A protective cover and shell structure for increasing the insulation performance of a contactor

A technology of insulation performance and protective cover, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as unfavorable miniaturization design, and achieve the effect of extending the shortest leakage distance, enhancing reliability, and enhancing insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

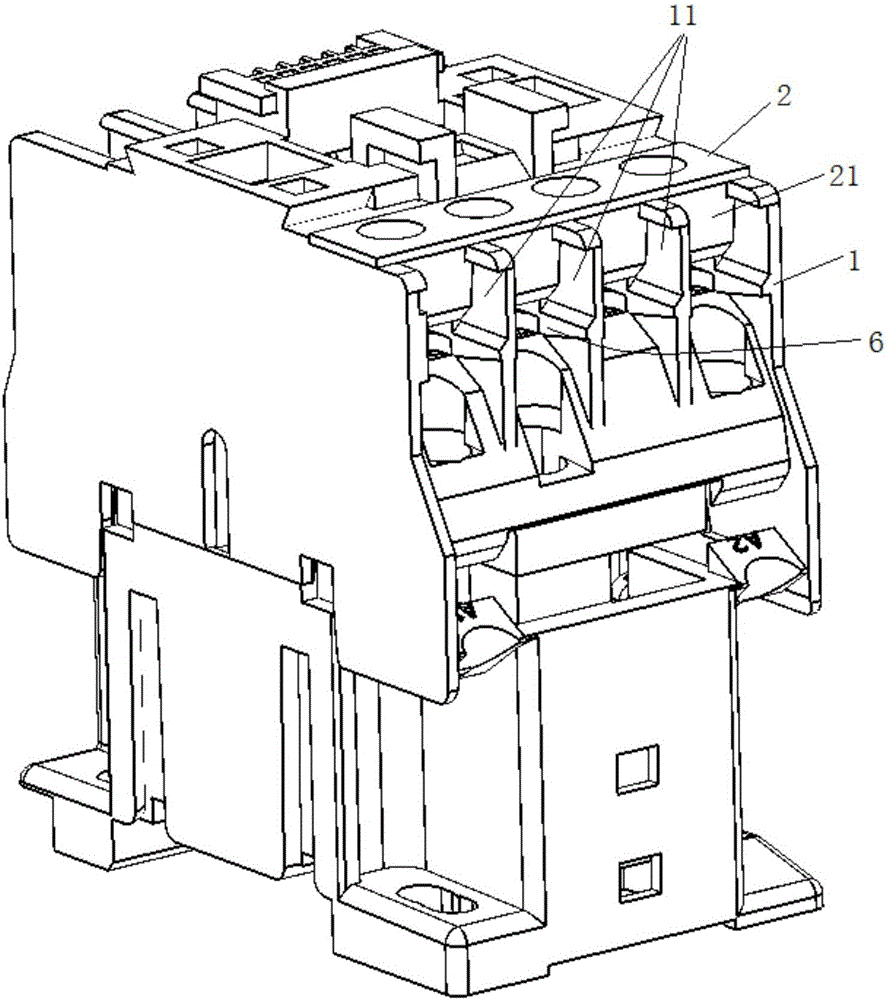

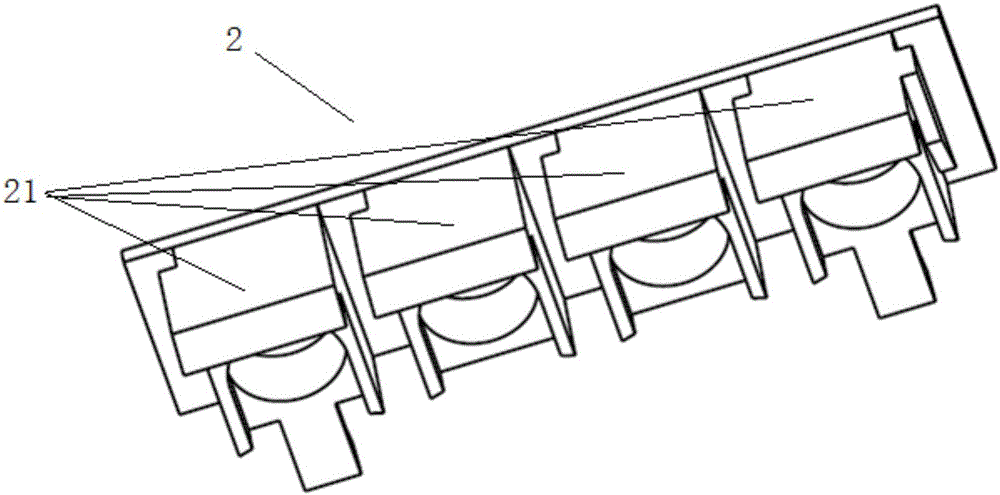

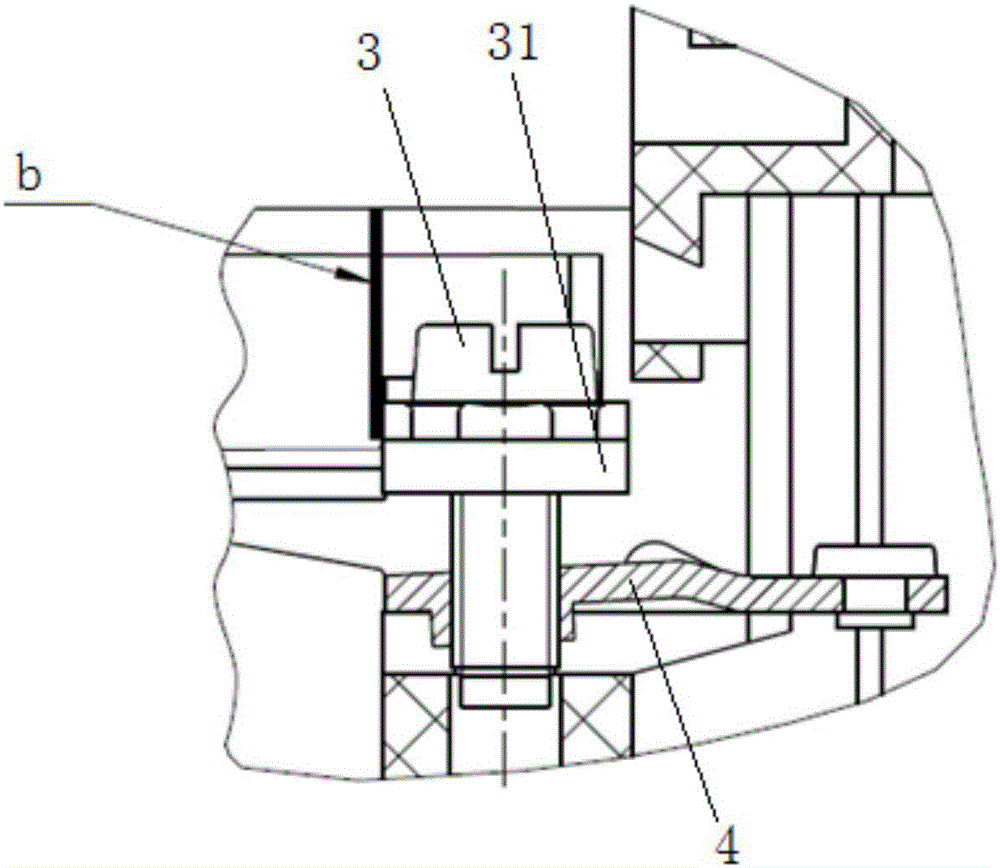

[0043] The invention provides a protective cover for increasing the insulation performance of the contactor, such as Figure 4-6 As shown, it is installed on the housing 1 of the contactor to prevent the operator from accidentally contacting several phase live conductors installed on the housing 1. The live conductors include the contact plate 4, installed on the contactor The tile-shaped terminal screw 3 and the wire 5 on the board 4, etc. The protective cover is fastened above the live conductor from the opening position of the housing 1 above the live conductor. In this example, if Figure 4-6 As shown, the protective cover includes a wiring protection wall 21 located on the outer side of the live conductor of each phase. It should be noted that the outer side refers to an edge of the live conductor close to the housing 1 On the side, the protective cover also includes several interphase insulating walls 22 arranged in the wiring protection wall 21 and forming a first sur...

Embodiment 2

[0063] This embodiment provides a shell structure, which is a part of the contactor, such as Figure 7 , Figure 9 and Figure 10 As shown, it includes the housing 1 and the above-mentioned protective cover, and the insulating walls 22 between the phases of the protective cover are partially inserted into the gap between the live conductor installed on the housing 1 and the adjacent insulating barrier wall 11 within 6.

[0064] In this example, if Figure 6-10 As shown, due to the setting of the interphase insulating wall 22 of the protective cover, the shortest creepage distance of the contactor with this shell structure is extended, therefore,

[0065] The molding position of the innermost edge position (that is, the corner position of the notch) on the shell closest to the live conductor can be lower, so the outer edge of the insulating barrier wall 11 and close to the installation position of the protective cover A notch structure 7 is formed, so as to start from the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com