Recycling mechanism for shot blasting process for robot joints

A recycling mechanism and robot technology, applied in the field of metal grinding, can solve the problems of various requirements and regardless of cost, and achieve the effect of improving production efficiency, reducing cost, and recycling quickly and clearly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

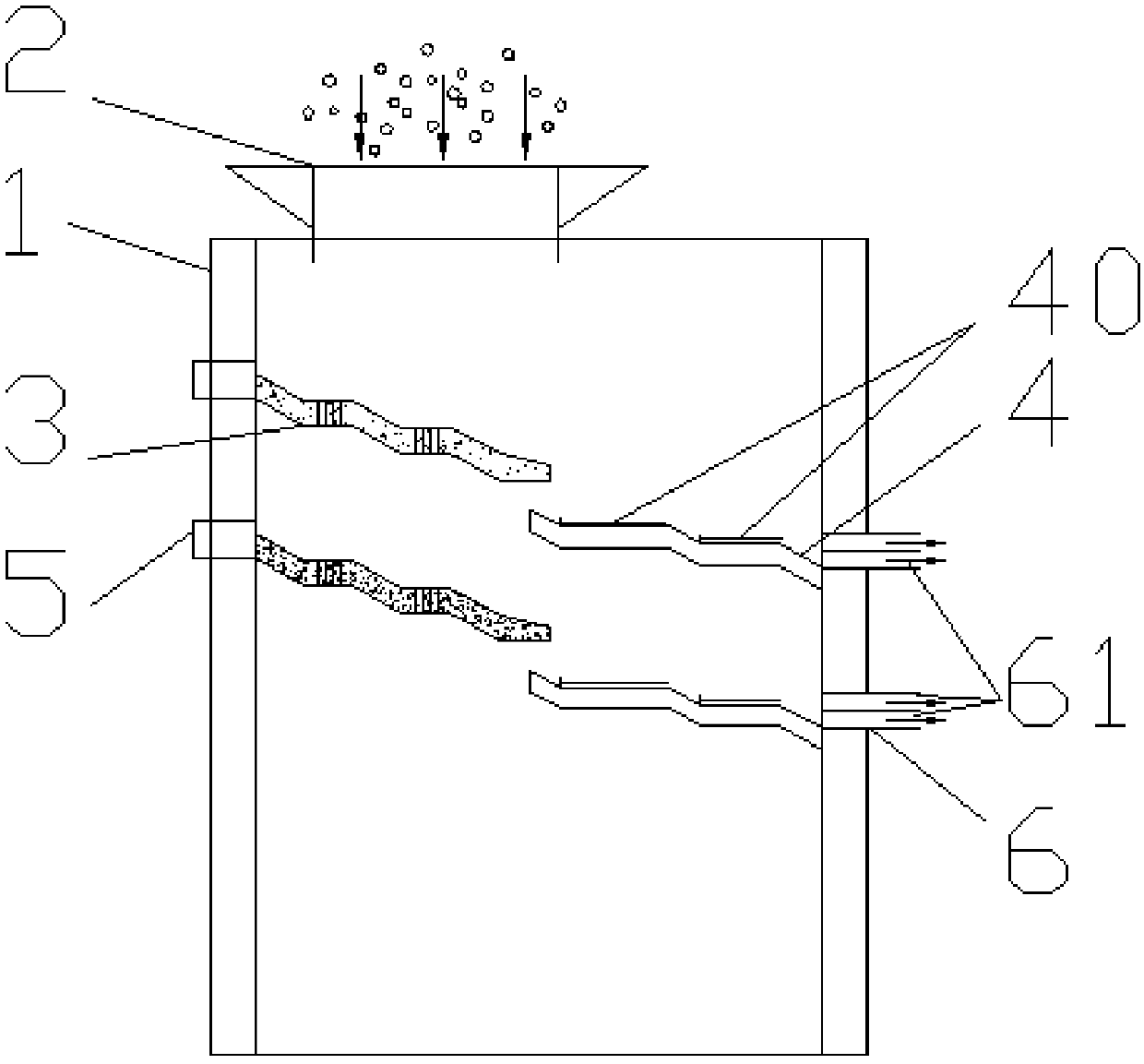

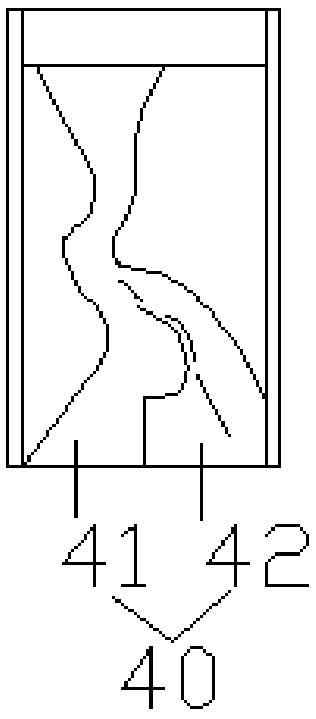

[0017] Such as Figure 1~2 , a recovery mechanism for the shot blasting process of robot joints, including a recovery box 1, a feed hopper 2, and a screen 3, the feed hopper 2 is installed on the top of the recovery box 1, and the feed hopper 2 passes into the shot The sieve 3 is installed on one side of the recovery box 1, the lower end of the sieve 3 has a trough plate 4, the trough plate 4 upper surface has a trough 40, the trough 40 is divided into several large grooves 41, The small groove 42, the large groove 41 and the small groove 42 are suitable for the particle size of the pellets and constitute a sorting mechanism (the sorting mechanism is similar to a coin sorter), and the screen 3 and the trough plate 4 have 1~2 respectively , the trough plate 4 and the screen 3 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com