Multipoint plug for electrically connecting metal strip conductors arranged on both sides of a circuit board

A printed circuit board, electrical contact connection technology, applied in the direction of circuits, contact parts, conductive connections, etc., can solve problems such as large space positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

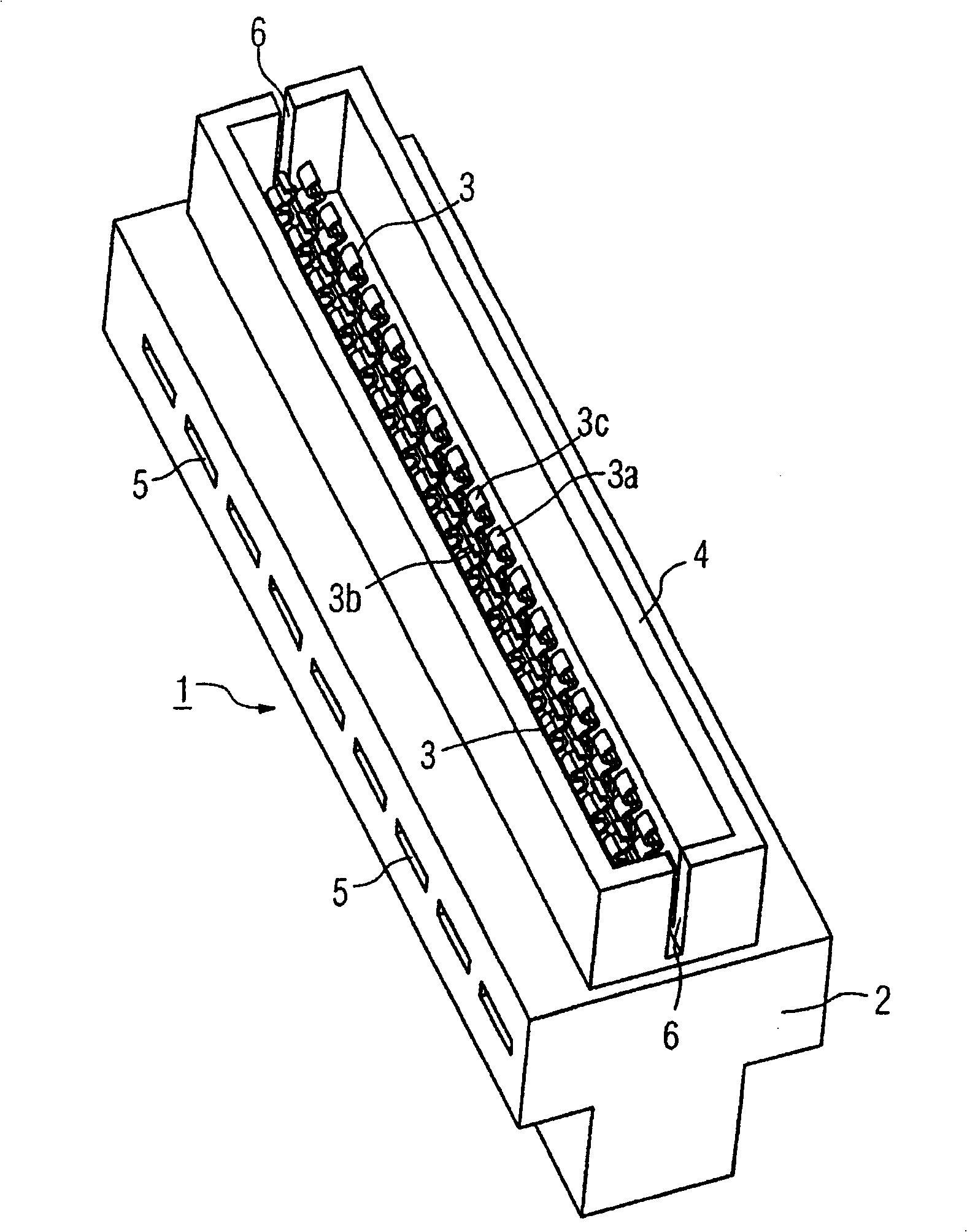

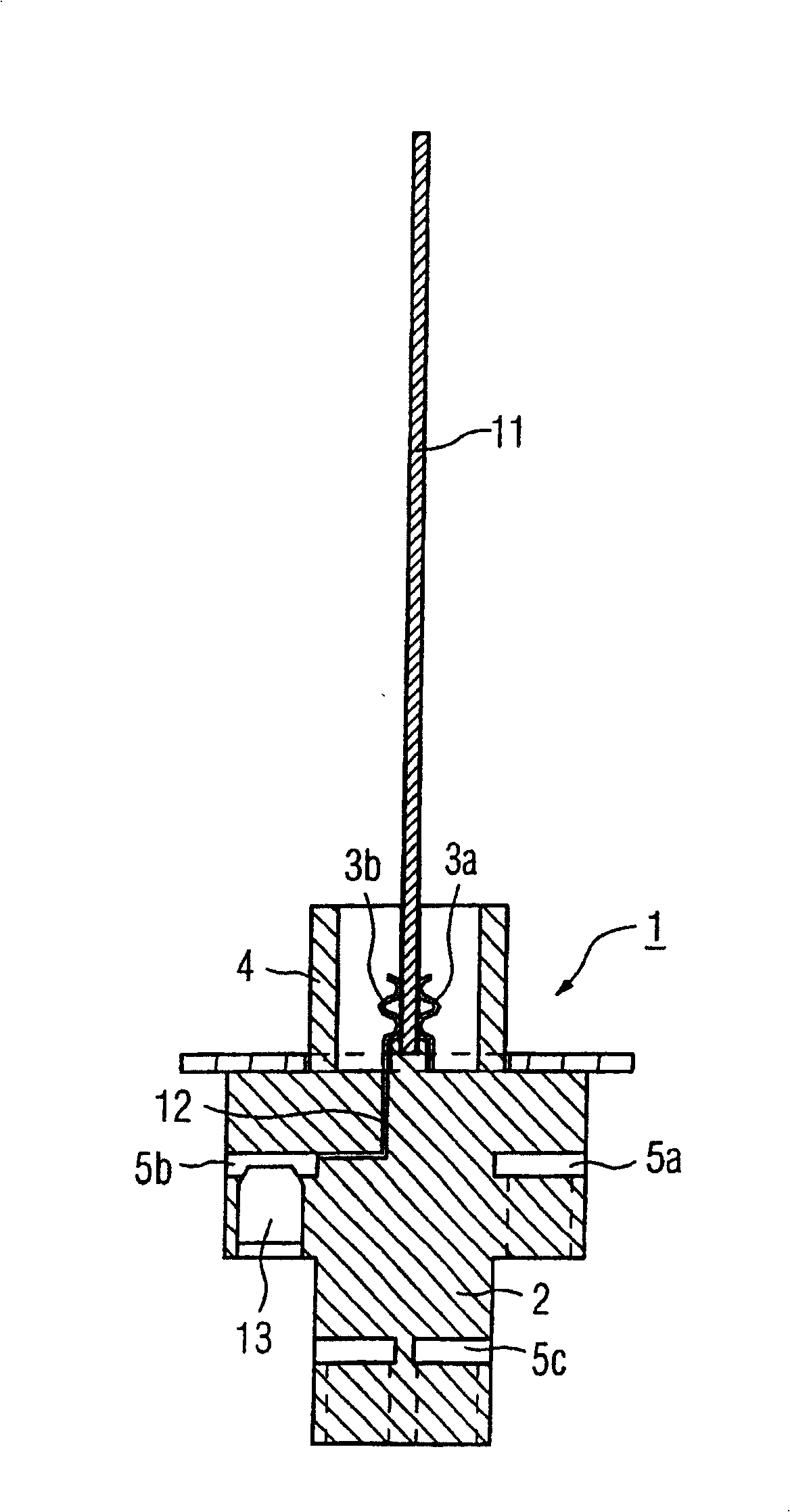

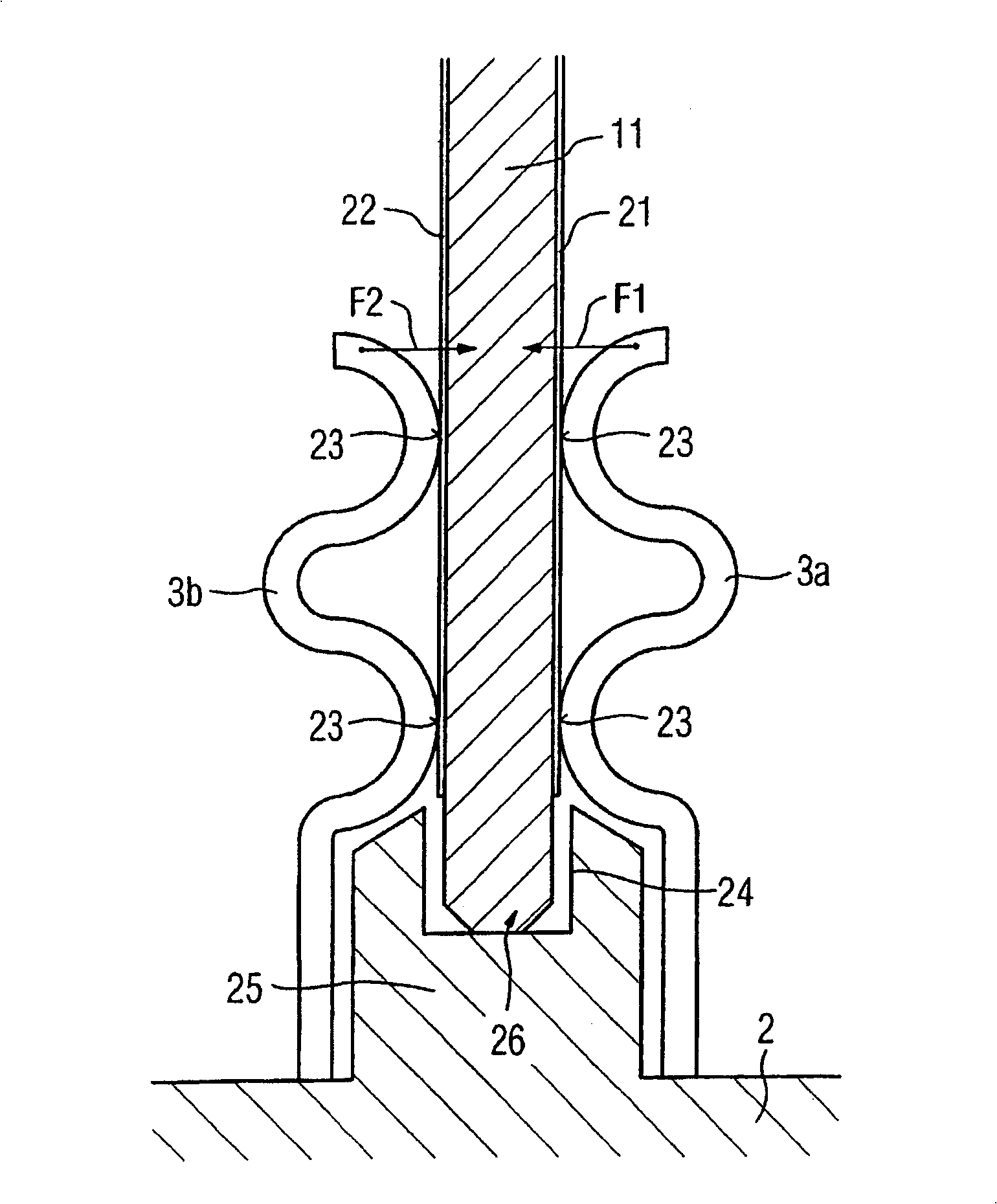

[0019] figure 1 A contact plate 1 with a base body 2 is shown. Two rows of oppositely positioned elastic contact elements 3 , 3 a , 3 b , 3 c are arranged on the base body 2 along its longitudinal direction. These contact elements are made of electrically conductive material and are designed to be elastic in opposite directions. In each case two mutually opposite contact elements (for example 3 a and 3 b ) are electrically isolated from each other. The spring elements 3 , 3 a , 3 b , 3 c are surrounded by a box-shaped enclosure 4 , thereby preventing mechanical damage to the contact elements, for example during storage, transport and careless handling of the contact plate. Inside the base body 2 there are electrical leads (in figure 1 not shown in ), these electrical leads connect each contact element 3, 3a, 3b, 3c to a connection on the outside of the base body.

[0020] For contacting conductor tracks arranged on a printed circuit board, the printed circuit board is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com