Wave-cut remaining edge type thin-film capacitor

A technology for film capacitors and capacitors, which is applied to film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc., can solve the problem of low adhesion between the gold spray layer and the core, low mechanical strength of the gold spray layer, and effective contact Small area and other problems, to achieve the effect of increasing the effective contact area, high mechanical strength, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

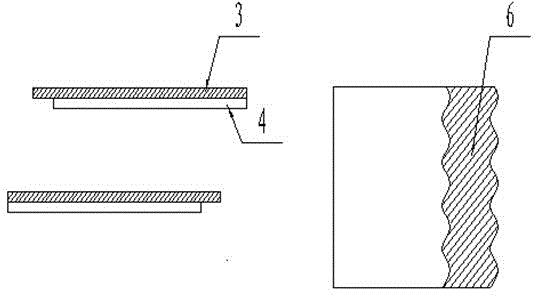

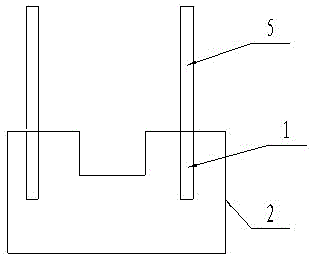

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a wave-cut edge-cut film capacitor includes a capacitor core 1 and a capacitor body 2, and the capacitor core 1 is composed of two layers of film dielectrics 3 arranged in parallel and metal plating electrodes 4 on the film dielectric 3 1. The gold-sprayed layer sprayed on the surface of the metal-plated electrode 4 and the lead wire 5 welded on the gold-sprayed layer are composed of four parts. The right edge of the metal-plated electrode 4 and the right edge of the film medium 3 are cut in the form of waves Formed wavy structure, the right edge of the metal plating electrode 4 and the right edge of the film medium 3 are provided with a margin 6; the film medium 3 is a polypropylene film; the left edge of the metal plating electrode 4 and the The left edge of the thin film medium 3 is a straight cut structure formed by straight cutting, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com