Centrifugal oil purifier capable of automatically collecting oil and use method thereof

A technology of centrifugal and oil purifiers, which is applied to centrifuges and centrifuges with rotating drums, etc. It can solve the problems of automatic oil collection, incomplete oil purification, complicated operation, etc., and achieves strong practicability and clean The effect of thorough oiling and ingenious mechanism coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

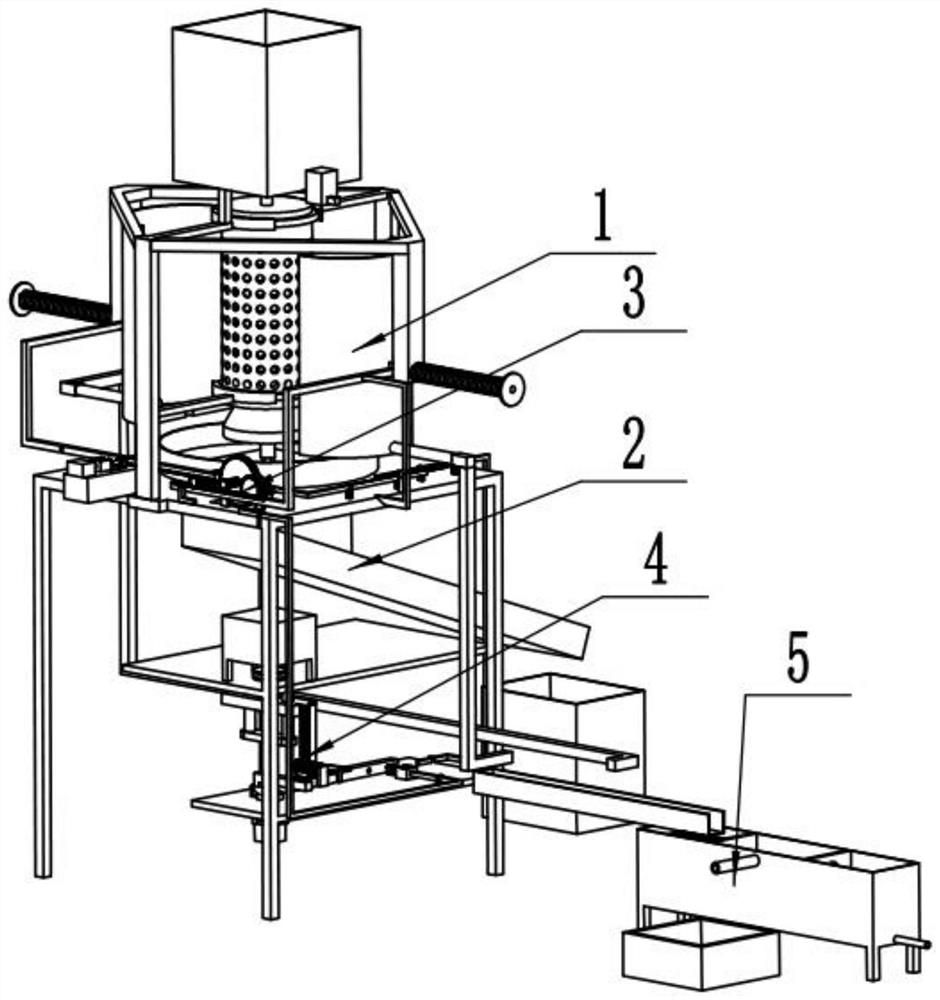

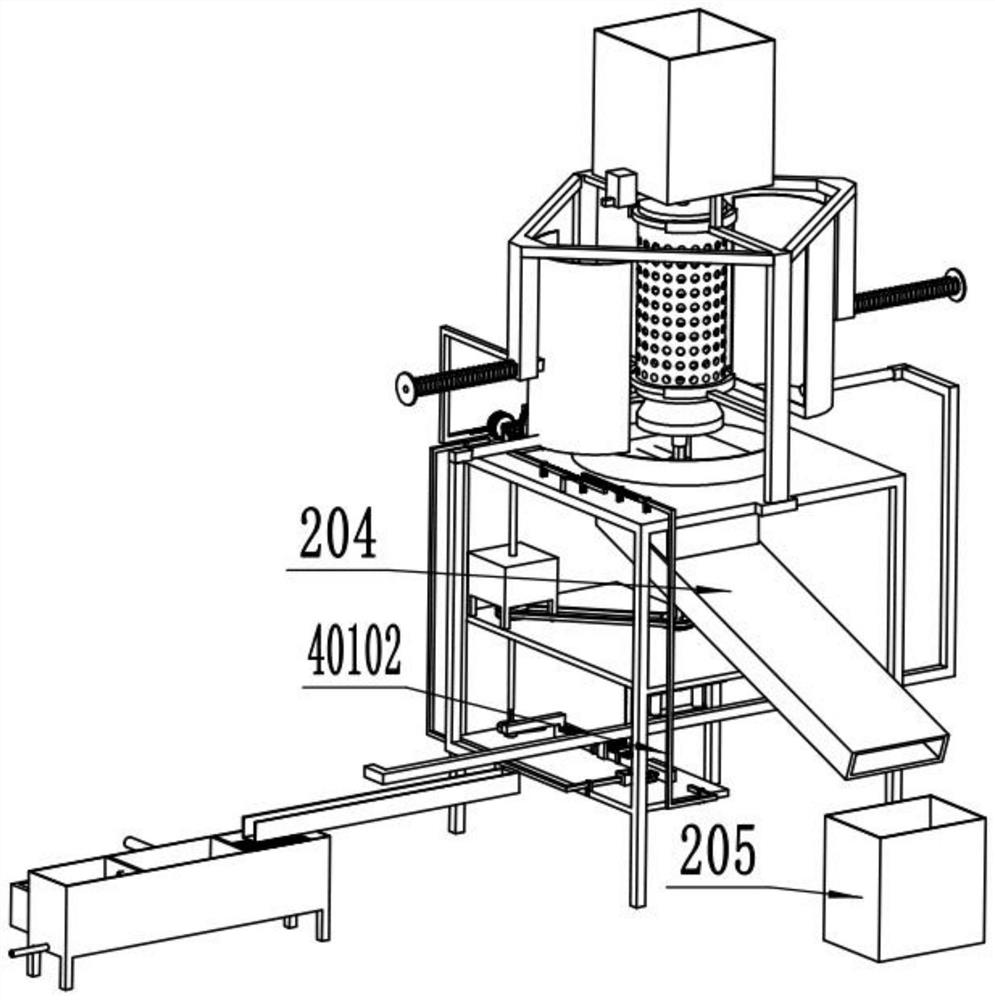

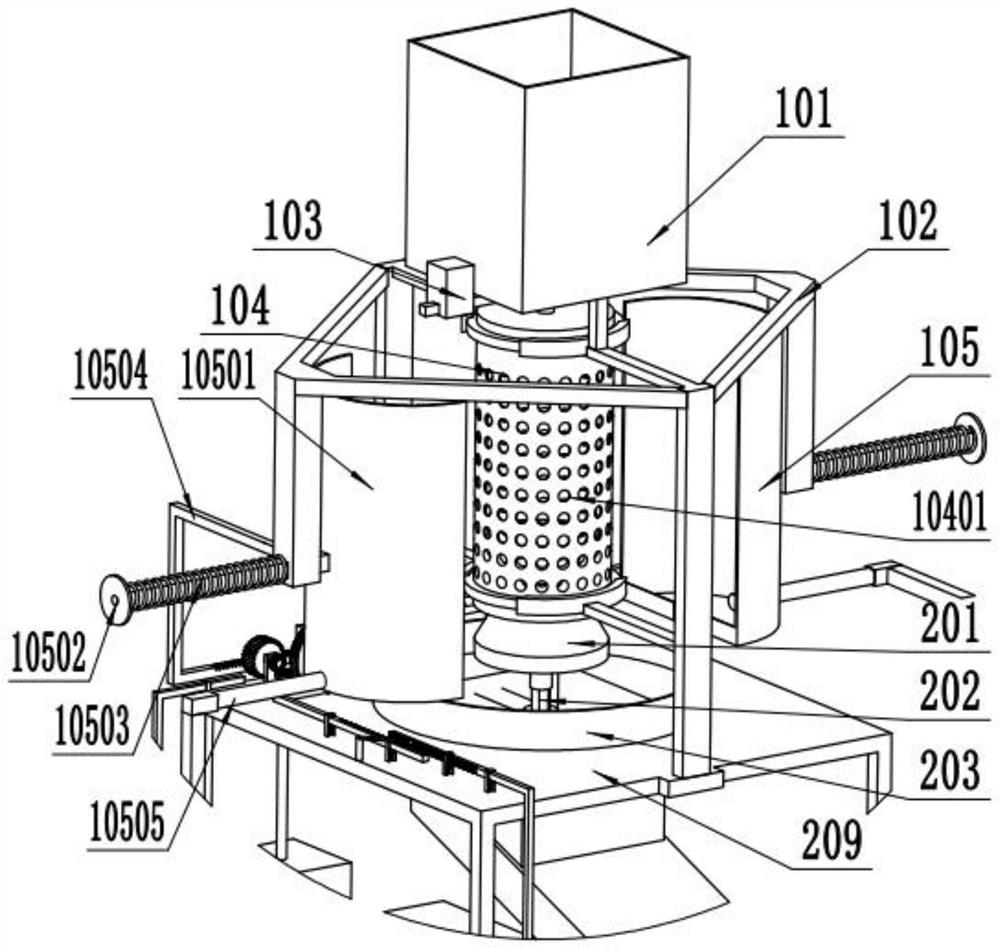

[0029] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 The shown automatic oil collecting centrifugal type oil purifier includes an impurity removal mechanism 1 , a processing mechanism 2 , a transmission mechanism 3 , a power mechanism 4 , and a separation mechanism 5 .

[0030] like image 3In the impurity removal mechanism 1 shown, the feeding box 101 is fixedly installed on the feeding bracket 102, the feeding bracket 102 is fixedly installed on the processing frame 208, the impurity removal cylinder 104 is fixedly installed inside the feeding bracket 102, and the valve 103 is arranged on the Between the loading box 101 and the impurity removal cylinder 104, the valve 103 controls the flow between the upper material box 101 and the impurity removal cylinder 104. The impurity removal cylinder 104 is provided with a round hole 10401, and the water-oil mixture with impurities enters from the upper material box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com