Nut crushing device

A crushing device and nut technology, used in grain processing, hulling, pod removal, etc., can solve the problems of heavy workload, insufficient wall breaking, poor nut wall breaking effect, etc., to improve the crushing effect, facilitate transportation, and facilitate The effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

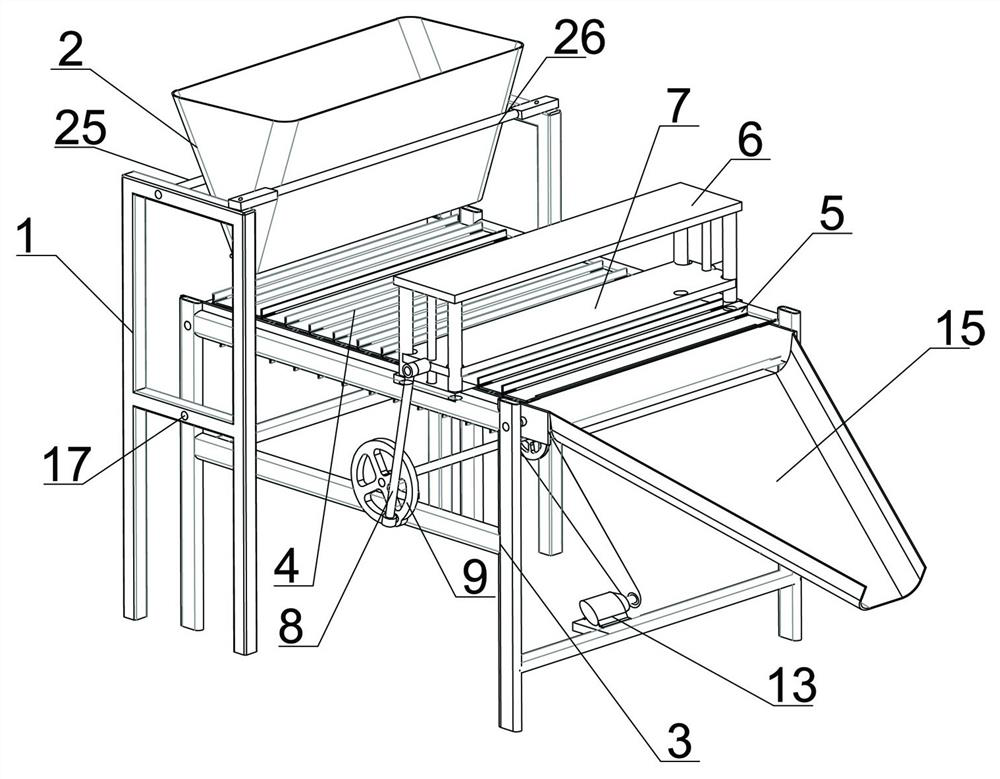

[0034] Embodiment 1: This embodiment aims to provide a nut crushing device, which is mainly used for industrially mechanized crushing of nuts. When the existing crushing device is in use, the nuts are easy to spread outside the crushing area during extrusion, causing The crushing effect of nuts is poor, and it is easy to miss broken nuts. It still needs to be manually cleaned again, which is troublesome to use, and the existing crushing structure has only been crushed once, and the crushing degree is poor, and the crushing device is basically a complete machine. The cost is high, so this embodiment provides a nut crushing device, the specific structure is as follows.

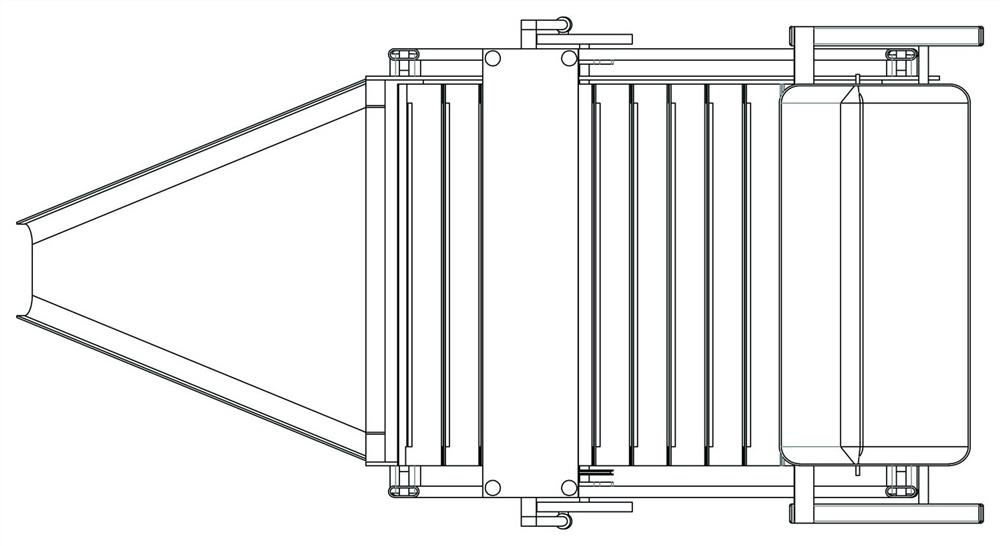

[0035] Such as Figure 1-4 As shown, the device includes a feeding mechanism, a conveying mechanism, a crushing mechanism, and a feeding hopper; the feeding mechanism includes a support 1, a feeding hopper 2, and an equalizing device; the feeding mechanism is used for temporarily storing nuts, and evenly feeding...

Embodiment 2

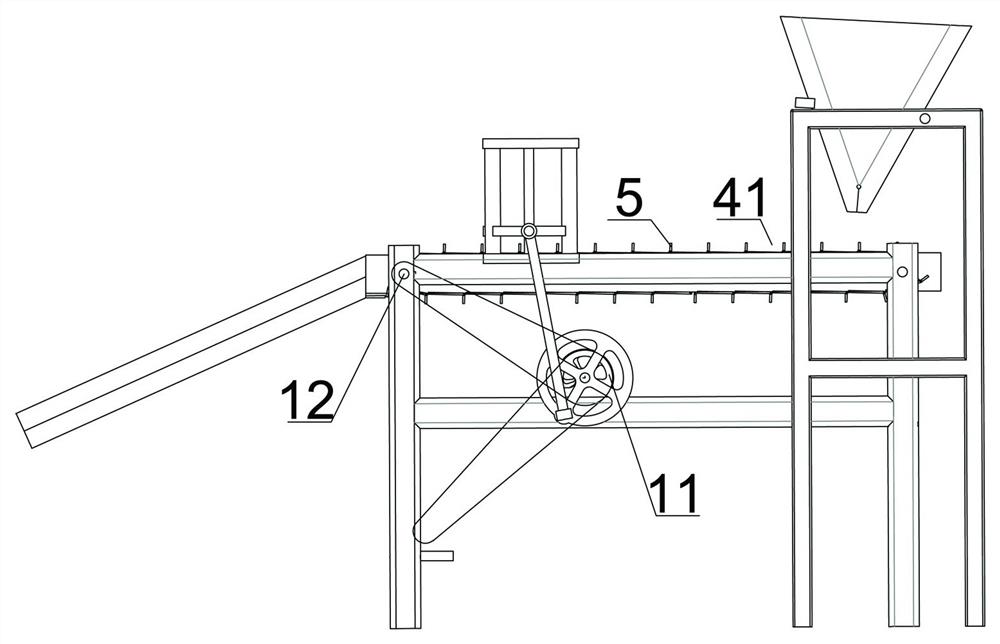

[0044] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the structure of the rack 3 and the support.

[0045] Described frame 3 is positioned at support, and the upper part of frame 3 and the middle part are provided with connection hole 17 correspondingly, can connect frame 3 and support 1 together by connecting bolt in connection hole 17, and at the height of support It is basically adapted to the length of the rack to facilitate packaging and transportation.

[0046] Therefore, in this embodiment, the bracket and the frame can be disassembled and assembled together, and they can be bundled together during transportation, which is convenient for transportation and low in cost, and can be assembled together through a simple combination method, which is convenient for installation.

Embodiment 3

[0047] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference lies in that this embodiment provides a homogenizing device with another structure.

[0048] Such as Figure 10 As shown, the uniform material device includes a regulating roller 24 and a stepping motor; the bottom of the lower hopper is provided with a discharge port, and the regulating roller 24 is an incomplete circular structure, and the circular structure is greater than one-half Circle, its diameter is suitable for the discharge port, the discharge port is a square structure, the adjustment roller 24 is set in the discharge port, the adjustment roller 24 is provided with a rotating shaft, and the rotating shaft on one side extends out of the lower hopper, and the stepping motor It is connected with the rotating shaft transmission, and the rotation of the adjustment roller 24 is realized by the stepping motor, so that the discharge port has different opening sizes, and the feeding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com