Wire bending processing equipment

A technology for processing equipment and wire rods, applied in the field of wire rod bending processing equipment, can solve the problems of easy fatigue, low production efficiency, and high labor costs, and achieve the effects of regular and uniform shape, stable bending quality, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

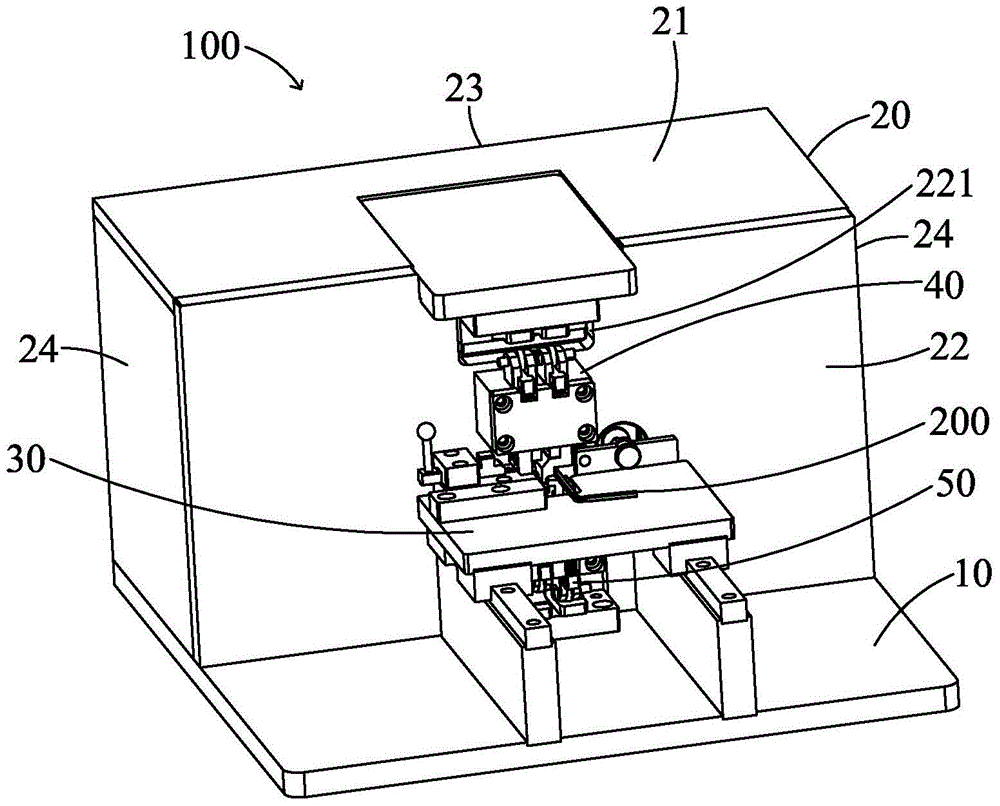

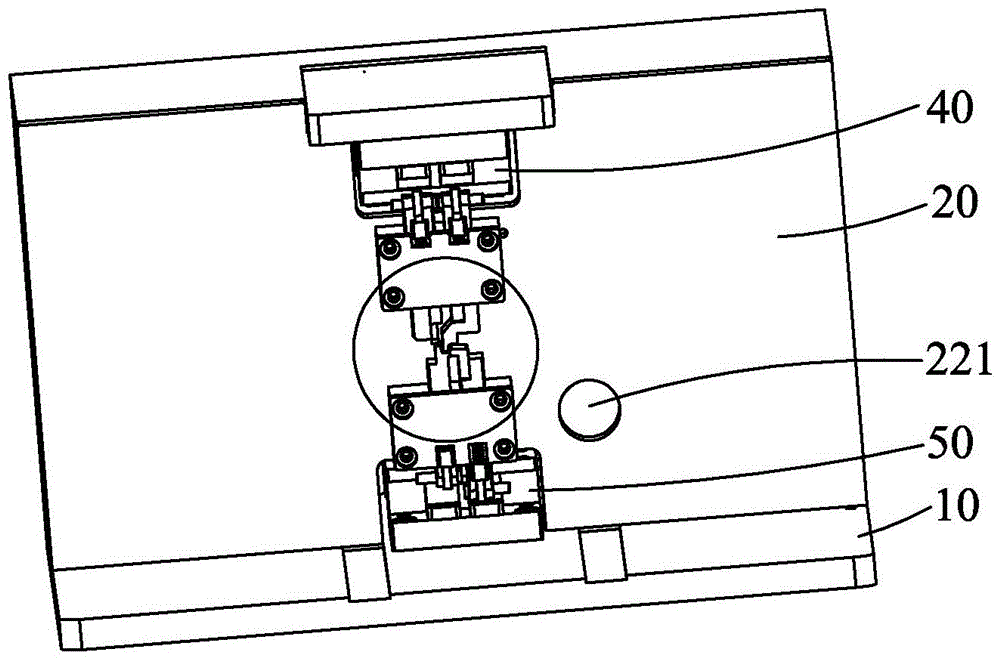

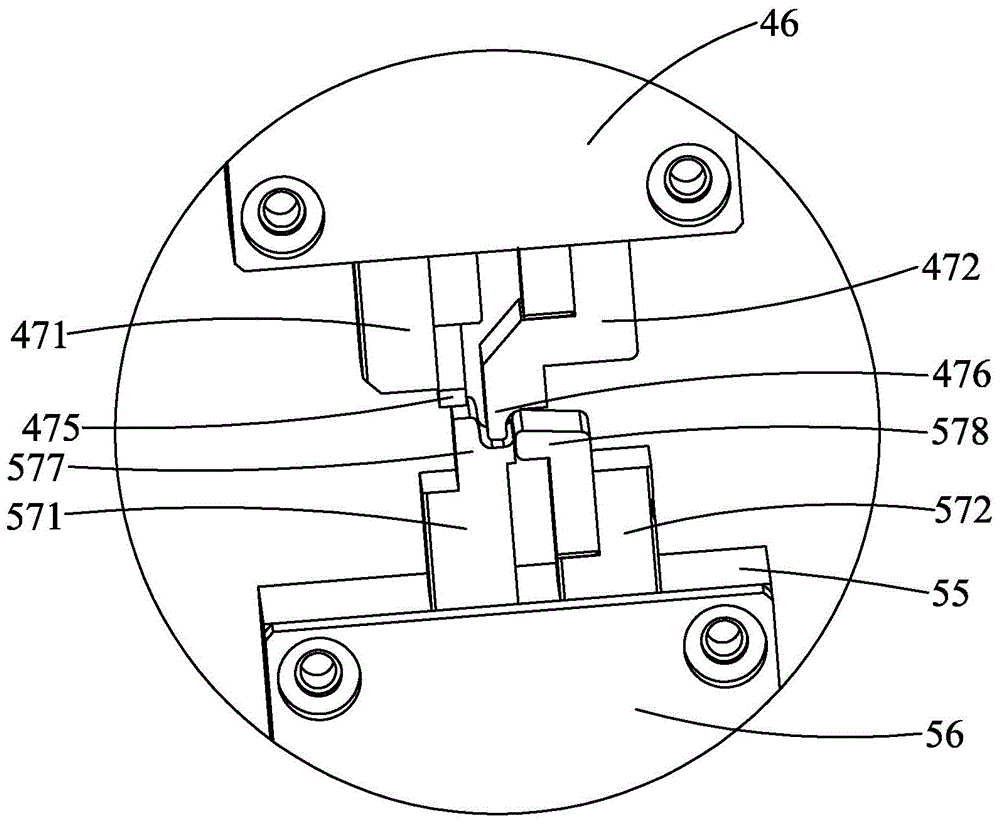

[0025] see Figure 1 to Figure 10 As shown, the wire bending processing equipment 100 of the present invention is used to bend a certain part of the wire 200 twice to form a U-shaped bending part 202, so that the wire 200 can be easily matched with the structure of the corresponding mechanism. The wire bending processing equipment 100 includes a base 10 , a box body 20 , a placement mechanism 30 , an upper bending mechanism 40 and a lower bending mechanism 50 .

[0026] The base 10 is a horizontal plate, and the box body 20 is fixed on the base 10 rear portion. The box body 20 includes a top plate 21, a front end plate 22, a rear end plate 23 opposite to the front end plate 22, and left and right opposite side plates 24. The top plate 21, the front and rear end plates 22, 23 and the two side plates 24 surround and form a storage space (not shown), the front end plate 22 has an opening 221 for the upper bending mechanism 40 to pass through, and the front and rear end plates 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com