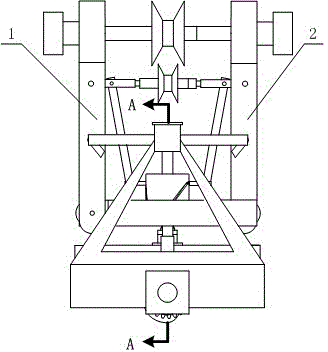

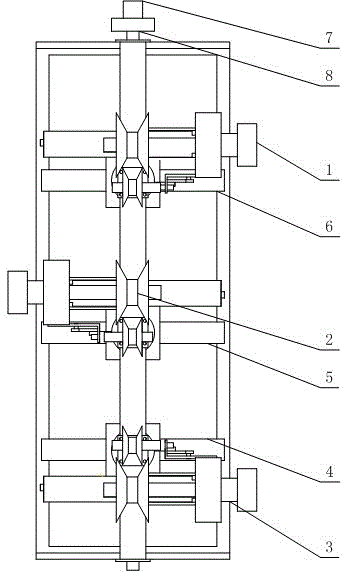

[0047] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the figure, 1 is the first mechanical arm, 2 is the second mechanical arm, 3 is the third mechanical arm, 4 is the right side bracket support, 5 is the middle bracket support, 6 is the left side bracket support, 7 is the swing motor, 8 1 is the rotating shaft, 9 is the upper bearing, 10 is the track groove, 11 is the bolt, 12 is the right side bearing cover, 13 is the right bearing, 14 is the left bearing, 15 is the traveling motor, 16 is the clamping mechanism, 17 is the column pin Rod, 18 is a rectangular connecting rod, 19 is the main arm swing arm, 20 is the left support arm, 21 is the left inclined chute, 22 is the main arm support cross bar, 23 is the bracket, 24 is the lower bearing end cover, 25 is The lower bearing, 26 is the cylindrical cam, 27 is the cylindrical camshaft, 28 is the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com