Robot-dedicated mechanical fixture

A robot and mechanical technology, applied in the field of automated fixtures, can solve the problems of complex structure, difficult installation and unstable use of industrial robot fixtures, and achieve the effects of uniform force, ingenious coordination, and reduced damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

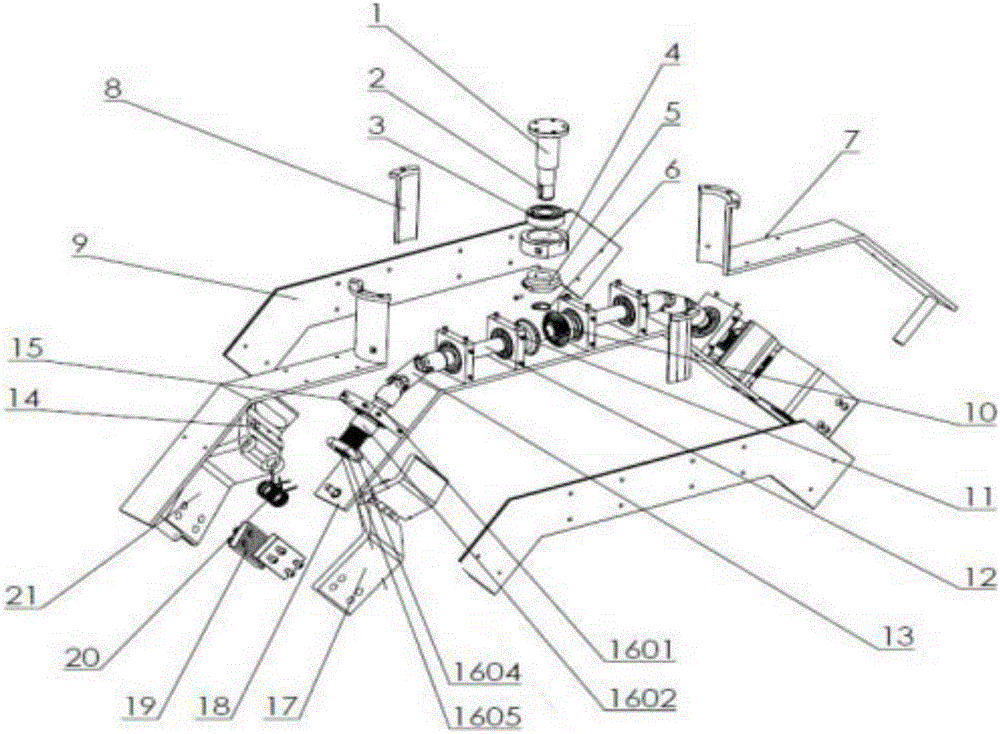

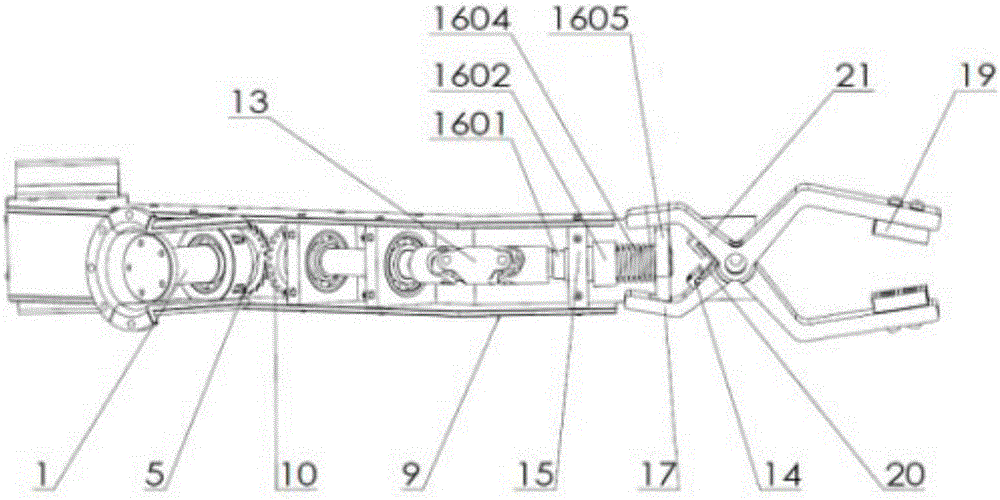

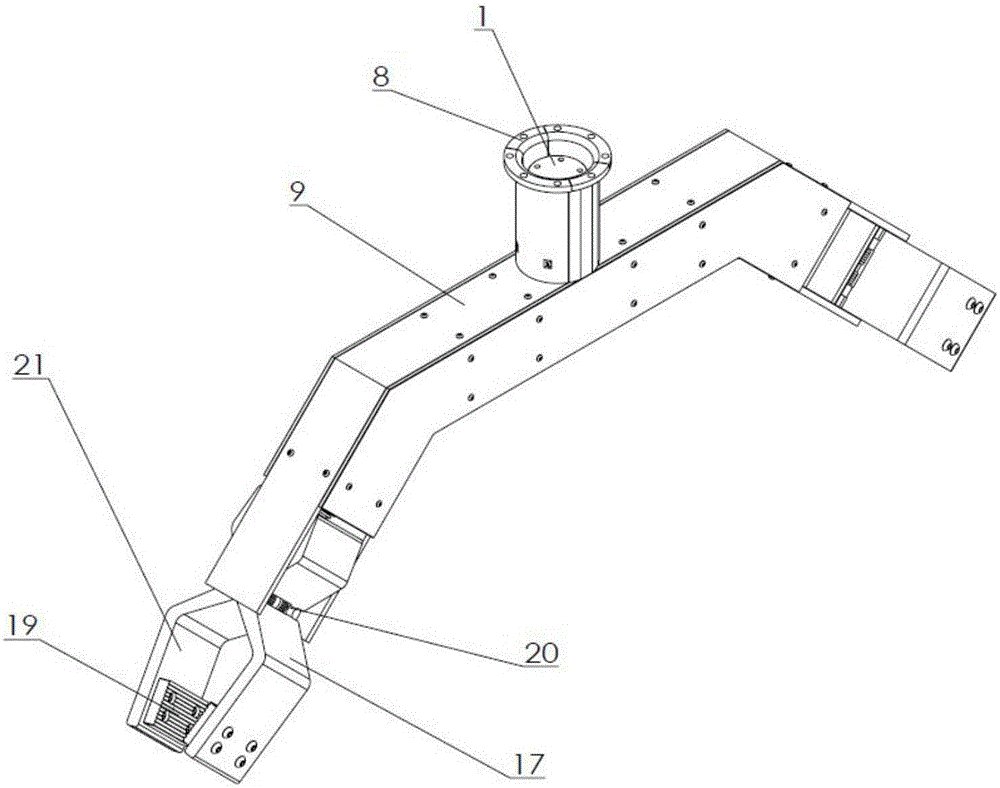

[0056] The embodiment of the present invention discloses a special mechanical fixture for robots. Using the end rotation shaft of the robot as the power source, the power of the end shaft of the robot is transmitted to the first step shaft by connecting the first stepped shaft with the end motion shaft of the robot. , and the power is transmitted to the cam through the half-tooth bevel gear, the second stepped shaft, and the third stepped shaft, and then the cam alternately rotates 180 degrees to realize the opening and closing of the grabbing plate, so as to realize the action requirement of clamping the workpiece and solve the problem The industrial robot fixture with an additional power source has complex structure, difficult installation, and unstable use.

[0057] see Figure 1 to Figure 4 , an embodiment of a robot-specific mechanical fixture is provided in the embodiment of the present invention, including: the first stepped shaft 1 connected to the fixed flange on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com