Diaphragm slitting machine

A technology of slitting machine and diaphragm, which is applied in the direction of winding strips, sending objects, cleaning methods and utensils, etc., can solve the problems of difficult replacement of cutters and difficult cutting, etc., achieve easy replacement, improve production efficiency, and ingenious mechanism coordination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

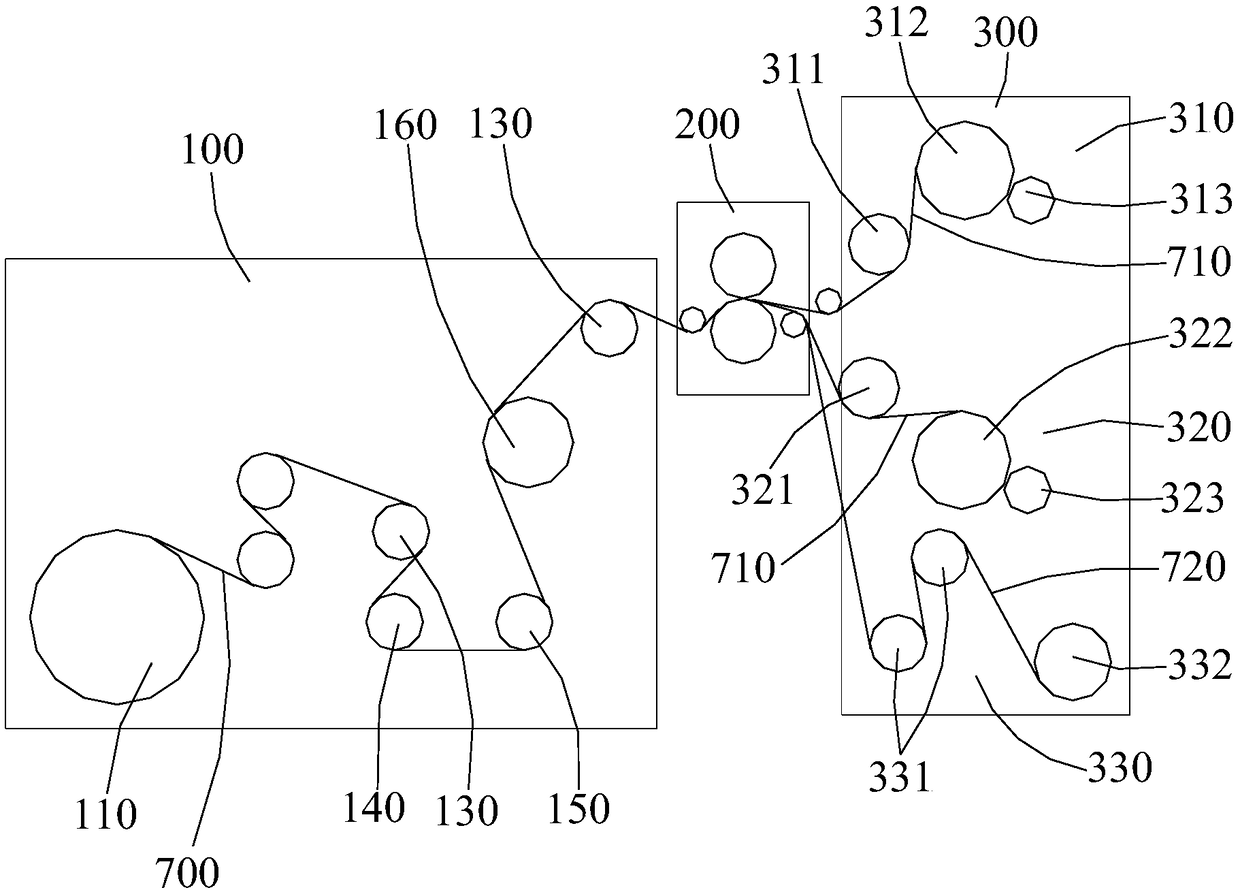

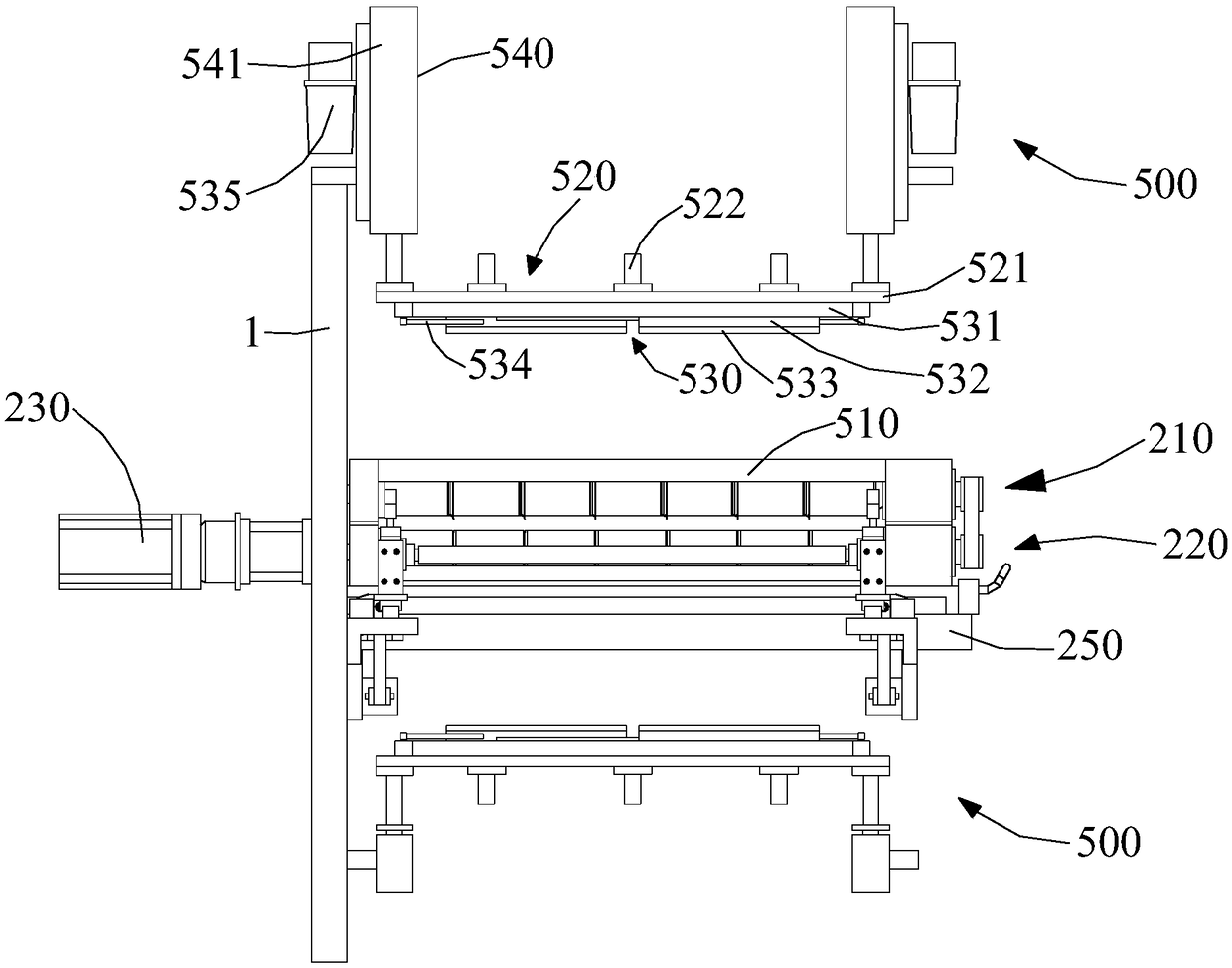

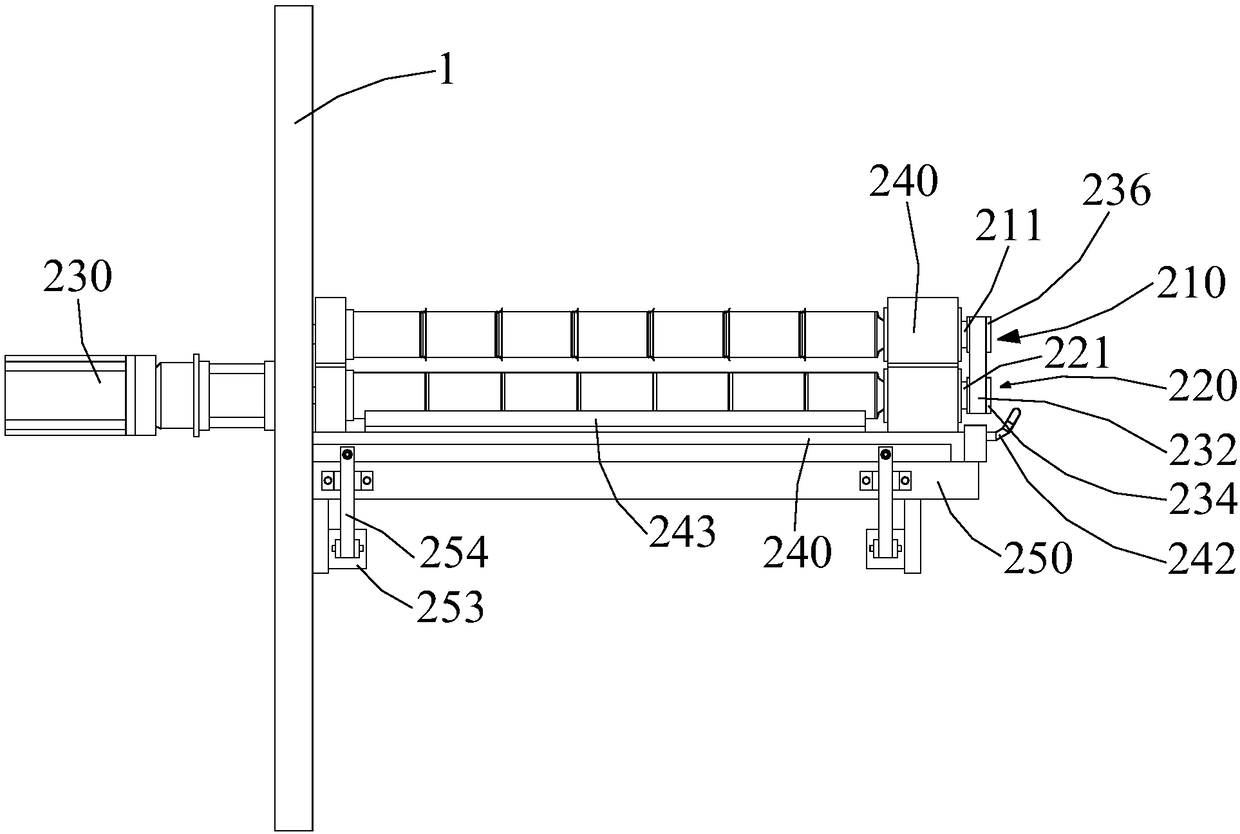

[0020] Please refer to Figure 1 to Figure 5 As shown, the present invention discloses a diaphragm slitting machine for cutting a diaphragm substrate 700 into a plurality of strip-shaped diaphragm strips 710, which includes an unwinding mechanism 100, a cutting mechanism 200, a winding mechanism 300 and Two dust suction mechanisms 500 , one of which is disposed above the cutting mechanism 200 , and the other dust suction mechanism 500 is disposed below the cutting mechanism 200 .

[0021] see figure 1 As shown, the unwinding mechanism 100 includes a material roll 110 and a roller 140; the diaphragm base material 700 is wound on the material roll 110, and the material roll 110 is driven by a material roll driving device (not shown) to perform unwinding in a rotating manner. ; The released separator substrate 700 is guided into the cutting mechanism 200 via the roller 140 .

[0022] In order to output the diaphragm substrate 700 better, the unwinding mechanism 100 also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com