Wire rod bending processing device

A technology for processing equipment and wires, applied in the field of wire bending processing equipment, can solve the problems that the bending shape cannot be guaranteed to be uniform, the wire quality is unstable, and the labor cost is high, and achieves stable bending quality, easy operation, and clever coordination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

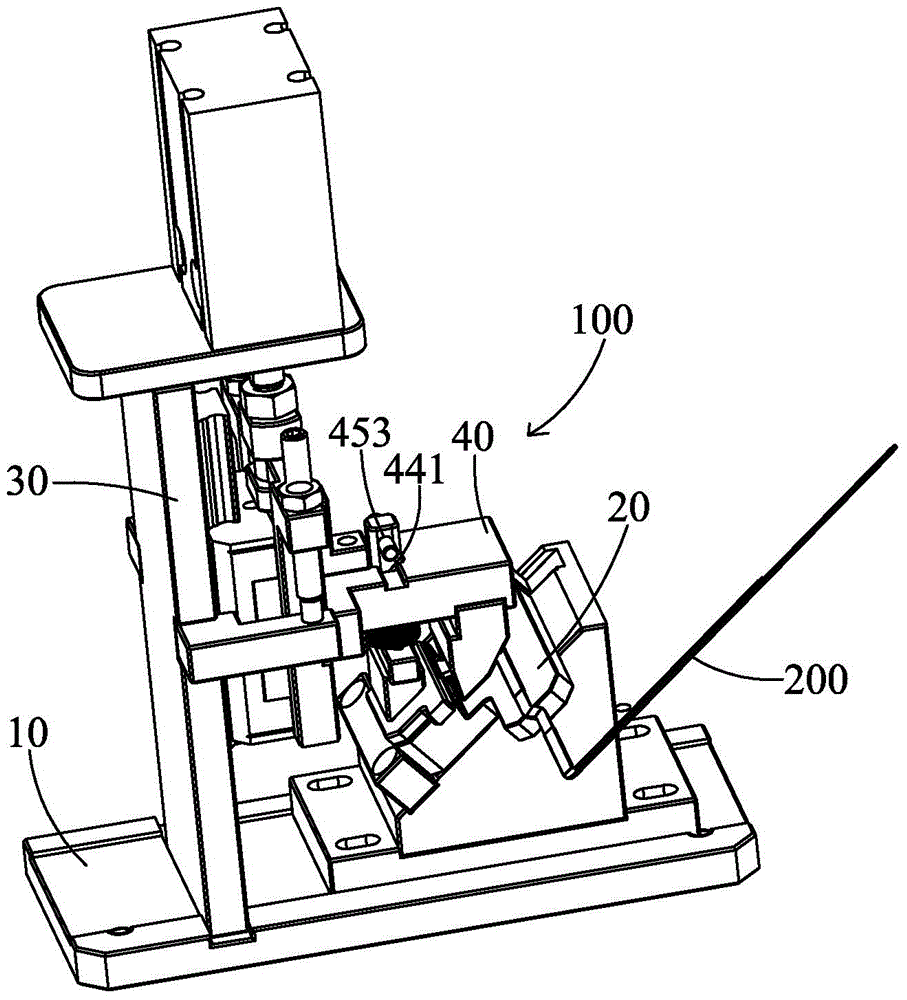

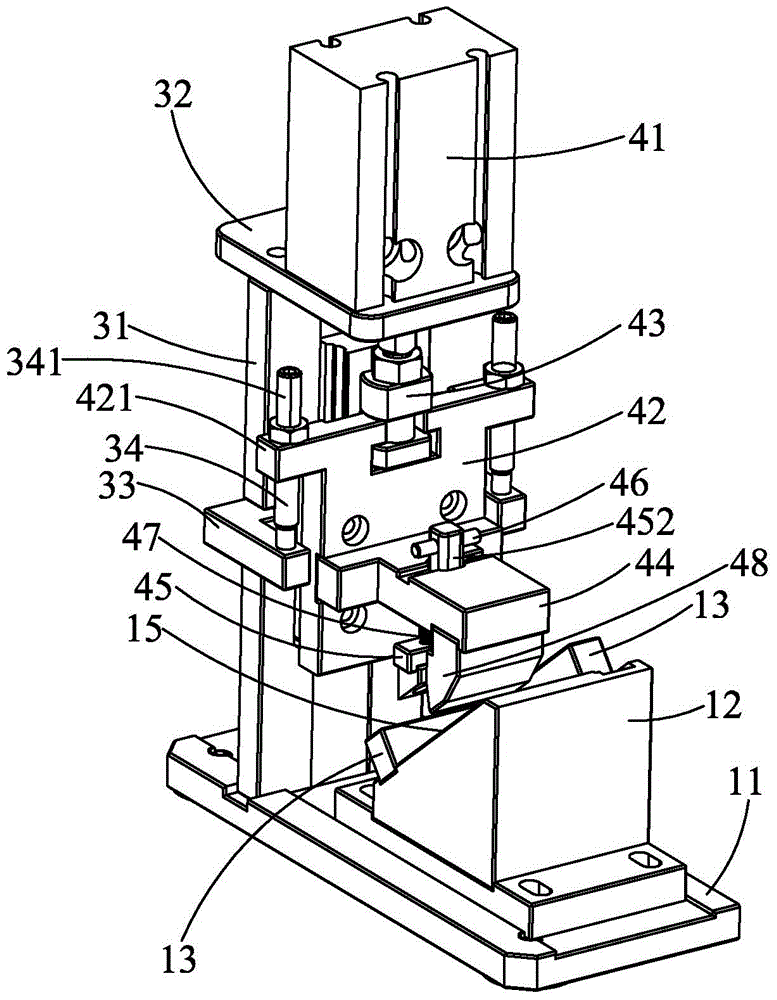

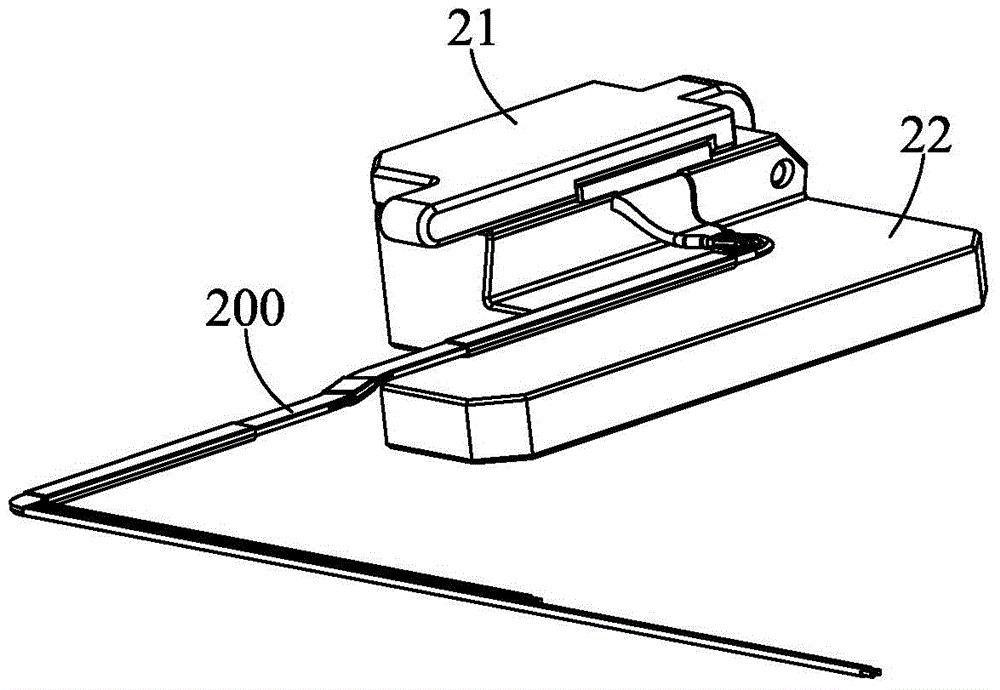

[0010] see Figure 1 to Figure 2 As shown, the wire bending processing equipment 100 of the present invention is used to bend a certain part of the wire 200 so that the wire 200 is conveniently matched with the structure of the corresponding mechanism. The wire bending processing equipment 100 includes a base 10 , a placement mechanism 20 , a bracket 30 and a bending mechanism 40 disposed on the bracket 30 .

[0011] The base 10 includes a horizontal bottom plate 11, a seat body 12 fixed on the bottom plate 11 and two limit blocks 13 fixed on the seat body 12, the seat body 12 is provided with an inclined surface 15 for placing the placement mechanism 20, a limit The position block 13 is fixed on the rear end of the inclined surface 15, and the other limit block 13 is fixed on the lower end of the inclined surface 15. The ends of the two limit blocks 13 intersect to form a right angle. On the inner side of the limiting block 13, it is limited to move backward and downward.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com