High-frequency absorptive film of capacitor

A high-frequency absorption and capacitor technology, applied in the field of high-frequency absorption films and metallized films, can solve problems such as low yield, loose capacitor cores, and inability to meet application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described below in conjunction with specific embodiments.

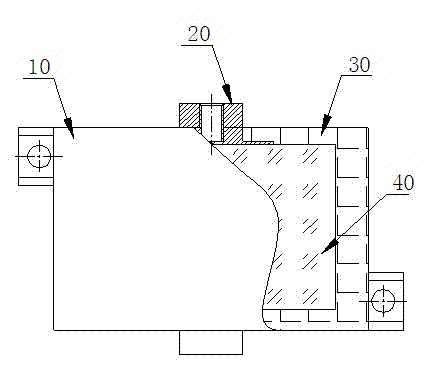

[0013] like figure 2 Shown is a schematic diagram of the capacitor structure of the present invention. The capacitor of the present invention includes: a casing 10 , a connection terminal 20 , a potting resin 30 , and a capacitor core 40 . The connecting terminal 20 is directly welded on the capacitor core 40 , embedded in the casing 10 , and filled with epoxy resin 30 in the casing 10 .

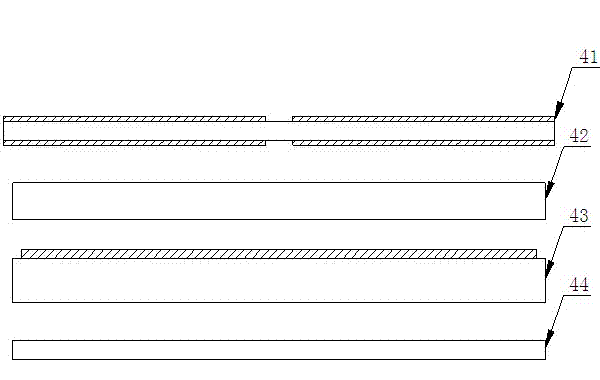

[0014] like image 3 As shown, the capacitor core 40 of the present invention is formed by coaxially winding four layers of films, and includes in order from inside to outside: a first metallized film 41, a second metallized film 42, a third metallized film 43 and the fourth metallized film 44, the first metallized film 41 is a double-sided metallized film, the third metallized film 43 is a single-sided metallized film, the second metallized film 42 is the same as the fourth me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com